High-temperature endurance test fixture for full pipe sample of small-diameter metal thin-walled pipe

A long-lasting test and metal thin technology, applied in the field of metal material test research, can solve the problems of insufficient clamping force, neutrality can not meet the requirements, and is not feasible, so as to achieve accurate and reliable high-temperature durable strength results and neutrality of the sample Good, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings.

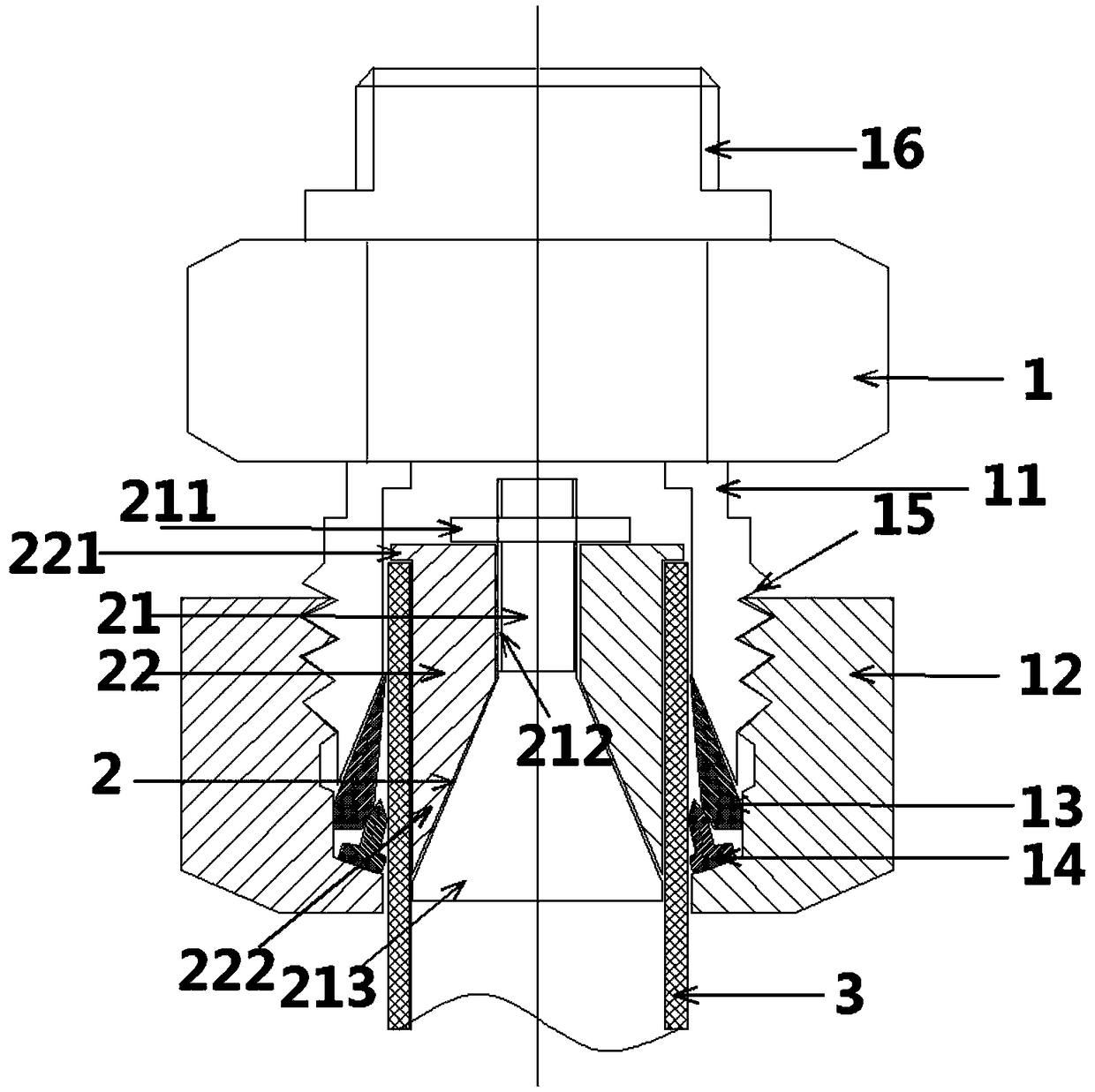

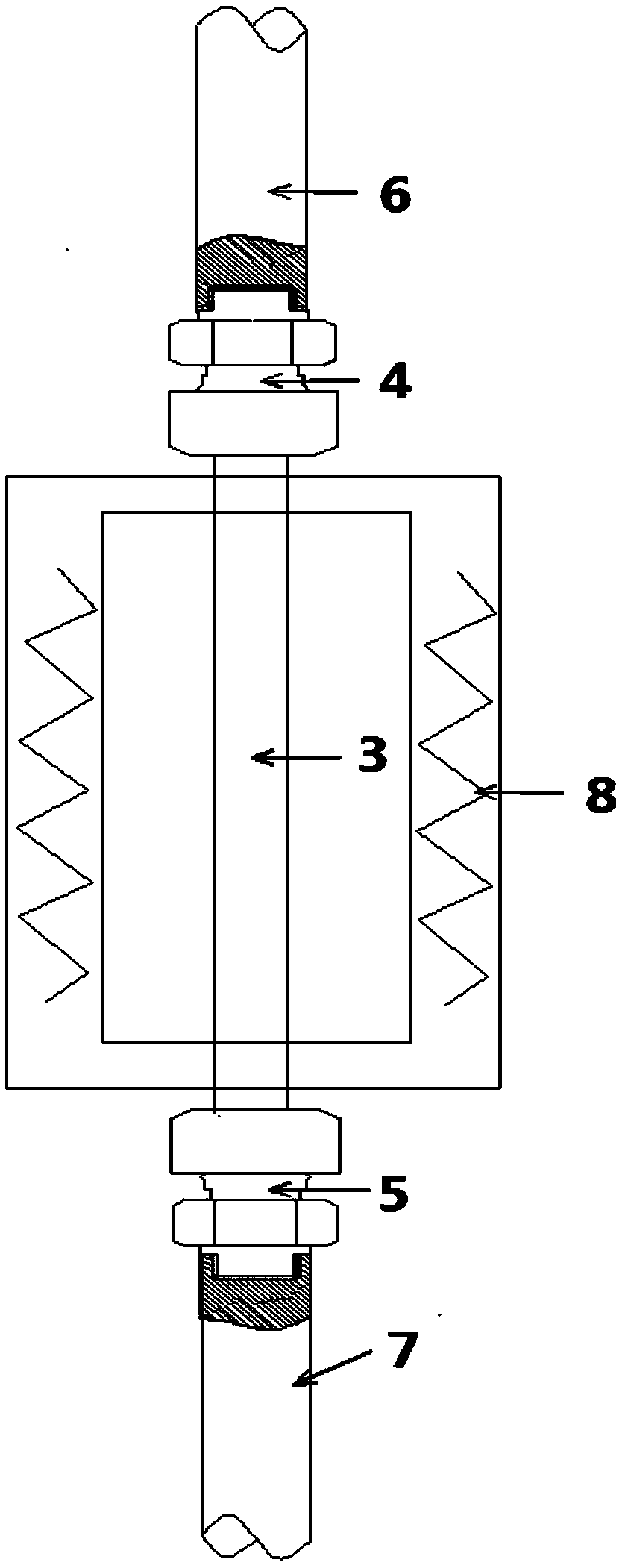

[0029] Such as figure 1 with figure 2 As shown, the present invention provides a small-diameter metal thin-walled tube full-tube sample high-temperature endurance test fixture, including an outer fixture 1 and an inner fixture 2; the outer fixture includes an adapter body 11, a clamping nut 12, a front ferrule 13, The rear ferrule 14, the external thread 15 of the adapter and the connecting thread 16; the inner clamp 2 specifically includes a shaft 21 and a shaft sleeve 22. Among them: the upper end of the shaft 21 is provided with a fixing nut 211, the middle part is provided with an external thread 212, and the lower part is a cone structure 213; the upper end of the shaft sleeve 22 is provided with a double shaft shoulder 221, and the lower end is a symmetrical six-petal inner cone sleeve 222.

[0030] The specific installation steps are as follows:

[0031] First, instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com