Underwater mechanical arm wrist portion structure for high strength operation underwater robot

A technology of underwater robots and underwater machinery, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve problems such as difficult sealing, and achieve the effects of safe and reliable work, high rotational torque, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

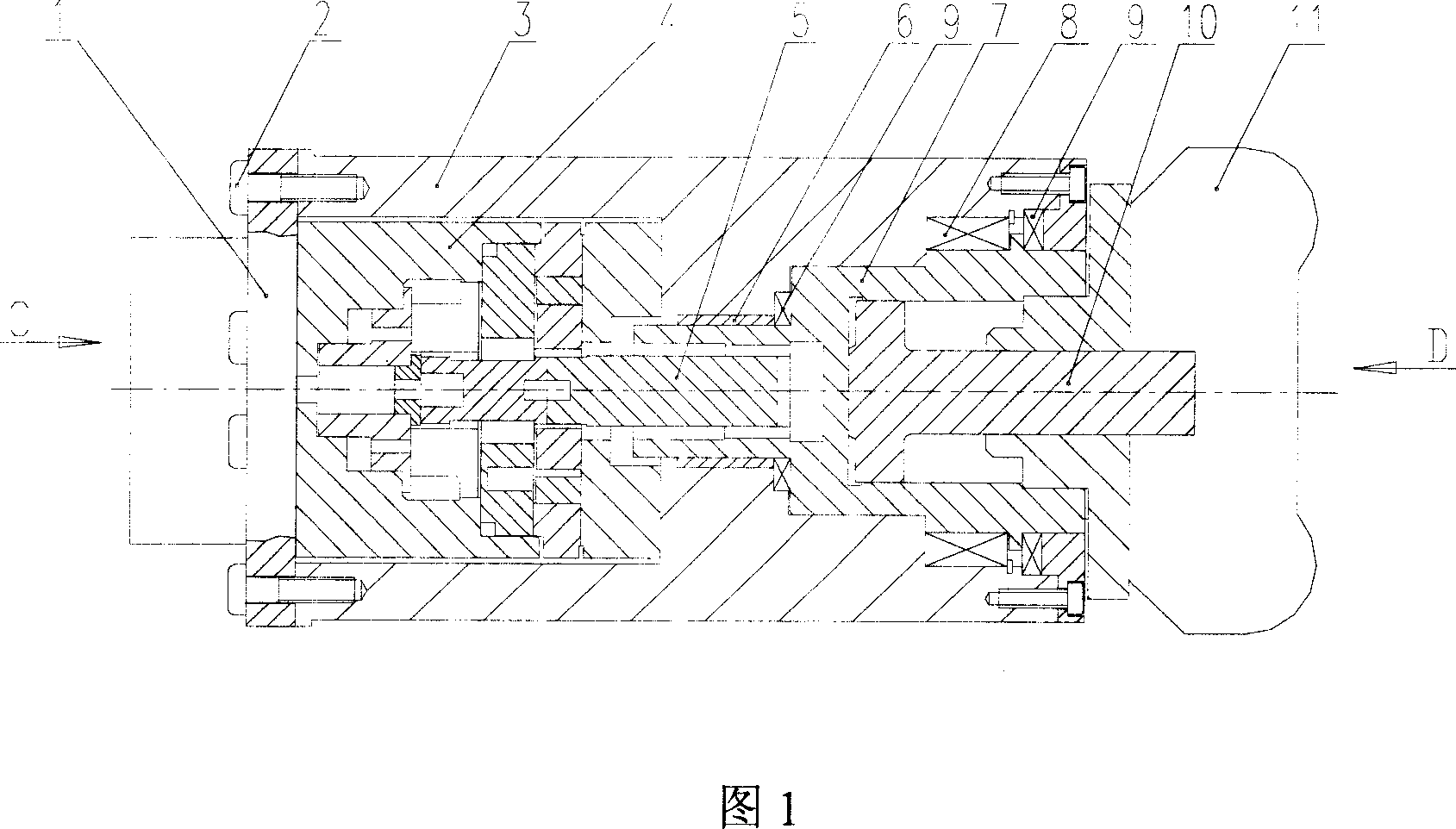

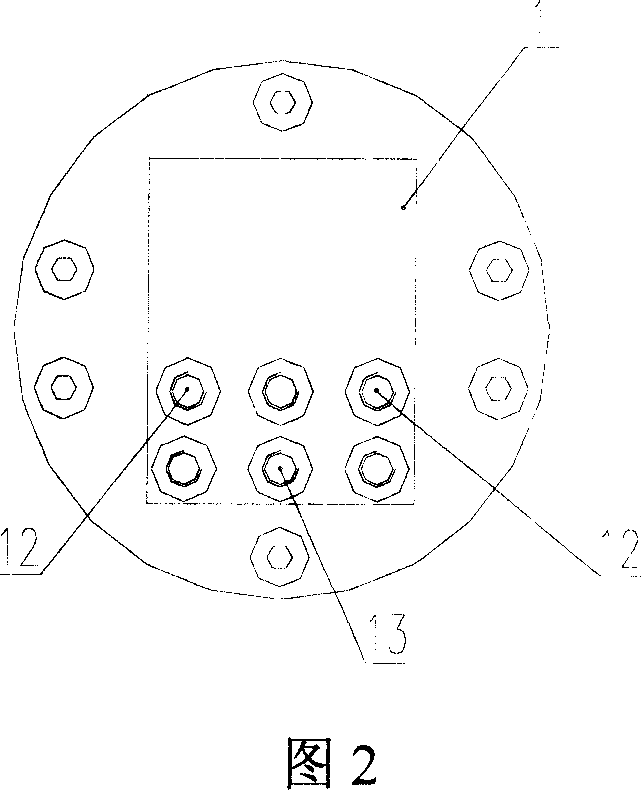

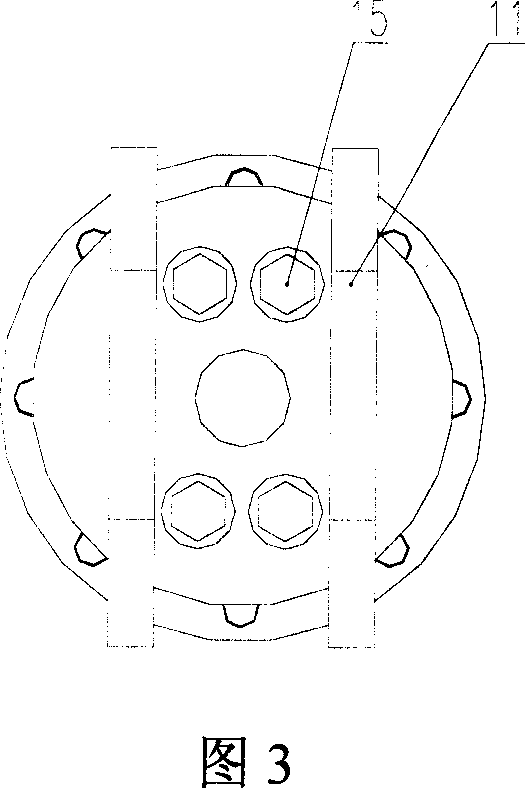

[0013] As shown in FIG. 1, the present invention consists of a wrist back seat 1, a wrist sleeve 3, a cycloid motor assembly 4, a long spline connecting shaft 5, a shaft sleeve 6, a rotating sleeve 7, a radial needle roller bearing 8, and a thrust needle roller. The bearing 9, the short piston rod 10, and the clamp rotating seat 11 are composed, wherein: the cycloid motor assembly 4 is installed in the cavity on one side of the wrist sleeve 3, and the wrist rear seat 1 is sealed on the end face of the wrist sleeve 3 with the sealing screw 2; One end of the long spline connecting shaft section 5 is inserted into the cycloid motor assembly 4, and the other end is inserted into the inner spline groove at one end of the rotating sleeve 7; One end of the rotary sleeve 7 is provided with a cylindrical cavity with a built-in short piston rod 10, and the clamp rotating seat 11 is inserted into the cylindrical cavity of the rotary sleeve 7, and is fixedly connected by screws 15, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com