Method and device for measuring particle size of nano particle jet minimum quantity lubrication grinding droplets

A technology of nano-particles and micro-lubrication, which is applied in the field of particle size measurement of nano-particle jet micro-lubrication grinding droplets, which can solve the problems of difficult measurement of droplet size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with the drawings and embodiments.

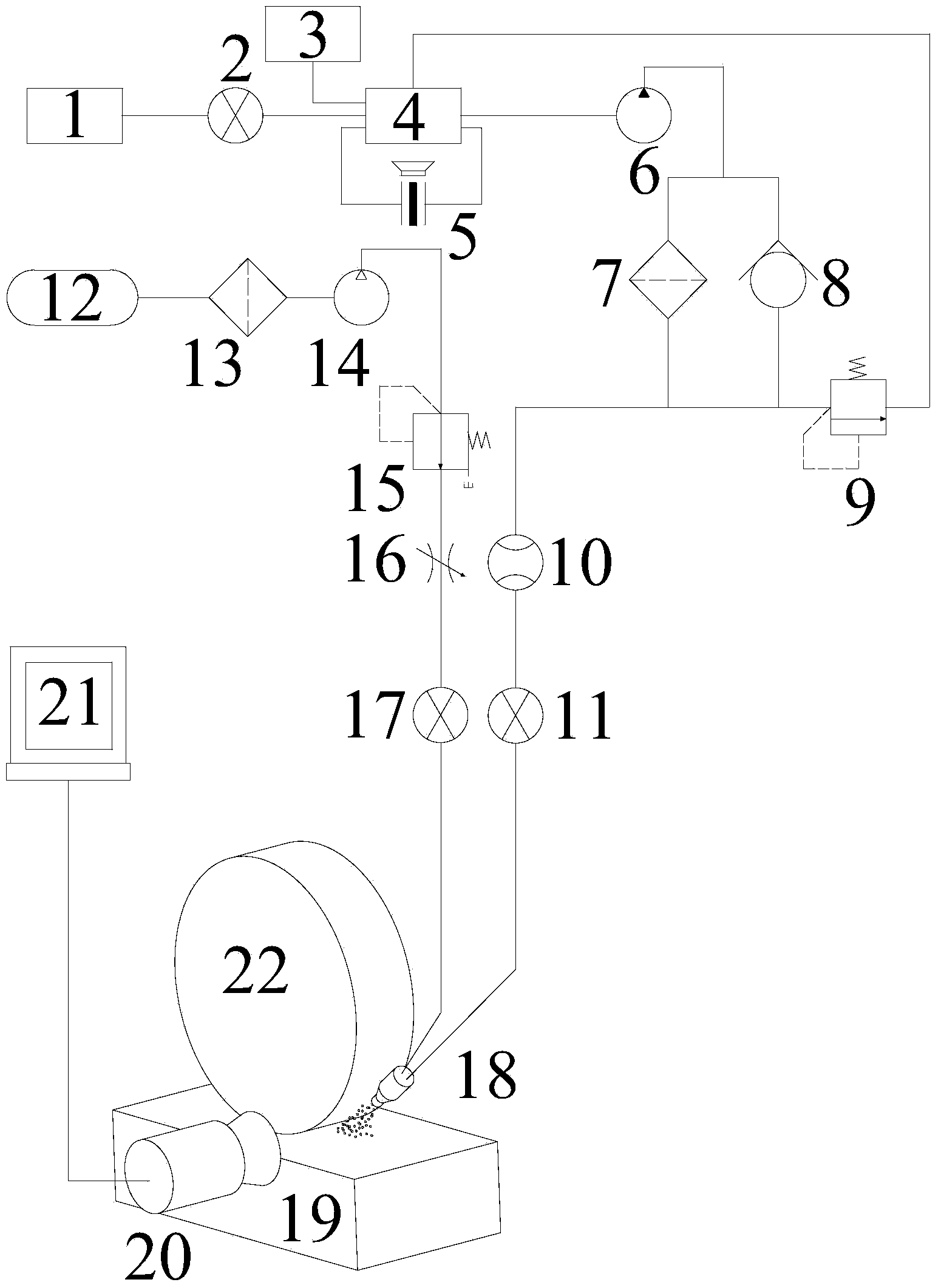

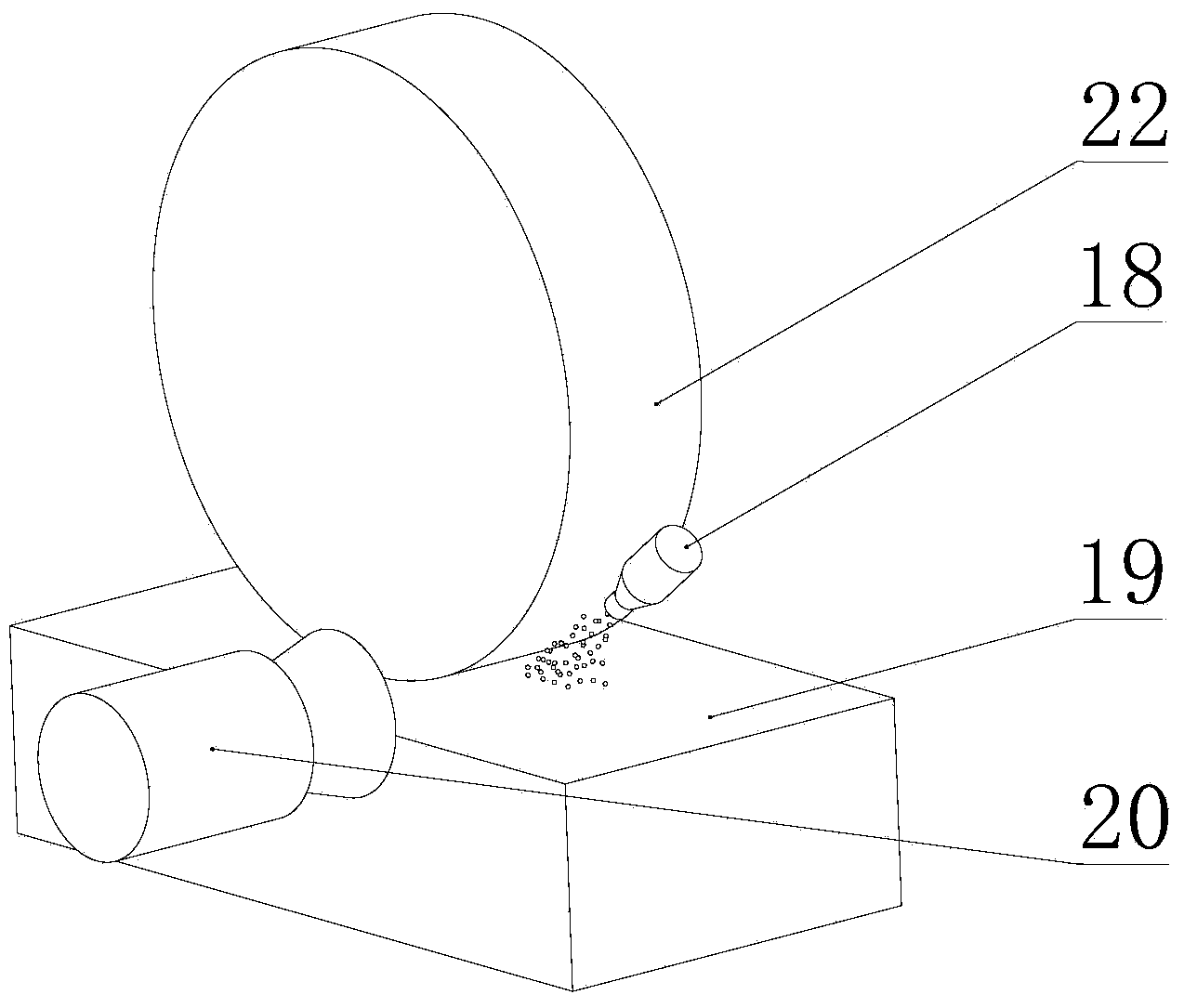

[0074] figure 1 Shows the various components of the nanoparticle jet microlubricating oil circuit system, combined figure 1 , The connection and working method of each part is as follows: select the appropriate base fluid 1 according to the processing conditions, measure the volume of the base fluid 1 required by the nanoparticle jet micro-lubricating grinding fluid through the flowmeter I2, and weigh a certain mass of nanoparticles 3 , The nanoparticles 3 and the base fluid 1 are directly stored in the liquid storage tank 4 after stirring. The nanoparticles 3 in the grinding fluid cannot be completely mixed and uniformly mixed by mechanical mixing, so the liquid storage tank 4 is directly placed in the ultrasonic field In the ultrasonic vibrator 5, the appropriate frequency and power are selected according to the size of the nanoparticle 3 to vibrate, overcome the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com