Wave-guide coupling microstrip/strip line filter

A filter and stripline technology, applied in the field of filters, can solve problems such as unfavorable scale production, characteristic deterioration, filter offset, etc., and achieve the effects of avoiding surface mount technology, improving out-of-band suppression, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Please refer to the accompanying drawings for a further description of the present invention.

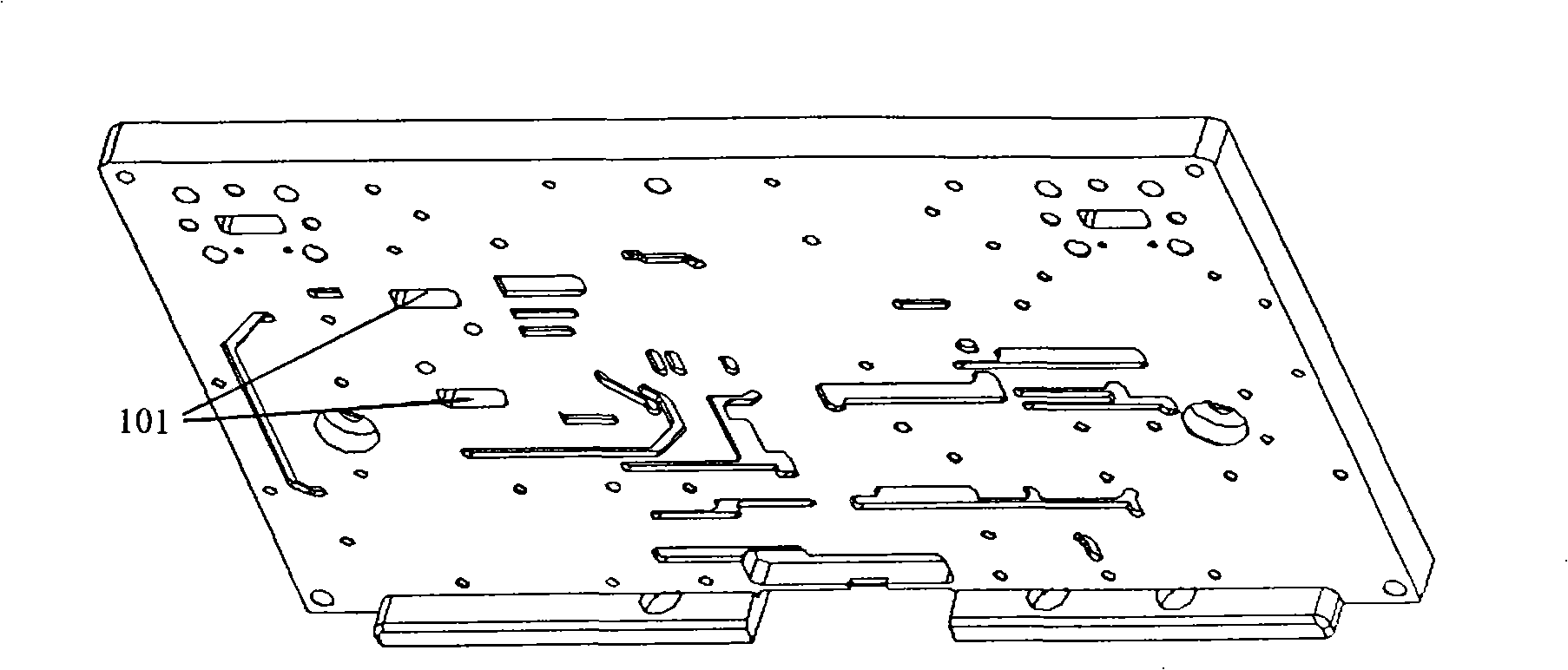

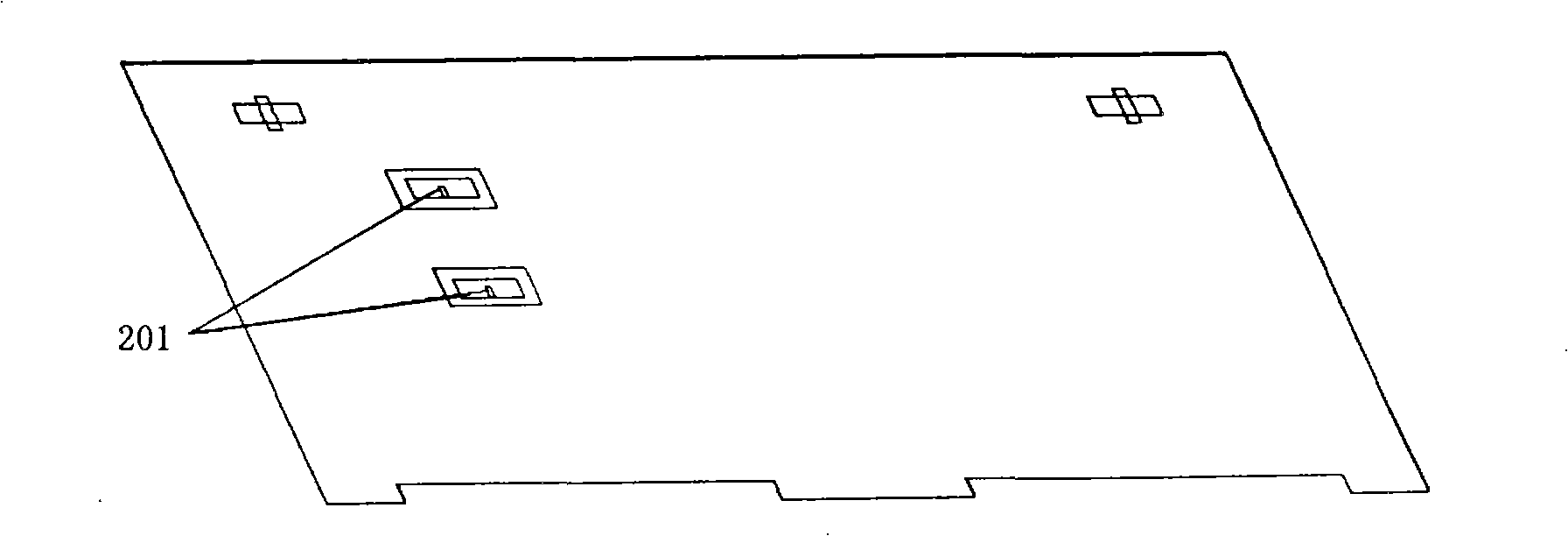

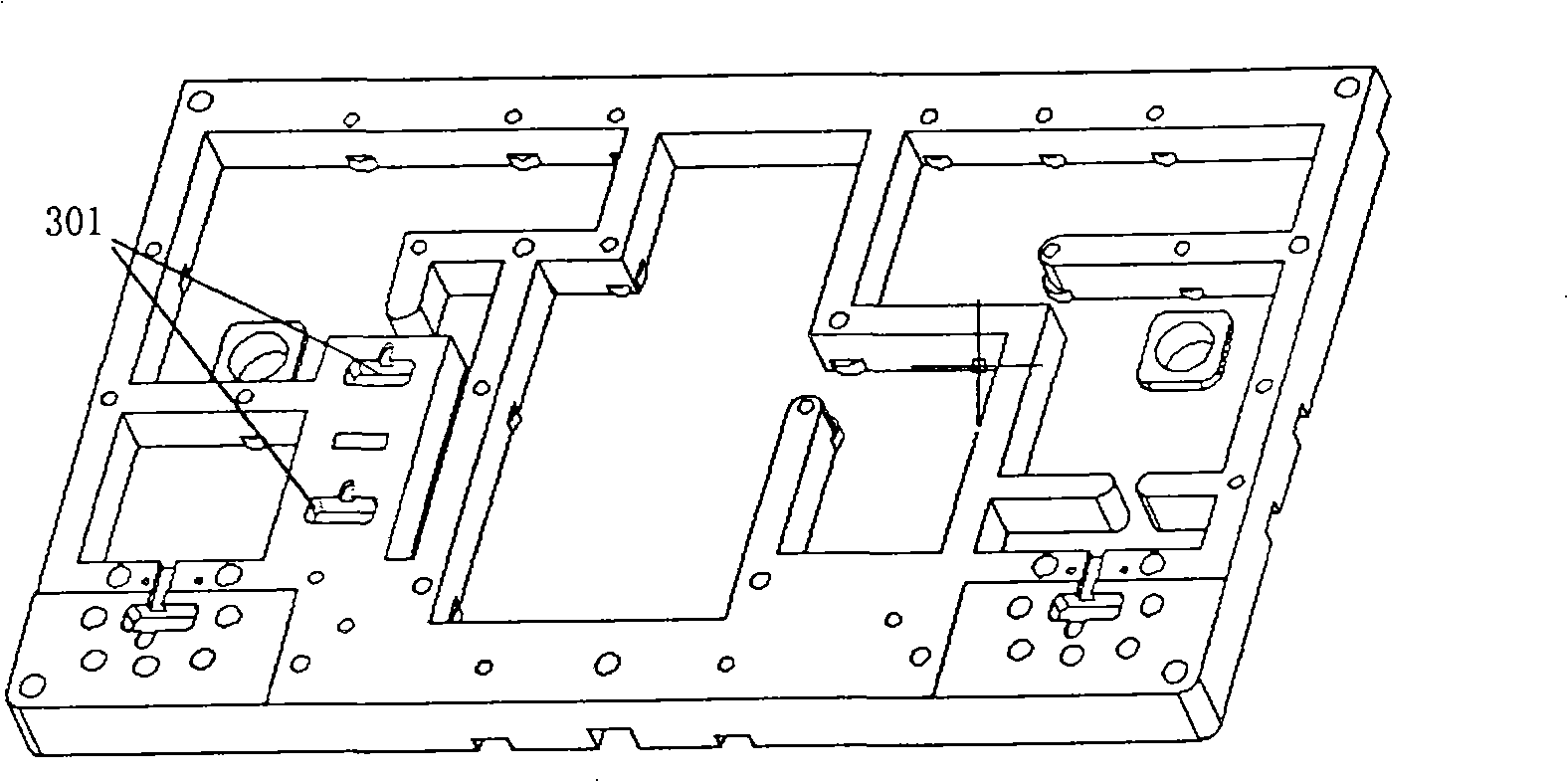

[0034] The present invention provides a waveguide coupling microstrip / stripline filter, which includes a shielding box cover plate 3, a microwave hybrid circuit board 2, a shielding box bottom plate 1, a filter plate 4 and a filter cover plate 5 in a microwave transceiver module , the filter board 4 is separated from the microwave hybrid circuit board 2, and after separation, the two adopt waveguide coupling, that is, two rectangular waveguide ports 101 are opened on the bottom plate 1 of the shielding box, corresponding to the filter board 4 and the microwave hybrid circuit board 2 position, setting the microstrip or stripline-to-waveguide transition.

[0035] Such as figure 1 and figure 2 As shown, the two rectangular waveguide openings 101 on the bottom plate 1 of the shielding box correspond to the microstrip or stripline-waveguide conversion positions on the microwave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com