Steel wire rope tensile fixture and horizontal steel wire rope tensile testing machine thereof

A technology of tensile testing machine and steel wire rope, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., which can solve the problems of many unsafe hidden dangers, waste of electric energy, and high cost, and achieve energy saving and high cost in the testing process. Reduced labor and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

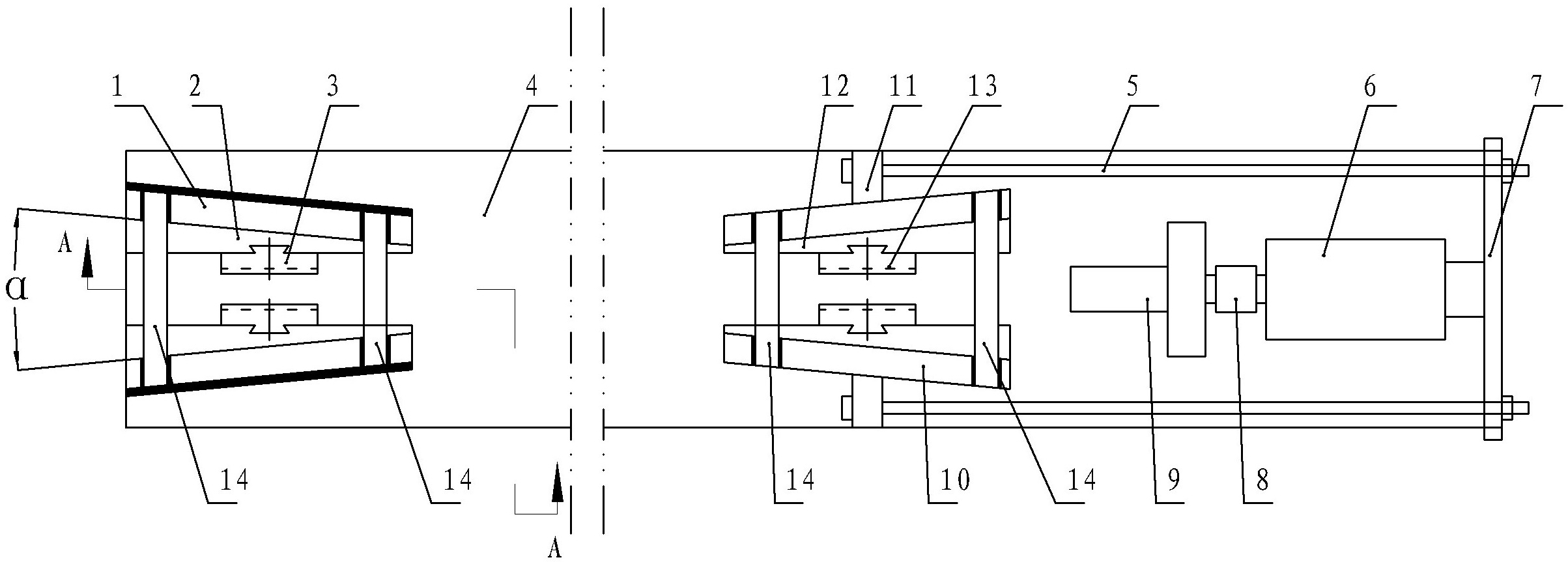

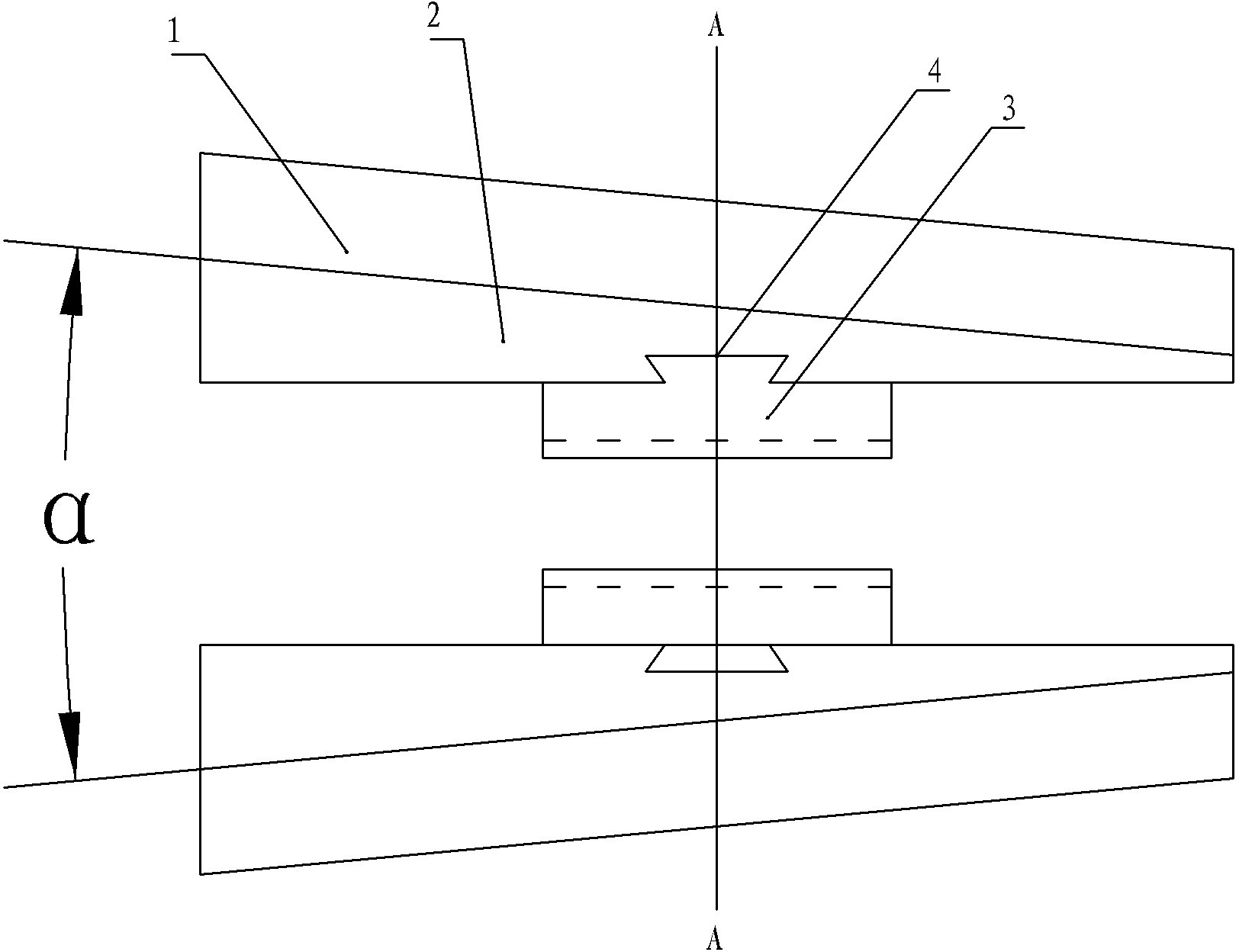

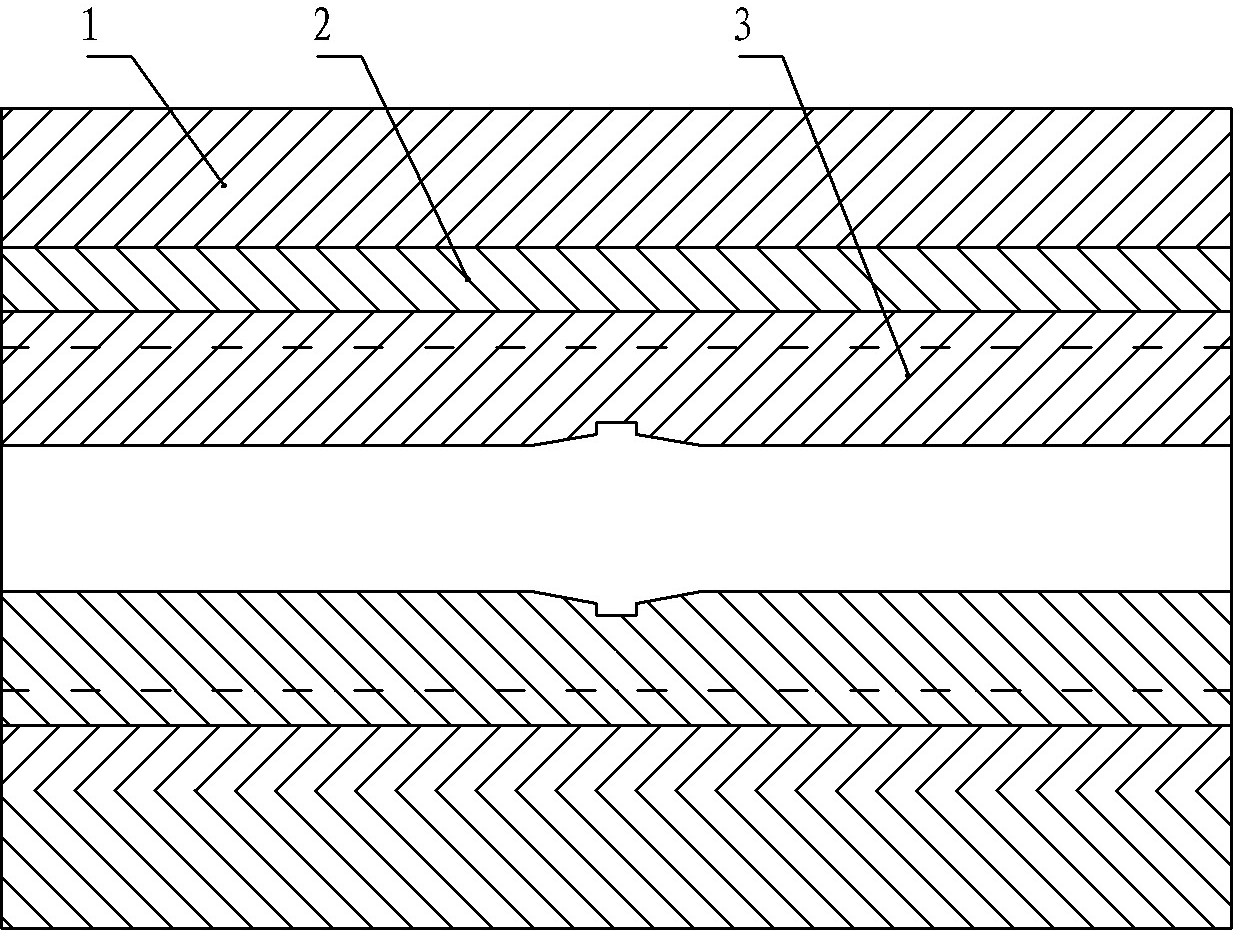

[0033] Embodiment one: Figure 1-Figure 7 , a steel wire rope tensioning fixture in the figure, including a symmetrically arranged frame body, a wedge-shaped slide plate, and a friction block. The frame body includes two vertical plates whose inner surfaces are arranged at an angle α, and the inclination angle of the wedge-shaped slide plate is the same as The above fixture α is matched; the inner surface of the wedge-shaped slide plate and the friction block are connected through a vertical dovetail groove structure; the angle 13°≤α≤17°; the width L of the friction block is between 190mm and 220mm between. A reinforcing connecting plate can also be added between the above two vertical plates, so as to ensure that the positional relationship between the two vertical plates remains unchanged after loading and prevent deformation. The middle part of the friction block is provided with a horizontal V-shaped clamping groove, and the surface of the V-shaped clamping groove is prov...

Embodiment 2

[0036] Embodiment two: Figure 1-Figure 7 , a steel wire rope tensioning fixture in the figure, including a symmetrically arranged frame body, a wedge-shaped slide plate, and a friction block. The frame body includes two vertical plates whose inner surfaces are arranged at an angle α, and the inclination angle of the wedge-shaped slide plate is the same as The above fixture α is matched; the inner surface of the wedge-shaped slide plate and the friction block are connected through a vertical dovetail groove structure; the included angle is 16°≤α≤20°; the width L of the friction block is between 200mm and 230mm between. A reinforcing connecting plate can also be added between the above two vertical plates, so as to ensure that the positional relationship between the two vertical plates remains unchanged after loading and prevent deformation.

[0037] The middle part of the friction block is provided with a horizontal V-shaped clamping groove, and the surface of the V-shaped cl...

Embodiment 3

[0040] Embodiment three: Figure 1-Figure 7 , a steel wire rope tensioning fixture in the figure, including a symmetrically arranged frame body, a wedge-shaped slide plate, and a friction block. The frame body includes two vertical plates whose inner surfaces are arranged at an angle α, and the inclination angle of the wedge-shaped slide plate is the same as The above fixture α is matched; the inner surface of the wedge-shaped slide plate and the friction block are connected through a vertical dovetail groove structure; the included angle is 19°≤α≤23°; the width L of the friction block is between 210mm and 340mm between. A reinforcing connecting plate can also be added between the above two vertical plates, so as to ensure that the positional relationship between the two vertical plates remains unchanged after loading and prevent deformation.

[0041] The middle part of the friction block is provided with a horizontal V-shaped clamping groove, and the surface of the V-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com