Evaporator shell casting die

A technology for casting molds and evaporators, which is applied in the field of casting molds for evaporator shells. It can solve the problems of blocked workpiece forming, troublesome operation, and easy insertion of push rods into the mold cavity, so as to ensure the quality of workpieces and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

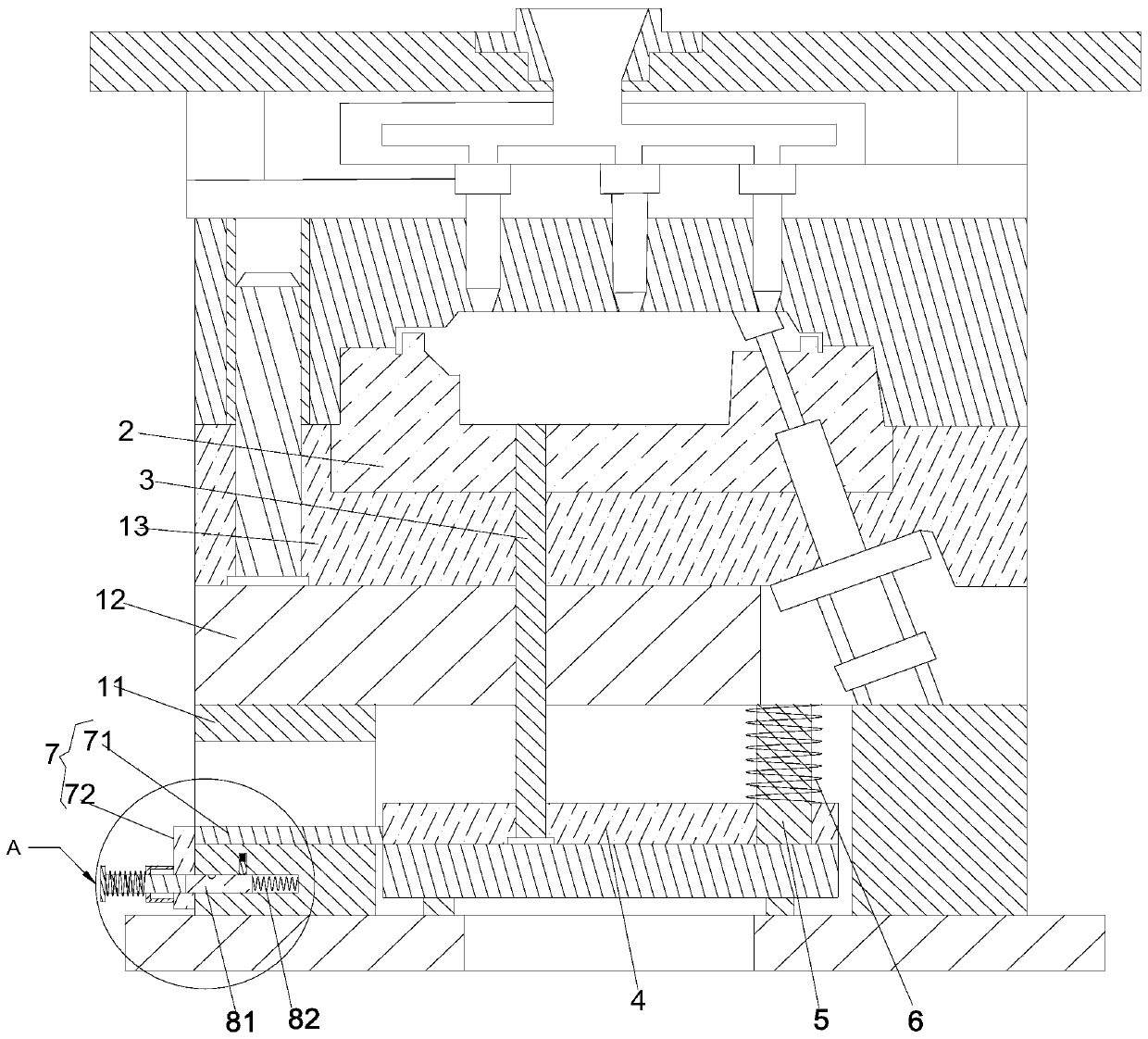

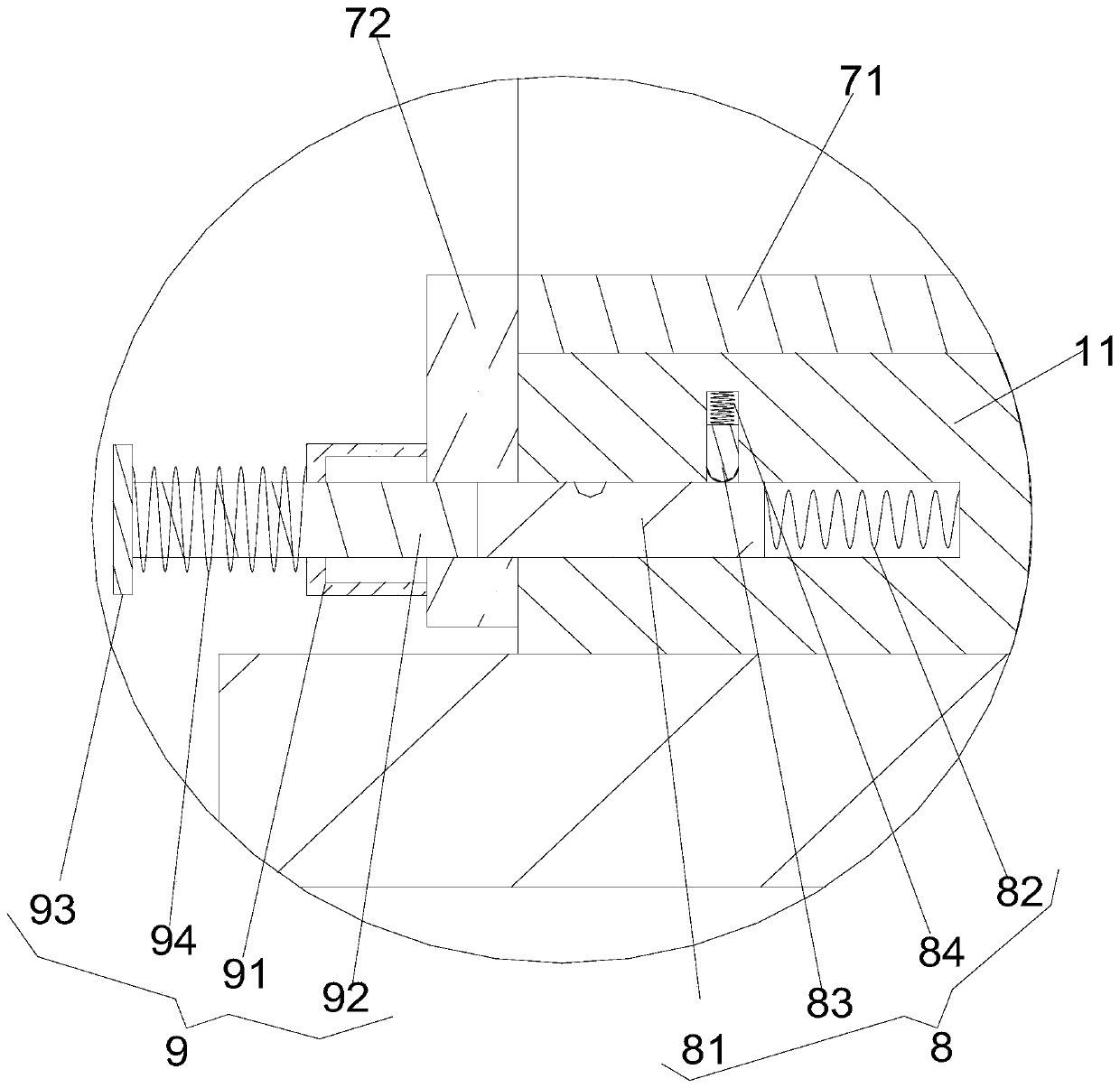

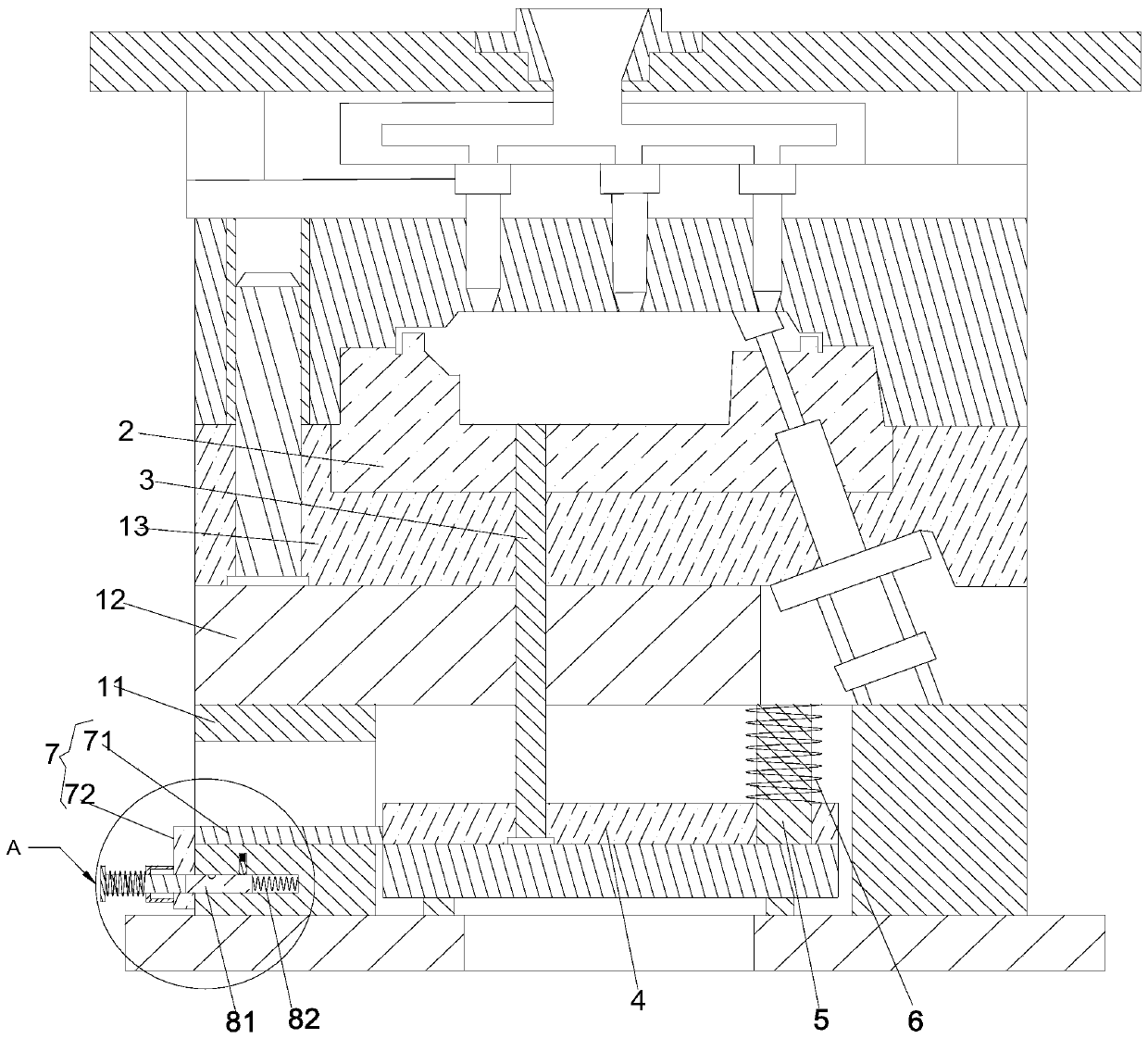

[0016] Such as figure 1 as well as figure 2 As shown, the present invention proposes a casting mold for an evaporator shell, including: a support seat 11, a support plate 12, a fixed plate 13, a core 2, a push rod 3, a guide plate 4, a guide rod 5, and a first spring 6 , the pulling aid mechanism 7 and the clamping mechanism 8, the support plate 12 is supported on the support seat 11, the core 2 is installed on the support plate 12 through the fixed plate 13, and the push rod 3 passes through the support plate 12, the fixed plate 13 and the core 2. The end of the push rod 3 located below the support plate 12 is fixed to the guide plate 4, the push rod 3 can move in the vertical direction relative to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com