Patents

Literature

55results about How to "Meet the punching needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

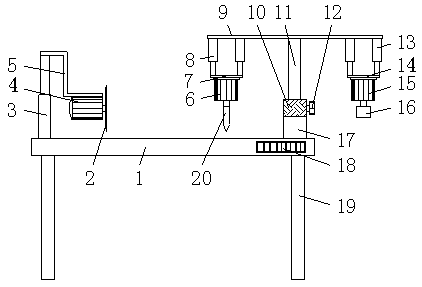

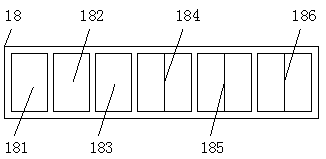

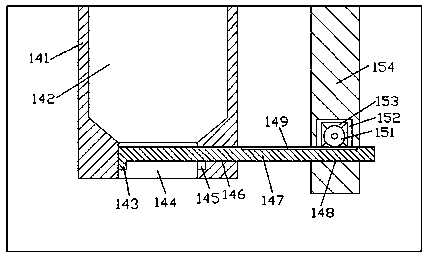

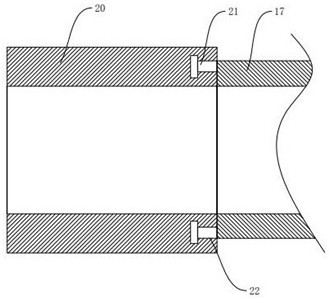

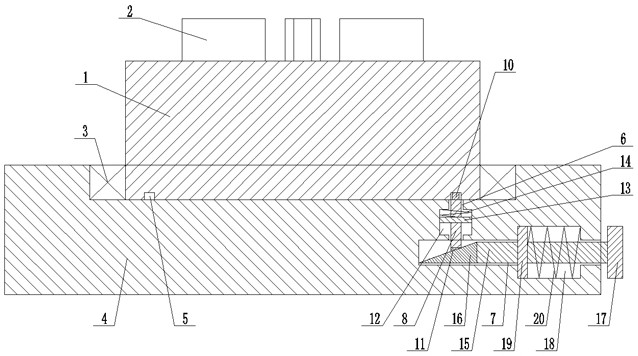

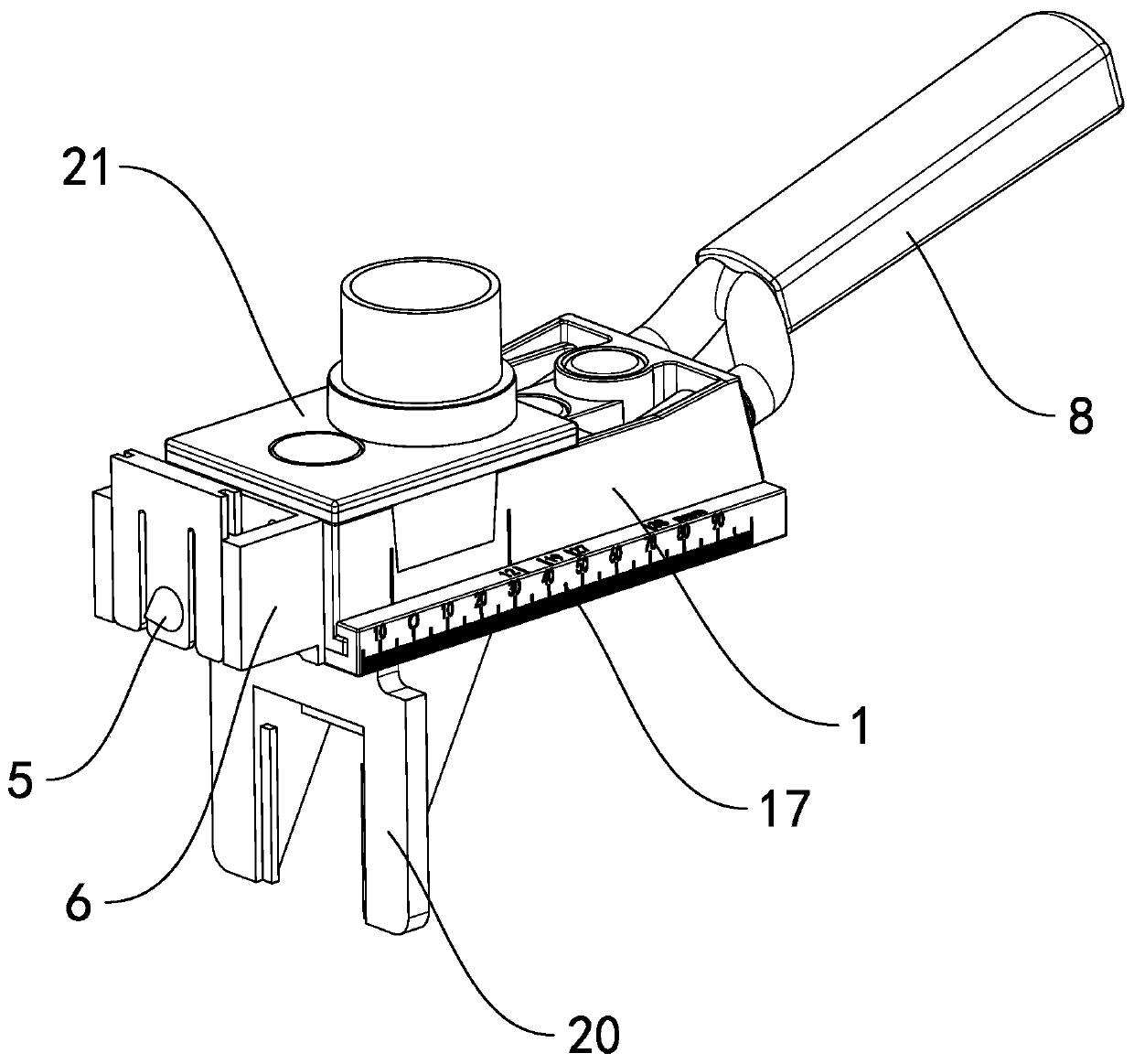

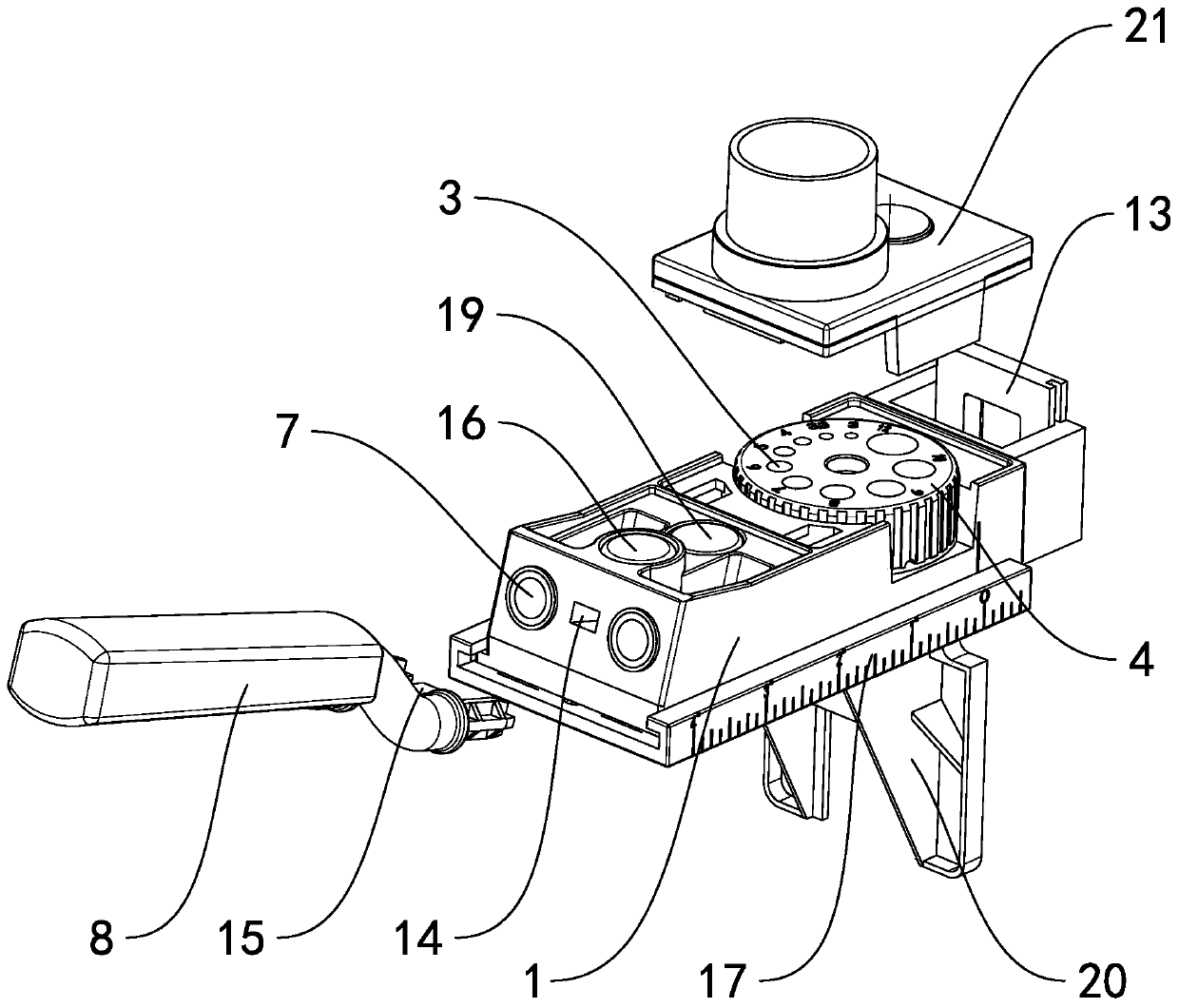

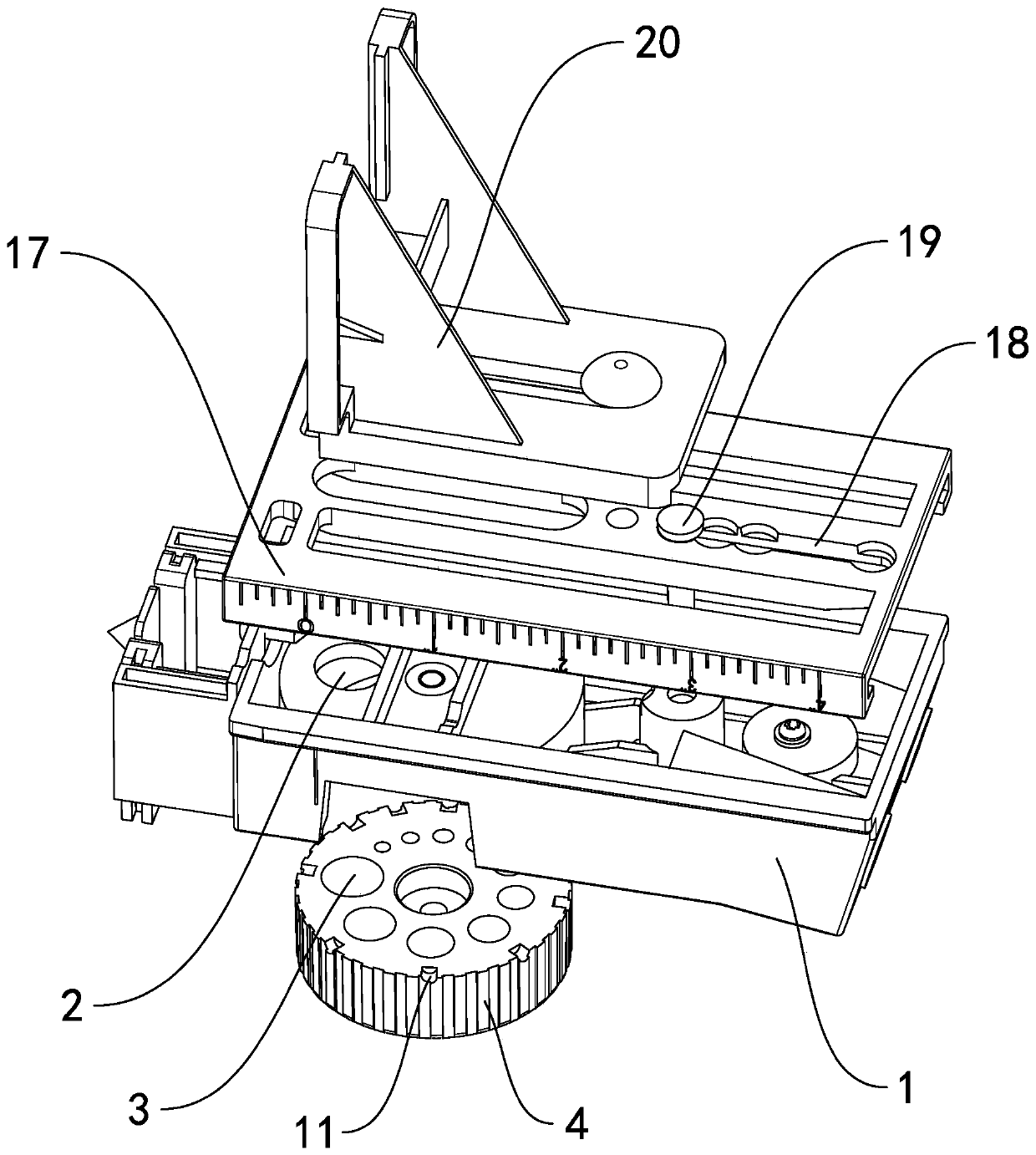

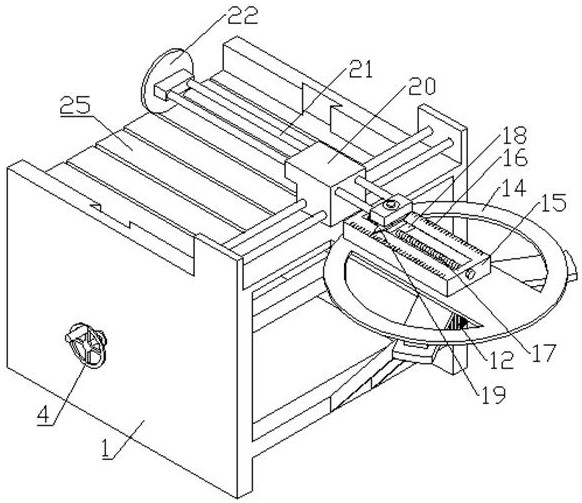

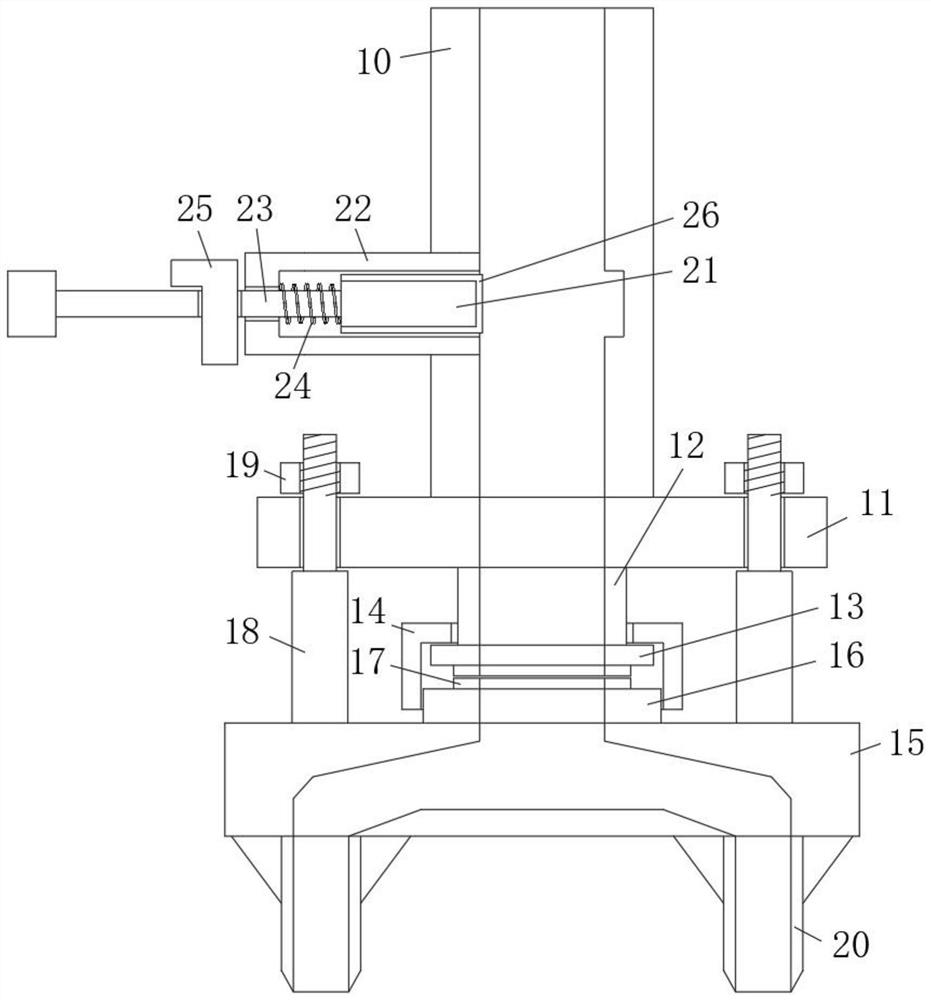

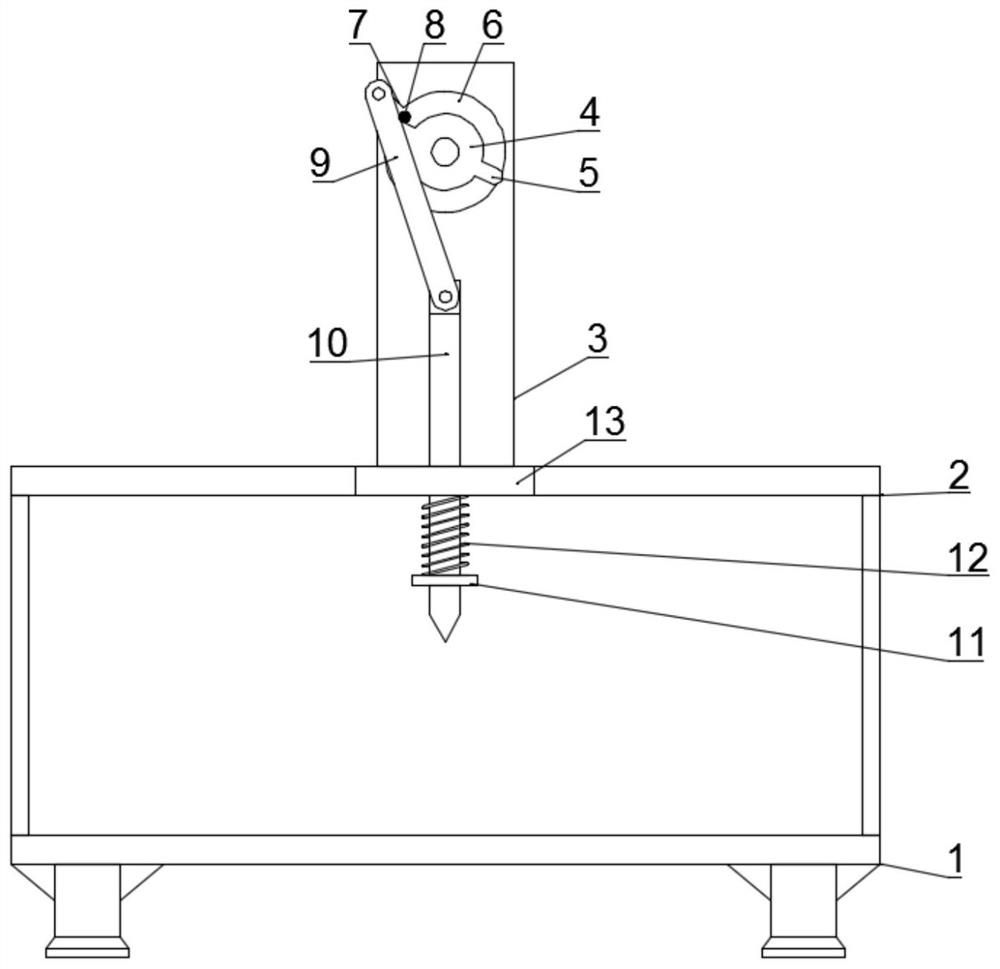

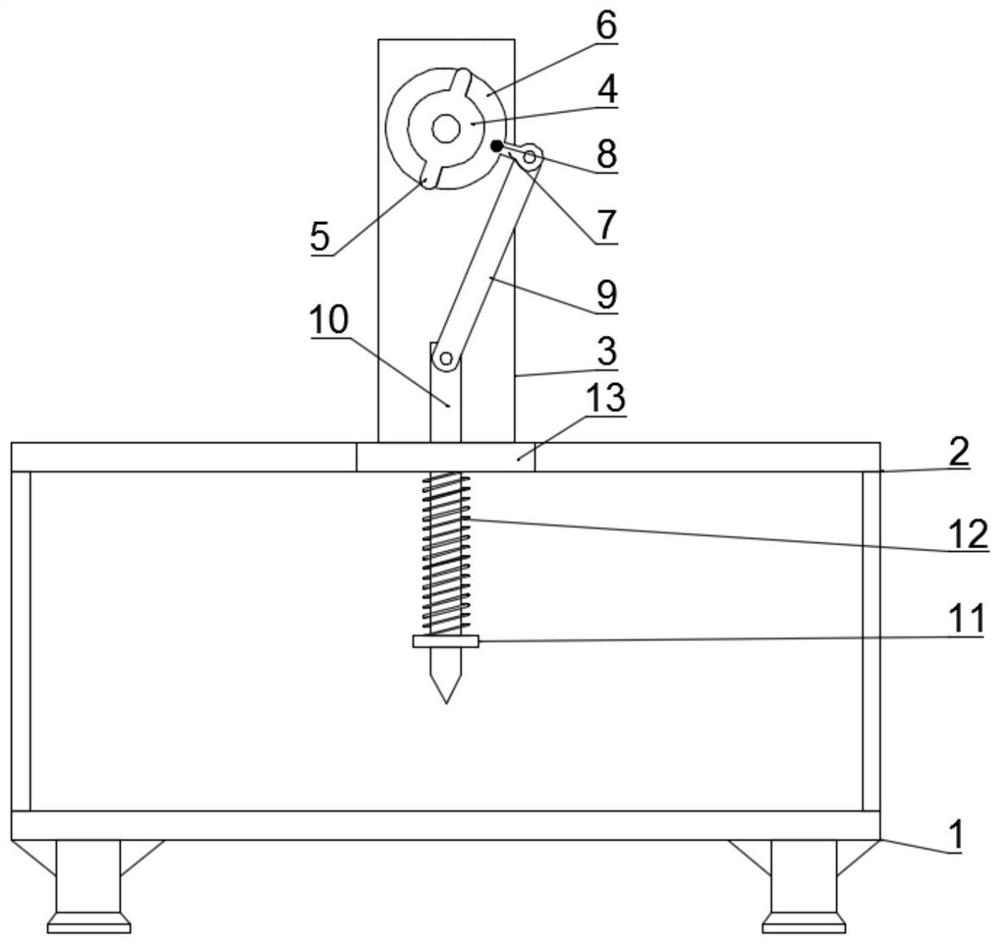

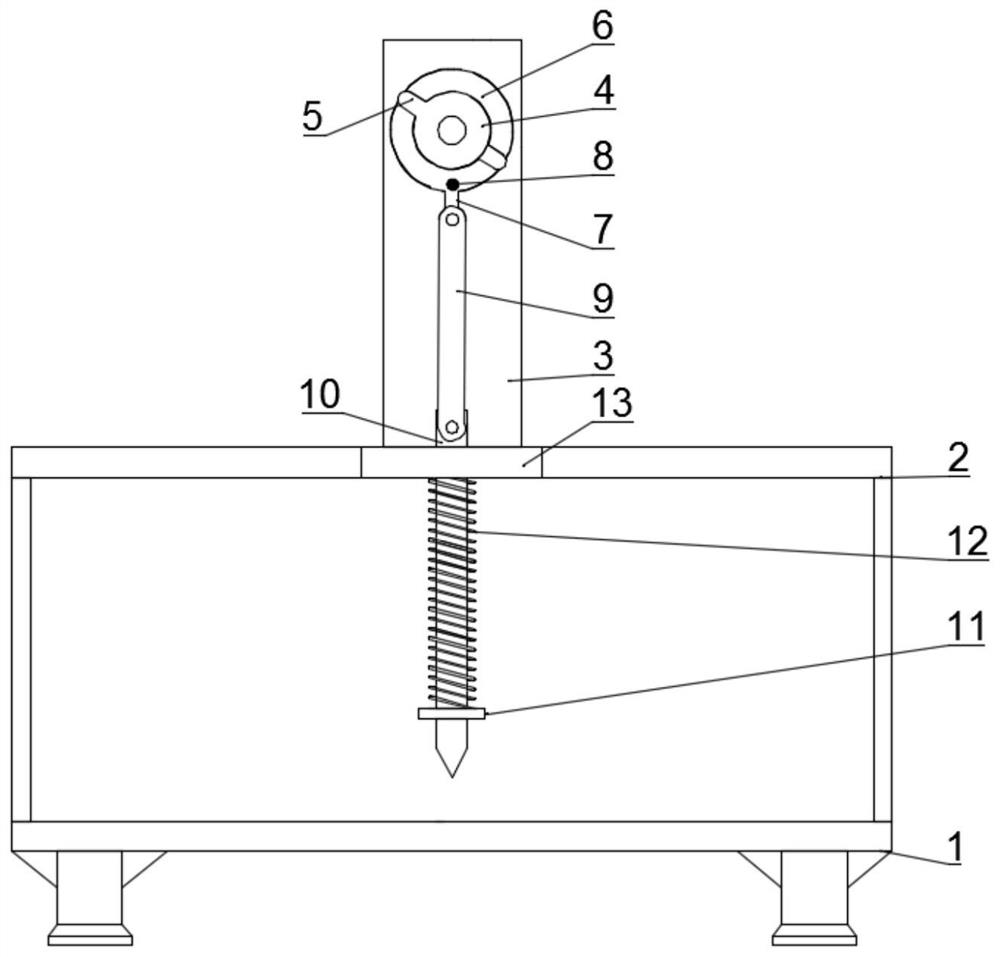

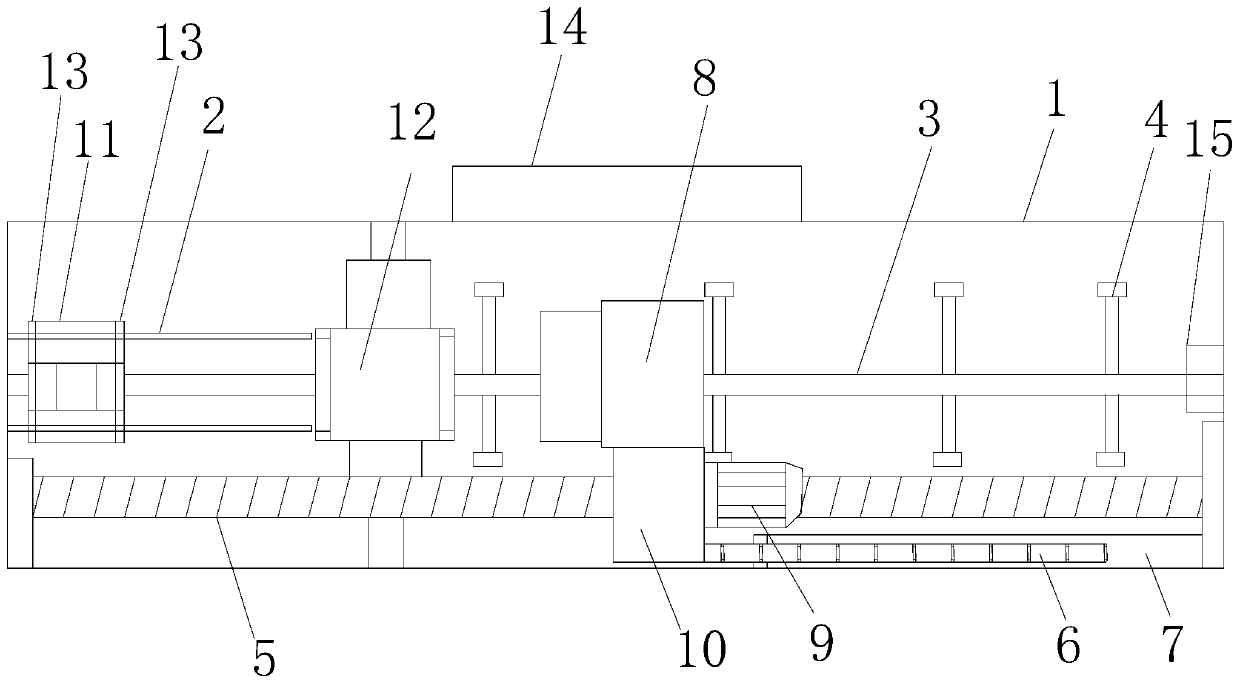

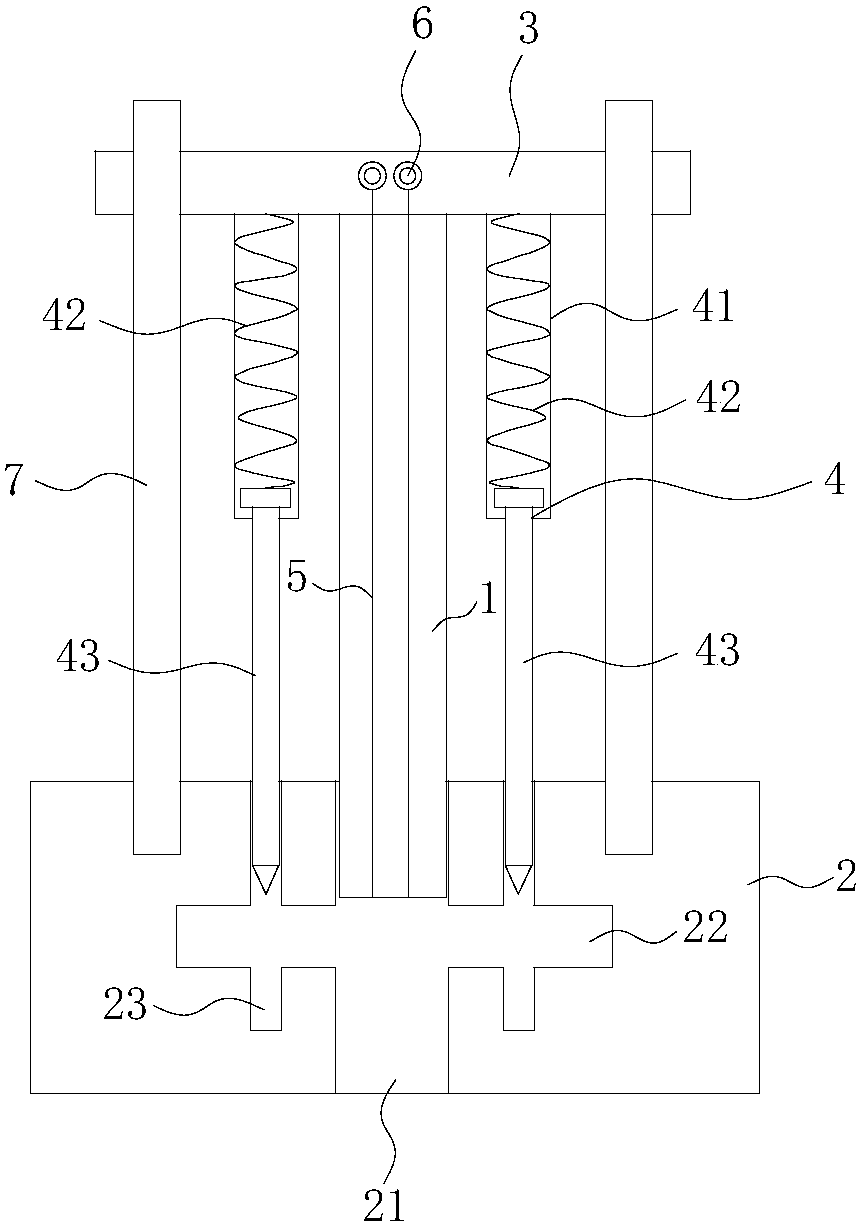

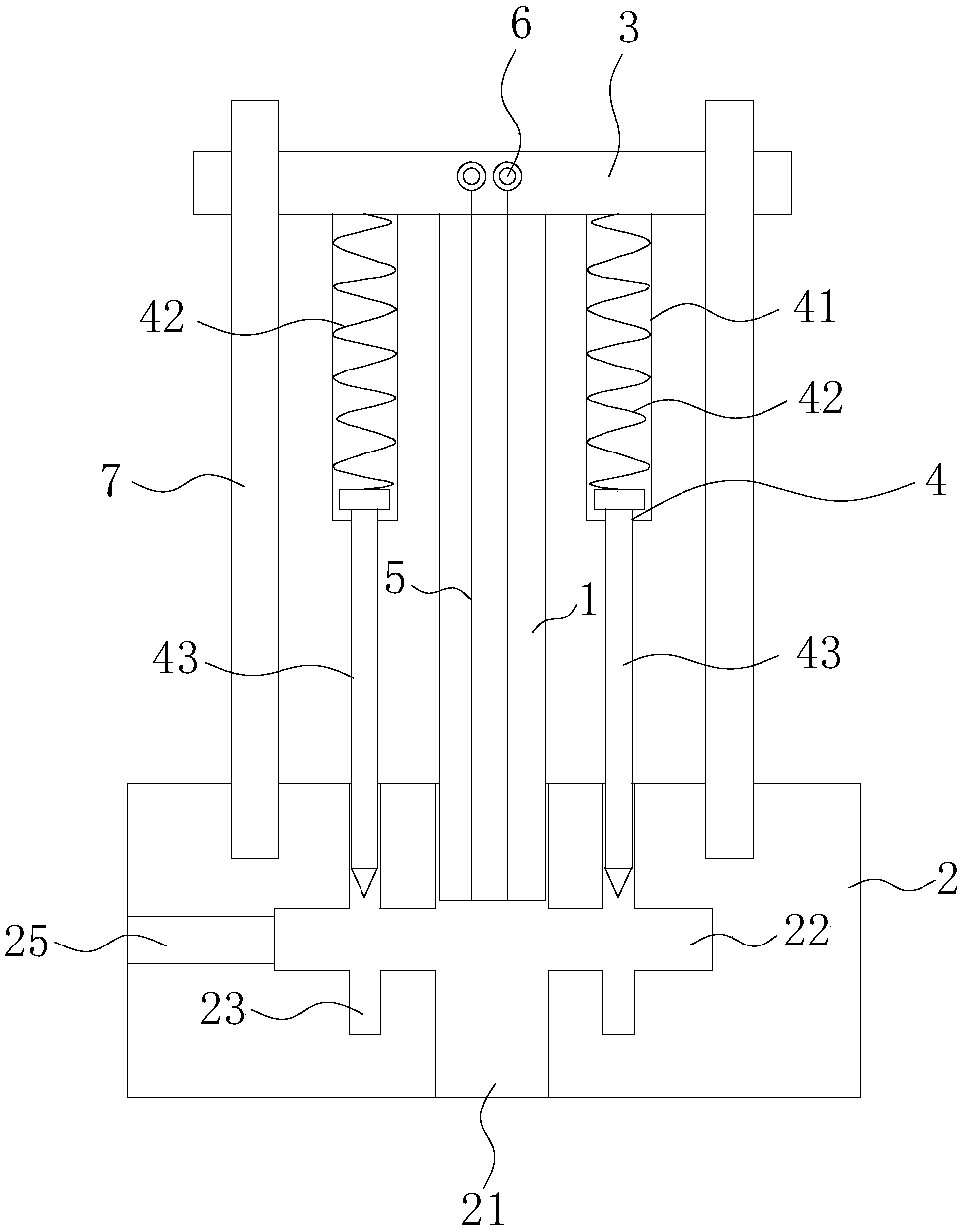

Clamping mechanism for drilling of round seat plate of round seat

ActiveCN110640182AEasy to drillImprove efficiencyPositioning apparatusMetal-working holdersEngineeringMachining time

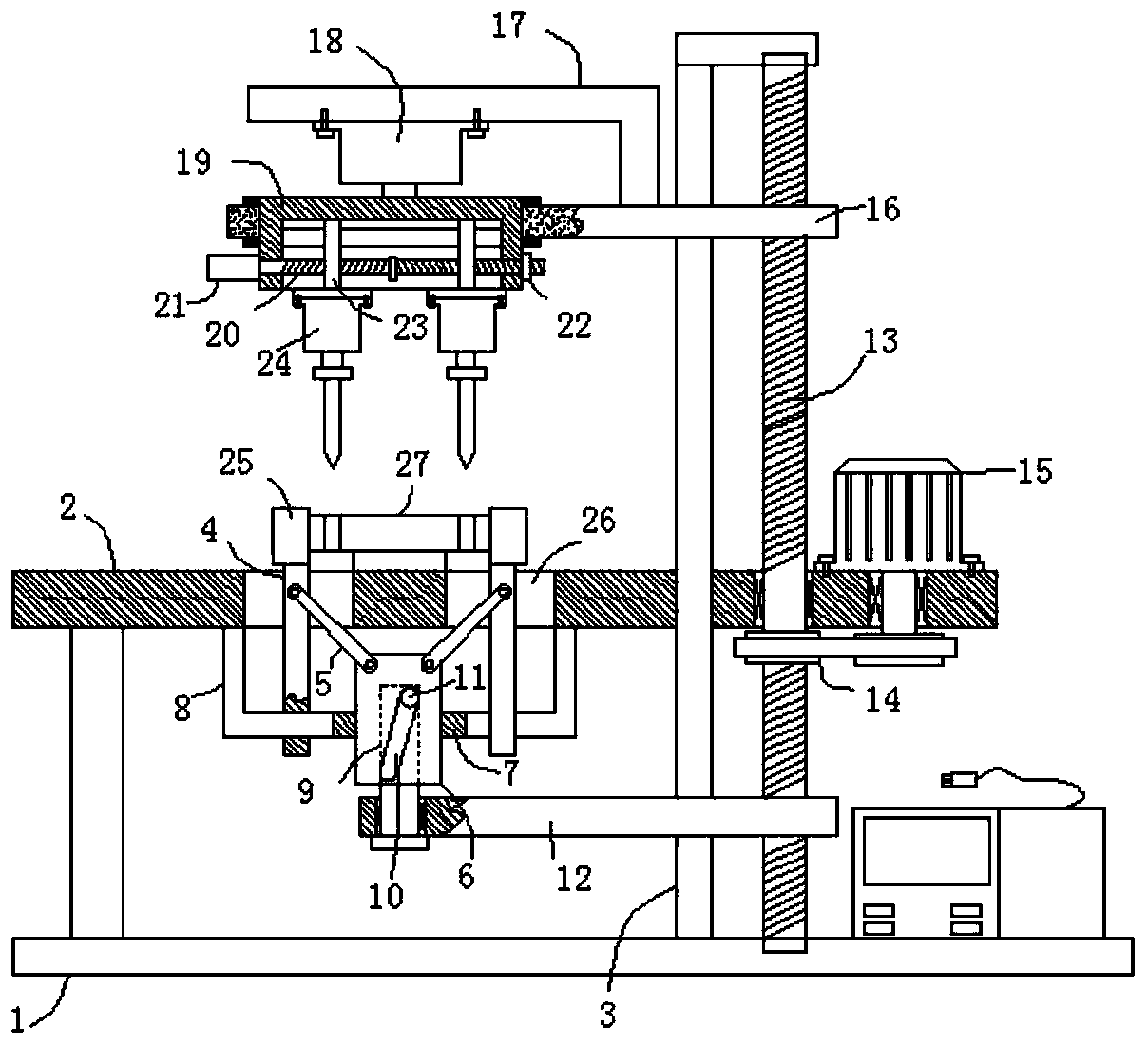

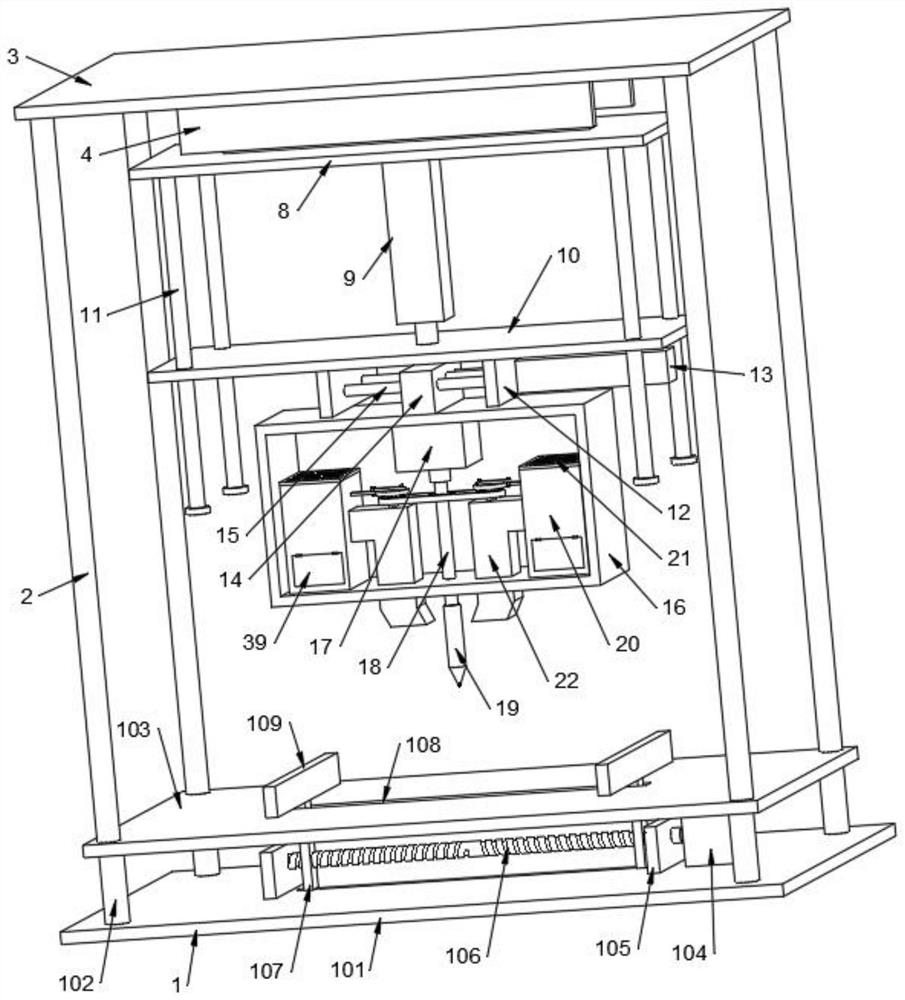

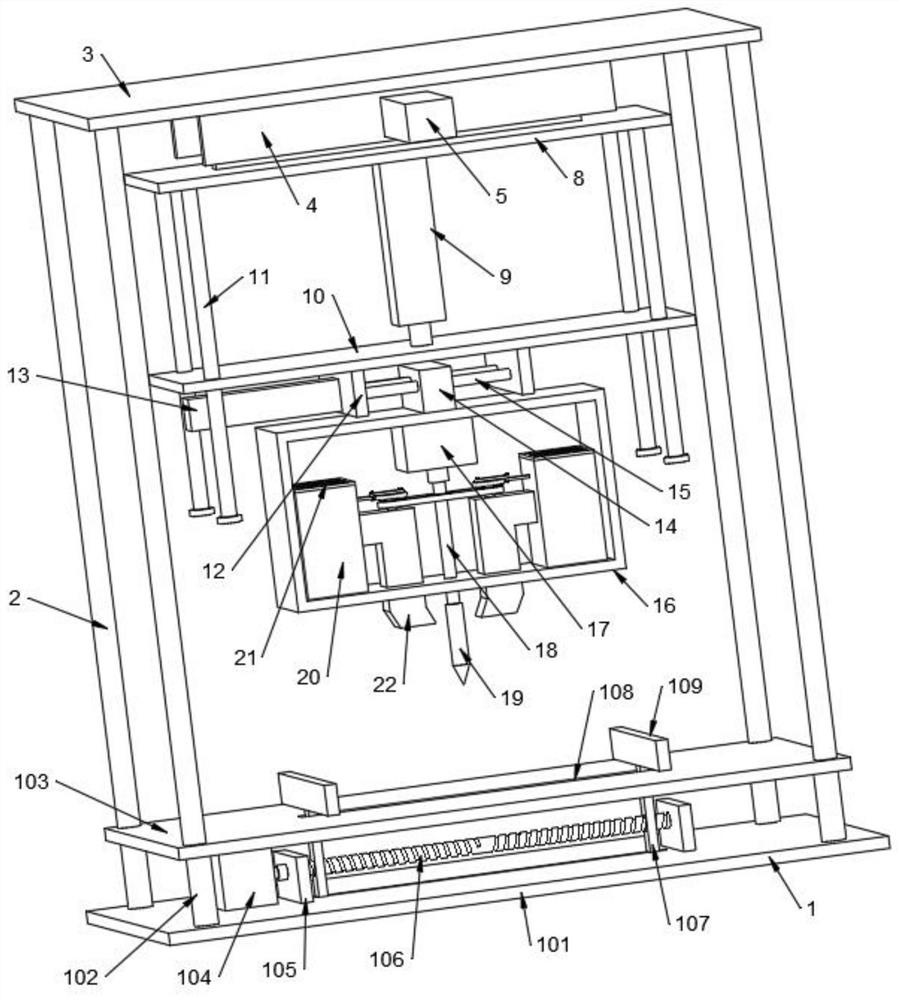

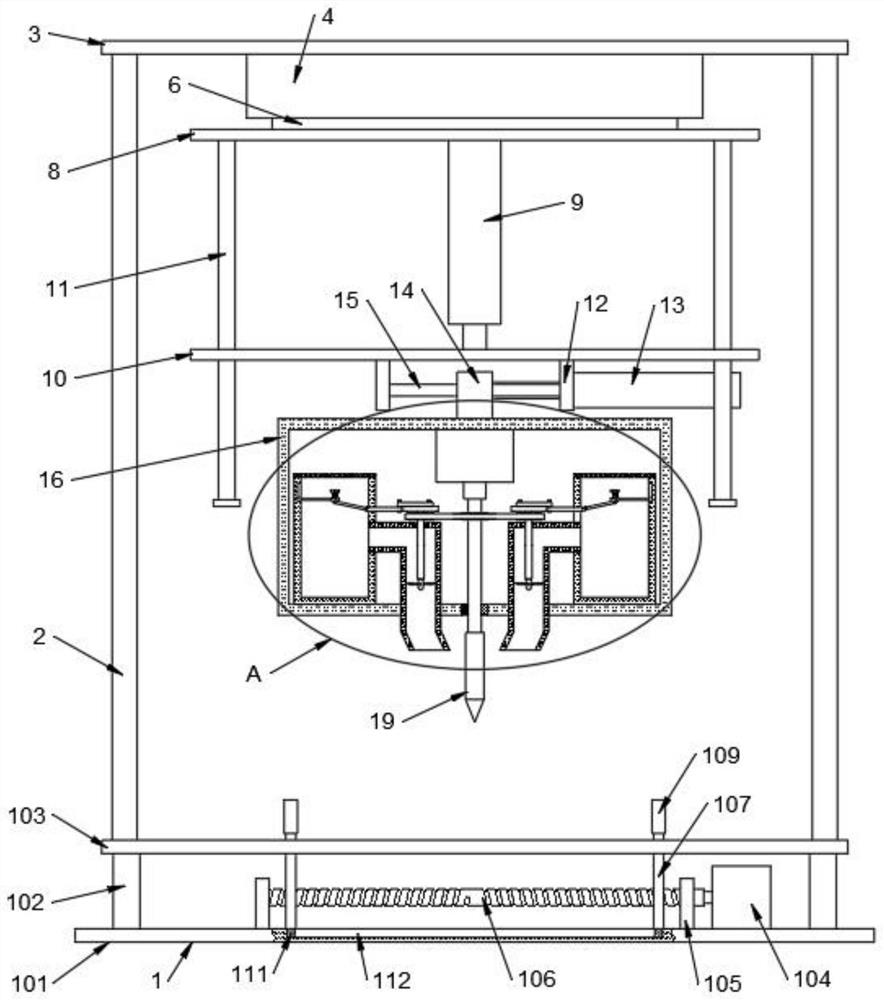

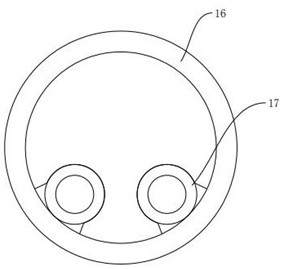

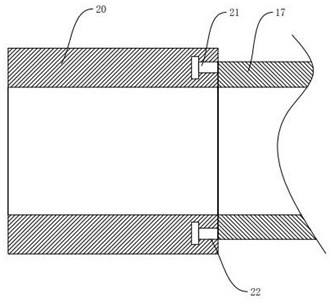

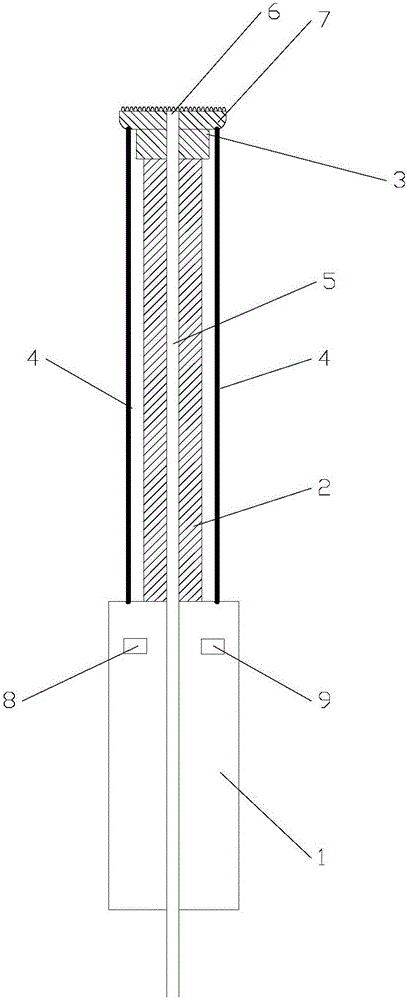

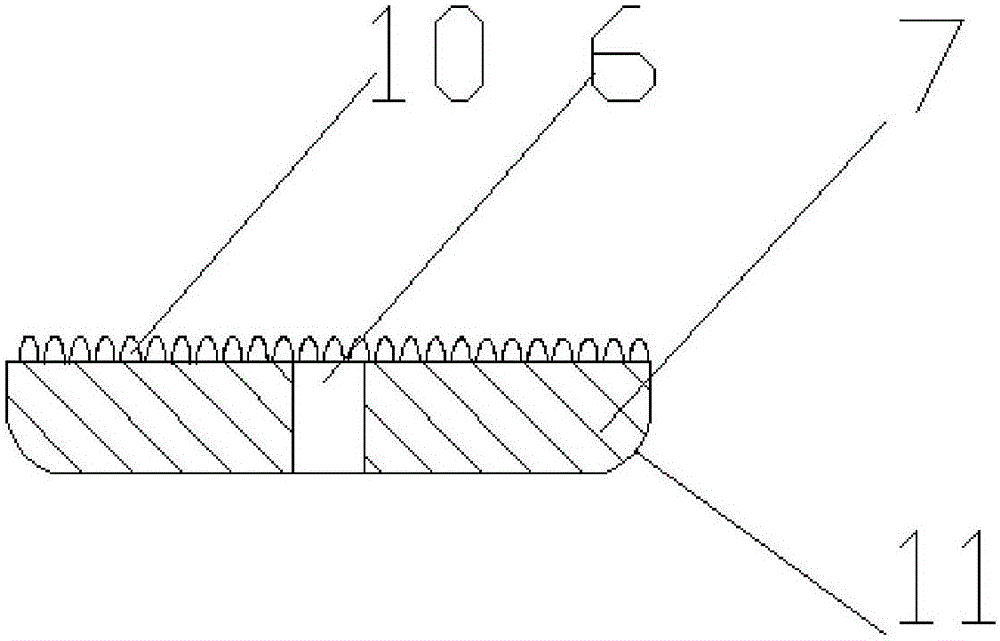

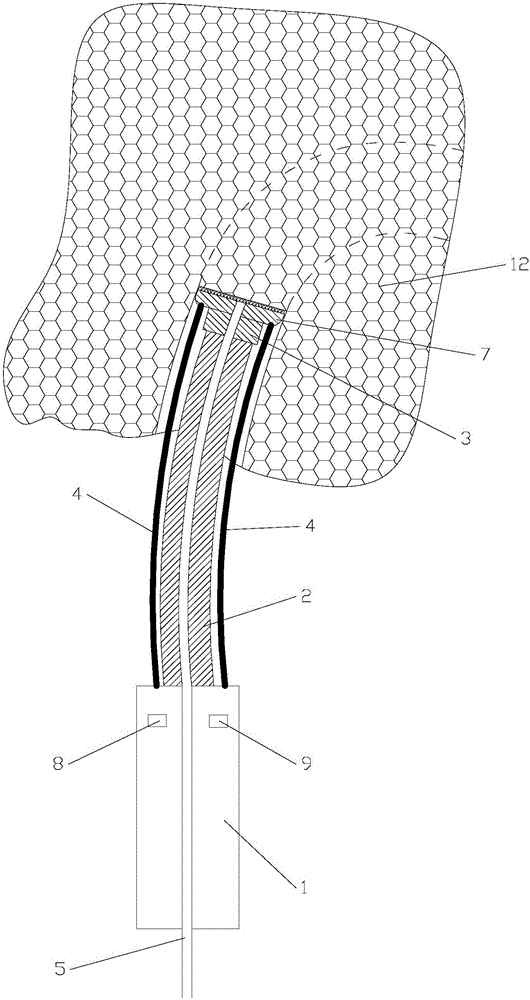

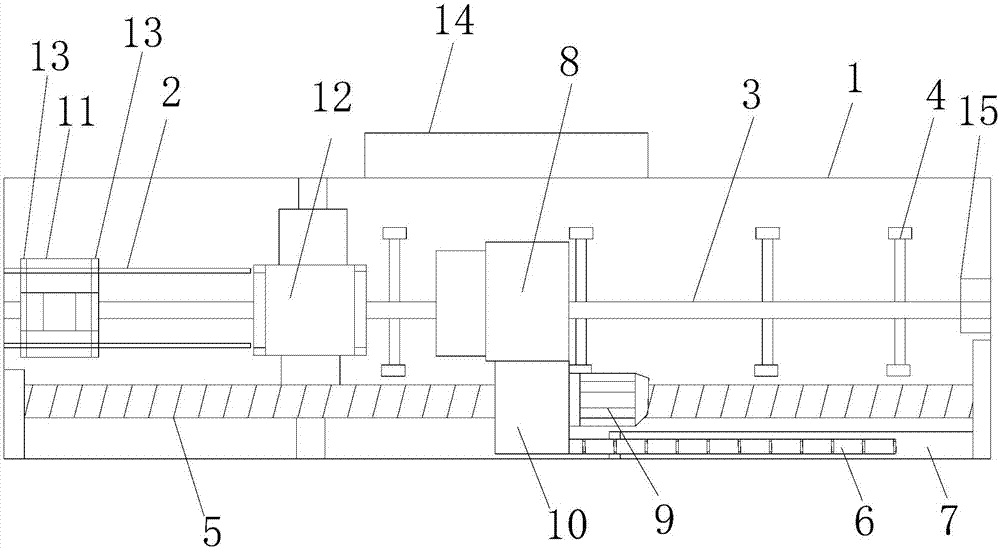

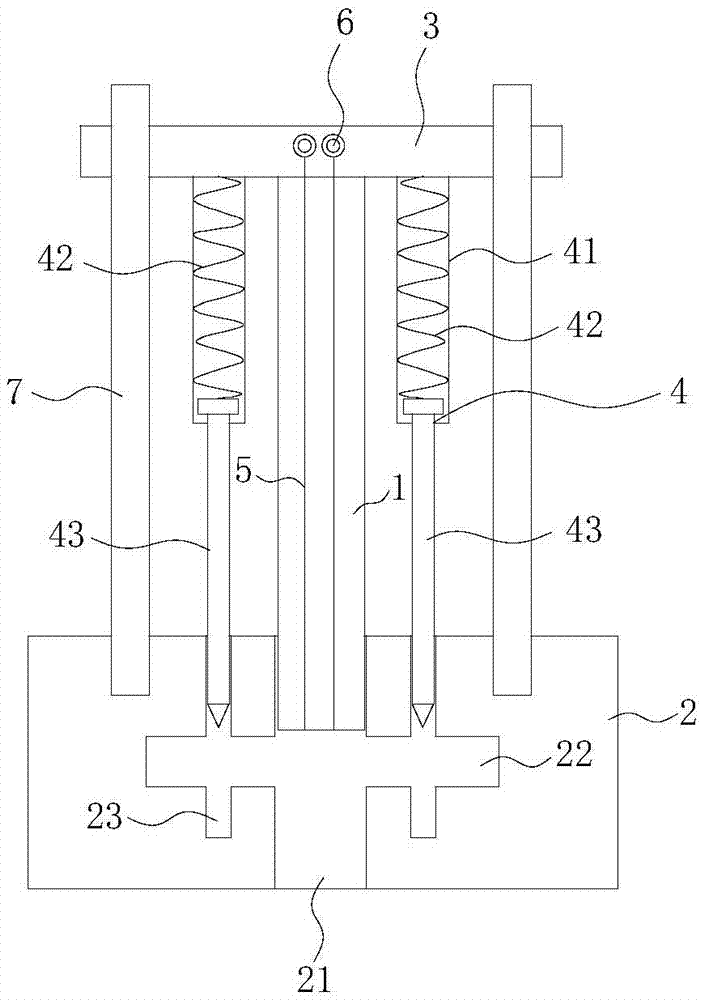

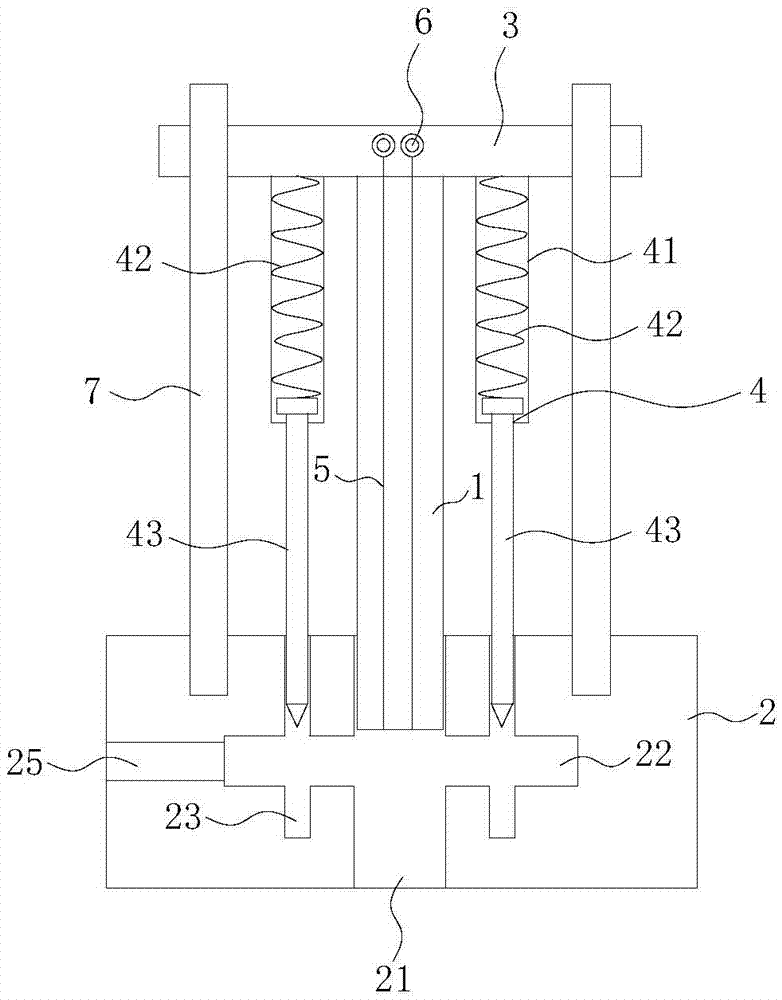

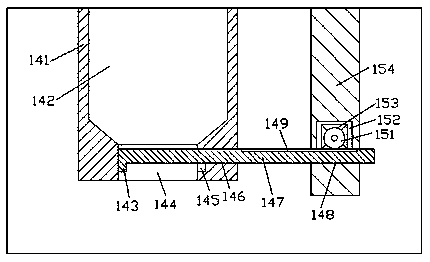

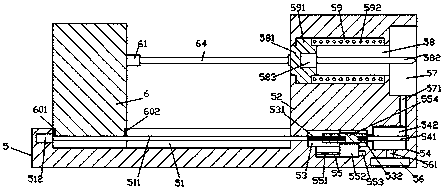

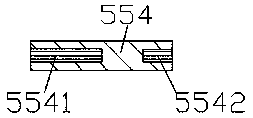

The invention discloses a clamping mechanism for drilling of a round seat plate of a round seat, and relates to the field of plate machining. According to the problems that an existing plate machiningdevice is long in drilling time and low in efficiency, the following scheme is provided, wherein the clamping mechanism comprises a workbench fixed to a base; vertical rectangular supporting rods arranged left and right are arranged on the workbench; the upper end of the rectangular supporting rod located on the right side penetrates through the workbench and extends to the upper portion of the workbench; a clamping assembly, a drilling assembly and an adjusting assembly are mounted on the workbench; the drilling assembly is mounted on the adjusting assembly; and the adjusting assembly is intransmission connection with the clamping assembly. Clamping and fixing of the round plate and lifting of a drilled hole are linked, and therefore the round plate can be automatically clamped in the process of moving the drilled hole downwards; and in the process that the drilled hole continues to move downwards after clamping, the round plate is clamped firmly and cannot be loosened, and drillingis convenient.

Owner:HUZHOU TEACHERS COLLEGE

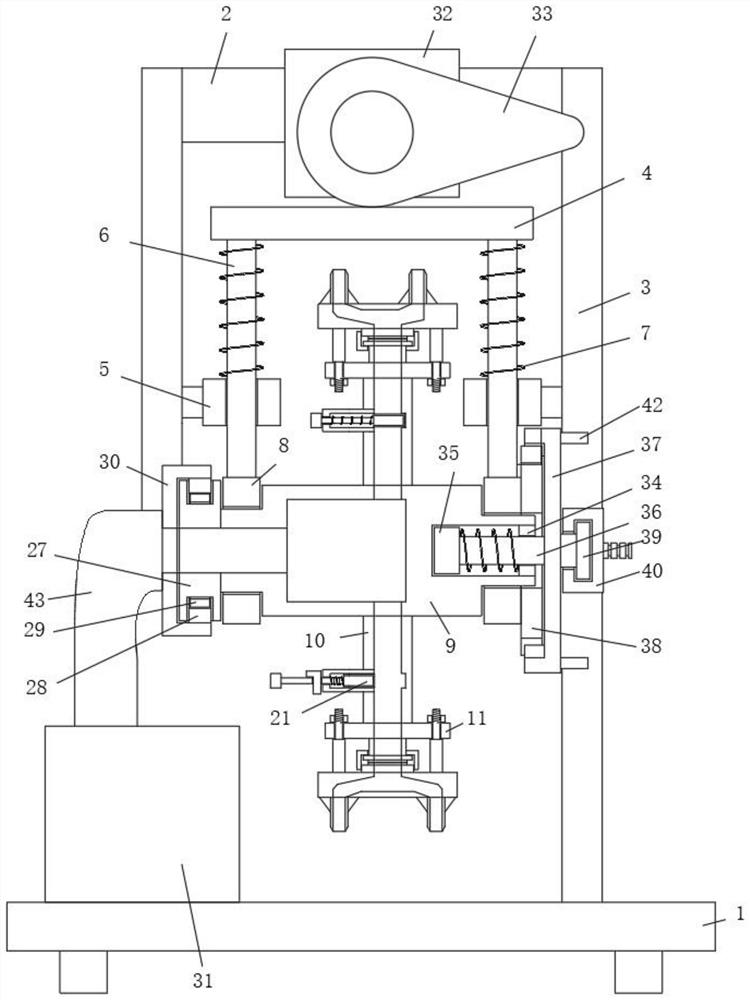

Working method of high-precision stamping die which is easy to replace

ActiveCN109092959AHigh precisionSimple structureShaping toolsMetal-working feeding devicesMachine pressEngineering

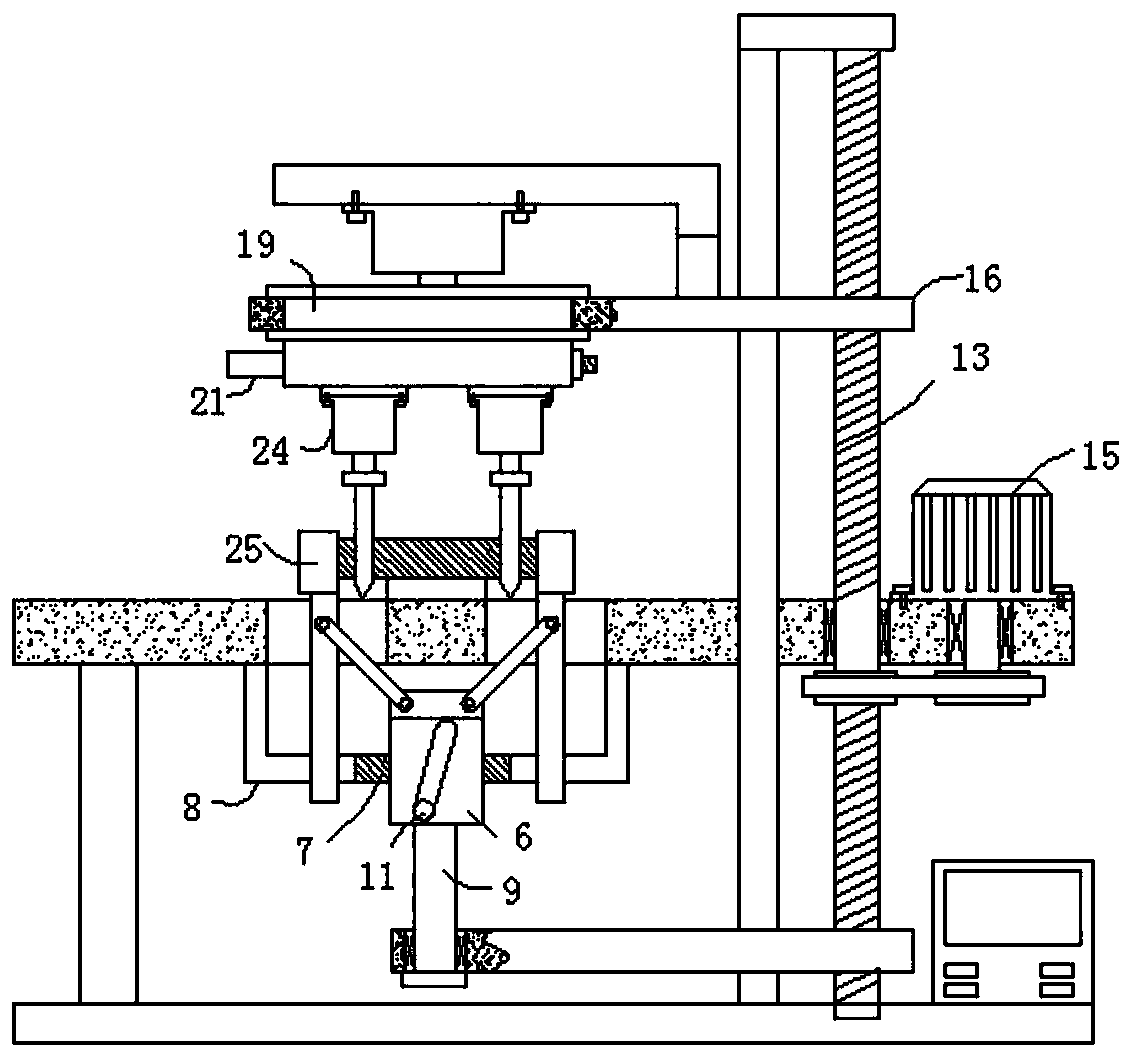

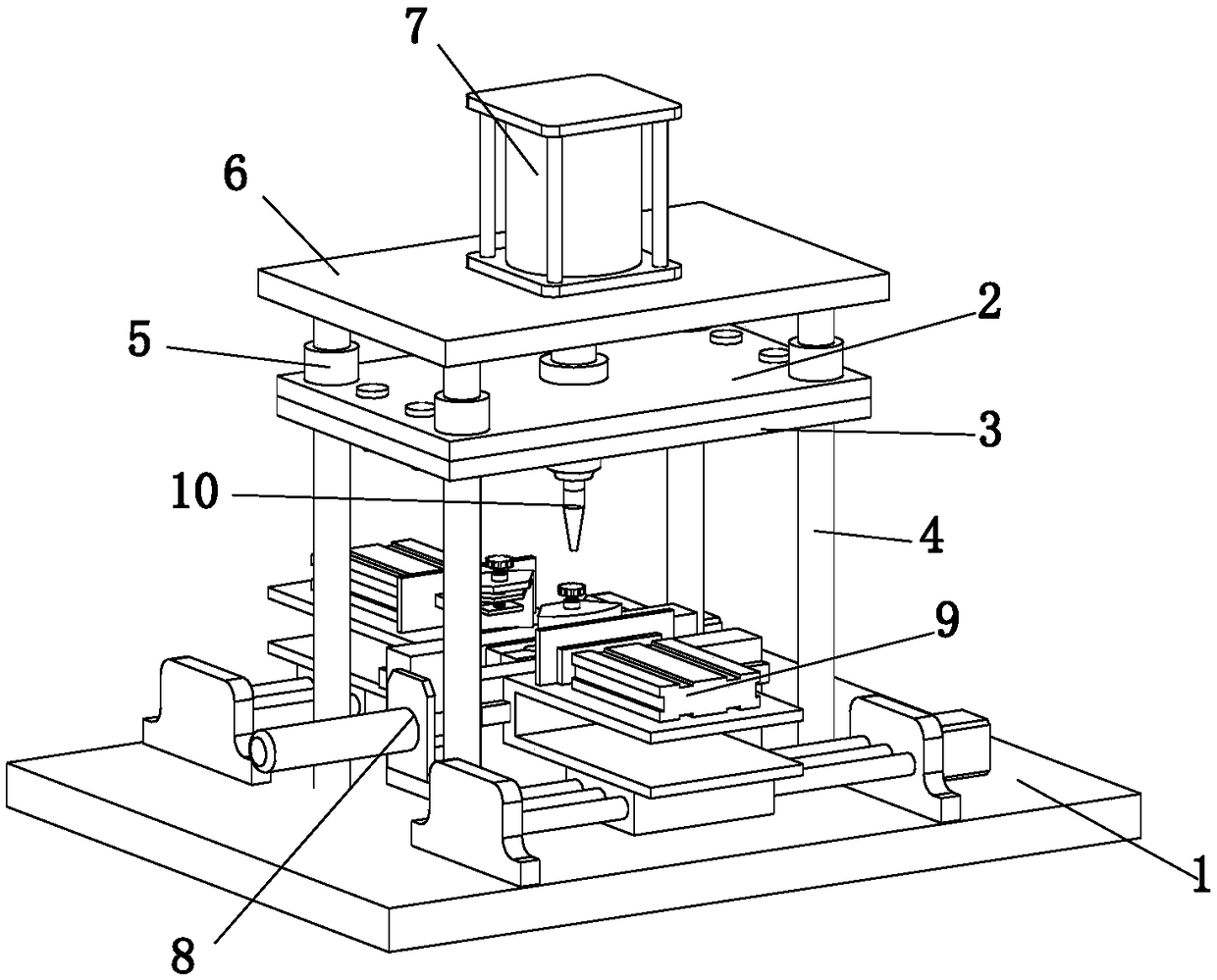

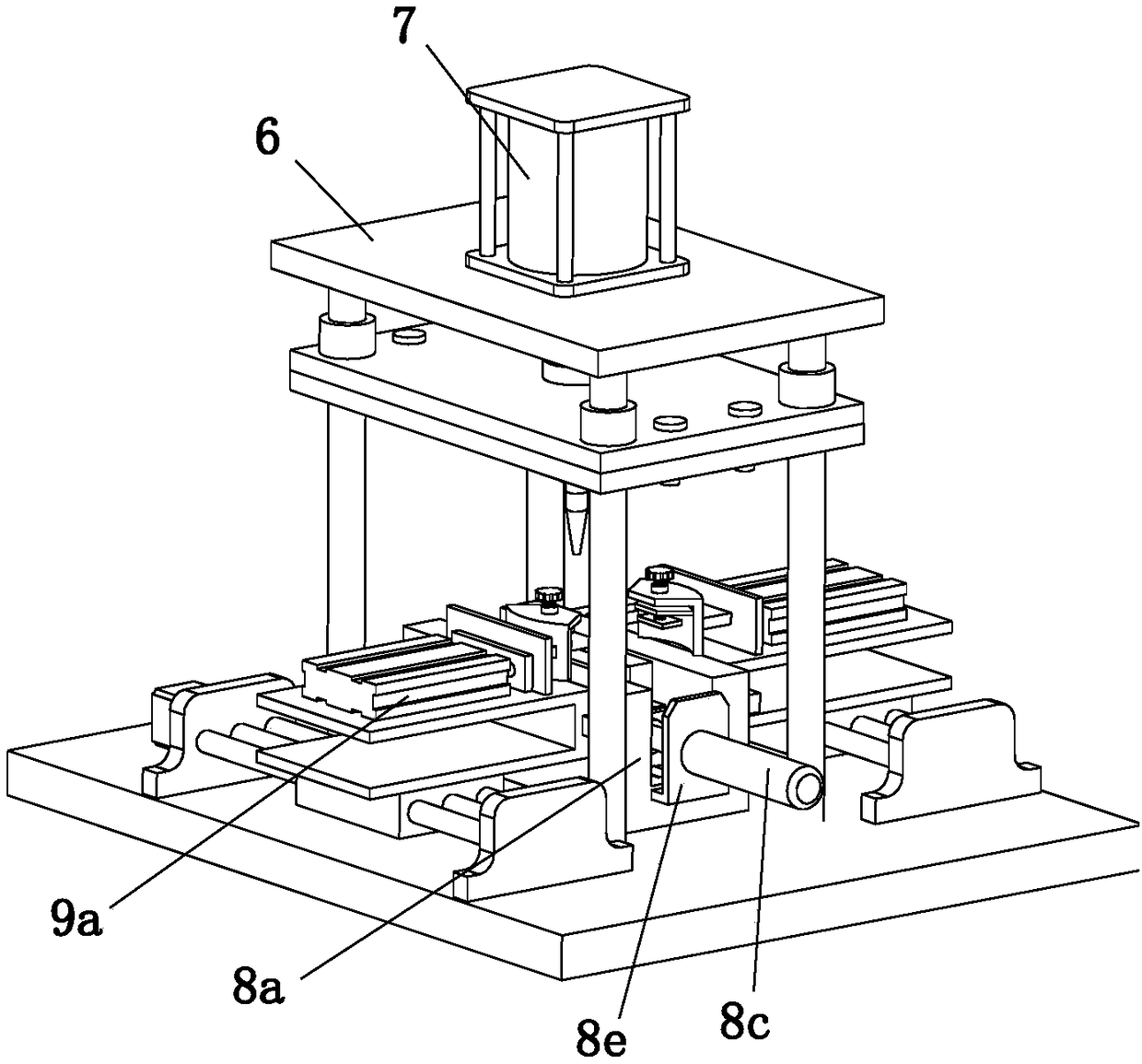

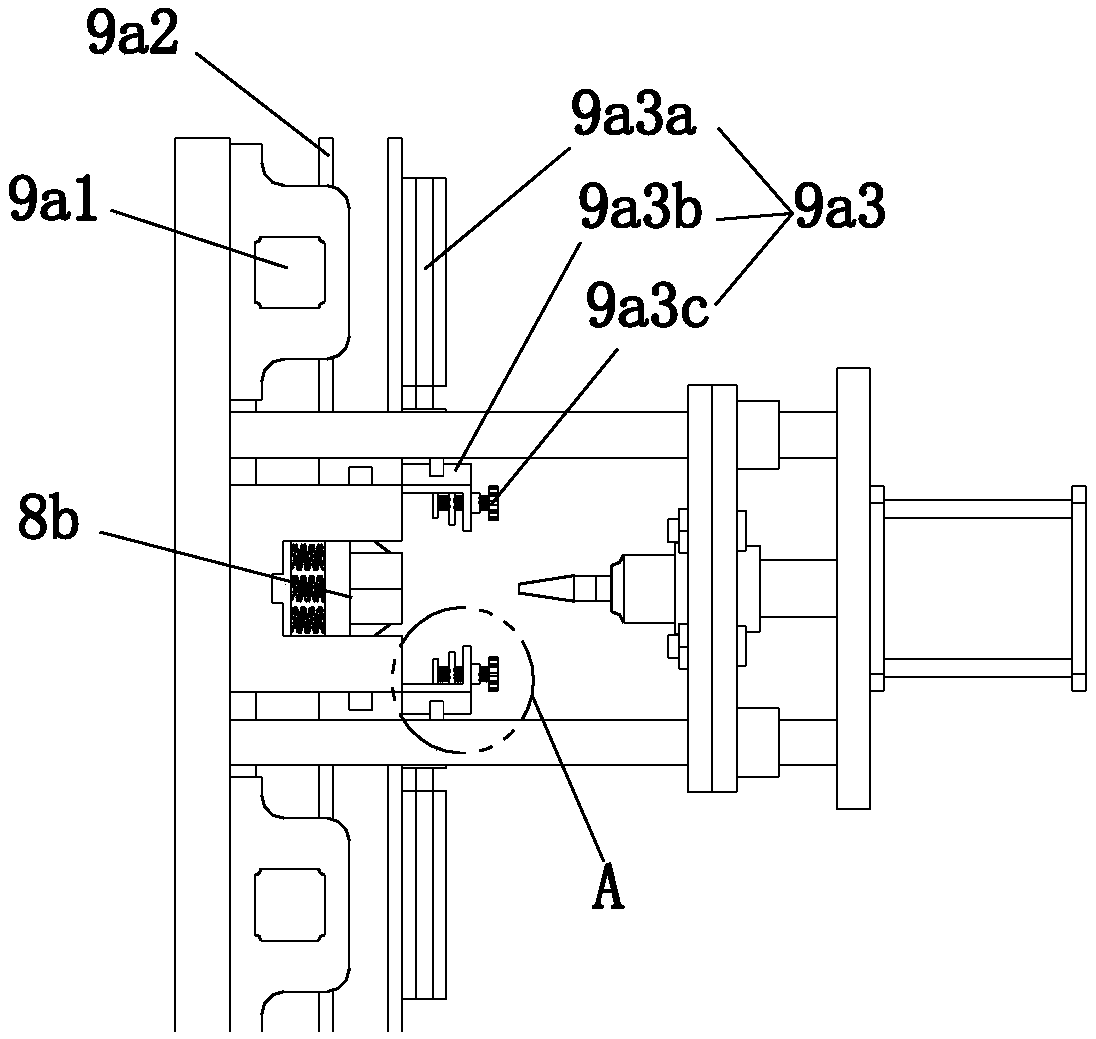

The present invention relates to the field of dies, in particular to a working method of a high-precision stamping die which is easy to replace, the die comprises a base plate arranged horizontally, an upper template and a lower template arranged in parallel with the base plate are arranged directly above the base plate, the upper template and the lower template are fixedly connected by bolts, four vertically arranged guide columns which are in rectangular arrangement are arranged on the top of the base plate, the upper template and the lower template slidably sleeve the four guide columns, the top of the upper template is provided with four guide sleeves which are slidably fitted with the four guide columns, a load-bearing plate in parallel with the upper template is arranged above the upper template, the two ends of each guide column are fixedly connected with the base plate and the bearing plate respectively, the top of the bearing plate is provided with a press, the top of the baseplate is provided with an adjusting limiting device for carrying the part to be stamped and a positioning device for positioning the part to be stamped, and the bottom of the lower template is provided with a stamping device. The invention has the advantages of simple structure and high stamping precision, the punching requirements of different stamping parts can be satisfied, the working efficiency is improved and strong practicability is realized.

Owner:中山市祥亿精密五金模具制品有限公司

Trimming mechanism based on automobile injection molding part

InactiveCN109228070AMeet cutting needsMeet the punching needsEdge grinding machinesDomestic articlesPunchingEngineering

The invention discloses a trimming mechanism based on an automobile injection molding part. The trimming mechanism based on the automobile injection molding part comprises a supporting base, supporting legs, a bearing pedestal, a supporting rod, a first electric telescopic rod, a second electric telescopic rod and a third electric telescopic rod. The trimming mechanism based on the automobile injection molding part is characterized in that the left end of the top of the supporting base is fixedly connected with the first electric telescopic rod; the top end of the first electric telescopic rodis fixedly connected with a first supporting plate; a first motor is fixedly arranged at the bottom of the first supporting plate; an output shaft of the first motor is fixedly connected with a cutting knife; the right end of the top of the supporting base is fixedly connected with the bearing pedestal; and the top end of the bearing pedestal is fixedly connected with a sleeve. The trimming mechanism based on the automobile injection molding part has the following advantage: the problems in the prior art that the trimming work such as cutting, punching and polishing of the automobile injection molding part is conducted separately, the labor amount of people is increased and the processing efficiency is reduced are solved. The requirement on horizontal rotation of the supporting rod and afourth supporting plate by people can be met, so that people can use a drill rod and a grinding head conveniently.

Owner:XUZHOU YUNTAI AUTOMOBILE ELECTRICAL APPLIANCE

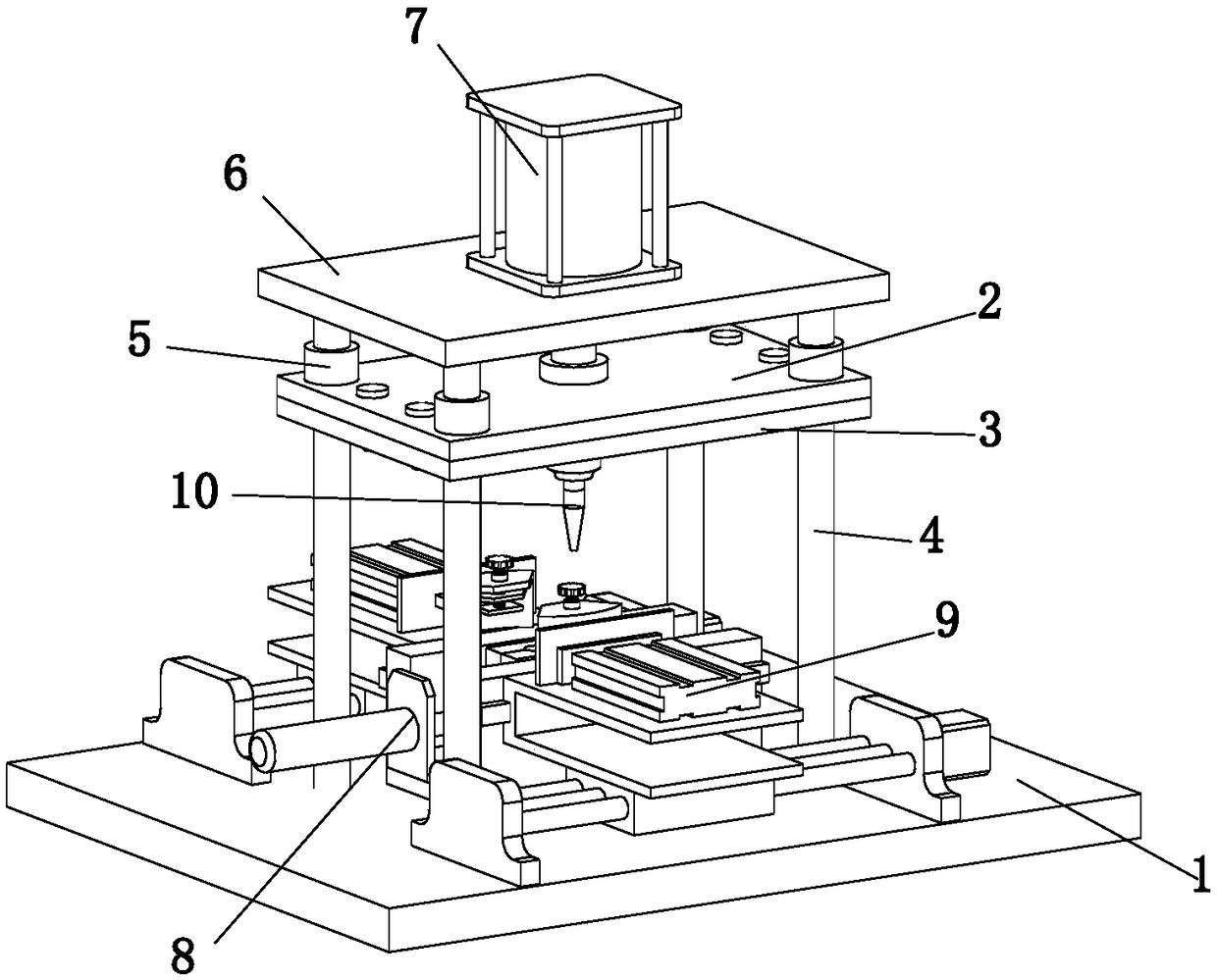

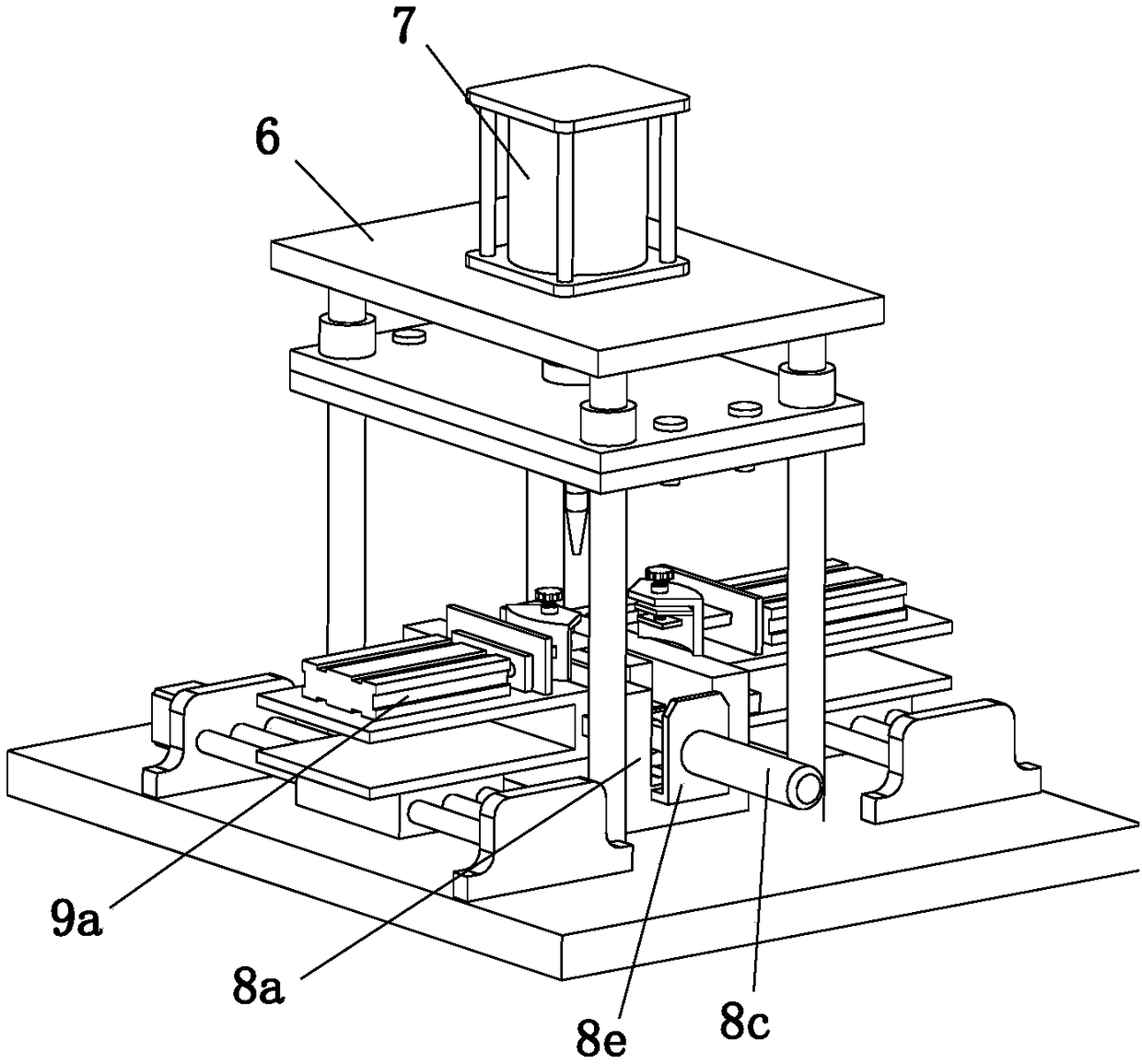

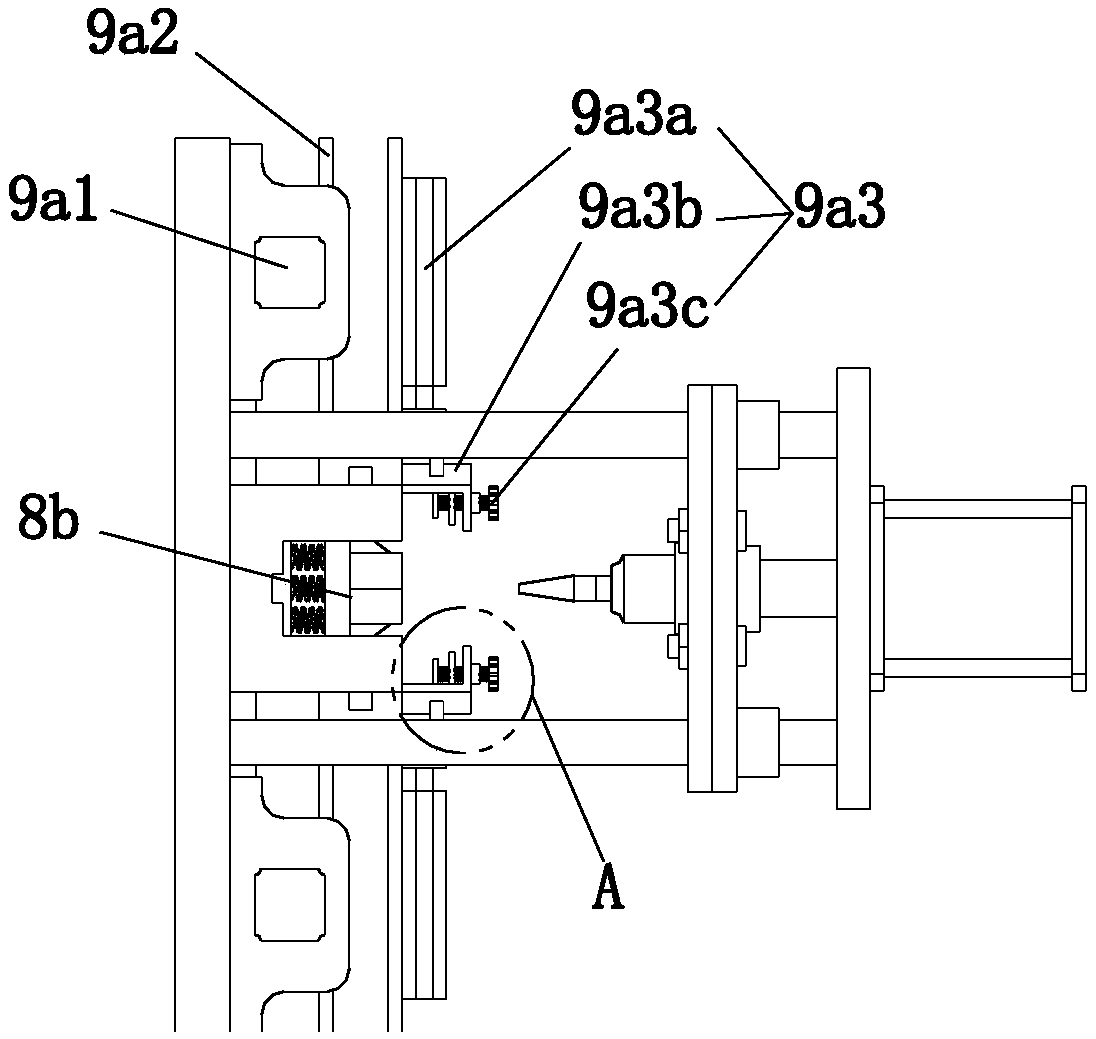

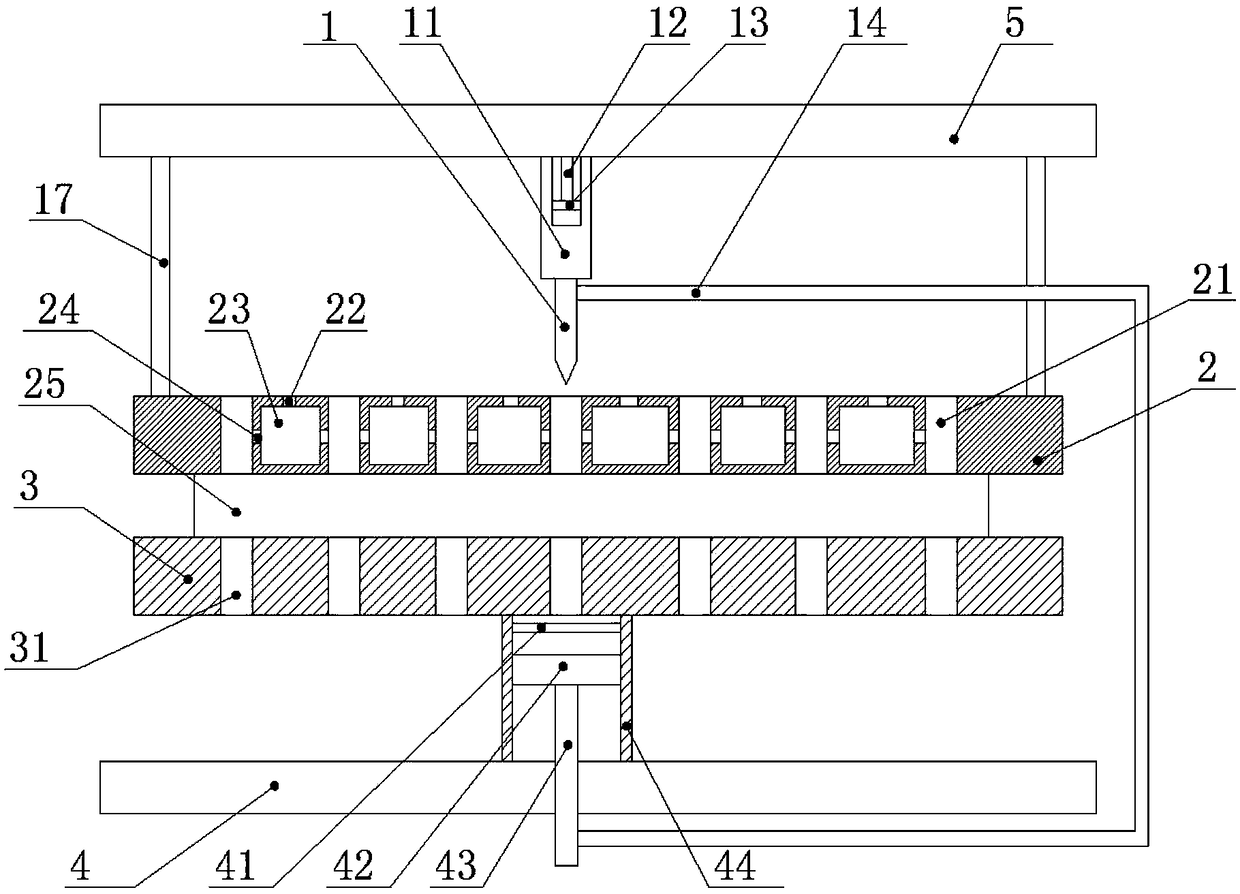

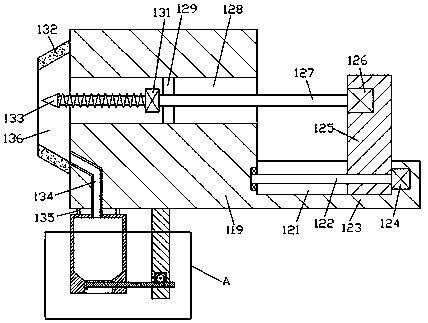

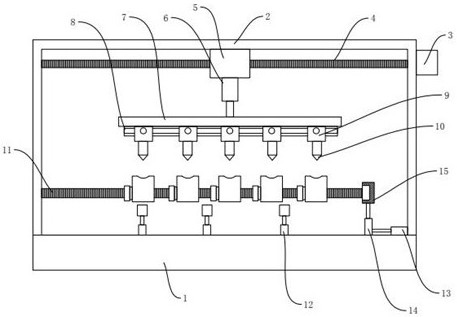

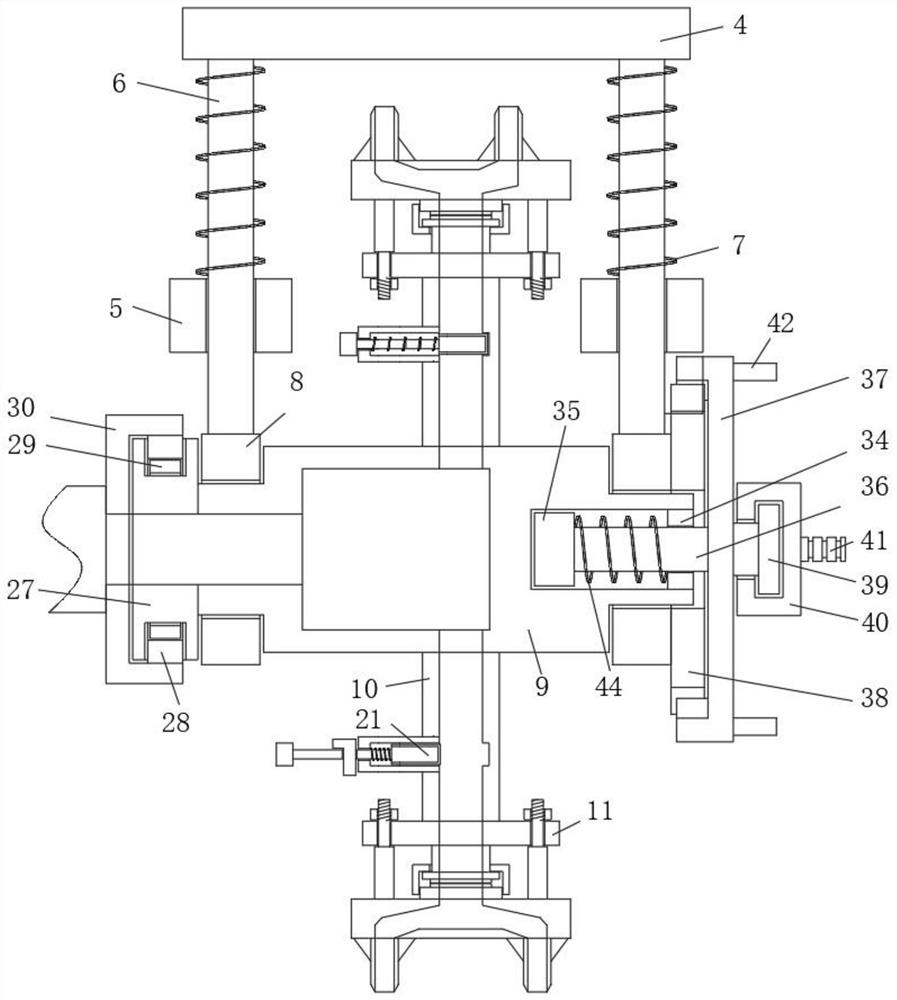

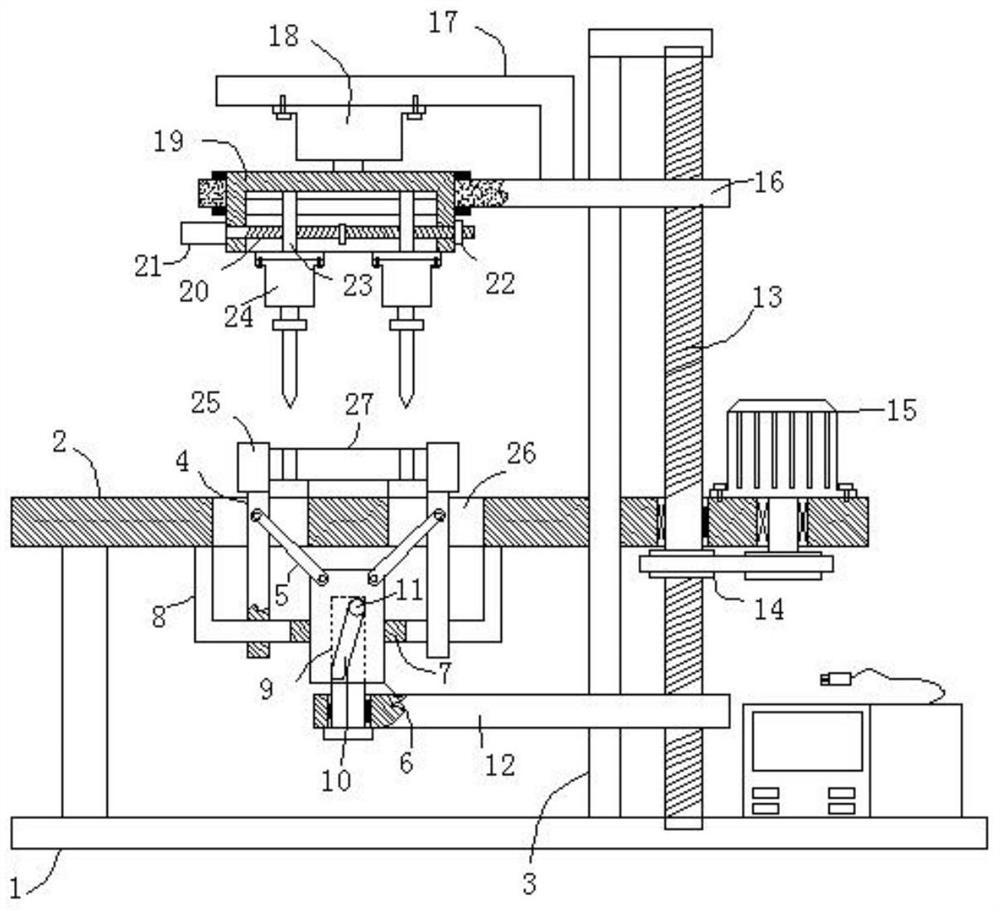

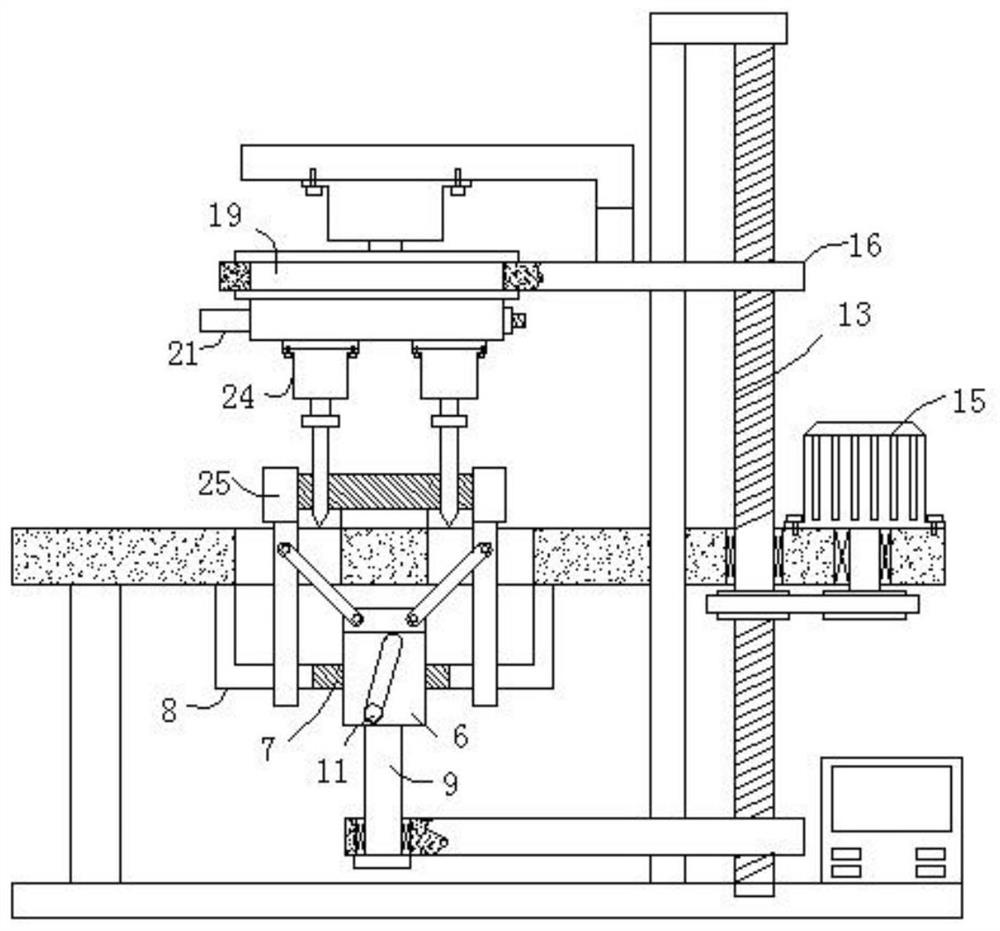

Motor base inner hole machining equipment

InactiveCN111906565ARealize punching needsAvoid blockageFeeding apparatusPositioning apparatusPunchingElectric machine

The invention discloses motor base inner hole machining equipment, and belongs to the technical field of motor base machining equipment. The motor base inner hole machining equipment comprises a clamping device, four stand columns are symmetrically arranged at the top of the clamping device, a top plate is fixed to the tops of the four stand columns, and vertical plates are symmetrically fixed tothe bottom of the top plate, wherein a first electric push rod is fixed to one side wall of one vertical plate; and the output end of the first electric push rod penetrates through one side wall of the adjacent vertical plate and is fixedly provided with a first connecting plate, and first guide rods are symmetrically arranged below the top plate. According to the motor base inner hole machining equipment, a motor base can be relatively conveniently and rapidly fixed, and front-back movement, up-down movement and left-right movement of a drill bit can be achieved, so that the punching requirement for the motor base can be met, generated dust can be sucked into a box body in the punching process, and the situation that meshes of a stainless steel filter screen plate are blocked can be prevented.

Owner:缪新建

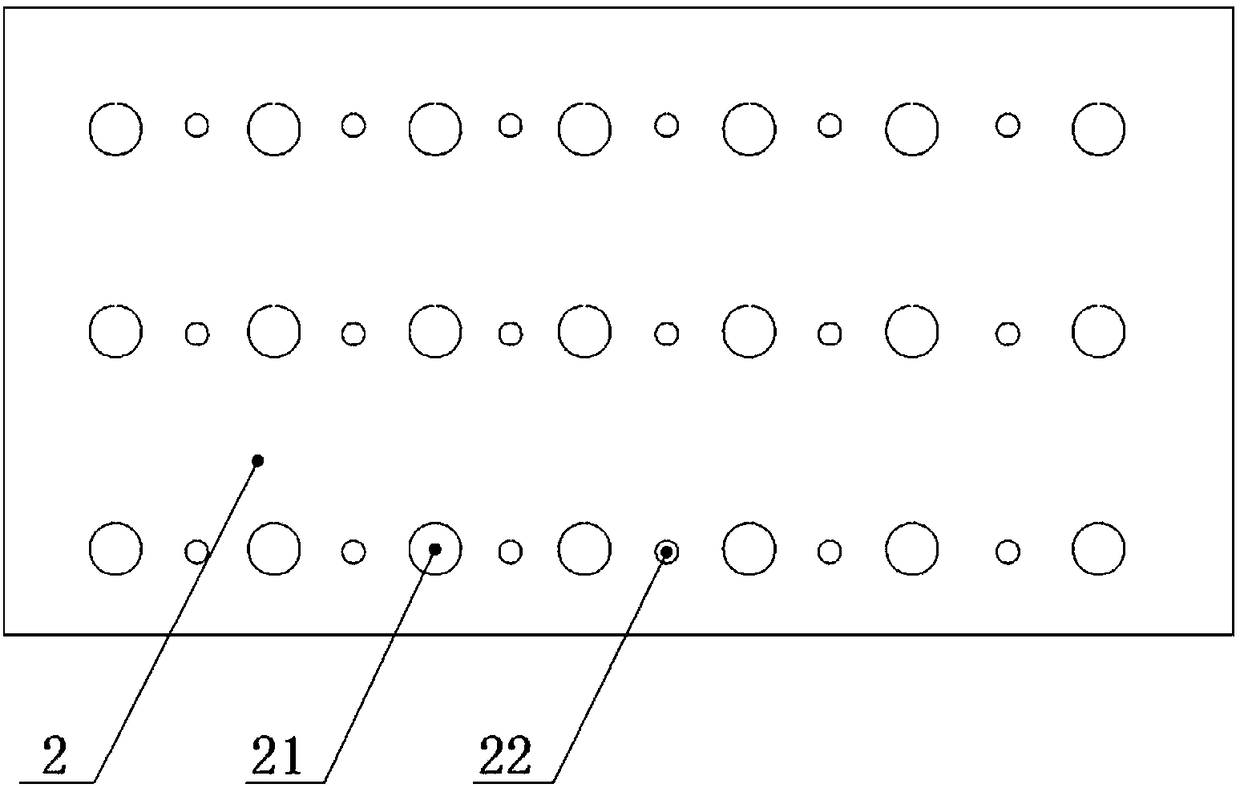

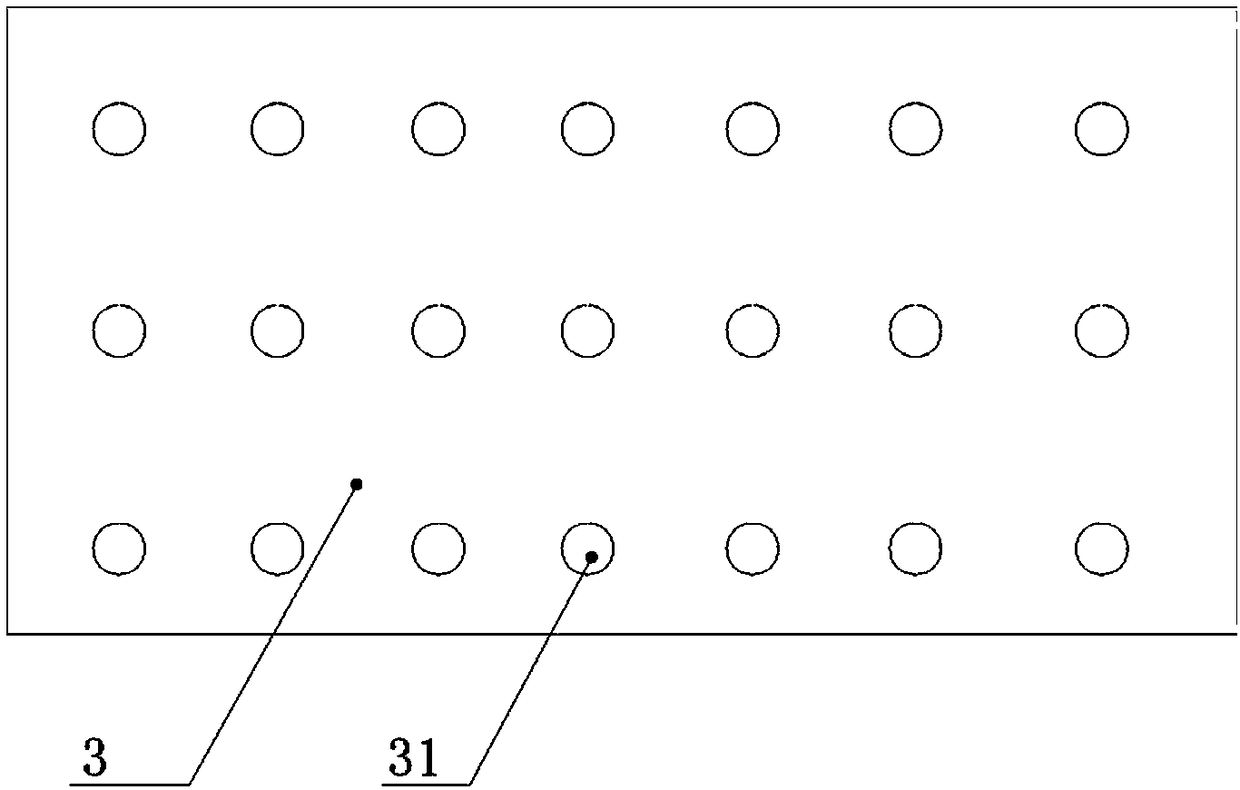

Notebook shell processing device

InactiveCN108176999AAchieve positioningPrevent movementWork clamping meansPositioning apparatusMechanical engineeringEngineering

The invention relates to the technical field of notebook part processing, in particular to a notebook shell processing device. The notebook shell processing device comprises a supporting table, wherein a plurality of first through holes are formed in the supporting table; a pressure plate is arranged above the supporting table; a plurality of second through holes are formed in the pressure plate;a first slide rail is arranged above the pressure plate; a telescopic rod is connected between the first slide rail and the pressure plate; a plurality of positioning holes are formed in the first slide rail; chutes are formed in two sides of each positioning hole; slots are formed in the side walls of the chutes; a U-shaped rod is arranged below the first slide rail; a perforating cutter is connected below the U-shaped rod; the opening of the U-shaped rod faces upward; the side walls of the U-shaped rod are slidably connected to the chutes; wedge rods capable of being locked into the slots are slidably arranged on the side walls of the U-shaped rod; springs are connected between the wedge rods and the U-shaped rod; a push rod is slidably arranged in a groove of the U-shaped rod; and the end portion of the push rod is a wedge surface capable of being acted with the wedge rod. The notebook shell processing device provided by the invention solves the problem that in the prior art, the bottom shell of the notebook is easy to deform if being perforated.

Owner:英力电子科技(重庆)有限公司

Metal pipe stamping device

The invention relates to the field of metal pipe machining, in particular to a metal pipe stamping device. The metal pipe stamping device is characterized in that a metal pipe positioning mechanism is arranged on a rack and comprises a threaded adjusting rod and a plurality of metal pipe supporting sleeves, guide sliding sleeves are arranged in the metal pipe supporting sleeves, the guide sliding sleeves are in sliding connection with the threaded adjusting rod, the guide sliding sleeves are rotationally connected with a threaded adjusting sleeve through a rotary connecting piece, and the threaded adjusting sleeve is in threaded connection with a threaded adjusting rod. According to the structural arrangement of the device, when the punching position and the punching distance need to be adjusted, the threaded adjusting sleeve is driven to rotate, accordingly, the threaded adjusting sleeve drives the metal pipe supporting sleeve to move on the threaded adjusting rod through the guide sliding sleeve, the position of the metal pipe is adjusted, the punching position and distance can be adjusted according to needs, the number of the metal pipe supporting sleeves can be increased or decreased according to needs, the punching requirements of different numbers are met, and the application range is wide.

Owner:潍坊市工程技师学院

Arc bone hole puncher

The invention relates to an arc bone hole puncher which comprises a flexible arm and a vibratory punching device, wherein the front end of the flexible arm is connected with the vibratory punching device; a pair of steering stay ropes is arranged on the vibratory punching device, and located on the outer side of the flexible arm; the vibratory punching device comprises an ultrasonic transducer and a tool head connected with the ultrasonic transducer; the tool head is located at the most front end of the vibratory punching device. According to the arc bone hole puncher, a bent or arc hole can be unidirectionally processed in a bone by the combined action of the flexible arm and the steering stay ropes; a processing track can be adjusted as required during a processing course; the flexibility is high.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

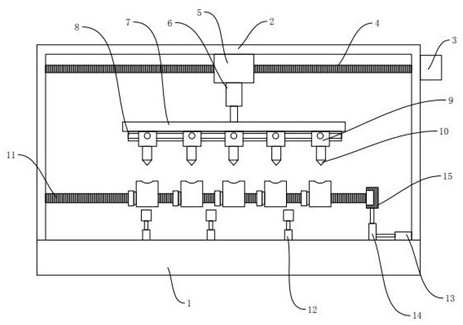

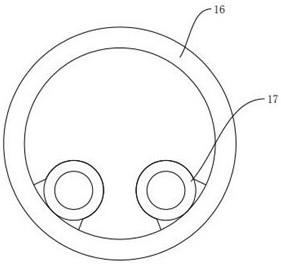

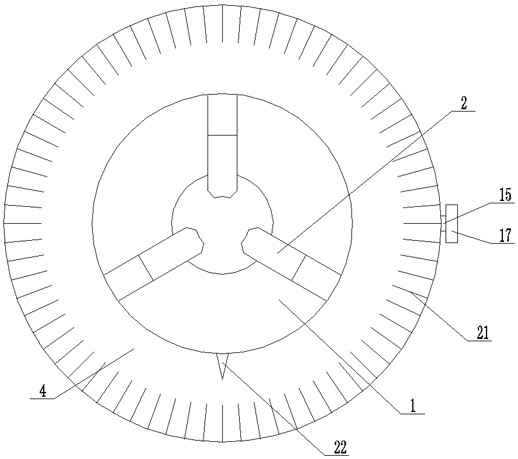

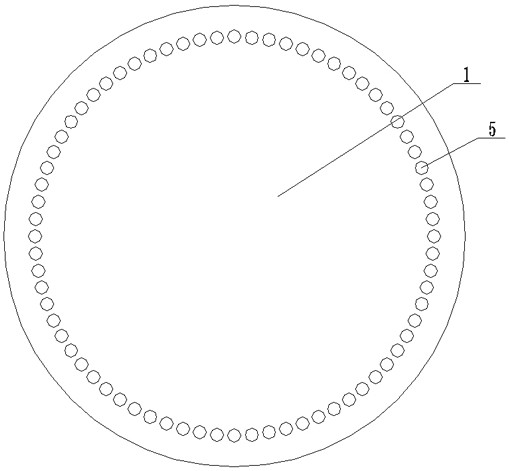

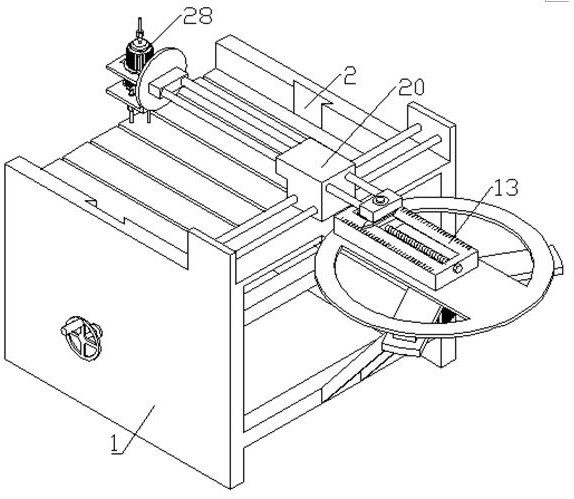

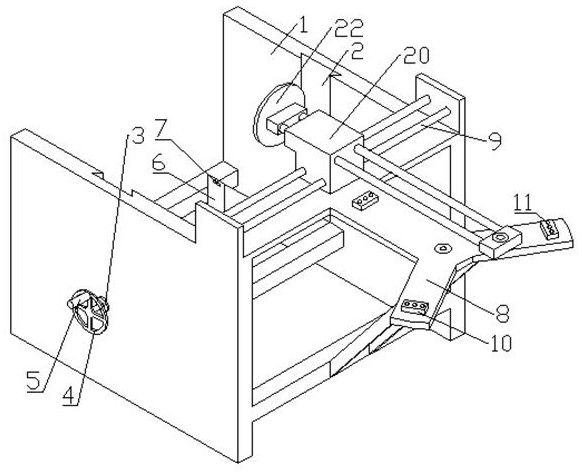

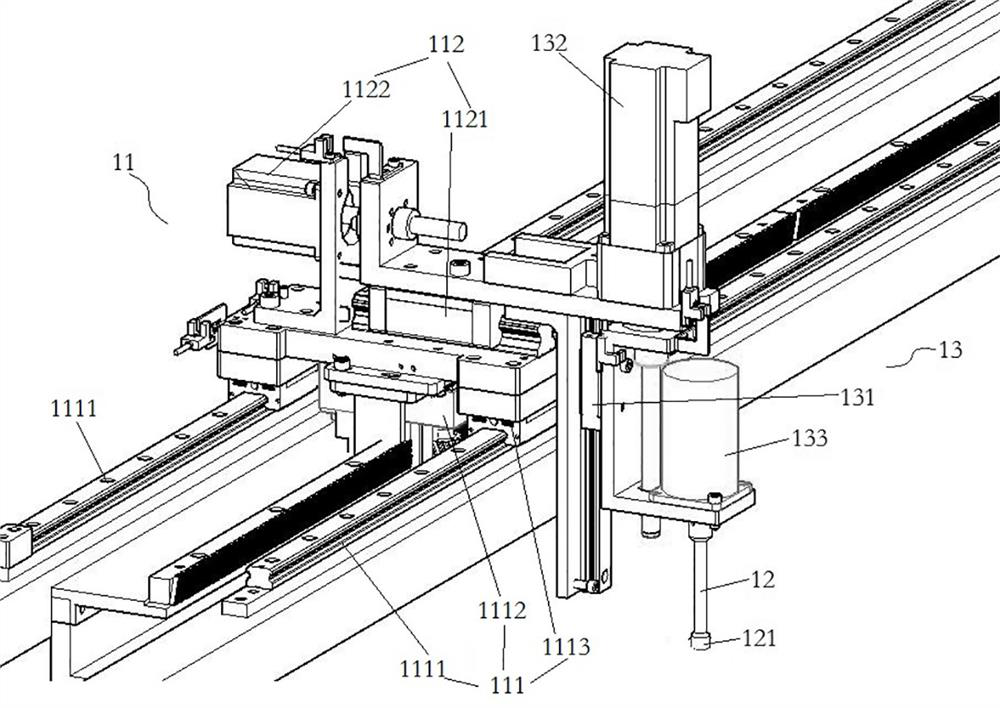

Laser processing platform for circular cylinder punching

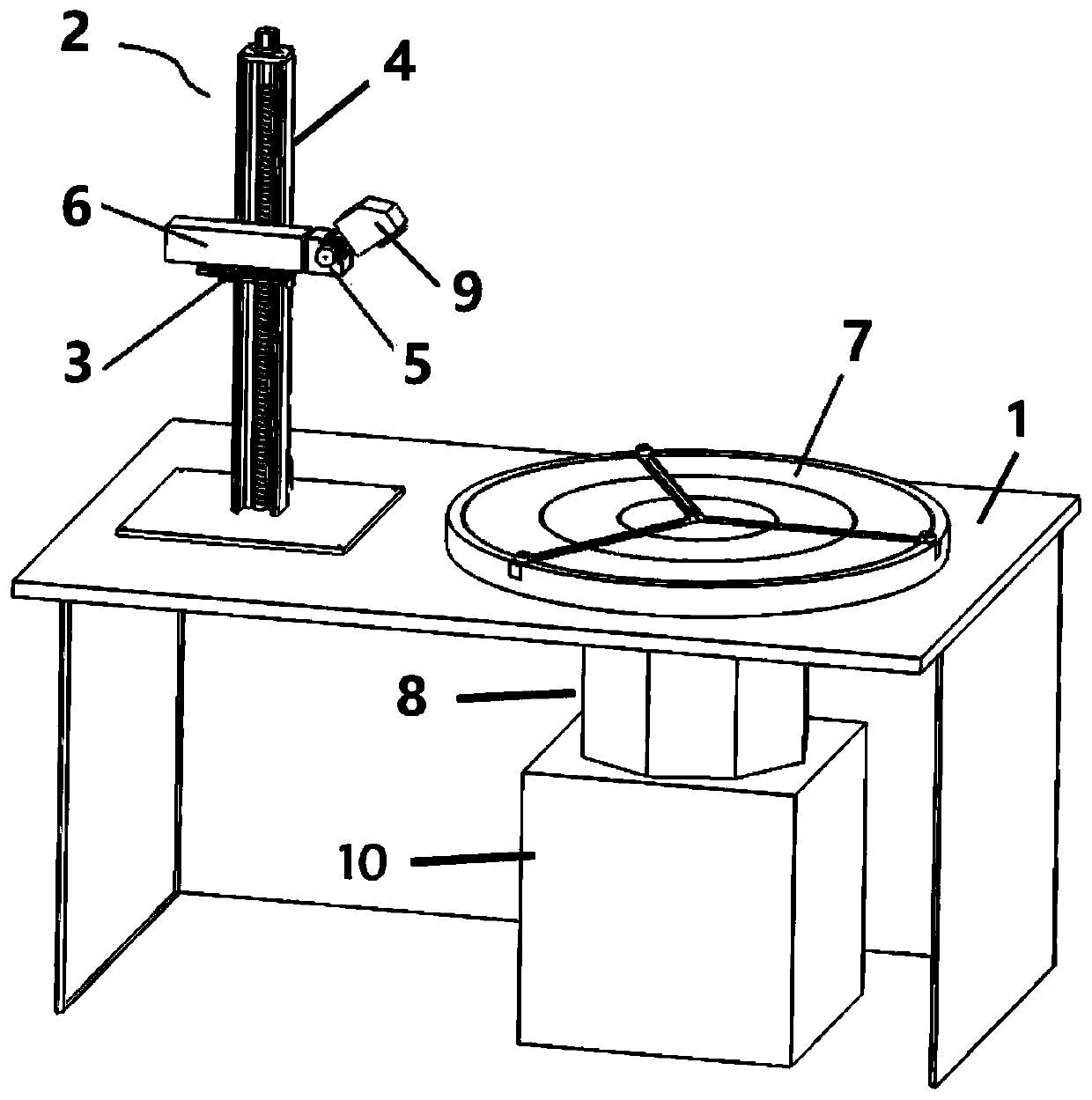

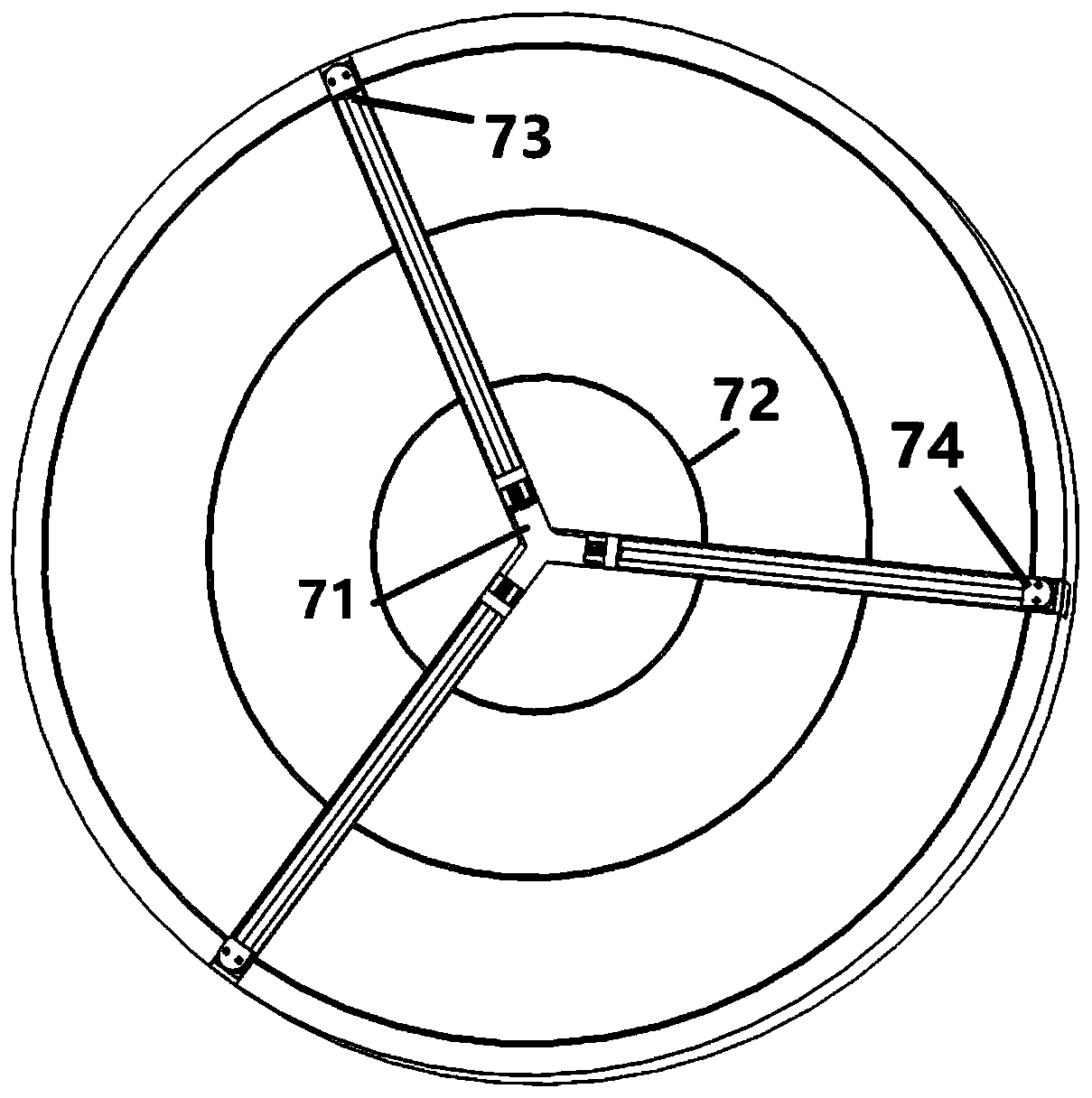

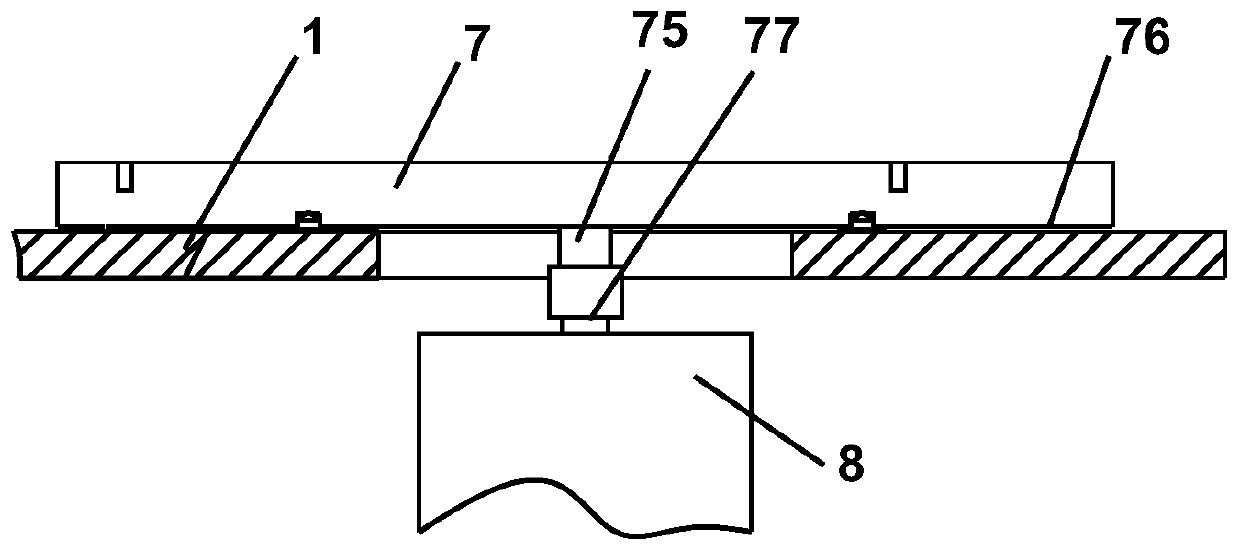

PendingCN109877471AMeet the punching needsSmall light spotLaser beam welding apparatusCircular discPunching

The invention relates to a laser processing platform for circular cylinder punching. The laser processing platform comprises a working table. The working table is provided with a rotating platform anda laser bracket. The laser bracket comprises a lifting sliding table, a translation sliding table and a laser generator, the lifting sliding table is provided with the translation sliding table, andthe laser generator is disposed on the translation sliding table. The front end of the laser generator is fixedly connected with an angle adjustment joint, and a laser head is connected with the lasergenerator through the angle adjustment joint. The rotating platform is driven by the rotating platform motor on the lower part of the working table, and the rotating platform is a disc table. Three radial grooves and a plurality of annular grooves with the center of the disc as the center of the circle are uniformly distributed on the rotating platform. The three radial grooves are internally provided with rodless cylinders, and rubber blocks are disposed on sliding blocks of the rodless cylinders. The laser processing platform meets the punching requirements of large-sized cylindrical workpieces, the translation sliding table is arranged to realize the laser rapid focusing adjustment, the laser head for angle adjustment realizes processing of a vertical cylinder, a cone cylinder and a cylinder plane, and the rotating platform is arranged to realize rotary curved surface processing.

Owner:UNIV OF SCI & TECH LIAONING

Automatic feed punching machine

InactiveCN107262620AMeet punching needsThe feeding effect is stable and continuousMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses an automatic feed punching machine which comprises a rack, sliding rails, a limiting rod, auxiliary conveying rollers, a stroke screw, an arrangement chain, a chain groove, a claw machine, a servo motor, a rotary screw sleeve, a vertical stamping die set, a horizontal stamping die set, auxiliary clamping devices and a control center. According to the automatic feed punching machine, the punching machine can automatically push pipes needing to be machined; the feed effect is stable and continuous; meanwhile, multi-face synchronous punching can be carried out on the pipes; the punching requirements of the pipes can be fully met; the punching quality and punching efficiency can be improved; and application and popularization are facilitated.

Owner:海盐三鑫机械有限公司

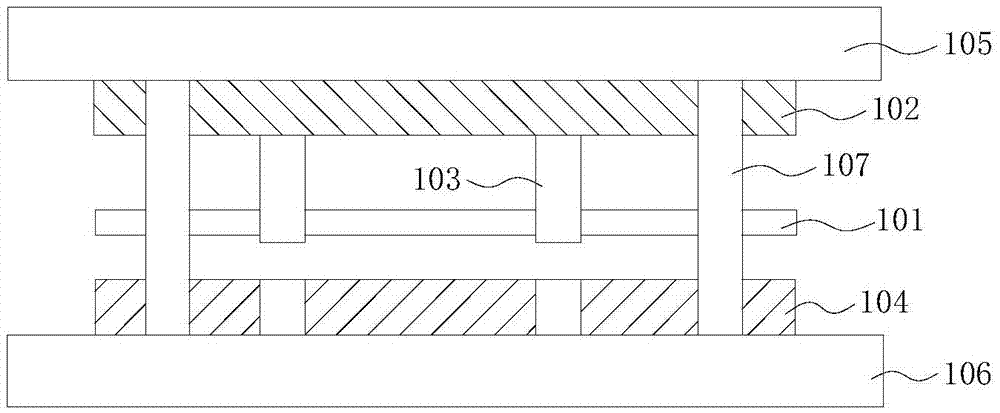

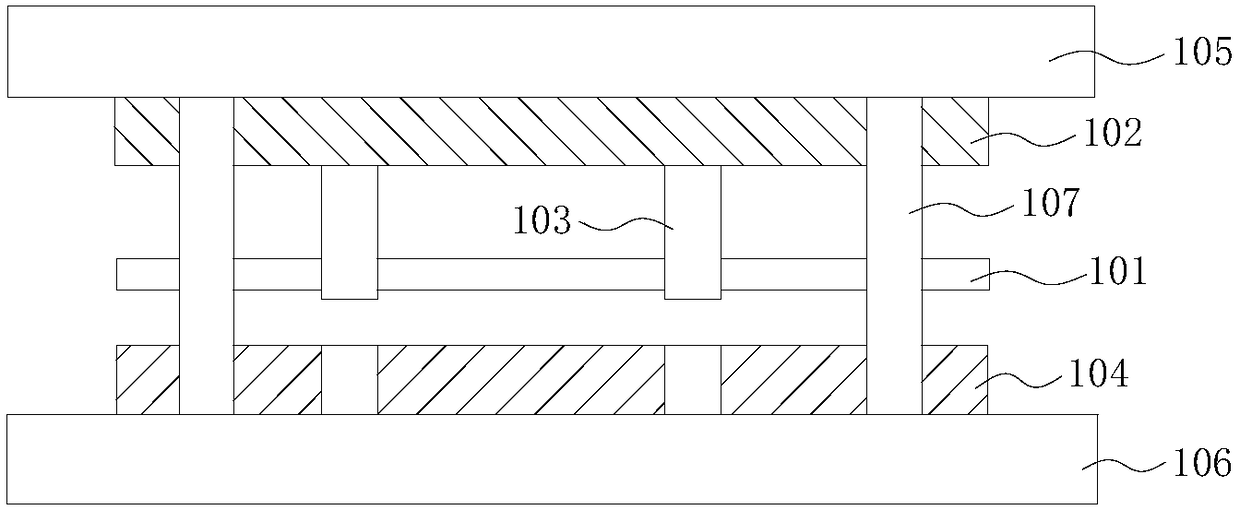

High-precision stamping die convenient to replace

InactiveCN109092960AEasy to replaceHigh precisionShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention relates to the field of dies, in particular to a high-precision stamping die convenient to replace. The high-precision stamping die comprises a horizontally-arranged base plate. An upperdie plate and a lower die plate which are parallel to the base plate are arranged over the base plate and fixedly connected through bolts. Four guiding columns which are vertically arranged and rectangularly distributed are arranged at the top of the base plate, and the upper die plate and the lower die plate are slidably mounted on the four guiding columns in a sleeving mode. Four guiding sleeves which are in sliding fit with the four guiding columns are arranged at the top of the upper die plate. A bearing plate parallel to the upper die plate is arranged over the upper die plate, and the two ends of the four guiding columns are fixedly connected with the base plate and the bearing plate correspondingly. A pressure machine is arranged at the top of the bearing plate, and the top of thebase plate is provided with an adjusting limiting device used for bearing to-be-stamped pieces, and a positioning device used for positioning the to-be-stamped pieces. A stamping device is arranged atthe bottom of the lower die plate. The high-precision stamping die is simple in structure and high in stamping precision, punching demands of the different stamped pieces can be met, the working efficiency is improved, and practicability is high.

Owner:长春华舜汽车部件有限公司

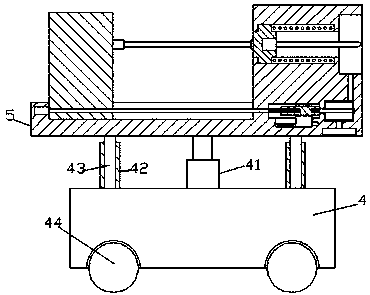

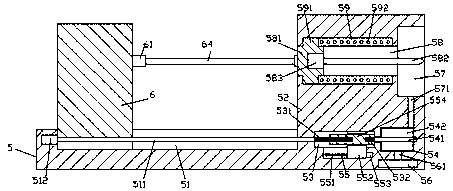

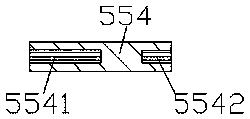

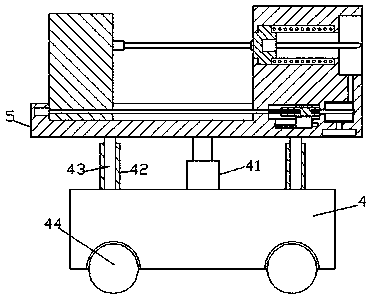

Machining production device for medical treatment facilities

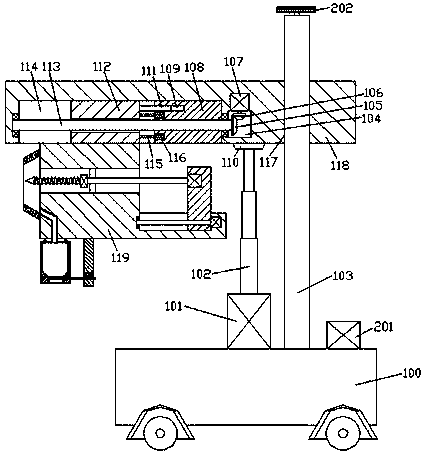

InactiveCN109047819AReduce the cushioning forceImprove work efficiencyBoring/drilling componentsMaintainance and safety accessoriesVehicle frameRight-Sided

The invention discloses a machining production device for medical treatment facilities. The machining production device comprises a traveling vehicle frame, wherein the top end of the traveling vehicle frame is fixedly provided with a vertical arm; a first sliding cavity is formed in the vertical arm in an up-down penetrating manner; a rising and falling rack is mounted in the first sliding cavityin a sliding fit manner; a second sliding cavity is formed in the bottom end surface of the rising and falling rack; a first dovetail block and a second dovetail block are respectively mounted in thesecond sliding cavity in a sliding fit manner; a first spiral rod is mounted in the second dovetail block in a threaded fit manner and is in clearance fit with the first dovetail block; the extensiontail end of the left side of the first spiral rod is connected with the inner wall of the left side of the second sliding cavity in a rotating fit manner; depressed cavities are symmetrically formedin the left-sided end surface of the second dovetail block upwards and downwards; buffer elastic plates are fixedly mounted between the inner side walls of the depressed cavities and the right-sided end surface of the first dovetail block; a third sliding cavity is formed in the left-sided end surface of the second dovetail block and positioned on the upper sides of the depressed cavities; and a guiding block is mounted in the third sliding cavity in a sliding fit manner.

Owner:广州爵诺医疗器械有限公司

Positioning punching die

ActiveCN106984692AQuality assuranceImprove punching efficiencyStripping-off devicesPunchingEngineering

The invention discloses a positioning punching die. The positioning punching die comprises a male die and a female die. The female die is provided with a punching opening and a feeding opening perpendicular to the punching opening in a cut-through manner. One end of the male die is located above the punching opening and can move into the punching opening, the other end of the male die is connected with a fixing plate, and the fixing plate is fixedly connected with a plurality of sets of positioning assemblies fixing materials to be punched. The male die is internally provided with a plurality of gas channels in a cut-through manner, the gas channels communicate with a gas pipe connector on the fixing plate, and the gas pipe connector is connected with a gas sucking device. According to the positioning punching die, the male die is provided with the gas channels, when punching is carried out, the gas sucking device adsorbs the materials to be punched through the gas channels, then, the male die and the female die are matched to complete punching, after punching is completed, the male die continues to press to send a finished product to an appointed position, an adsorbing device is stopped to put the finished product down, the punching efficiency of the die can be improved, the quality of the finished product obtained after punching is guaranteed, the punching cost is reduced, and the punching requirements of small products are met.

Owner:达翔技术(恩施)有限公司

Metal pipe stamping device

The invention relates to the field of metal pipe processing, in particular to a metal pipe stamping device. A metal pipe positioning mechanism is arranged on the frame. The metal pipe positioning mechanism includes a threaded adjustment rod and a plurality of metal pipe support sleeves. There is a guide sliding sleeve, which is slidingly connected with the threaded adjustment rod, and the guide sleeve is rotatably connected with a threaded adjustment sleeve through a rotating connector, and the threaded adjustment sleeve is threadedly connected with the threaded adjustment rod. The structure of the device needs to be adjusted. When the position and the punching distance are adjusted, the threaded adjusting sleeve is driven to rotate, so that the threaded adjusting sleeve drives the metal pipe support sleeve to move on the threaded adjusting rod through the guide sliding sleeve, so as to realize the adjustment of the position of the metal pipe. The position and spacing can also increase or decrease the number of metal tube support sleeves according to needs, to meet the needs of different numbers of punching holes, and have a wide range of applications.

Owner:潍坊市工程技师学院

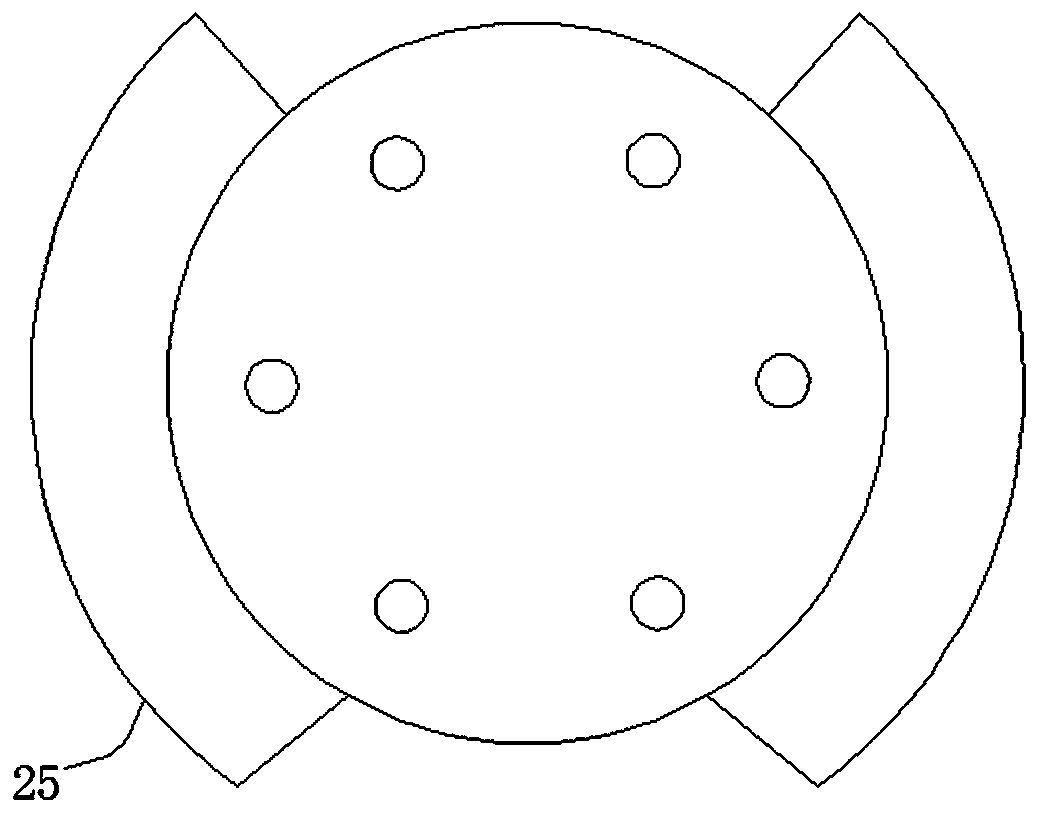

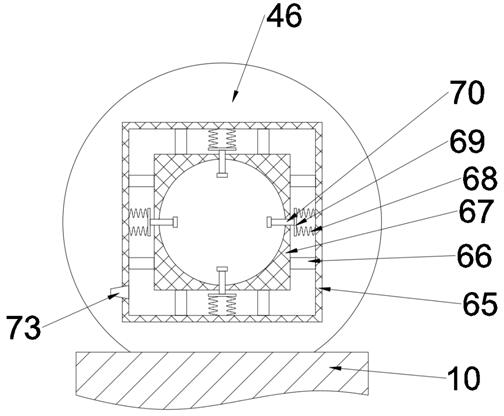

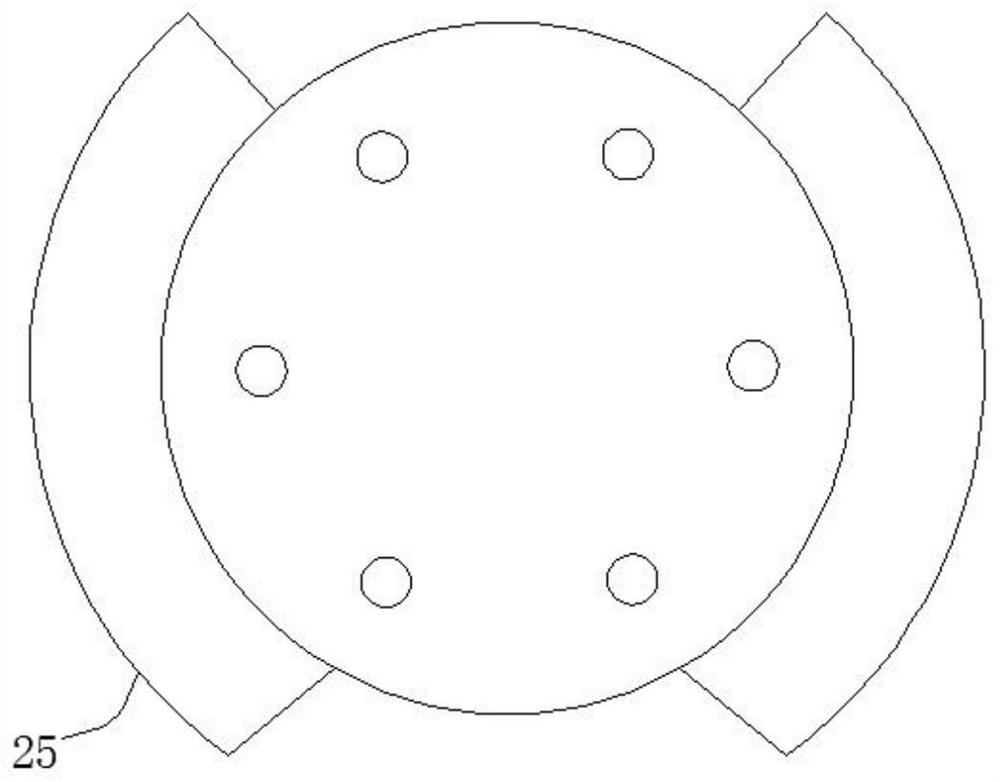

Three-jaw chuck clamp for synchronous belt wheel machining

InactiveCN112108938AMeet the punching needsNovel structurePrecision positioning equipmentChucksControl theoryMechanical engineering

The invention discloses a three-jaw chuck clamp for synchronous belt wheel machining. A three-jaw chuck and three clamping jaws arranged on the three-jaw chuck are included, the three-jaw chuck is rotationally arranged in a base through a bearing pedestal, a plurality of positioning holes are evenly formed in the edge of the lower end of the three-jaw chuck, and a vertical sliding hole is formed in one end of the base. A transverse sliding hole communicating with the vertical sliding hole is formed in the position, at the lower end of the vertical sliding hole, in the base, a vertical ejectorrod matched with the vertical sliding hole is arranged in the vertical sliding hole in a sliding mode, and a positioning column head matched with a positioning hole is arranged at the upper end of thevertical ejector rod. A first inclined wedge is arranged at the lower end, stretching into the transverse sliding hole, of the vertical ejector rod, and a vertical limiting hole communicating with the vertical sliding hole is formed in the portion, in the middle of the vertical sliding hole, of the base.

Owner:盐城市同达机械科技有限公司

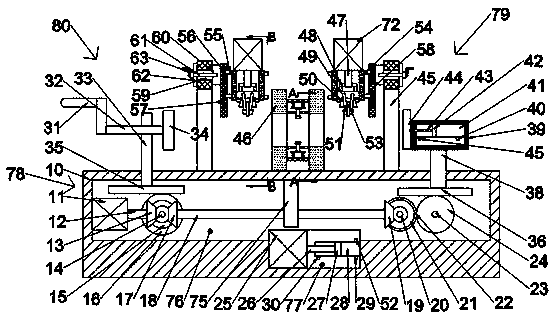

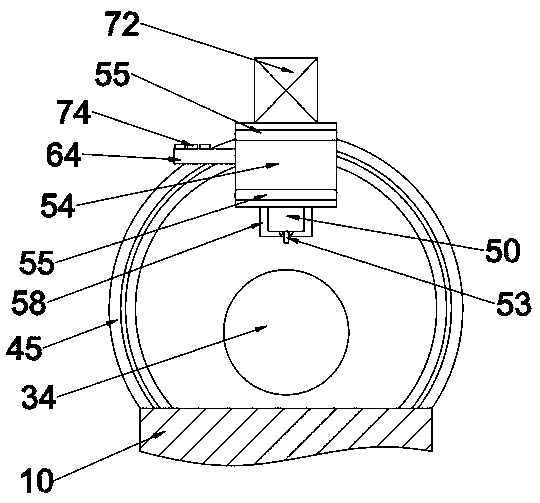

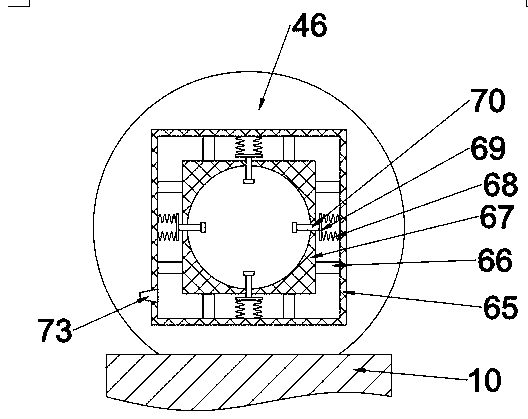

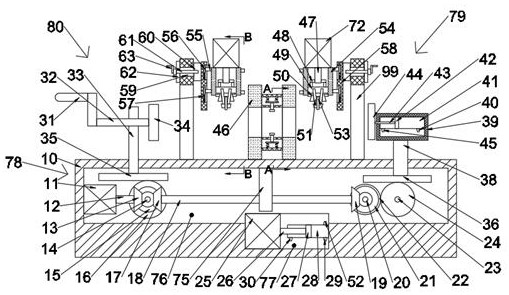

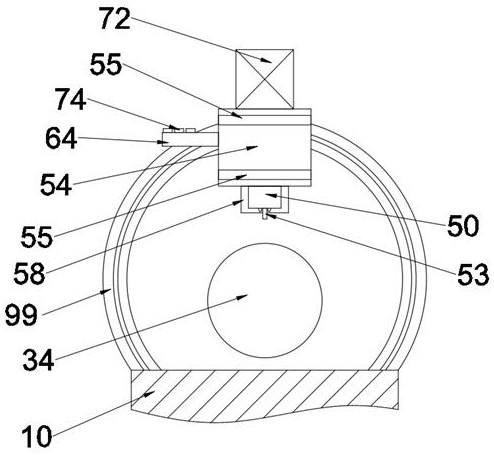

Special machine tool for radial drilling of shaft

ActiveCN110883359AChange torqueAdjust the rotation speedLarge fixed membersDriving apparatusThermodynamicsMachine

The invention discloses a special machine tool for radial drilling of a shaft. The special machine tool comprises a machine body; a power cavity 76 is formed in the machine body 10; a communicated hydraulic cavity 77 is formed in the lower side of the power cavity 76; two left hydraulic interfaces 45 are fixedly arranged on the upper side surface of the machine body 10; a driving device 78 for providing power is arranged in the power cavity 76; a drilling device can be used for drilling a shaft, can be used for directly drilling at different angles of the shaft, can also be used for adjustingthe rotating speed of a drill bit and changing the drilling torque during drilling at the same time, can be used for drilling shafts made of different materials, and can meet the radial drilling requirements of different positions of most shafts.

Owner:宁波精鑫机床有限公司

Manufacturing method for printed circuit board for portable card type equipment

InactiveCN110868804AIncrease the maximum thicknessMeet the punching needsPrinted circuit manufactureSurface oxidationPrinted circuit board

The invention provides a manufacturing method for a printed circuit board for portable card type equipment. The manufacturing method comprises the following steps of S1, mechanically drilling a positioning hole in a TF board substrate, S2, thinning copper on the surface of the TF board substrate, S3, carrying out oxidation treatment on the thinned copper surface so that the copper surface is in adark rough state, and S4, positioning the TF board substrate on a laser tabletop according to positioning holes, and performing laser drilling to obtain required via holes. A laser drilling mode is used for replacing a mechanical drilling mode, a drill point is not needed, and the problems that the drill point is difficult to manufacture due to the fact that the hole diameter of a hole to be drilled is reduced, and meanwhile the drilling effect is greatly reduced due to change of the drill point are solved; copper reduction treatment and copper surface oxidation treatment are carried out on the TF board substrate, and the laser drilling effect is guaranteed.

Owner:QUZHOU SUNLORD CIRCUIT BOARD CO LTD

Multifunctional puncher

PendingCN109968461AEasy to useMeet the punching needsOperator-supported drilling machinesPunchingRotating disc

The invention discloses a multifunctional puncher, which comprises a base. The base is provided with a base hole and a rotating disc, wherein the rotating disc is provided with through holes with different opening diameters; the rotating disc is rotatably arranged above the base hole and can adjust the through holes to be coaxial with the base bole; a limiting block with a convex pin is movably mounted on the front end face of the base, and oblique holes penetrating through the bottom face are obliquely formed in the rear end face of the base; and a handle is detachably mounted in the obliqueholes. The hole diameter of punching can be adjusted, positioning punching is conducted on spliced boards, and the oblique holes are punched in the boards of different thicknesses.

Owner:NINGBO WENKAI ABRASIVE TOOLS

Punching device for machining

InactiveCN113458460AReduce usageEasy to adjustMeasurement/indication equipmentsLarge fixed membersPunchingElectric machinery

The invention discloses a punching device for machining. The punching device comprises a main body, dovetail grooves, a transmission screw rod, a transmission disc, a handle, a lower wedge-shaped block, a T-shaped groove, a supporting frame, first polish rods, mounting bases, balls, a right speed adjusting motor and an adjusting part; and the front end and the rear end of the inner wall of the main body are each provided with one vertical dovetail groove, and the bottom of the main body is rotationally connected with the horizontal transmission screw rod. By controlling rotation of the right speed adjusting motor and a left speed adjusting double-shaft motor, three punching modes of drilling, cutting and milling can be considered at the same time, the use number of needed punching equipment is reduced, and meanwhile, the punching efficiency is indirectly improved; and the punching angle can be adjusted by adjusting the position of a rotating frame on an index plate, the hole diameter of milled holes and cut holes can be adjusted by adjusting the position of a sliding block, so that various punching requirements can be better met, and the punching angle and the punching diameter can be adjusted more conveniently due to the arrangement of length scales and angle scales.

Owner:西安精诚企服信息科技有限公司

Perforating device for capacitor film machining

InactiveCN113334489AConvenient location changeStable drillingMetal working apparatusEngineeringWaste material

The invention discloses a perforating device for capacitor film machining. The perforating device comprises a bottom plate, two rotating cylinder mounting rings are arranged on the vertical upper side of the bottom plate, a middle shaft cylinder is rotationally erected between the two rotating cylinder mounting rings, a plurality of mounting mechanisms are arranged on the outer side of the middle shaft cylinder in a divergent mode, a cutting assembly is detachably mounted at the end of each mounting mechanism, a downward-pressing assembly is arranged at the top of the middle shaft cylinder, a suction cavity is formed in one end of the middle shaft cylinder, a dust collector is further mounted on the top side of the bottom plate, a communicating pipe is mounted on the dust collector, one end of the communicating pipe communicates with the suction cavity, a fixing mechanism is arranged between the middle shaft cylinder and each rotating cylinder mounting ring, and each mounting mechanism comprises a side pipe fixedly connected with the middle shaft cylinder. The perforating device is high in applicability, can meet the perforating requirements of different capacitor films, can collect waste materials in time, is convenient to use, is ingenious and stable in structure, reduces the production cost, and meets the use requirements of people in production and life.

Owner:东莞市普隆电子有限公司

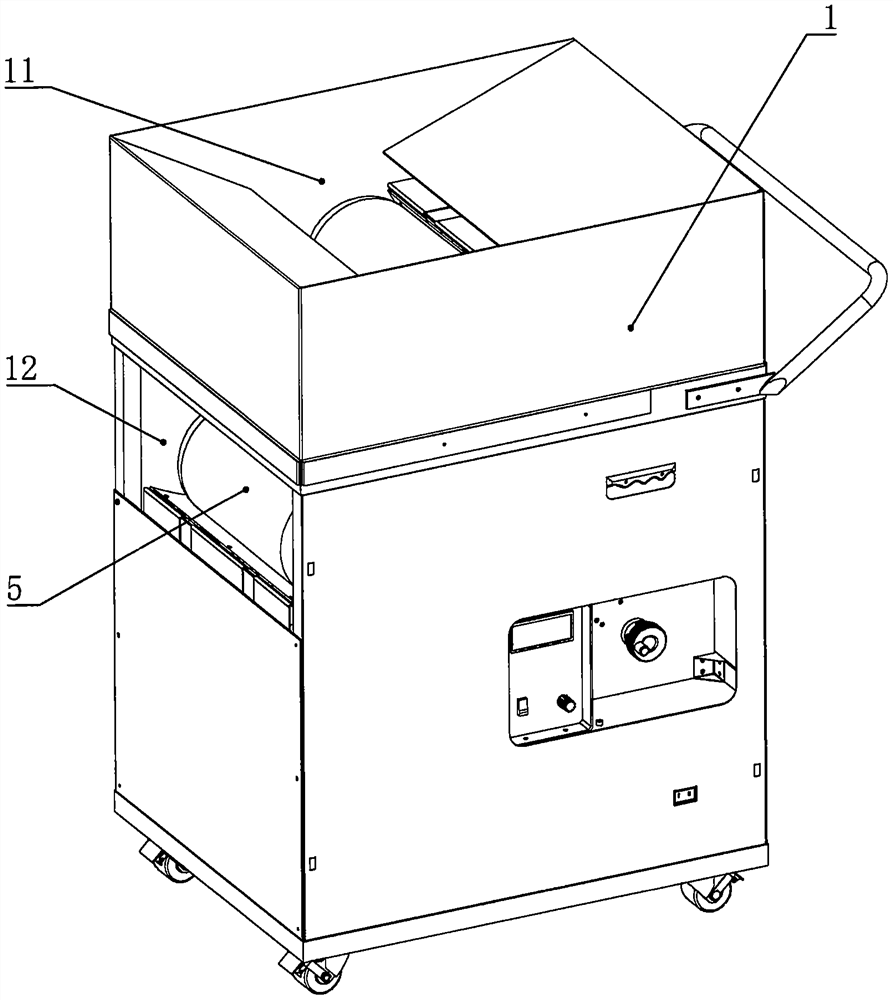

Punching device for automobile lateral trimming side maintenance

InactiveCN112474998AIngenious structureGuaranteed punching qualityVehicle componentsHydraulic cylinderPunching

The invention provides a punching device for automobile lateral trimming side maintenance, and relates to the technical field of punching dies. The punching device for automobile lateral trimming sidemaintenance comprises a machining table and a rack mounted on the machining table; a vertical plate is mounted on the rack; a rotating wheel is rotatably mounted on the vertical plate; the rotating wheel can be driven by a first driving mechanism installed on the vertical plate to rotate; protruding blocks are formed on the circumferential end face of the rotating wheel; and a rotating disc is arranged between the rotating wheel and the vertical plate. The punching device is ingenious in structure; punching operation of automobile lateral trimming sides made of hard materials can be achievedthrough a simple structure; the punching quality can be guaranteed; compared with punching operation completed through a large hydraulic cylinder assembly in the prior art, the use cost and the manufacturing cost can be reduced to a large extent; the punching device is especially suitable for purchasing and using of a small automobile maintenance center and the like; and the automobile maintenancecost of the small automobile maintenance center and the like is effectively reduced.

Owner:ZHENGZHOU YUNQI IND EQUIP TECH CO LTD

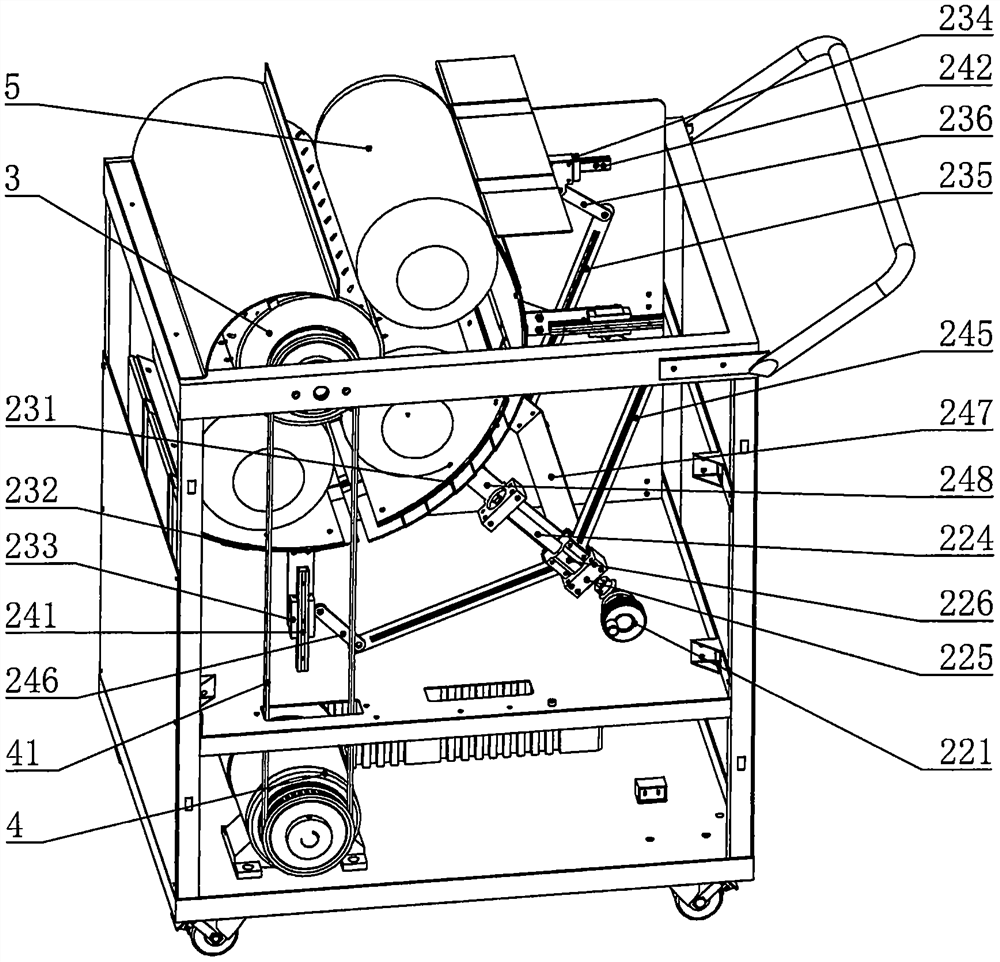

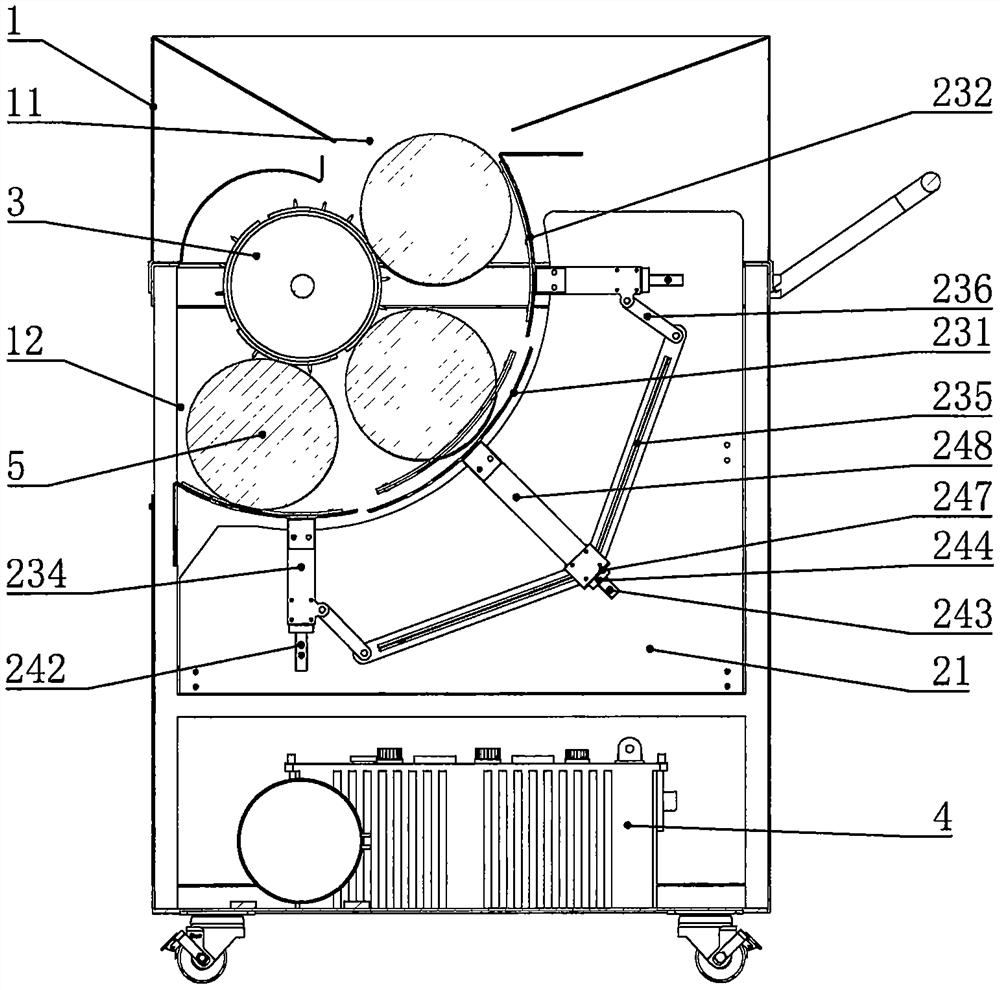

Adjustable mushroom stick punching equipment

ActiveCN113966696AMeet the punching needsImprove work efficiencyCultivating equipmentsMushroom cultivationPunchingChanging equipment

The invention discloses adjustable mushroom stick punching equipment which comprises a shell and a power mechanism, wherein a punching mechanism and a mushroom stick supporting mechanism are arranged in the shell, the mushroom stick supporting mechanism comprises a rolling plate and a supporting frame fixed to the inner wall of the shell, the supporting frame is provided with a driving adjusting mechanism, a mushroom stick rolling channel is formed between the rolling plate and the punching mechanism, when the driving adjusting mechanism pushes the rolling plate to be close to the punching mechanism, the mushroom stick rolling channel is gradually shrunk, and when the driving adjusting mechanism pulls the rolling plate to be away from the punching mechanism, the mushroom stick rolling channel is gradually enlarged. The mushroom stick rolling channel is adjusted to the corresponding width according to mushroom sticks with different diameters, so that the punching requirements of the mushroom sticks with different diameters are met, the time and cost for replacing equipment are saved, the working efficiency of mushroom stick punching is improved, and the workload of personnel is reduced.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Improved anti-theft packaging box equipment

InactiveCN109262732AReduce the cushioning forceImprove work efficiencyMetal working apparatusVehicle frameEngineering

The invention discloses improved anti-theft packaging box equipment. The equipment includes a vehicle frame body, the top of the vehicle frame body is fixedly provided with a vertical rod, a first sliding cavity runs through vertical rod and is internally, slidably and cooperatively provided with a lifting base, the end face of the bottom of the lifting base is internally provided with a second sliding cavity, the second sliding cavity is internally, slidably and cooperatively provided with a first dovetail block and a second dovetail, the second dovetail is internally and cooperatively provided with a first spiral rod through a thread, the first spiral rod is in clearance fit with the first dovetail block, the extending tail end of the left side of the first spiral rod is rotatably and cooperatively connected with the inner wall of the left side of the second sliding cavity, the end face of the left side of the second dovetail block is provided with a sunk cavity which is longitudinally symmetrical, a buffer spring clip is fixedly installed between the inner side wall of the sunk cavity and the right side end face of the first dovetail block, the left side end face of the portion,on the upper side of the sunk cavity, of the second dovetail block is internally provided with a third sliding cavity, and the third sliding cavity is internally, slidably and cooperatively providedwith a movement guiding block.

Owner:广州军鸿科技有限公司

Automatic identification sponge drilling machine

The invention relates to the technical field of sponge processing equipment, in particular to an automatic identification sponge drilling machine. The automatic identification sponge drilling machine comprises a cutter assembly, a detection device, a conveying track and a control device; the conveying track is used for conveying the sponge into a working area of the cutter assembly and the detection device; the cutter assembly can move in the direction close to the conveying track so as to punch holes in the sponge; the detection device is used for detecting the punching position on the sponge to obtain punching position information; and the control device is used for controlling the cutter assembly to act according to the punching position information. In the prior art, a mold is used for punching a sponge, but the mold is mostly placed manually, so that placement errors are easy to generate, and punching deviation is caused; along with the increase of the service time, the mold also needs to be replaced in time; and compared with the prior art, the punching position is obtained in a detection mode, then punching is conducted, no mold is needed in the whole process, and therefore the problems that due to the mold, the punching position deviates, and the mold needs to be replaced are effectively avoided.

Owner:ANJI BATA ROBOT CO LTD

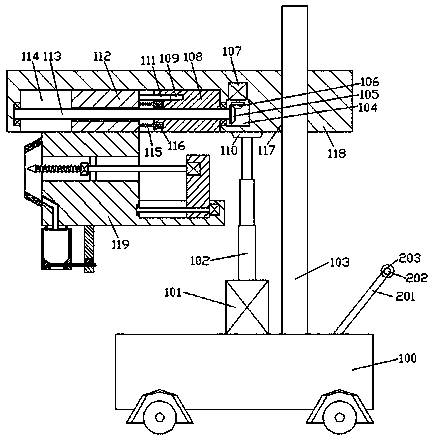

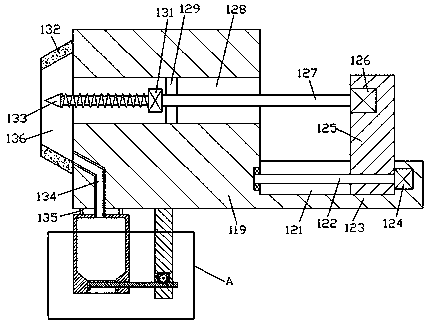

A device for punching holes in a building wall

InactiveCN107100542BImprove work efficiencyImprove working environmentDrilling rodsConstructionsPunchingThreaded rod

The invention discloses building-wall-surface drilling equipment. The building-wall-surface drilling equipment comprises a walking structure and a drilling driving structure, wherein the drilling driving structure is installed above the walking structure. A first sliding chute is formed in the end surface of the top of the left side of the drilling driving structure, a drilling supporting element is fixedly arranged on the end surface of the top of the right side of the drilling driving structure, and a first threaded rod is arranged in the first sliding chute in a left-right extending mode; a sliding block is connected on the first threaded rod in a thread fit mode, wherein the top of the sliding block extends out of the outer portion of the end surface of the top of the first sliding chute, a first cavity body is formed in the drilling driving structure of the right side of the first sliding chute, and a second cavity body is formed in the drilling driving structure of the right side of the first cavity body; and a second sliding chute is formed in the bottom of the first cavity body, a second threaded rod is arranged in the second sliding chute in a left-right extending mode, and a guide sliding block is connected on the second threaded rod in a thread fit mode, wherein the top of the guide sliding block extends into the first cavity body. According to the building-wall-surface drilling equipment, the structure is simple, the operation is convenient, automatic in-depth drilling and dust-absorbing and dust-collecting operation can be achieved, the working efficiency is improved, and the environmental pollution caused by dust-flying is prevented.

Owner:YIWU FENGQING TECH CO LTD

Efficient building wall surface punching equipment

InactiveCN107842309AImprove work efficiencyImprove working environmentDrilling rodsConstructionsTop drivePunching

The invention discloses a high-efficiency punching device for building walls, which includes a walking structure and a punching driving structure installed above the walking structure. The top end surface on the right side is fixed with a perforated support member, and the first threaded rod is extended left and right in the first sliding groove. A first cavity is provided in the punching drive structure on the right side of the first cavity, a second cavity is provided in the punching drive structure on the right side of the first cavity, and a second slide slot is provided at the bottom of the first cavity. The second threaded rod extending from the left and right of the second sliding groove is threaded and connected with a guide sliding block whose top extends into the first cavity; the invention has simple structure, convenient operation, and can realize automatic deep drilling and suction Dust collection work, improve work efficiency and prevent environmental pollution caused by dust.

Owner:广州猎狗信息咨询有限公司

A special machine tool for axial radial drilling

ActiveCN110883359BChange torqueAdjust the rotation speedLarge fixed membersDriving apparatusThermodynamicsMachine

Owner:宁波精鑫机床有限公司

An automatic feeding punching machine

InactiveCN107262620BMeet the punching needsThe feeding effect is stable and continuousMetal-working feeding devicesPositioning devicesPunchingMachine

The invention discloses an automatic feed punching machine which comprises a rack, sliding rails, a limiting rod, auxiliary conveying rollers, a stroke screw, an arrangement chain, a chain groove, a claw machine, a servo motor, a rotary screw sleeve, a vertical stamping die set, a horizontal stamping die set, auxiliary clamping devices and a control center. According to the automatic feed punching machine, the punching machine can automatically push pipes needing to be machined; the feed effect is stable and continuous; meanwhile, multi-face synchronous punching can be carried out on the pipes; the punching requirements of the pipes can be fully met; the punching quality and punching efficiency can be improved; and application and popularization are facilitated.

Owner:海盐三鑫机械有限公司

A clamping mechanism for drilling a circular seat plate of a circular seat

ActiveCN110640182BEasy to drillImprove efficiencyPositioning apparatusMetal-working holdersClassical mechanicsStructural engineering

The invention discloses a clamping mechanism for drilling a circular sitting plate of a circular seat, and relates to the field of plate processing. Aiming at the problems of long drilling time and low efficiency of the existing plate processing device, the following scheme is proposed , which is fixed on the workbench on the base, with vertical rectangular support rods arranged on the left and right on the workbench, the upper end of the rectangular support rod on the right runs through the workbench and extends to the top of the workbench, the workbench A clamping assembly, a drilling assembly and an adjusting assembly are installed on the platform, the drilling assembly is installed on the adjusting assembly, and the adjusting assembly is in transmission connection with the clamping assembly. The present invention links the clamping and fixing of the circular plate with the lifting and lowering of the drilling, so that the circular plate can be automatically clamped during the downward movement of the drilling, and the circular plate can be automatically clamped during the downward movement after clamping. The shaped plate is firmly clamped and not loose, which is convenient for drilling.

Owner:HUZHOU TEACHERS COLLEGE

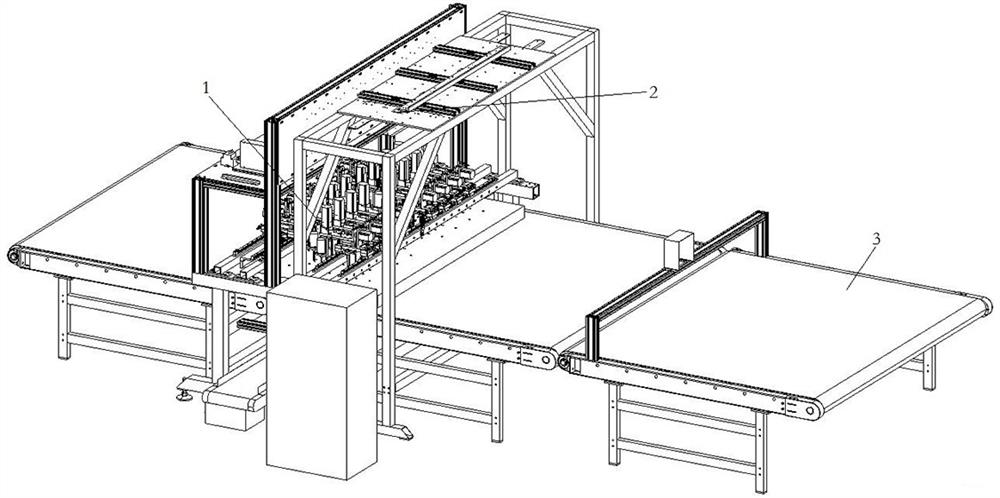

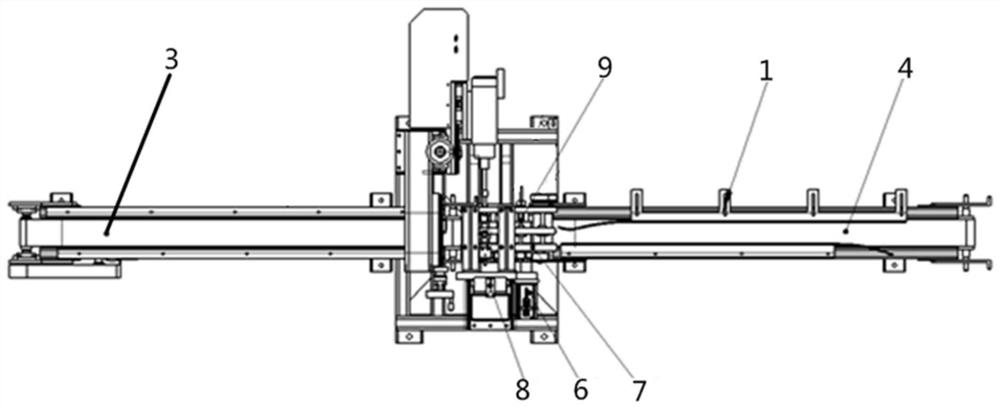

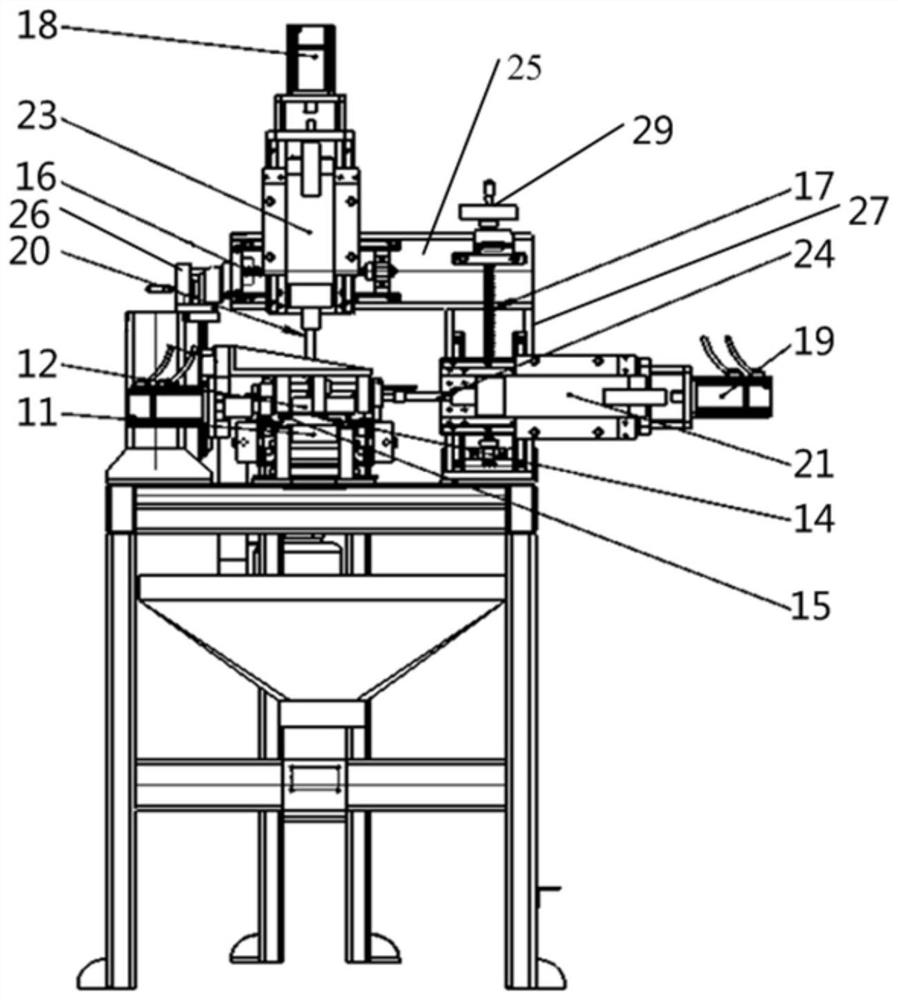

Pass-type two-side punching system

ActiveCN113021529AMeet the punching needsImprove drilling efficiencyStationary drilling machinesGauging meansPunchingButt joint

The invention provides a pass-type two-side punching system. The pass-type two-side punching system comprises a punching mechanism and a punching control device. An operation platform is provided with a punching area, a batten conveying belt and a batten output belt. A material clamping conveying device, a top punching assembly and a side punching assembly are connected with the punching control device. The material clamping conveying device is in butt joint with the batten conveying belt and the batten output belt in a matched mode. The material clamping conveying device receives a control instruction of the punching control device, clamps a to-be-machined batten and conveys the to-be-machined batten to a punching position. The top punching assembly and the side punching assembly receive control instructions of the punching control device correspondingly, and punching is conducted on the side and the top of the to-be-machined batten. The system achieves punching on the upper face or the side face or the two faces of the batten through material clamping transmission. The system can set the punching position and size information according to the punching process requirements, rapid and automatic punching is achieved, and the punching efficiency is improved. And the punching position can be automatically calculated, automatic single-face or double-face punching is achieved, and the multi-angle punching requirement is met.

Owner:济南快克广宣数控机械有限公司

A set of punching dies

ActiveCN106984692BQuality assuranceImprove punching efficiencyStripping-off devicesPunchingEngineering

The invention discloses a positioning punching die. The positioning punching die comprises a male die and a female die. The female die is provided with a punching opening and a feeding opening perpendicular to the punching opening in a cut-through manner. One end of the male die is located above the punching opening and can move into the punching opening, the other end of the male die is connected with a fixing plate, and the fixing plate is fixedly connected with a plurality of sets of positioning assemblies fixing materials to be punched. The male die is internally provided with a plurality of gas channels in a cut-through manner, the gas channels communicate with a gas pipe connector on the fixing plate, and the gas pipe connector is connected with a gas sucking device. According to the positioning punching die, the male die is provided with the gas channels, when punching is carried out, the gas sucking device adsorbs the materials to be punched through the gas channels, then, the male die and the female die are matched to complete punching, after punching is completed, the male die continues to press to send a finished product to an appointed position, an adsorbing device is stopped to put the finished product down, the punching efficiency of the die can be improved, the quality of the finished product obtained after punching is guaranteed, the punching cost is reduced, and the punching requirements of small products are met.

Owner:达翔技术(恩施)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com