Structure for preventing encoder button from coming out of place

An anti-off structure and encoder technology, which is applied in the field of anti-off structures of encoder knobs, can solve the problems that it is difficult to avoid the elastic locking claws coming out, and it is difficult to avoid the accidental disintegration of the anti-off structures of the encoder knobs, so as to prevent the off-off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the present invention will be specifically described based on the illustrated embodiments.

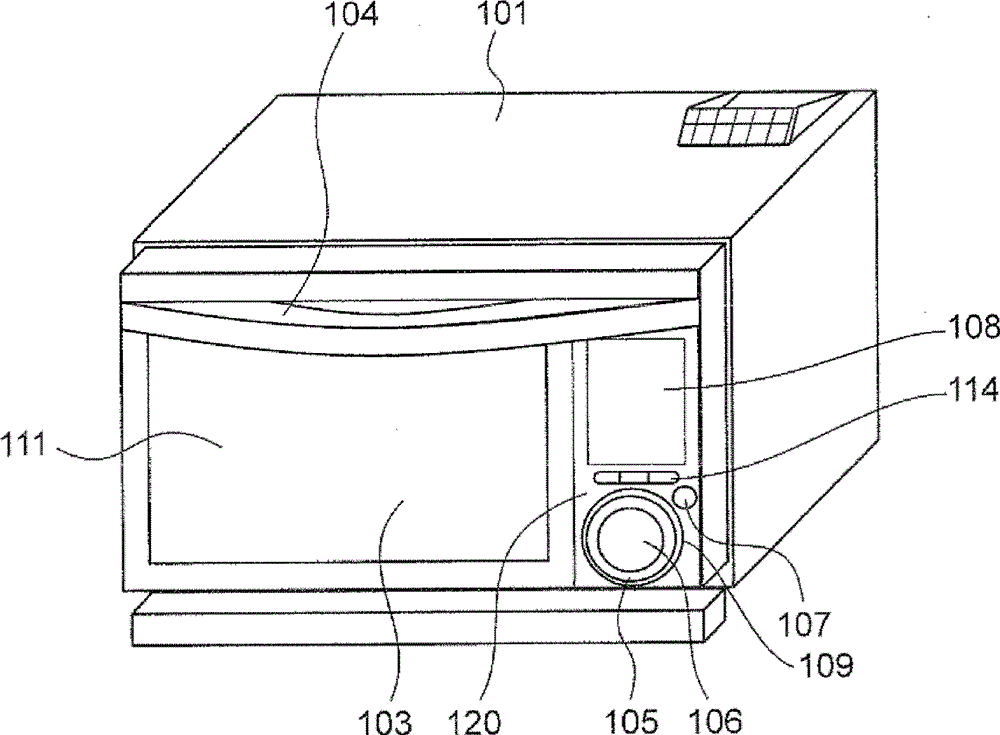

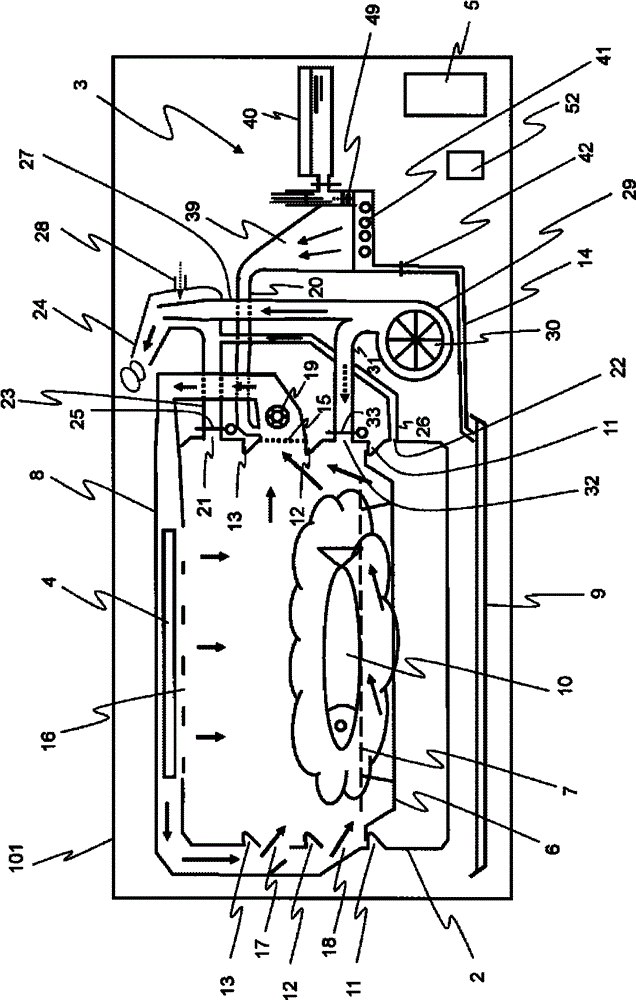

[0048] figure 1 It is a perspective view which looked at the steam cooker which concerns on one Embodiment of this invention from the front side.

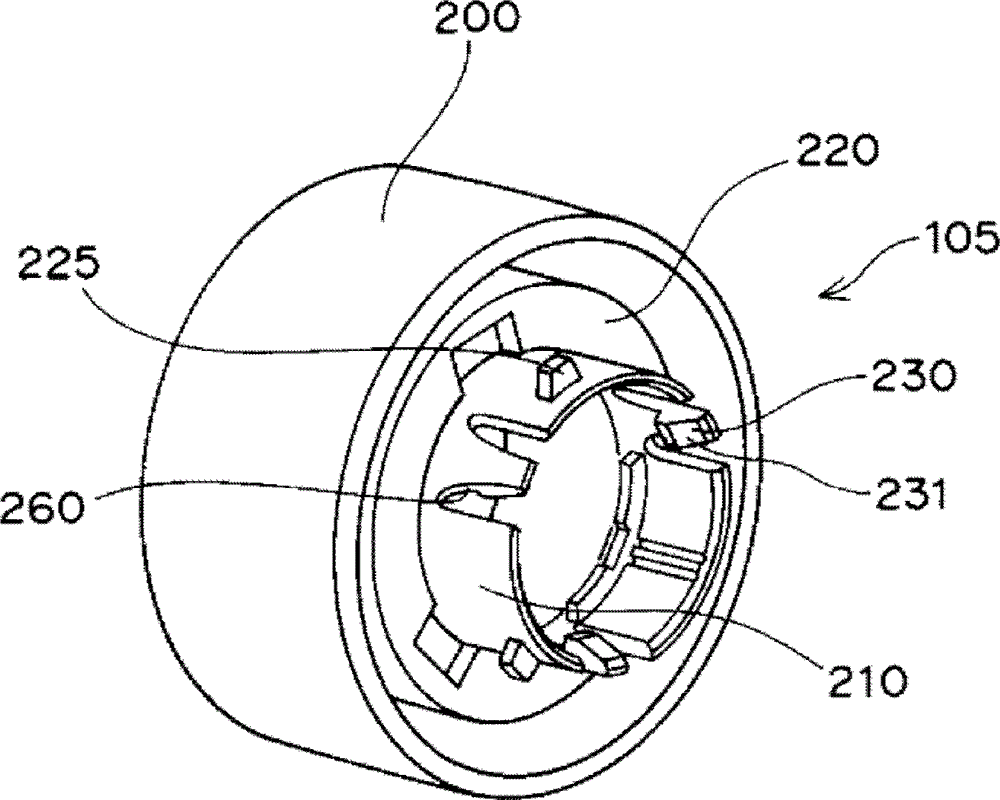

[0049] Described steam cooker comprises: the shell 101 of cuboid shape, heating chamber 2 (referring to figure 2 ), switch door 103 and handle structure 104. The opening and closing door 103 opens and closes the opening of the door frame 120 on the front side of the heating chamber 2 by rotating about its lower edge as a substantially central axis. A heat-resistant glass 111 is disposed at a substantially central portion of the opening and closing door 103 , through which the user can visually confirm the state of the heating chamber 2 . A gasket (not shown) made of heat-resistant resin is fixedly attached to the rear surface of the opening and closing door 103 so as to surround the heat-resistant glass 111 . In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com