A device for punching holes in a building wall

A technology for drilling equipment and construction, applied in drilling equipment and methods, construction, drilling equipment, etc., can solve the problems of drilling crooked, environmental pollution, increasing labor and economic costs, etc., to facilitate sliding and handling, and prevent environmental pollution Pollution, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

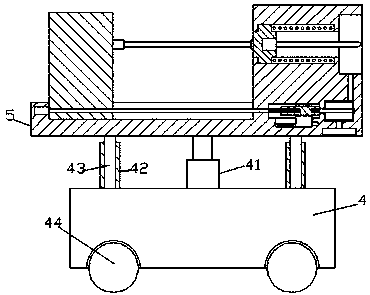

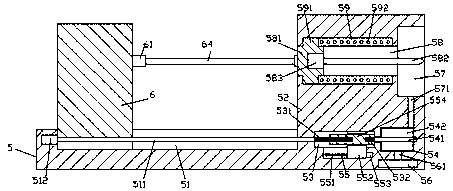

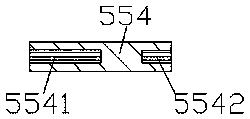

[0021] like Figure 1-Figure 5 As shown, a kind of construction wall punching equipment of the present invention includes a walking structure 4 and a punching driving structure 5 installed above the walking structure 4, and a first A sliding groove 51, the top end surface of the right side of the punching drive structure 5 is fixed with a punching support 52, and the left and right extensions in the first sliding groove 51 are provided with a first threaded rod 511, and the first threaded rod 511 The upper thread is mated with a sliding block 6 whose top protrudes from the top end surface of the first sliding groove 51, and the perforating drive structure 5 on the right side of the first sliding groove 51 is provided with a first cavity 53. The punching drive structure 5 on the right side of the first cavity 53 is provided with a second cavity 54, the bottom of the first cavity 53 is provided with a second sliding groove 55, and the left and right sides of the second sliding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com