A cutting machine tool for crankshaft connecting rod production

A technology for cutting machine tools and crankshafts and connecting rods, which is applied in the direction of sawing machine devices, metal sawing equipment, and metal processing equipment. The effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

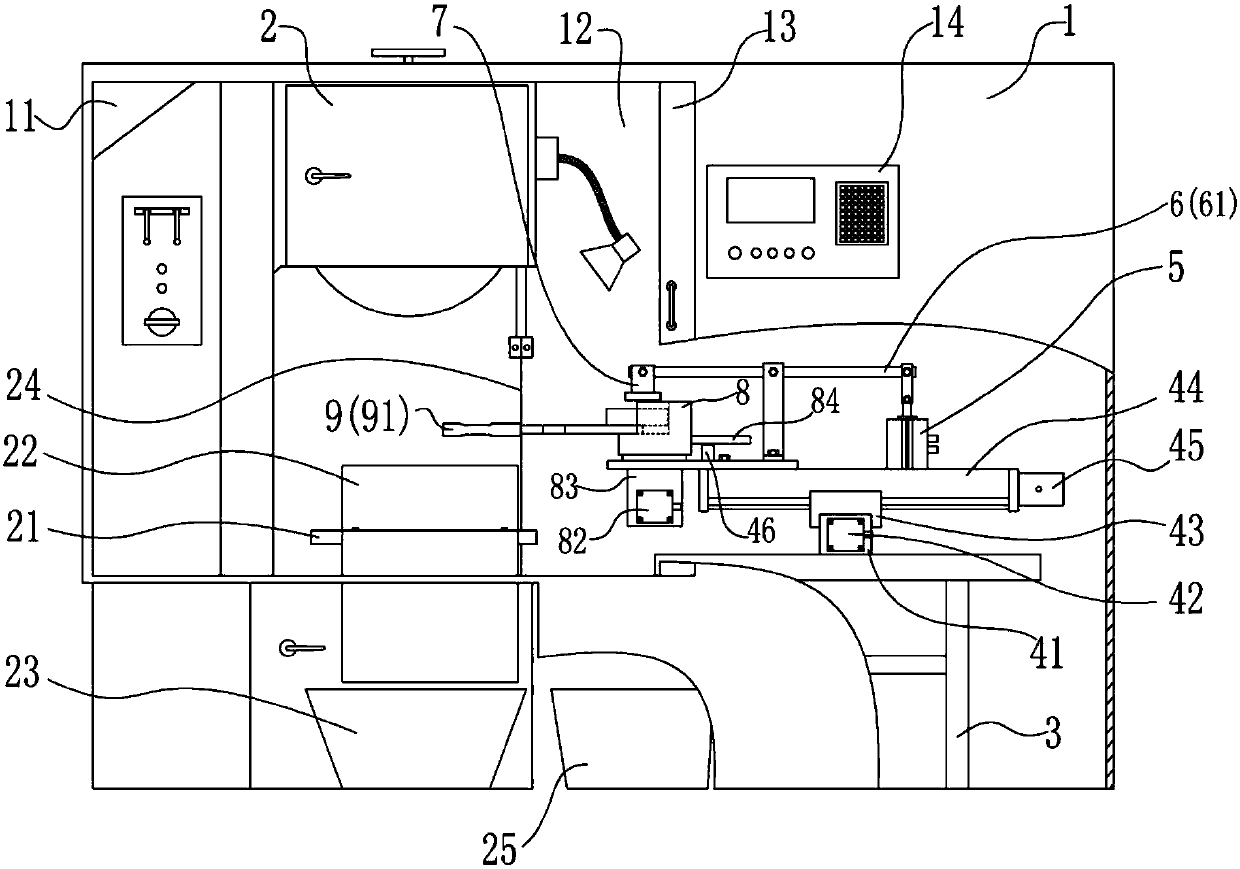

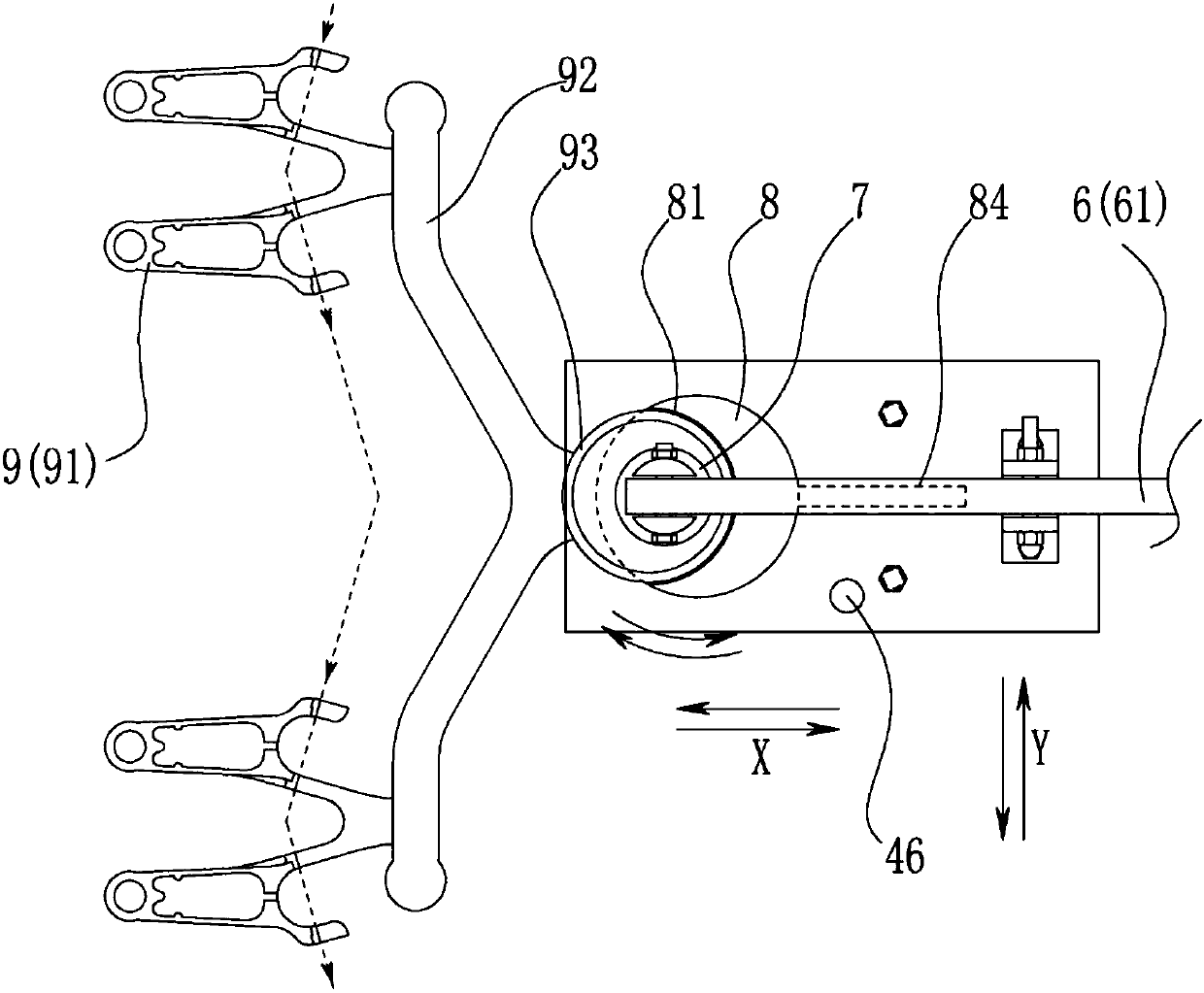

[0019] Such as figure 1 As shown, the present invention proposes a cutting machine tool for the production of crankshaft connecting rods, including a box body 1 and a sawing machine 2 arranged in the inner cavity of the box body 1, a clamping device and a numerical control host 14, wherein: the box body 1 A sawing machine operation window 11 and a clamping operation window 12 are provided, wherein a movable protective door 13 is provided at the clamping operation window 12, and the sawing machine 2 and the clamping device can be closed in by setting the box body 1 when idle, thereby avoiding The sawing machine 2 is damaged or accidentally injured;

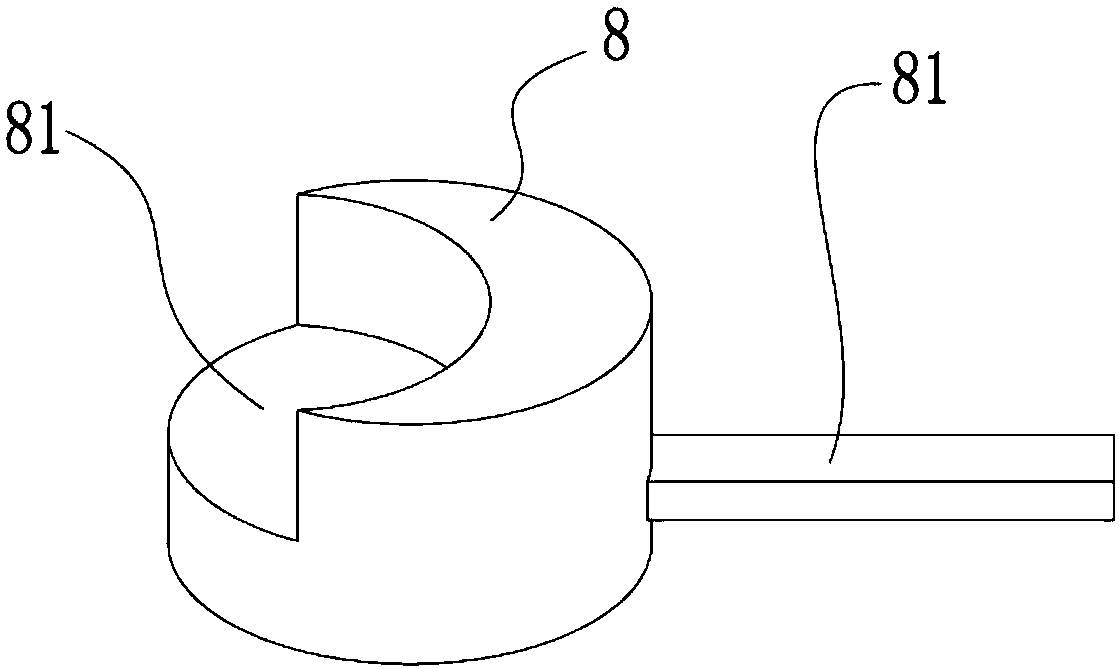

[0020] The sawing machine 2 is a vertical sawing machine using a band saw blade 24, a hopper 22 is provided on the workbench 21 of the sawing machine 2, and a material box 23 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com