Cooling system for numerically-controlled machine tool

A technology of cooling system and CNC machine tool, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, measuring/indicating equipment, etc., which can solve the problems of automatic adjustment of processing heat, inability to guarantee cooling, unstable surface quality of workpieces, etc., to achieve guaranteed The quality of the workpiece and the effect of ensuring effective cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

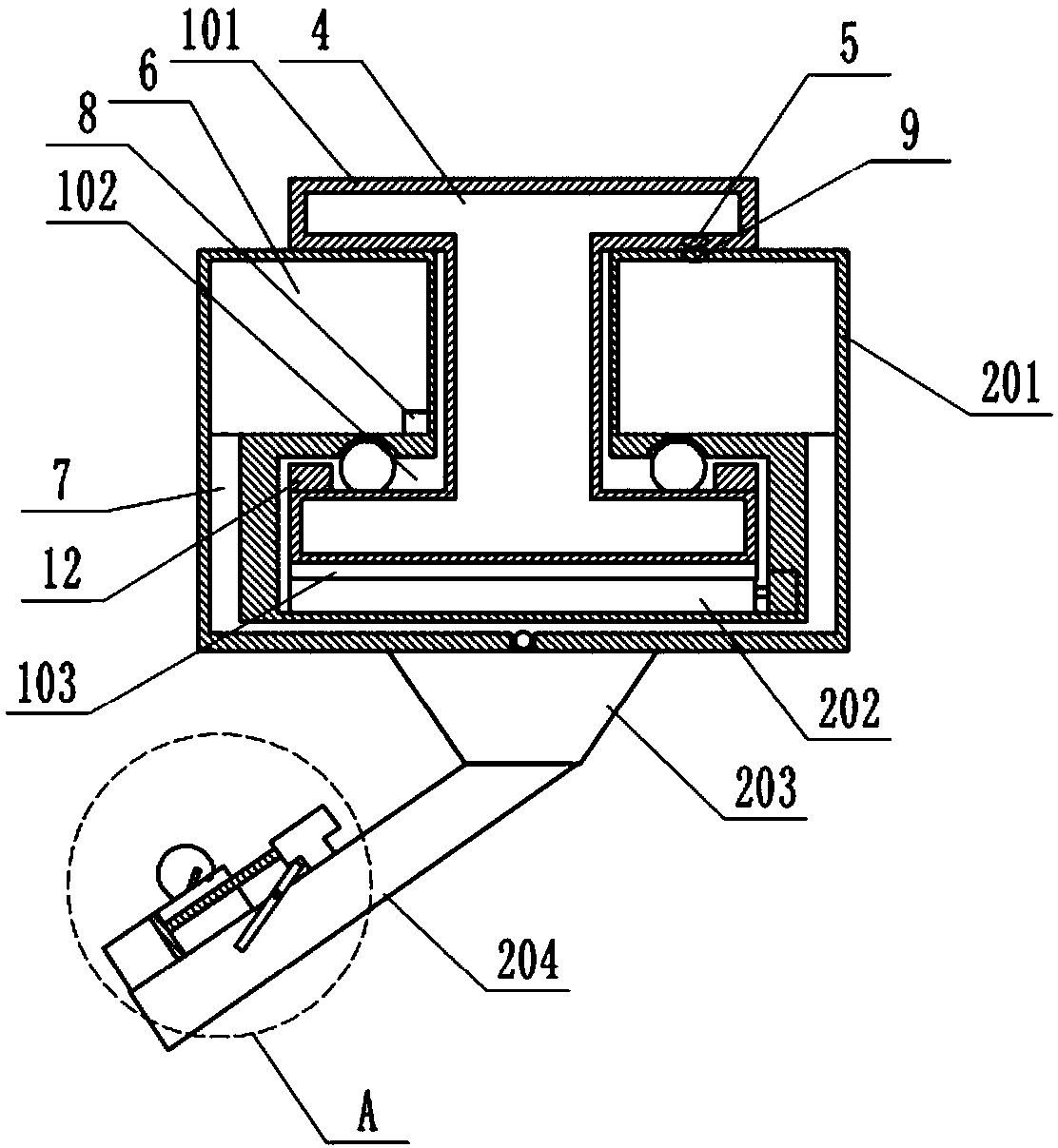

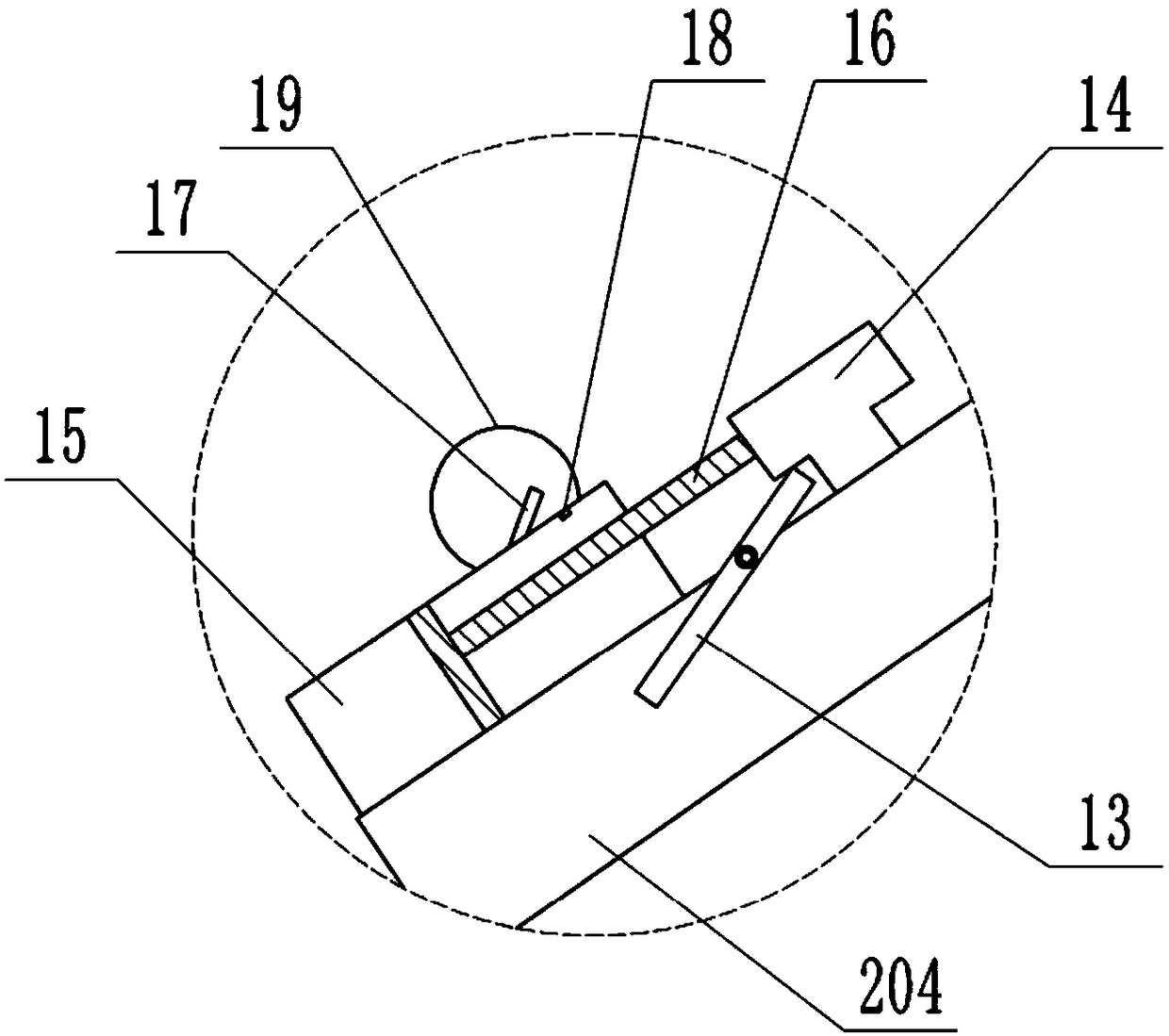

[0030] The reference signs in the drawings of the description include: ring guide rail 100, upper end surface 101, groove 102, lower end surface 103, motion mechanism 200, buckle ring 201, gear 202, connecting plate 203, nozzle 204, temperature sensor 3, cavity 4. The first solenoid valve 5, inner cavity 6, delivery channel 7, liquid level sensor 8, second solenoid valve 9, recovery tank 10, liquid storage tank 11, annular baffle 12, baffle 13, special-shaped air bag 14, cylinder Body 15, piston rod 16, first movable plate 17, first limiting block 18, filter screen 19.

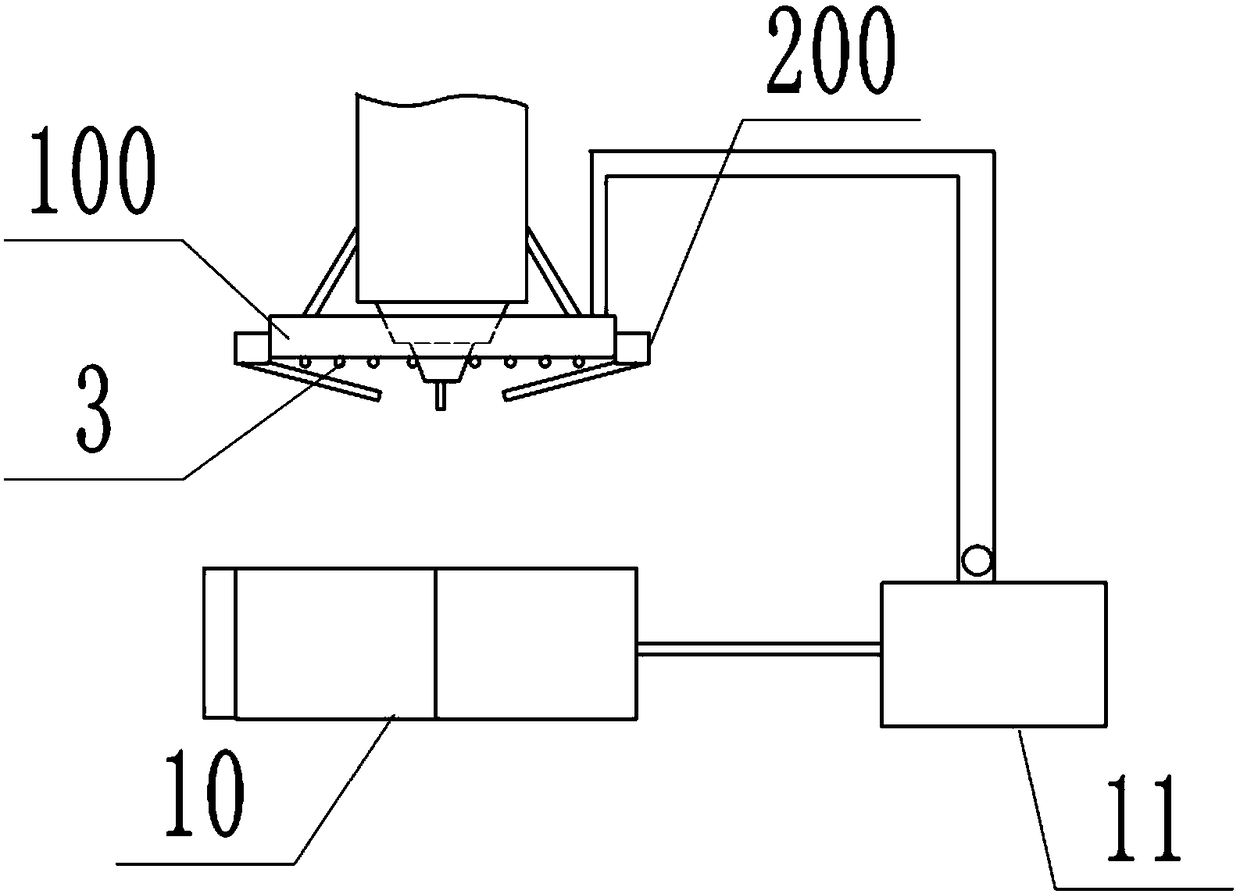

[0031] Such as figure 1 As shown, a cooling system for a numerically controlled machine tool of the present invention includes an annular guide rail 100 and a motion mechanism 200; the annular guide rail 100 is fixed on the machine tool through a bracket, such as figure 2 As shown, the ring guide rail 100 is I-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com