Laptop positioning rotary shaft

A notebook computer and positioning shaft technology, applied in pivot connection, engine components, engine lubrication, etc., can solve the problems of easy melting of lubricating oil in the oil tank, difficult formation of oil film, slow heat dissipation, etc., to ensure the continuity and stability of lubrication , high fixing strength and stability, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

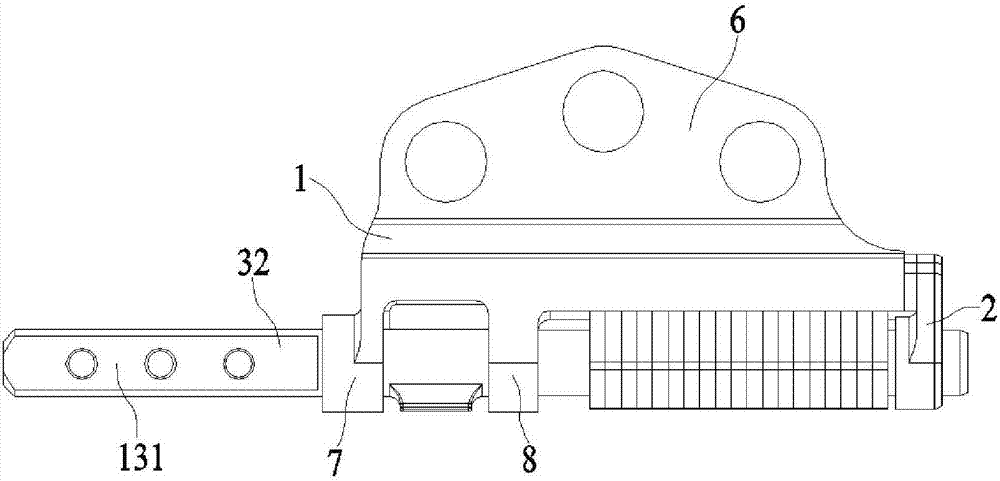

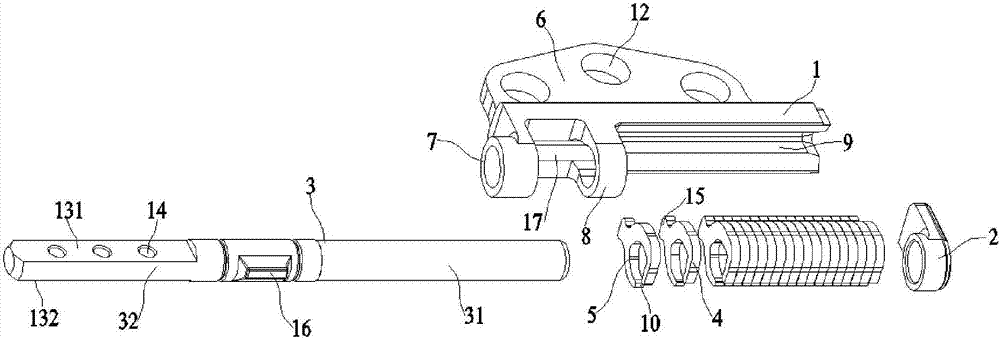

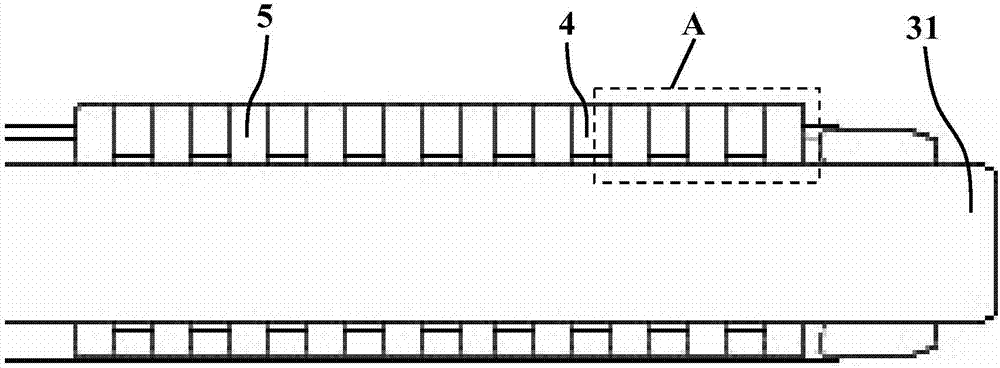

[0028] Embodiment 1: A positioning shaft for a notebook computer, including a rotating bracket 1, a stopper 2, a shaft core rod 3, several loose fin rings 4 and several tight fin rings 5, and the rotating bracket 1 further includes a support 6, the first bushing 7 and the second bushing 8, the first bushing 7 is located at one end of the lower end surface of the rotating bracket 1, the second bushing 8 is located at the middle of the lower end surface of the rotating bracket 1, and the rotating There is a dove-shaped groove 9 on the lower end surface of the bracket 1 between the other end and the second bushing 8. One side of the shaft core rod 3 is a polished rod portion 31, and the other side is a non-polished rod portion 32. The polished rod part 31 of the core rod 3 is embedded in the first bushing 7 and the second bushing 8 of the support part 6, and the lower part and the upper part of the stopper 2 are respectively fitted in the end of the polished rod part 31 and the do...

Embodiment 2

[0032] Embodiment 2: A positioning shaft for a notebook computer, including a rotating bracket 1, a stopper 2, a shaft core rod 3, several loose fin rings 4 and several tight fin rings 5, and the rotating bracket 1 further includes a support 6, the first bushing 7 and the second bushing 8, the first bushing 7 is located at one end of the lower end surface of the rotating bracket 1, the second bushing 8 is located at the middle of the lower end surface of the rotating bracket 1, and the rotating There is a dove-shaped groove 9 on the lower end surface of the bracket 1 between the other end and the second bushing 8. One side of the shaft core rod 3 is a polished rod portion 31, and the other side is a non-polished rod portion 32. The polished rod part 31 of the core rod 3 is embedded in the first bushing 7 and the second bushing 8 of the support part 6, and the lower part and the upper part of the stopper 2 are respectively fitted in the end of the polished rod part 31 and the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com