Hydraulic expansion device

A technology of hydraulic pressure and expansion block, which is applied in the direction of positioning device, expanding mandrel, clamping, etc., which can solve the problems of scrapped parts, excessive clamping deformation of thin-walled cylindrical parts, loose processing of thin-walled cylindrical parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments.

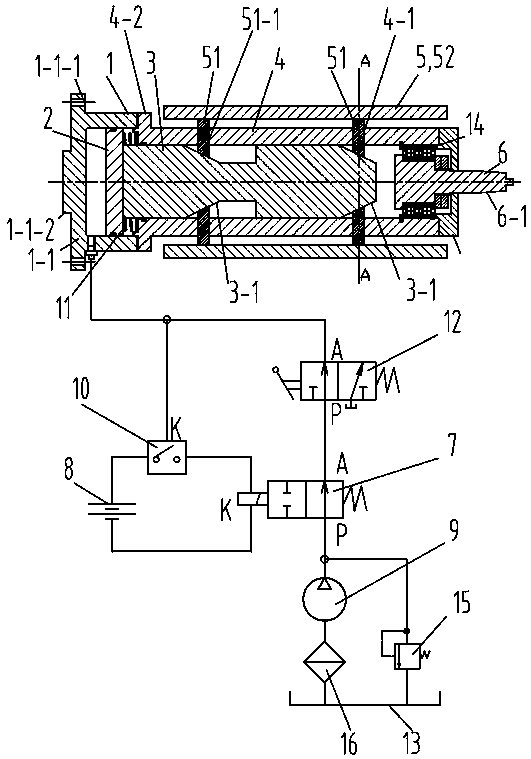

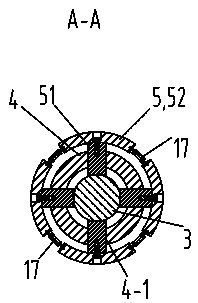

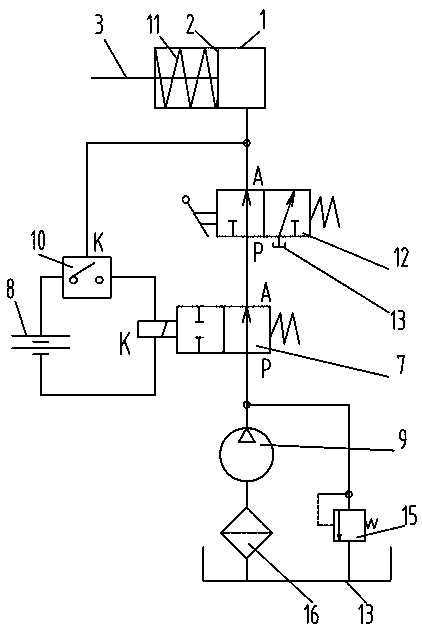

[0018] Such as Figure 1 to Figure 4 As shown, a hydraulic tensioning device includes a cylinder body 1, a piston 2, a piston rod 3, an expansion block mounting seat 4, an expansion block mechanism 5, a mandrel 6, a solenoid valve 7, a power supply 8, a hydraulic pump 9, Pressure relay 10, spring 11, manual reversing valve 12, oil tank 13 and tension spring 17; pressure relay 10 is the pressure relay of model MJCS-02-P-L produced by Wuxi Fulide Hydraulic Machinery Co., Ltd. The right end of the cylinder body 1 has an opening, the left end of the cylinder body 1 has a flange 1-1, the flange 1-1 is provided with a positioning hole 1-1-1 and the left end of the flange 1-1 is provided with a boss 1 -1-2. Flange 1-1 is used to connect with the lathe flange, the boss 1-1-2 is used to closely match with the positioning hole of the lathe flange, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com