PCB and connector flat pressing type crimping tool

A connector and tooling technology, applied in the direction of electrical components, electrical components, etc., can solve problems such as difficulty in ensuring accurate alignment of relative positional relationships, damage to connectors and printed boards, and a lot of time spent, to achieve flexible and changeable positions , crimping convenience, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

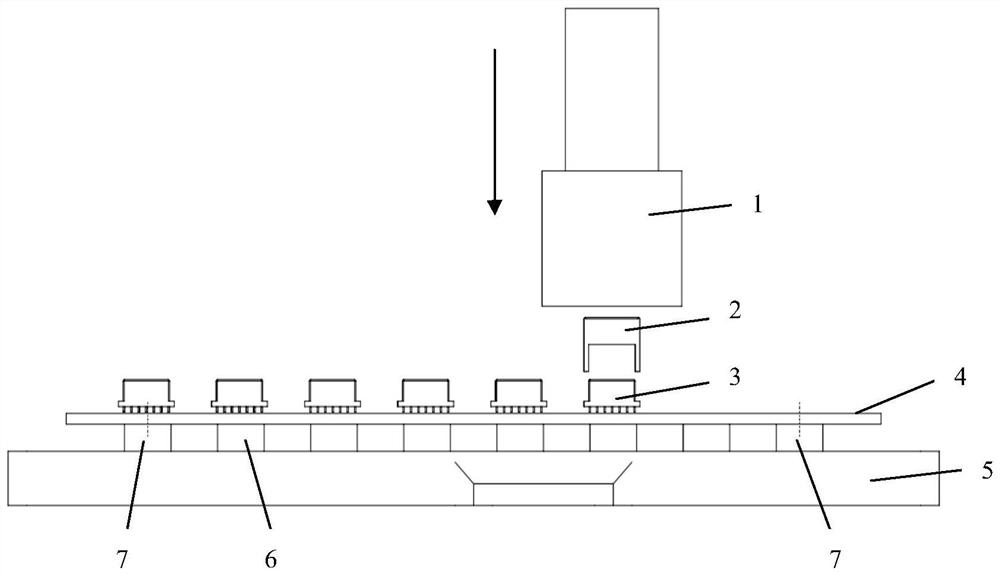

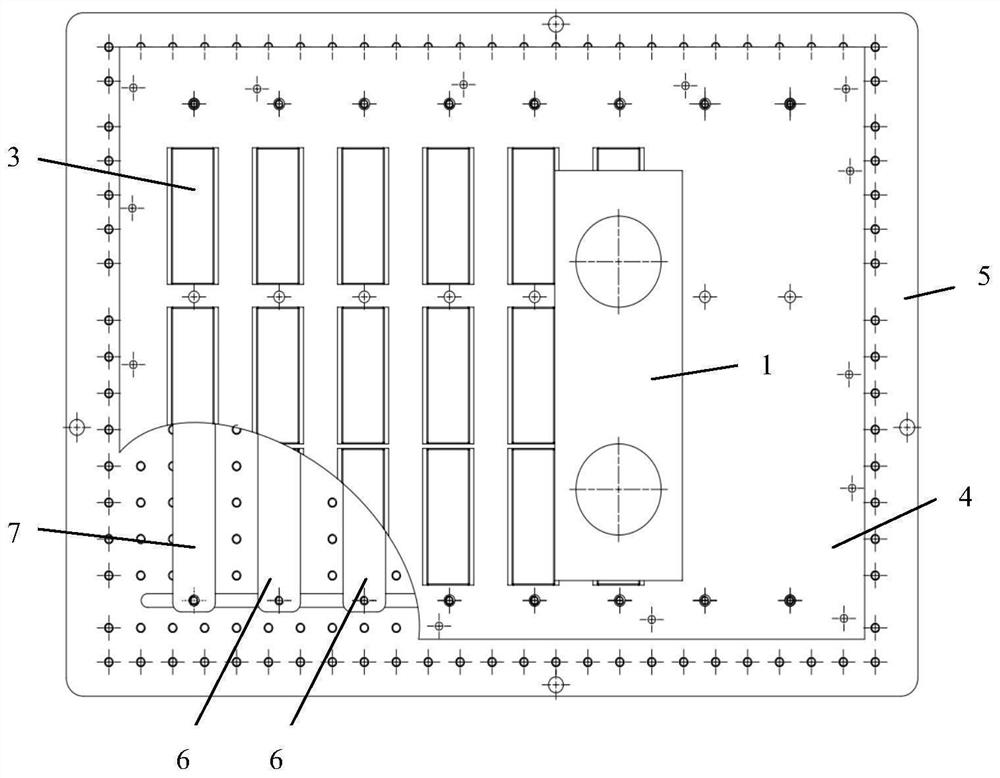

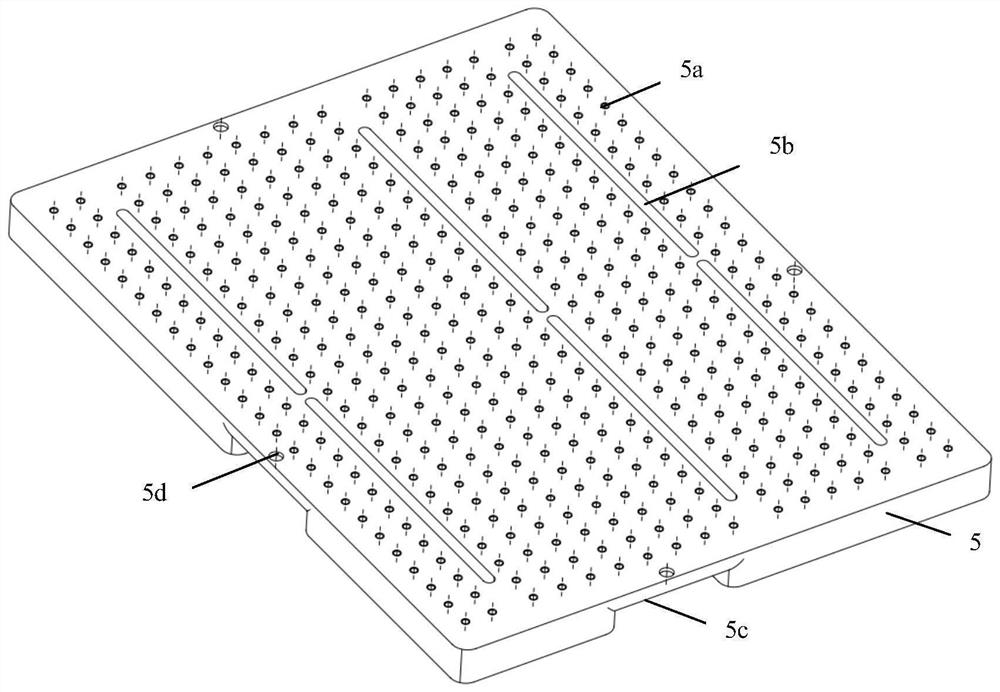

[0029] refer to Figure 1-Figure 8 . In the preferred embodiment described below, a PCB and connector flat pressure crimping tooling includes: the lower die 6 fixed on the lower die positioning plate 5 distributed in the horizontal direction of the strip groove and the lower die 6 and the The upper die 2 between the crimping heads 1 of the crimping machine is characterized in that the lower die positioning plate 5 is provided with a positioning pin 7 for positioning the PCB board 4 and a bar-shaped groove 5b separating a plurality of lower dies 6, and the bar-shaped The groove 5b divides a plurality of lower dies 6 into at least two crimping areas, as the lower dies 6 of the PCB motherboard 4 supports during crimping, and are distributed in the separated crimping areas; according to the PCB motherboard 4 each The length and width of each crimping position are made into a strip-shaped lower die 6, which is formed with a through-threaded hole consistent with the mounting hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com