Ultrasonic stitching and embossing machine

An ultrasonic and embossing machine technology, which is applied in textiles and papermaking, fabric surface trimming, puncture patterns, etc., can solve the problems of cumbersome adjustment operations, time-consuming work, and lack of convenience, so as to achieve clamping force and improve flatness , Stable and reliable effect of traction movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content, features and effects of the present invention, the following examples are provided for detailed description.

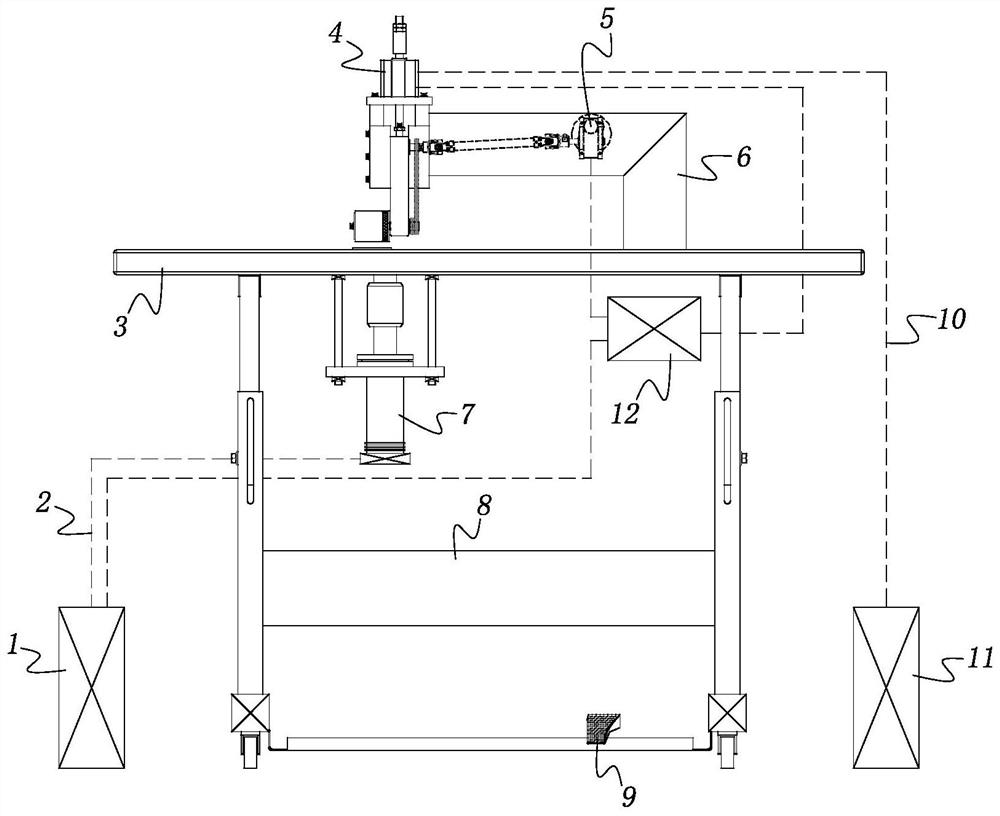

[0025] See figure 1 , The ultrasonic stitching embossing machine of the present invention includes an operating table 3 supported by a bracket 8, an ultrasonic device 7 is installed below the operating table 3, and an ultrasonic generator 1, which is connected to the ultrasonic device through a lead 2 7Connect.

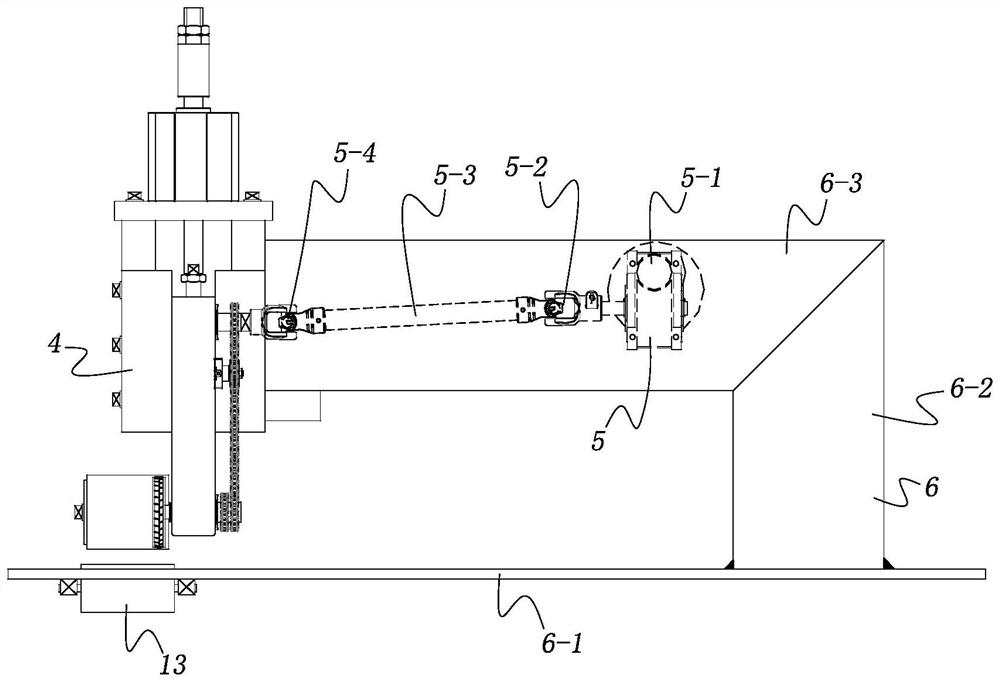

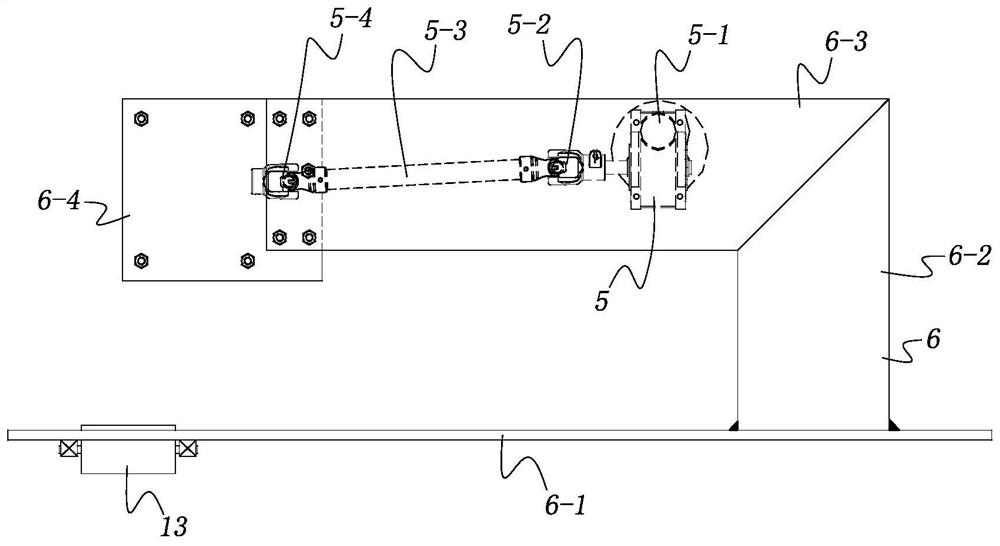

[0026] A support 6 is installed on the operating table 3, and a sewing and embossing device 4 and a driving device 5 for powering the sewing and embossing device 4 are installed on the support 6. It also includes an air compressor 11, which provides a compressed air source for the ultrasonic sewing embossing machine.

[0027] As shown in the figure, the bracket 8 and the operating table 3 together constitute an operating table, and the operator sits in front of the operating table to perform stitching and embossing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com