Three-item terminal welding machine

A welding machine and welding mechanism technology, applied in welding equipment, auxiliary devices, metal processing, etc., can solve the problems of inconvenient operation for workers and unguaranteed workpiece quality, and achieve the effects of guaranteed workpiece quality, high production efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

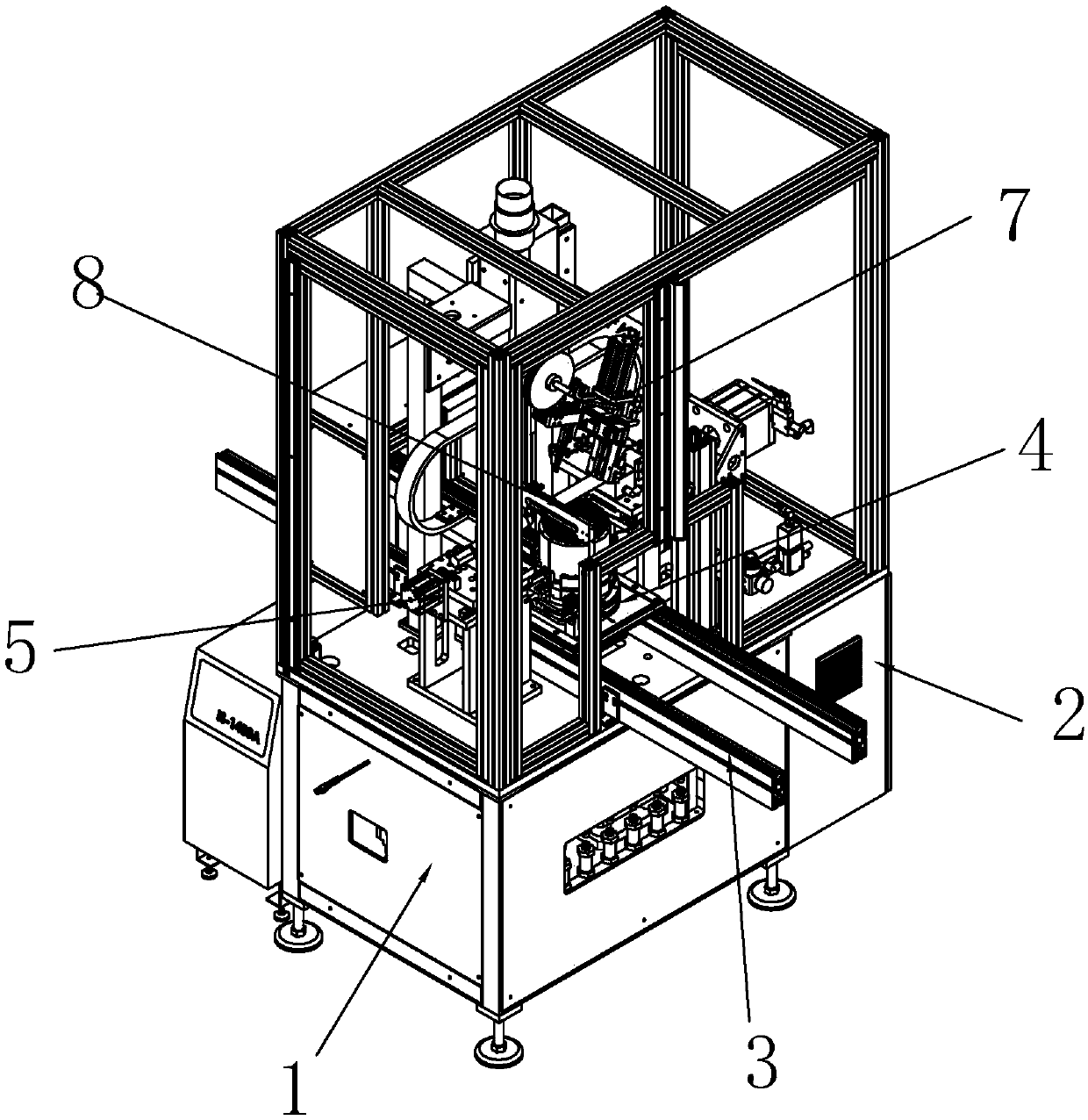

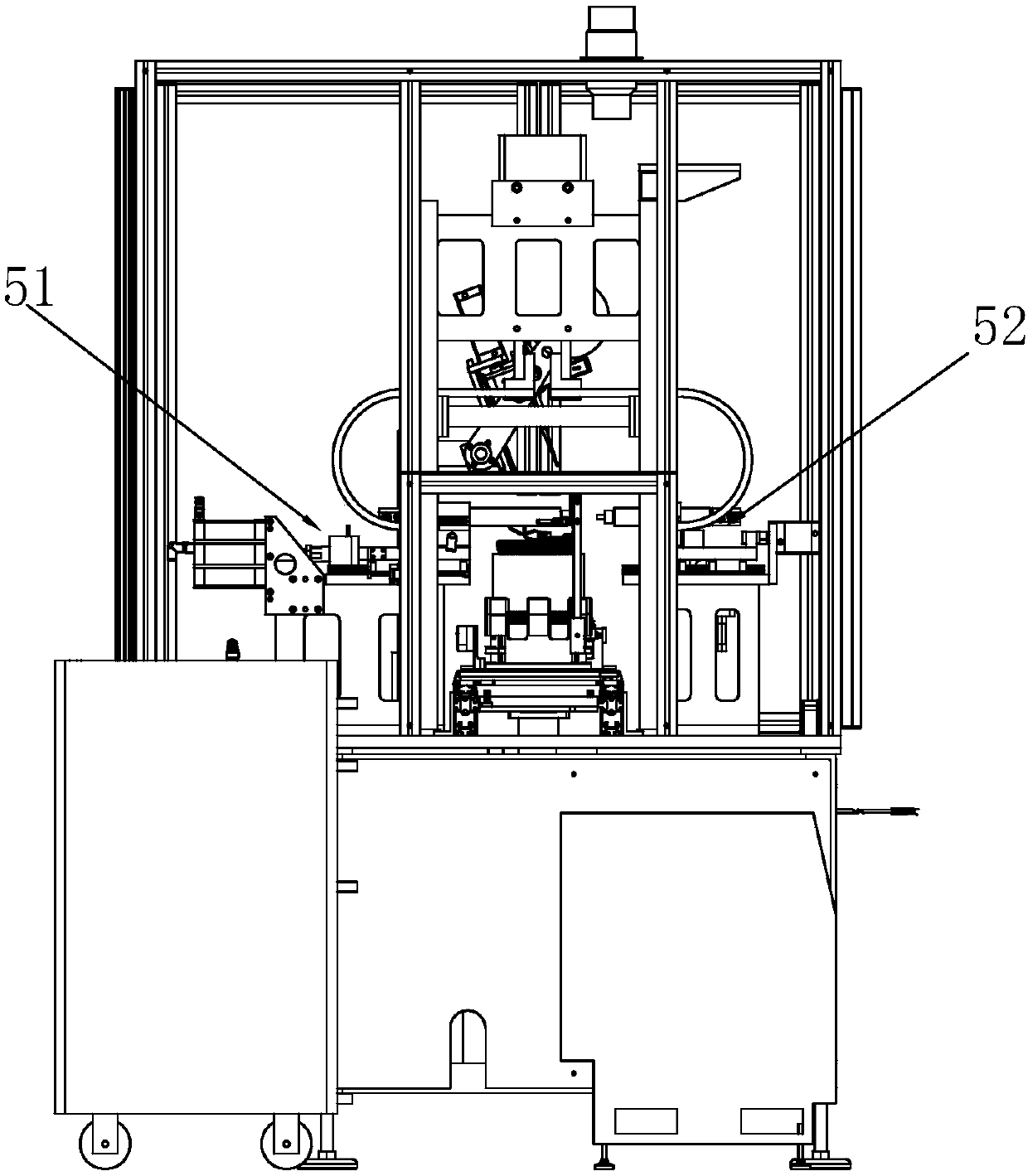

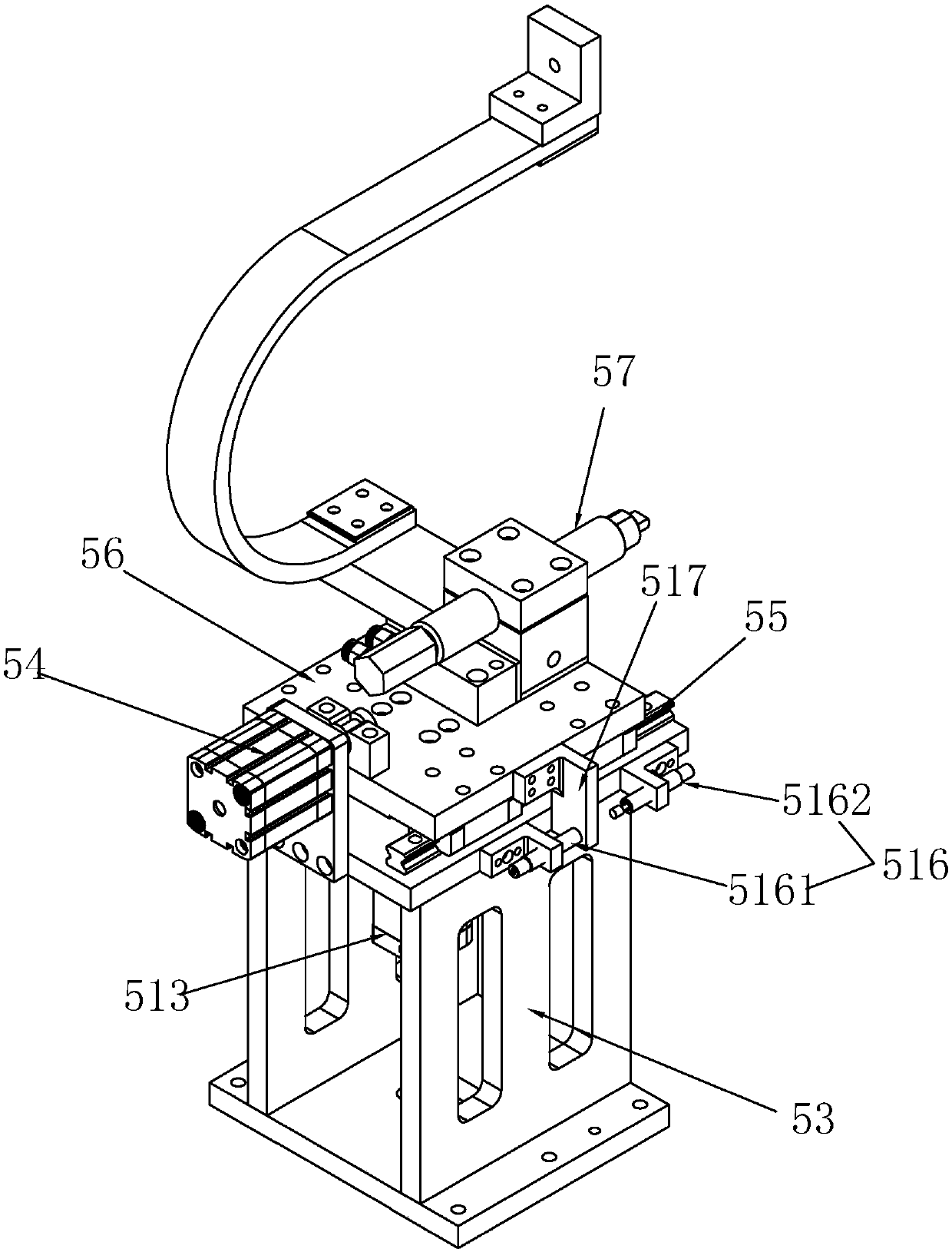

[0030] Such as figure 1 As shown, the three terminal welding machines include a frame 1, a PLC controller 2 installed on the frame 1, a linear guide rail 3 horizontally laid on the upper surface of the frame 1, a tooling table 4 sliding along the linear guide rail 3, The brazing material welding mechanism 5 arranged on the left and right sides of the tooling table 4 and oppositely arranged, the jacking displacement mechanism 6 located below the upper surface of the frame 1 and capable of jacking up the tooling table 4, and the brazing material installed on the frame 1 Material delivery device 7, positioning tooling device 8 is installed on the tooling platform 4. The PLC controller 2 is connected with the brazing material welding mechanism 5, the jacking displacement mechanism 6, and the brazing material conveying device 7 through cables, and controls their operation.

[0031] There are two linear guide rails 3, which are laid side by side on the frame 1. The tooling table 4...

Embodiment 2

[0049] After the lead-out wire is fused, irregular fusing surfaces may appear, which will affect the next welding process. Therefore, the solder trimming device 9 on the frame 1 and below the solder delivery device 7 is used for trimming the irregular fusing surface of the lead wire.

[0050] See Figure 10 , the brazing material trimming device 9 comprises a trimming frame 914, a trimming cylinder 915 installed on the trimming frame 914, a guide rod 916 arranged in parallel on the trimming frame 914 and a sliding frame 917 sleeved on the guide rod 916, and the trimming cylinder 915 and The sliding frame 917 is connected and can drive the sliding frame 917 to slide along the guide rod 916. The sliding frame 917 is equipped with a small cylinder 918 and the scissors 919 controlled by the small cylinder 918 to trim.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com