Aerostatic electric spindle and cooling device thereof

An air static pressure, electro-spindle technology, used in maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of precision drop, reduce shaft and rotor temperature, etc., to ensure workpiece quality and improve heat dissipation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

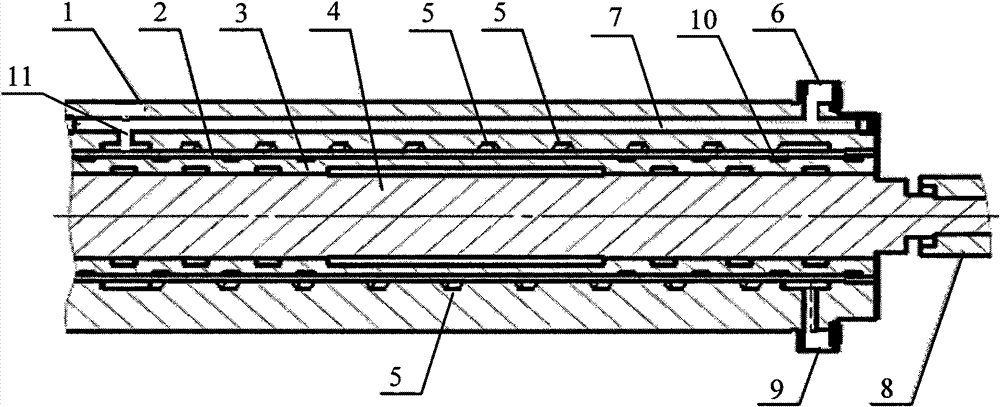

[0025] In view of the problem in the related art that due to the lack of heat dissipation measures for the radial bearing part, the thermal deformation of the rotating shaft and other components in the aerostatic electric spindle affects the accuracy, the present invention proposes to open a groove on the inner wall of the housing, and the sleeve Sealing, so that the groove forms a channel to accommodate the cooling material, and the radial bearing and the rotating shaft are cooled through heat exchange between the sleeve and the radial bearing, which can effectively improve the cooling effect and avoid The overheating of parts such as the rotating shaft leads to a decrease in accuracy, which in turn affects the quality of the processed workpiece. Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] According to an embodiment of the present invention, an aerostatic electric spindle is provided.

[0027] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com