Hobbing assembly clamp for gear shaft

A technology of tooling fixtures and gear shafts, which is applied in the direction of gear tooth manufacturing devices, manufacturing tools, belts/chains/gears, etc., which can solve problems such as not being firm enough, affecting the quality of processing and installation, and prone to loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

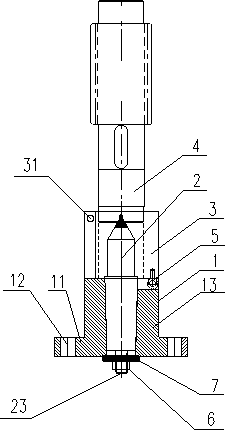

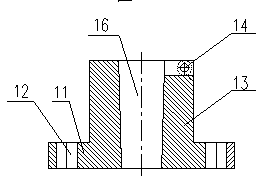

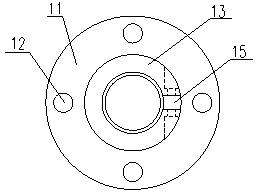

[0014] Such as figure 1 The gear shaft hobbing tooling fixture shown includes a clamping body 1, a center 2, a clamping sleeve 3 and a stopper 5; the clamping body 1 includes a cylinder 13 with a central cone hole, and the bottom of the cylinder A circle of bosses 11 is provided around the bosses 11, a plurality of bolt installation through holes 12 are provided on the bosses 11, a downward longitudinal groove 15 is provided on the upper end of the cylinder 13, and a fastening Bolt 14; the top 2 includes a top head 21, a top body 22 and a threaded end 21. The size and Morse taper of the top body 22 is matched with the central taper hole 16 of the clamping body 1, and the threaded end 23 of the top 2 is from the clamping body 1 through the tapered hole 16 and fixed at the bottom of the clamp body 1 through the nut 6 and the washer 7; the clamping sleeve 3 is an open annular sleeve, and the two ends of the ring are on the upper part of the annular sleeve The heads are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com