Method for manufacturing brazing monolayer diamond grinding wheel

A single-layer diamond and manufacturing method technology, which is applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems of large thermal stress, diamond graphitization, etc., and achieve improved grinding performance, high thermal stability, and reduced thermal damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

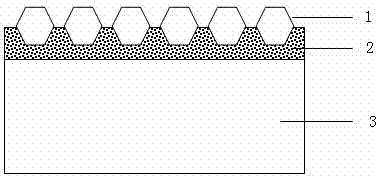

Image

Examples

Embodiment 1

[0024] A method for manufacturing a brazed single-layer diamond grinding wheel. The matrix of the diamond grinding wheel is prepared by machining, and the matrix is degreased and derusted. The matrix of the grinding wheel is No. 45 steel (the same below). The boron-containing diamond is 45-60 mesh, and its boron content is (50-260)×10 18 at / cm 3 , The amount of Cu-P alloy added in the solder is 2% of the mass of Ni-Cr-B-Si alloy, the content of P in Cu-P alloy is 7%, and the rest is Cu.

[0025] The boron-containing diamond used was obtained by the following method: adding 5wt% hexagonal boron nitride to the diamond synthesis powder, and using a hexagonal top press to synthesize boron-containing diamond at 1450°C and a pressure of 5.6Gpa.

[0026] Mechanically stir the solder for 15 minutes to mix well. Grinding wheel forming blanks were prepared in the order of grinding wheel substrate / brazing filler metal / diamond abrasive grains. Put the grinding wheel forming blank int...

Embodiment 2

[0028] The invention discloses a method for manufacturing a brazed single-layer diamond grinding wheel. The base body of the diamond grinding wheel is prepared by a machining method, and the base body is degreased and derusted. The mesh size of boron-containing diamond abrasive grains is 30-45, and its boron content is (50-260)×10 18 at / cm 3 , The amount of Cu-P alloy added in the solder is 3% of the mass of Ni-Cr-B-Si alloy, the content of P in Cu-P alloy is 10%, and the rest is Cu.

[0029] The boron-containing diamond used is obtained by the following method: adding 3wt% hexagonal boron nitride to the diamond synthesis powder, and using a six-sided top press to synthesize boron-containing diamond at 1420°C and a pressure of 5.7Gpa.

[0030] Mechanically stir the solder for 15 minutes to mix well. Grinding wheel forming blanks were prepared in the order of grinding wheel substrate / brazing filler metal / diamond abrasive grains. Put the grinding wheel blank into a protective...

Embodiment 3

[0032] The invention discloses a method for manufacturing a brazed single-layer diamond grinding wheel. The base body of the diamond grinding wheel is prepared by a machining method, and the base body is degreased and derusted. The mesh number of boron-containing diamond abrasive grains is 45-60, and its boron content is (50-260)×10 18 at / cm 3 , The amount of Cu-P alloy added to the solder is 5% of the mass of Ni-Cr-B-Si alloy, the content of P in Cu-P alloy is 8%, and the rest is Cu.

[0033] The boron-containing diamond used is obtained by the following method: adding 8wt% hexagonal boron nitride to the diamond synthesis powder, and using a six-sided top press to synthesize boron-containing diamond at 1500°C and a pressure of 5.5Gpa.

[0034] Mechanically stir the solder for 15 minutes to mix well. Grinding wheel forming blanks were prepared in the order of grinding wheel substrate / brazing filler metal / diamond abrasive grains. Put the grinding wheel forming blank into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com