Material loading trolley for sterilizing cabinet

A material loading and sterilizing cabinet technology, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of track bridges and bends, inconvenient operation, door jamming, etc., and achieve the effect of convenient cargo transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

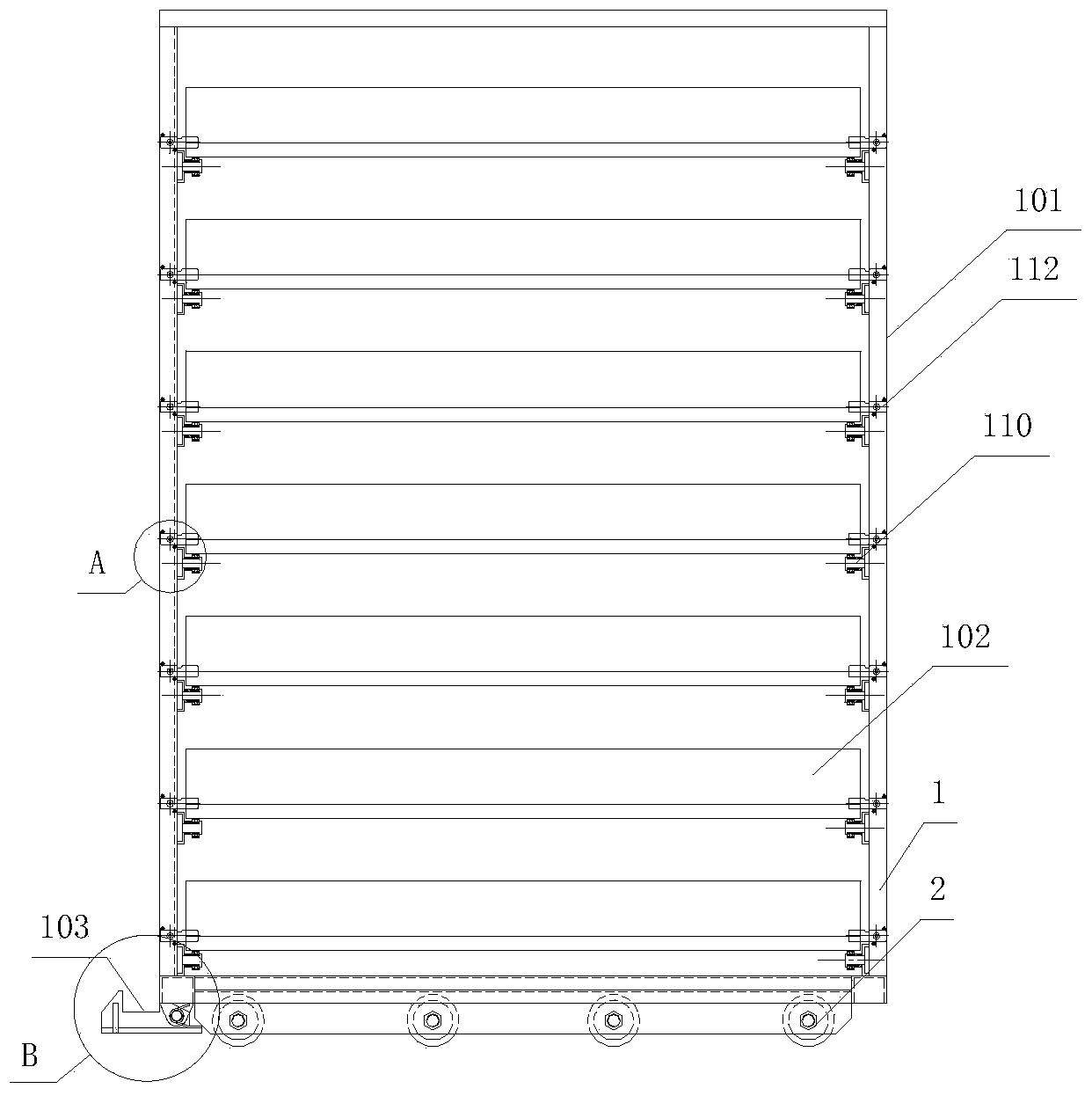

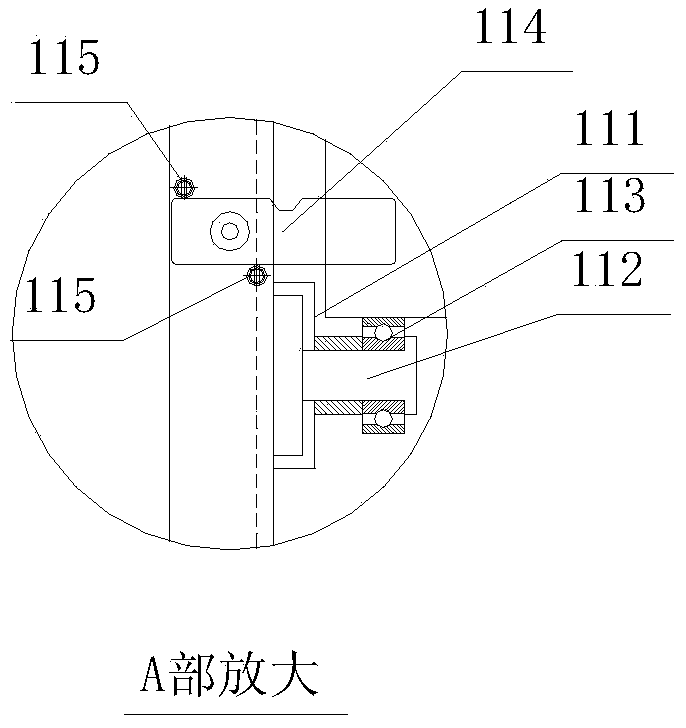

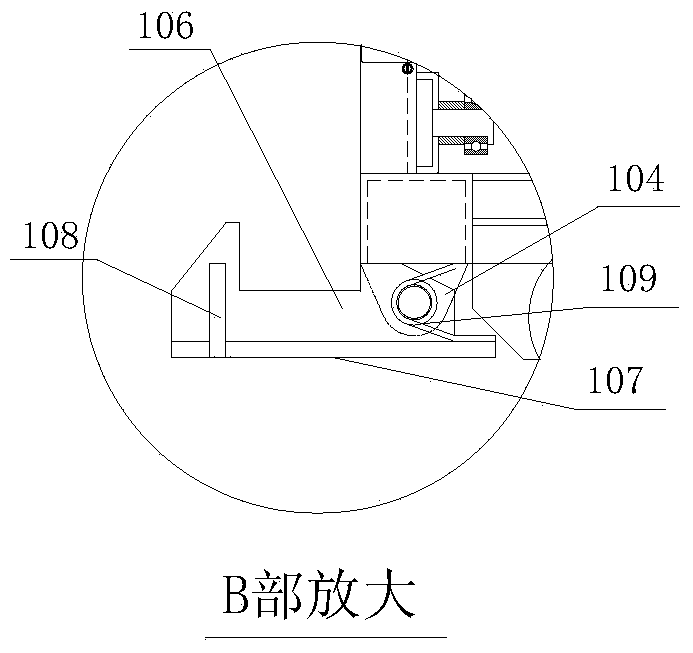

[0024] Such as Figure 1-5 As shown, a material loading trolley for a sterilization cabinet includes a car body 1 and two rows of casters 2 arranged at the lower part of the car body 1. Each row of casters 2 includes four casters 2 and the distance between the casters 2 is equal. The car body 1 includes a rectangular tube frame 101 and a storage tray 102 arranged in the frame 101. One end of the bottom of the frame 101 is provided with a hook device 103 for hooking an adjacent loading trolley. The support plate 104 at the bottom is hinged with a rotating shaft 105 between the two supporting plates 104. A pair of hook plates 106 for hooking adjacent loading trolleys are arranged on the rotating shaft 105. The bottom of the two hook plates 106 is fixedly provided with a connecting plate 107. The plate 107 is fixedly provided with an unlocking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com