Integrated circuit board welding foot cutting device

A technology for integrated circuit boards and cutting devices, which is applied in the direction of welding/welding/cutting items, auxiliary devices, welding equipment, etc. It can solve problems that affect the use of circuit boards, affect cutting quality, and loose solder feet, so as to improve quality and effect , Good supporting effect, avoiding the effect of welding leg bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

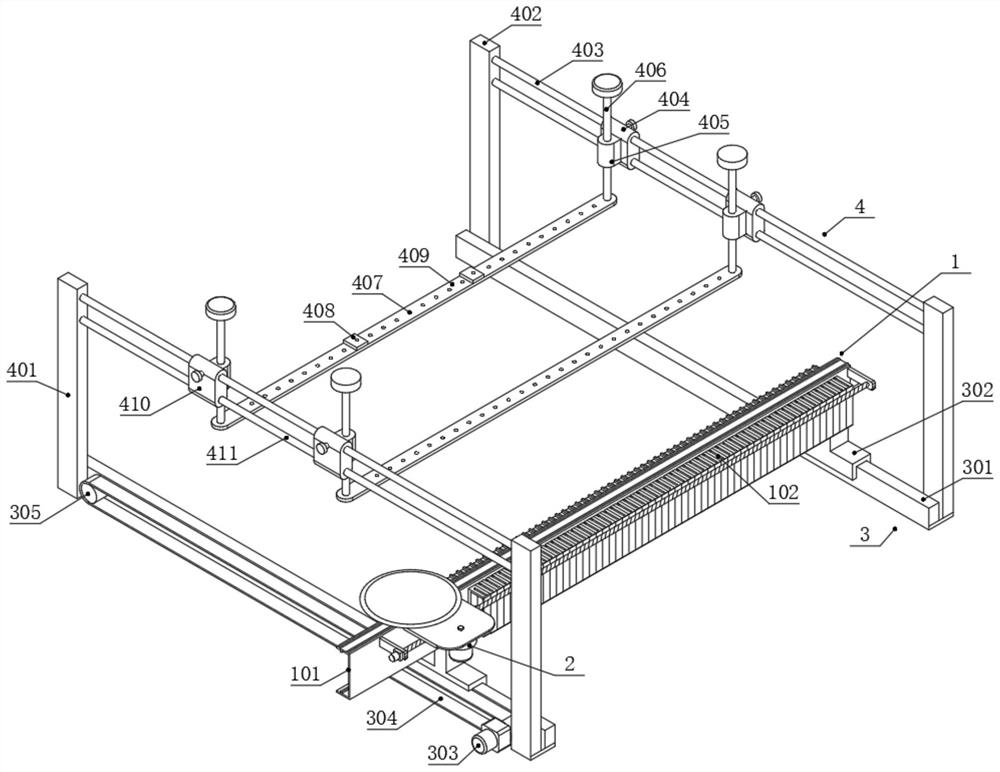

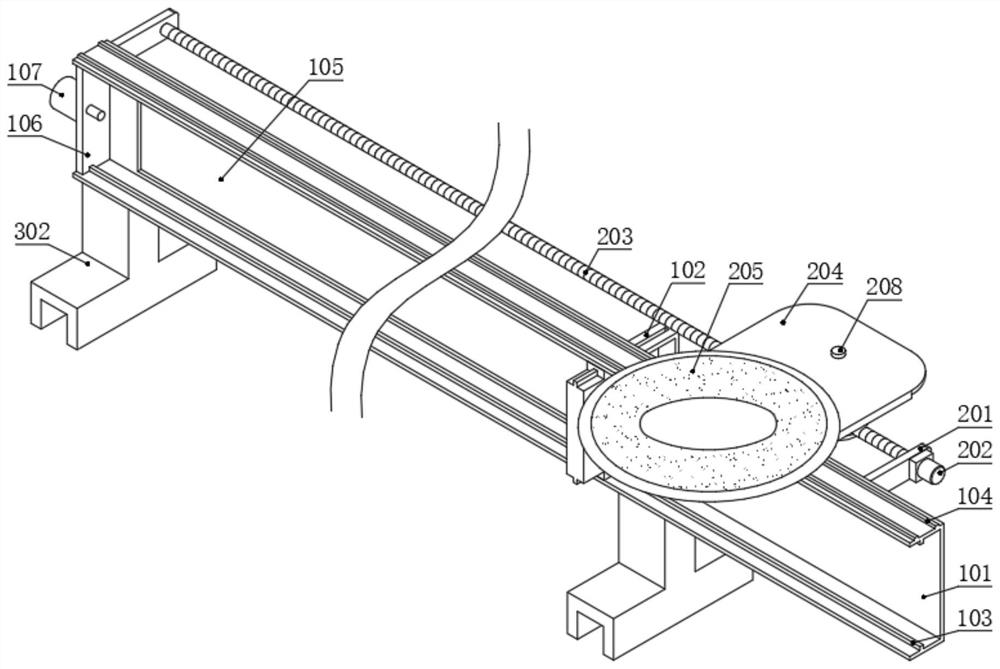

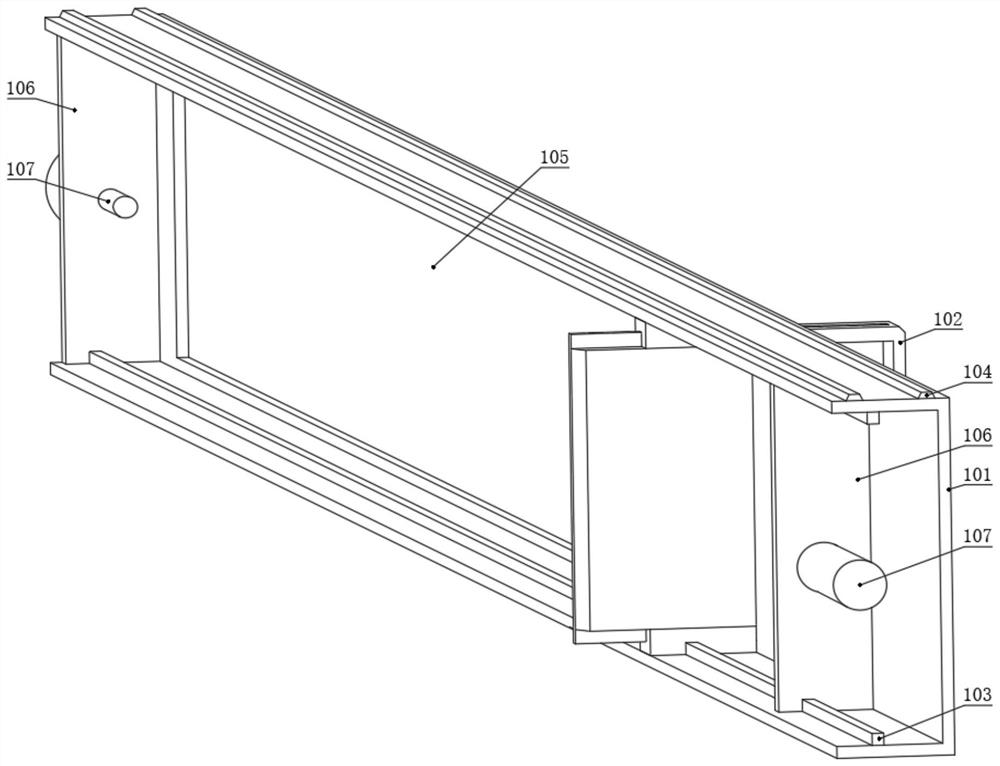

[0028] see figure 1 , an integrated circuit board welding leg cutting device, including a welding leg clamping mechanism 1, a mobile cutting mechanism 2, a support mechanism 3 and a fixing mechanism 4, and the welding leg clamping mechanism 1 is slidably connected to the top of the support mechanism 3, so The mobile cutting mechanism 2 is arranged on the top of the welding leg clamping mechanism 1 along the length direction of the welding leg clamping mechanism 1, the fixing mechanism 4 is arranged above the supporting mechanism 3, and the welding leg clamping The holding mechanism 1 and the moving cutting mechanism 2 are located between the supporting mechanism 3 and the fixing mechanism 4; the solder leg clamping mechanism 1 clamps the solder leg 5 of the circuit board.

[0029] The support mechanism 3 includes two or more guide rails 301 parallel to each other and a linear slide 302 movably connected to the guide rails 301. One side and two ends of the guide rails 301 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com