CBN grinding wheel of low temperature vitrified bond and preparation technique thereof

A vitrified bond and bond technology, which is applied in the field of abrasive tools and grinding, can solve the problems of difficult to maintain the shape of the grinding wheel, the abrasive is easy to fall off, and the strength is not enough, so as to improve some defects, good abrasive wettability, and high holding ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] CBN: 37.83%, SiC: 38.94%, binder: 22.93%, dextrin powder: 0.2%, walnut powder: 0.1%. The three-point bending strength of the abrasive layer with the above composition ratio was 95.2 MPa.

Embodiment 2

[0024] CBN: 35.57%, SiC: 35.73%, binder: 28.5%, dextrin powder: 0.1%, walnut powder: 0.1%. The three-point bending strength of the abrasive layer with the above composition ratio was 105.4 MPa.

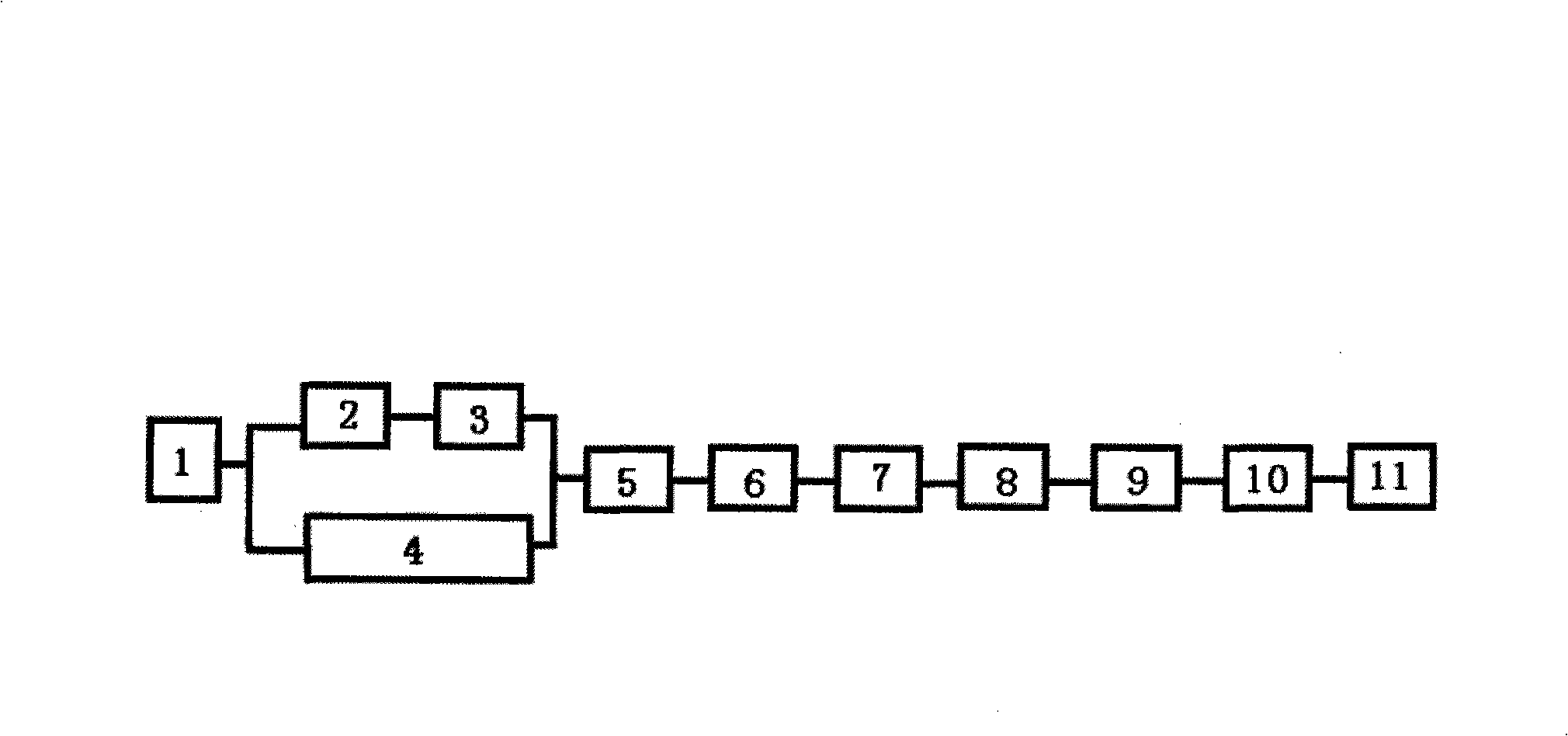

[0025] Since the burning temperature of CBN abrasive itself is 1000°C, in our designed sintering temperature curve, the highest sintering temperature is 750°C, and the sintering curve is:

[0026] 20°C (80min) 80°C (120min) 150°C (150min) 500°C (180min) 500°C (60min) 600°C (60min) 600°C (120min) 750°C (120min) 750°C (0min)

[0027] However, the sintering temperature of general ceramic products is above 1200°C. We have designed a high-strength bond suitable for ceramic CBN grinding wheels at 750°C.

[0028] The roasting method protected by inert gas (nitrogen) is used to ensure that the CBN abrasive is not oxidized under high temperature conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com