Annular hollow part additive manufacturing smoke-discharging and dust-removing device and method

A technology of additive manufacturing and dust removal device, which is applied in the field of additive manufacturing, can solve the problems of exhaust air velocity attenuation, lower forming quality, and damage to the powder bed surface, etc., to reduce the air flow area, avoid damage, and improve molding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

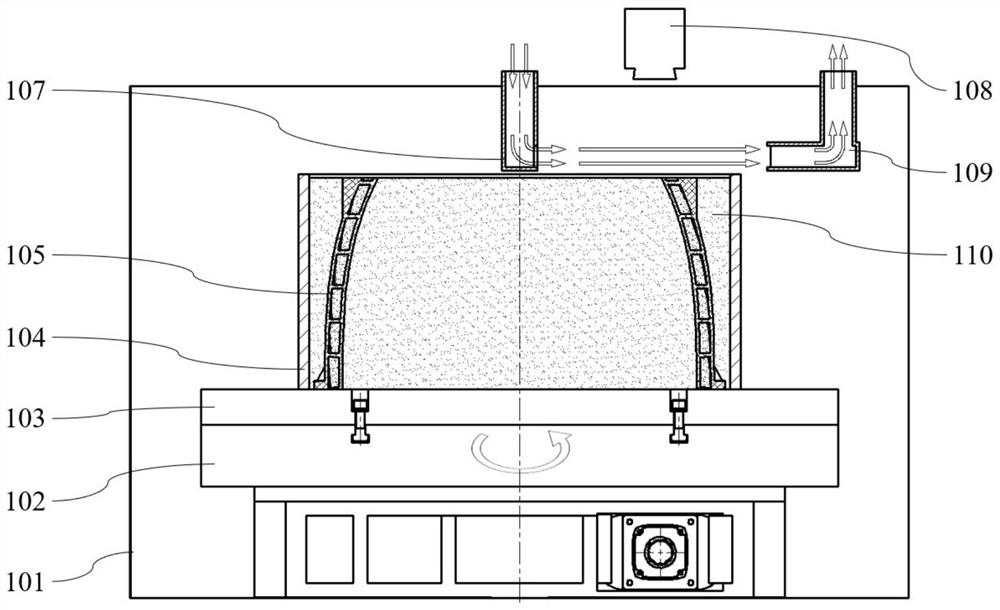

[0040] like figure 1 As shown, in the sealed forming chamber 101, a rotary table 102 is provided, and a substrate 103 is provided on the rotating table 102, and the substrate 103 is fastened to the rotary table 102. The substrate 103 is provided with a cylinder body 104 fixed to the substrate 103, and the outer cylinder 104 is formed in the forming workpiece 105. The area where the outer cylinder 104 is surrounded, that is, the molding region of the workpiece, in the forming region, and is laid in the process requirements.

[0041] For large formats of powder beds, the scanning area of a scanning system is generally not sufficient to cover the entire shaped area. However, if the scanning area of the scanning system has a contour diameter larger than the contour radius of the entire forming area, the scanning system 108 can be disposed at 1 / 2 of the outer cylinder body 104 contour radius. like figure 1 Indicated. Thus, when the rotating table 102 drives the substrate 103, the o...

Embodiment 2

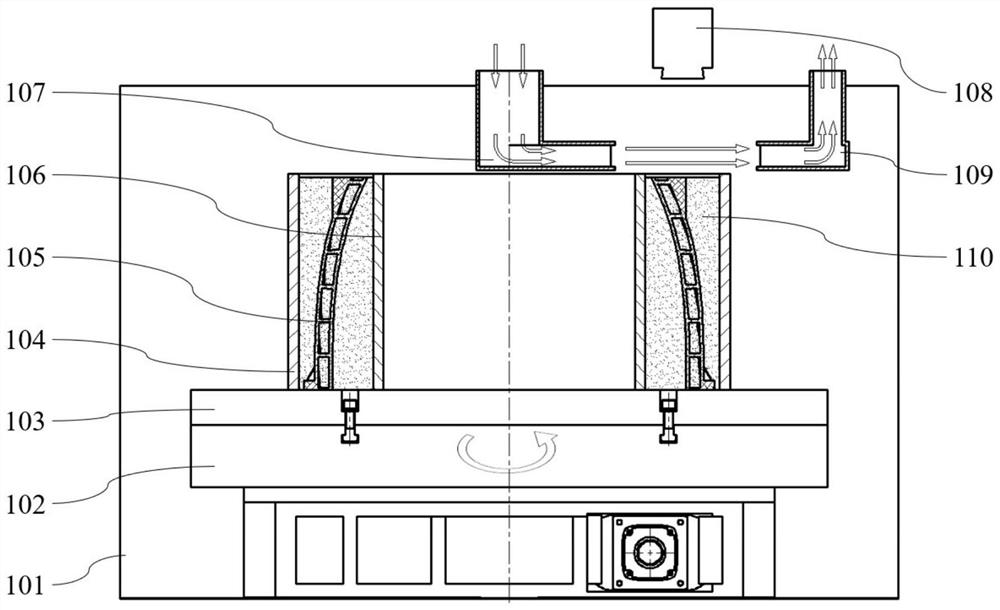

[0045] For barrel thin-walled parts, its overall contour is large, but its wall thickness is relatively thin, and there is no entity in which the center / internal position is not. Typical parts such as rocket hoses, vortex engine housings, rocket engines tail nozzle. Because these parts often have complex flow path structures inside the housing, such a large thin-walled complex member is produced using a powder bed molten forming process, the production cycle can be greatly shortened than the traditional manufacturing process.

[0046] like figure 2 As shown, an inner cylinder body 106 is provided in the outer cylinder 104, the forming workpiece 105, and the metal powder 110 are in the outer cylinder 104 and the inner cylinder body 106. Both the air opening of the blowing device 107 and the exhaust port of the exhaust device 109 are provided with a guide cover, and the two air-blown spacings are greater than the wall thickness of the shaped member, and the spacing of the blowing ...

Embodiment 3

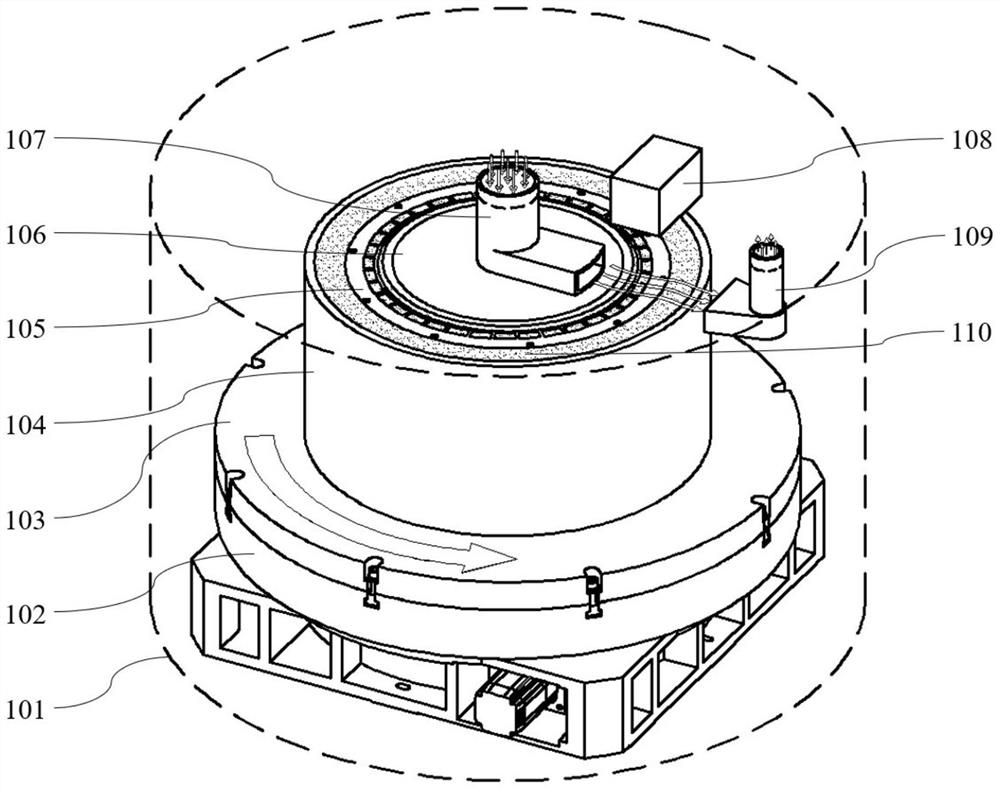

[0048] When the shape is large, the use of a multi-set scan system can significantly increase the forming efficiency of the workpiece. The larger forming formation also provides the necessary installation space for the arrangement of the multi-set scanning system.

[0049] like Figure 4 As shown, the blowing device 107 has four blowing ports evenly distributed on the circumference. Accordingly, in four corresponding directions, four sets of scanning systems and four sets of exhaust devices are provided. During the molding process, the blowing device 107, the exhaust device (109) and the scanning system are relatively positioned, and the molded member is rotationally formed, and the molded heat can be concentrated to prevent flue gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com