Gantry stone cutting device

A stone cutting and equipment technology, applied in the field of stone manufacturing and cutting, can solve the problems of poor cutting stability, limited moving range of cutting devices, limited use range, etc., and achieve the effects of improving stability, increasing movable range, and broadening use range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

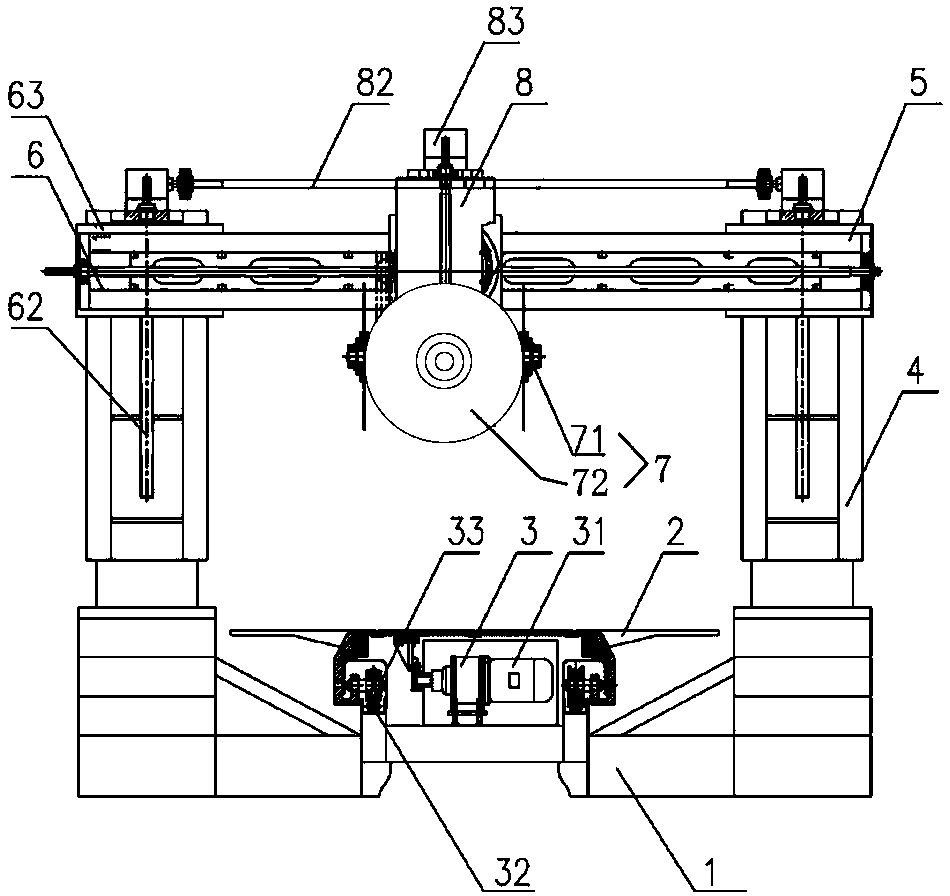

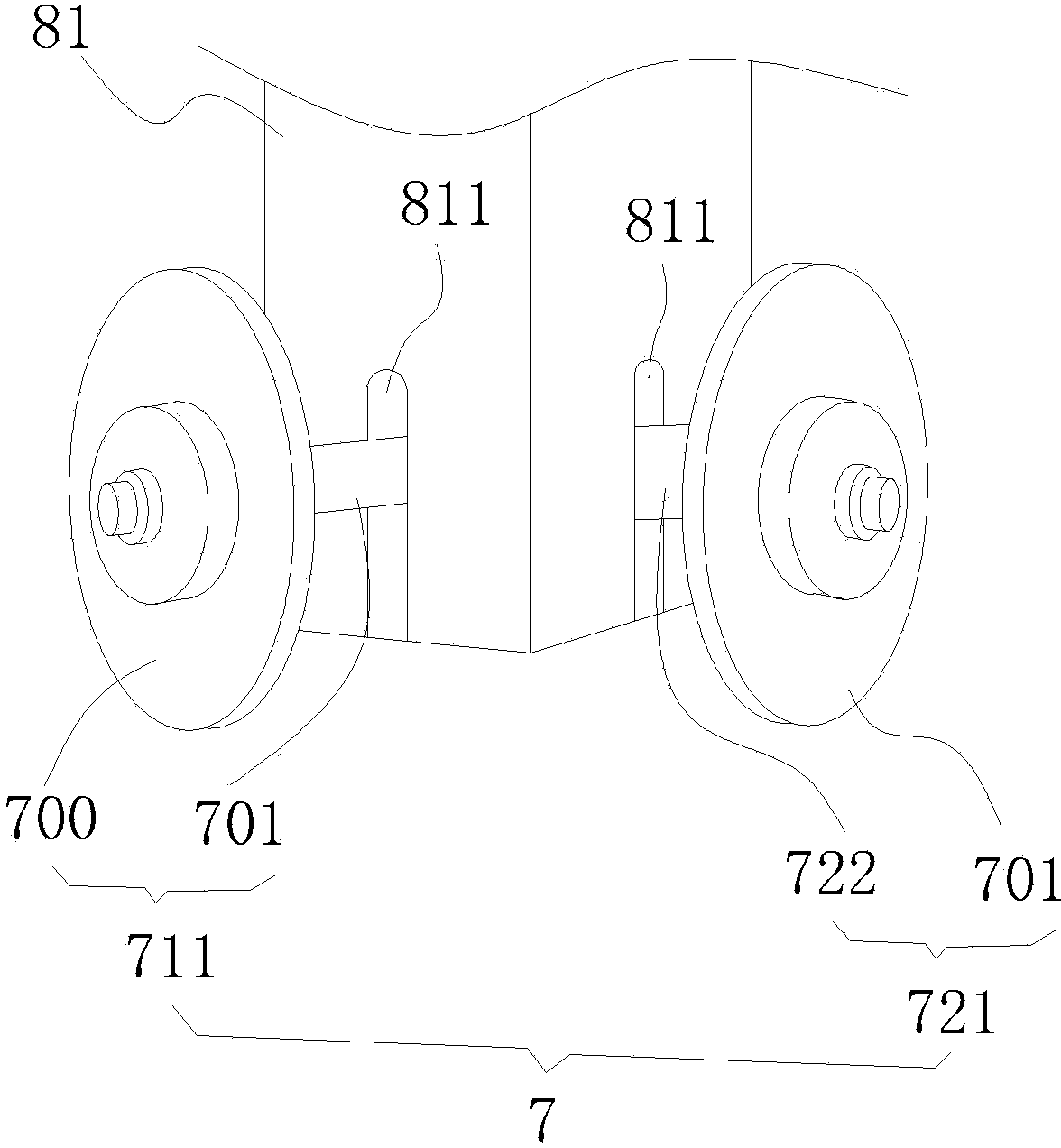

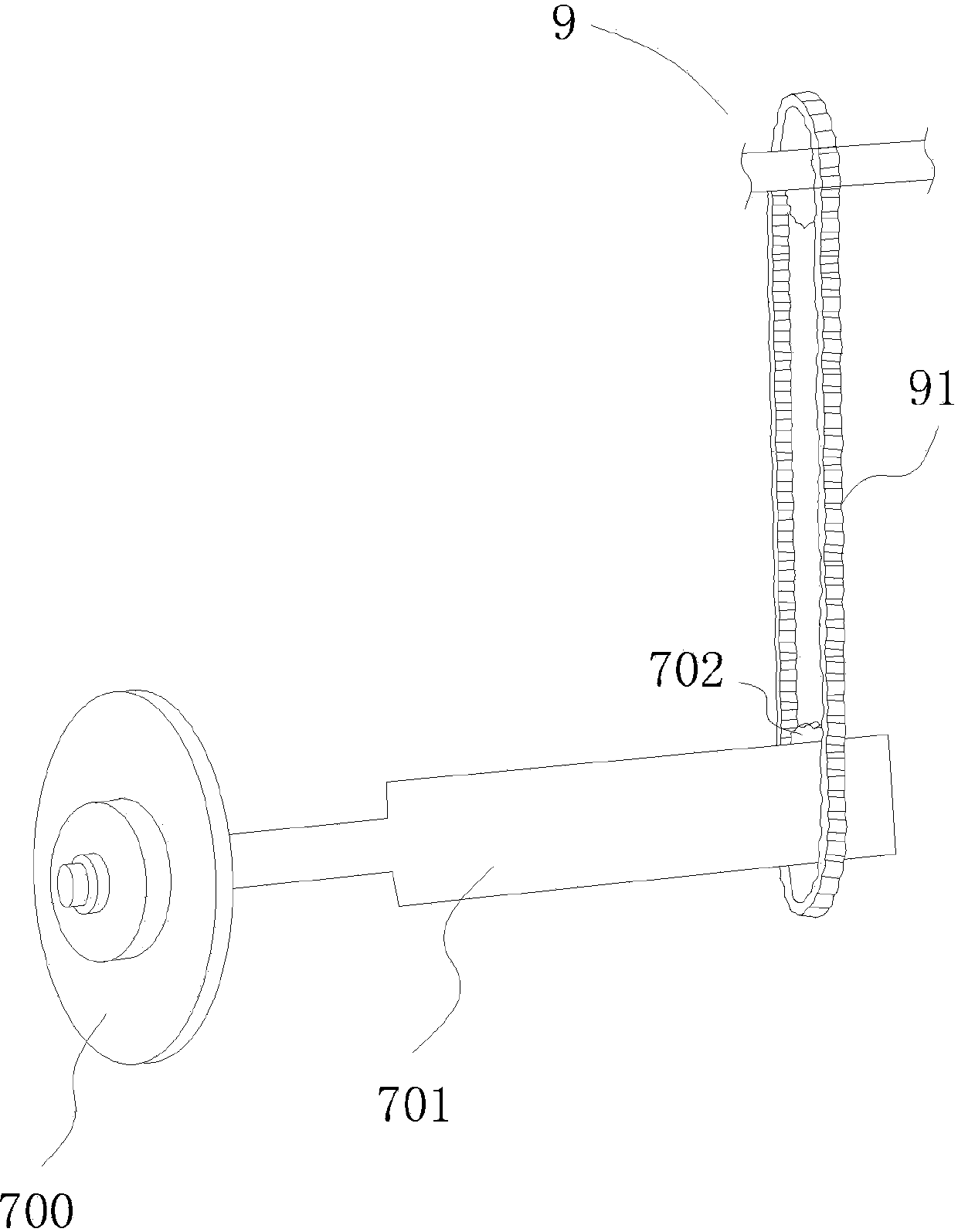

[0029] Example: see Figure 1 to Figure 3 As shown, the gantry line stone cutter provided by the invention includes a base 1, a workbench 2, a workbench drive mechanism 3, a column 4, a beam 5 arranged between the left and right columns, a beam drive mechanism 6, and a beam mounted on the beam. Cutting device 7, cutting device driving mechanism 8 and PLC programmable controller (not shown in the figure);

[0030] see Figure 1 to Figure 3 As shown, the workbench 2 is arranged on the base 1 through the workbench drive mechanism 3. The workbench drive mechanism 3 includes a workbench, a drive motor 31, a pulley shaft 32 arranged on the base, and a pulley 33 arranged at the bottom of the workbench. The table drive motor 31 drives the pulley 33 to move on the pulley shaft 32, and drives the workbench 2 to move on the base 1;

[0031] see Figure 1 to Figure 3 As shown, the column 4 is symmetrically arranged on the left and right sides of the base 1, the beam 5 is erected betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com