Minus-circled flake construction method for shield tunnel construction

A technology of tunnel construction and construction method, applied in the fields of tunnel construction and building construction, can solve the problems of scrapping of concrete segments, low reuse rate, environmental pollution, etc., and achieve the effects of low cost, high reuse rate and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

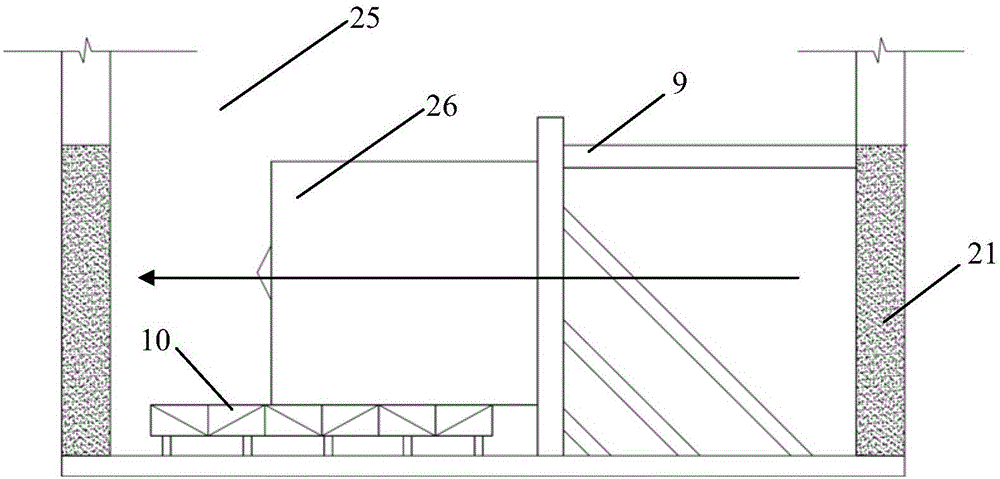

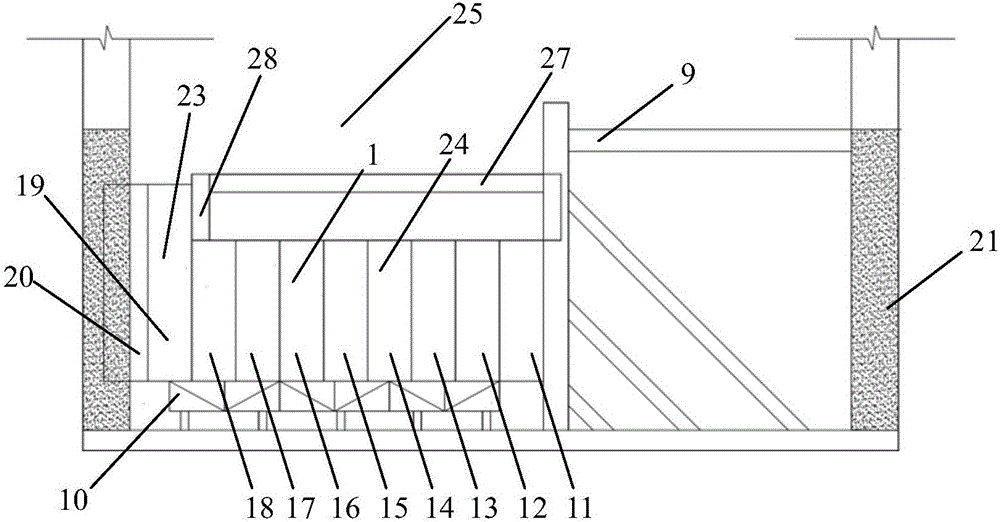

[0041] In order to understand the technical content of the present invention more clearly, the following examples are given in detail. In this embodiment, the installation of nine steel pipe negative rings 1 is taken as an example, and the shield machine 26 (Komatsu 6760mm earth pressure balance shield machine of Japan) is used for installation.

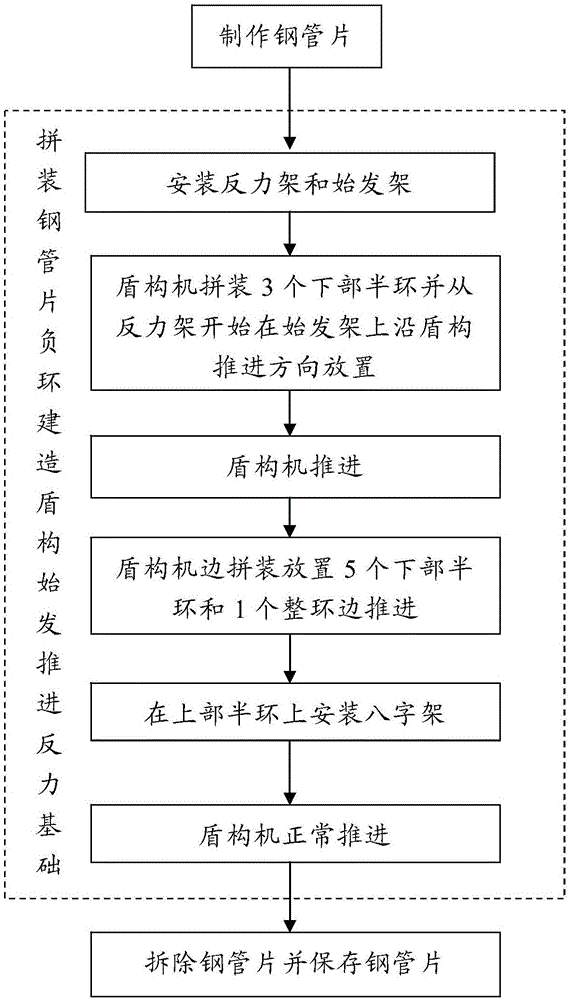

[0042] See figure 1 As shown, in step (1), the steel pipe sheet 2 required by the project is manufactured.

[0043] According to engineering needs, use steel to make steel pipe sheet 2: bottom steel pipe sheet 3, left lower steel pipe sheet 4, left upper steel pipe sheet 5, top steel pipe sheet 6, right upper steel pipe sheet 7 and right lower steel pipe sheet 8 (see Figure 5 shown). During the manufacturing process, the steel pipe sheet 2 is protected by spraying paint to reduce corrosion damage during use.

[0044] Step (2), assembling and using steel pipe sheet negative ring 1, wherein:

[0045] Step (21), such as figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com