Film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 23

(Example 23)

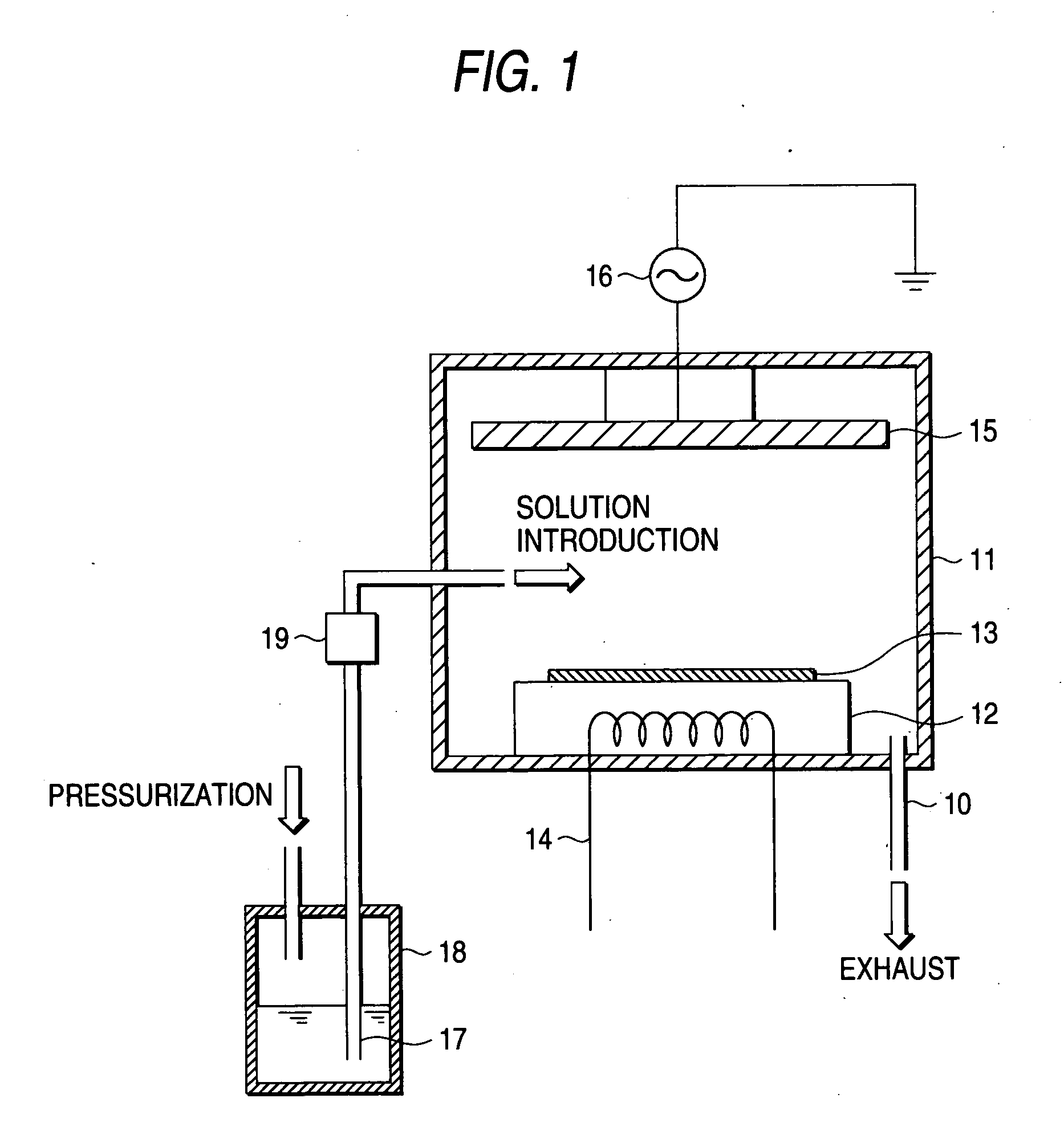

[0082] A high frequency power of e.g. 13.56 MHz was applied at 50 W to the plate-shaped counter electrode 15 while grounding the sample support 12, whereby a film was formed under plasma discharge. The other conditions are the same as in the thermal CVD process. In the case of thus using the plasma CVD process for polymerization, the film formation speed was increased by 1.5 times or more. Further, the films obtained by the process had dielectric constants equal to those of Tables 1 and 2.

[0083] The film of the present invention is a low-dielectric insulating film, and can be used as an interlayer insulating film of electronic devices, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com