Underwater acoustic-optical device precision testing method

A technology of precision testing and optical equipment, applied in radio wave measurement systems, instruments, etc., can solve the problem of inability to accurately judge the reliability of data detection data, and achieve the effects of low cost, wide application range and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0021] According to the equipment parameters and detection conditions, the detection test platform is designed and manufactured. The test platform is required to be stable and firm, and the underwater acousto-optic detection equipment and test model can be installed. The distance measurement is adjustable, that is, the distance between the underwater acousto-optic equipment and the test model can be adjusted. Tune.

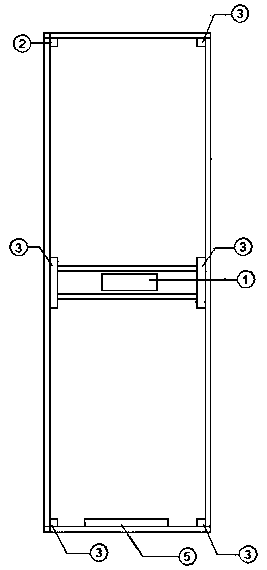

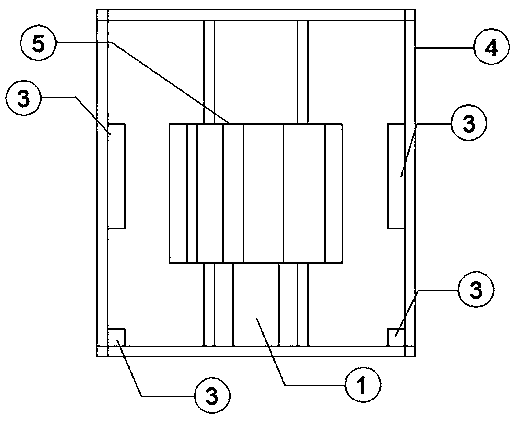

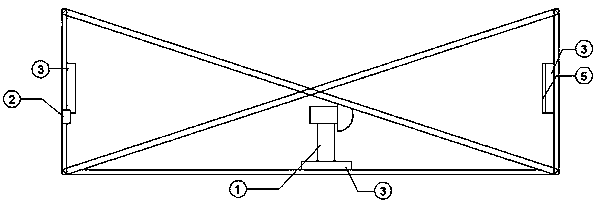

[0022] Such as figure 1 , figure 2 As shown, a test platform provided by the embodiment of the present invention includes a base, an equipment platform, and a model platform. The base is a rectangle surrounded by two short and two long beams, and the test model is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com