Method for preparing AlCrCN coating on surface of cold working die steel

A technology of cold work die steel and coating, which is applied to the preparation of AlCrCN coating on the surface of cold work die steel, and the surface modification treatment of cold work die steel, can solve the problems of wear and tear of Cr12MoV steel, and achieve the improvement of surface hardness, good bonding, The effect of ensuring the quality of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

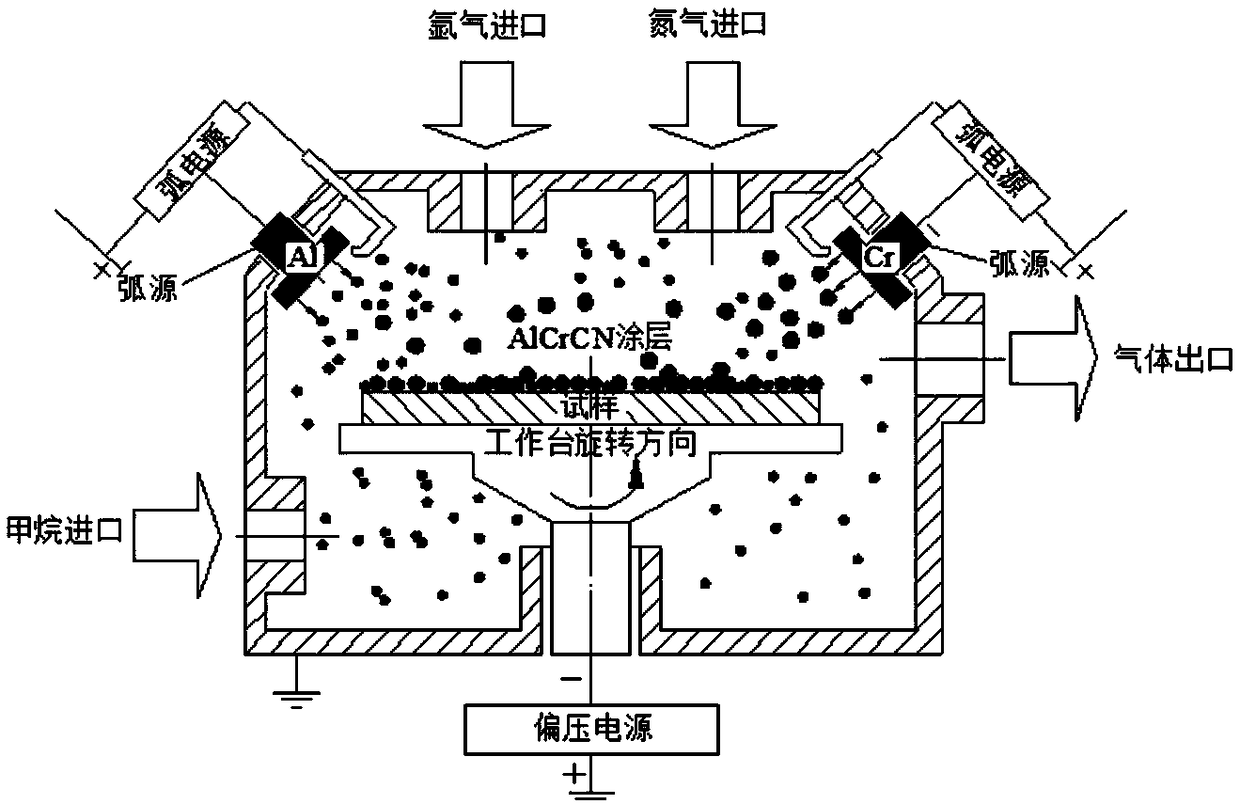

[0025] The technical scheme of the present invention is adopted below, and the present invention will be further described in conjunction with the accompanying drawings and examples.

[0026] (1) The substrate is Cr12MoV cold-work die steel. After grinding and polishing, the surface roughness Ra is 0.01 μm. It is ultrasonically cleaned in alcohol and acetone solutions for 15 minutes to remove oil stains, and it is dried before use.

[0027] (2) Put the sample into figure 1 Medium coating vacuum chamber with a vacuum degree of 10 -4 Pa, heated to 500°C and kept for 30 minutes. Firstly, argon gas was introduced to keep the pressure in the vacuum chamber at 1.0 Pa, the bias power was turned on, the voltage was 900V, the duty cycle was 0.2, the glow discharge was cleaned for 15 minutes, the bias voltage was reduced to 500V, and the ion source was turned on for 15 minutes of ion cleaning.

[0028] (3) Stop feeding argon, and after vacuuming the coating vacuum chamber to 0.5Pa, fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com