Positioning punching die

A punching die and nesting technology, used in manufacturing tools, metal processing equipment, stripping devices, etc., can solve the problem that the metal punching die cannot be punched at one time, cannot meet the requirements of product miniaturization, and the finished products are disorderly distributed, etc. problems, to achieve the effect of reducing punching costs, reducing mold costs and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

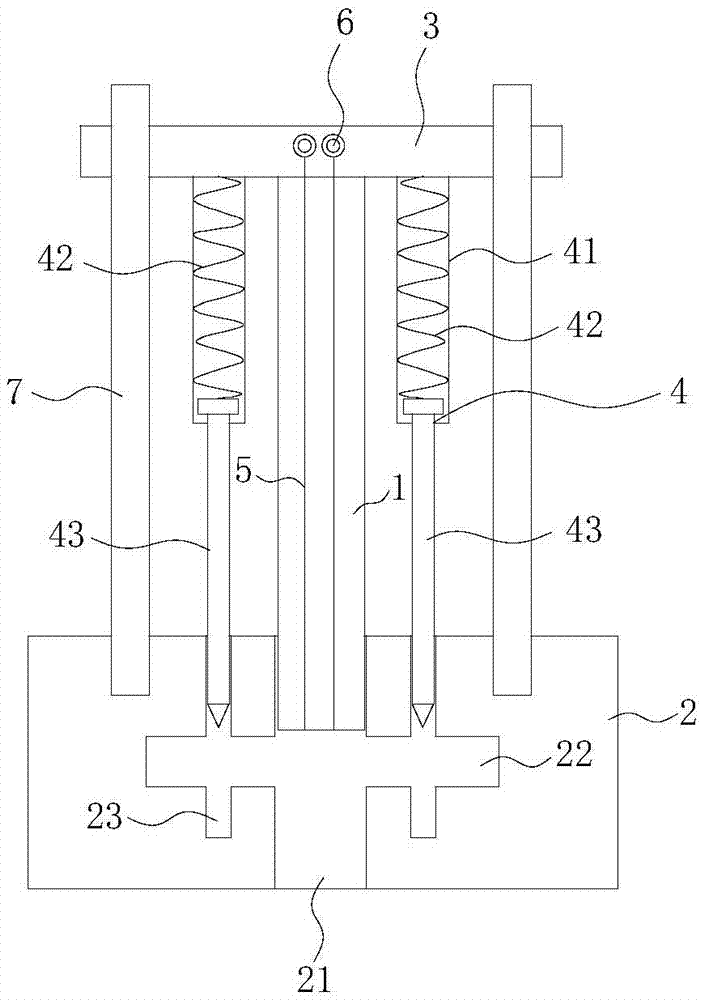

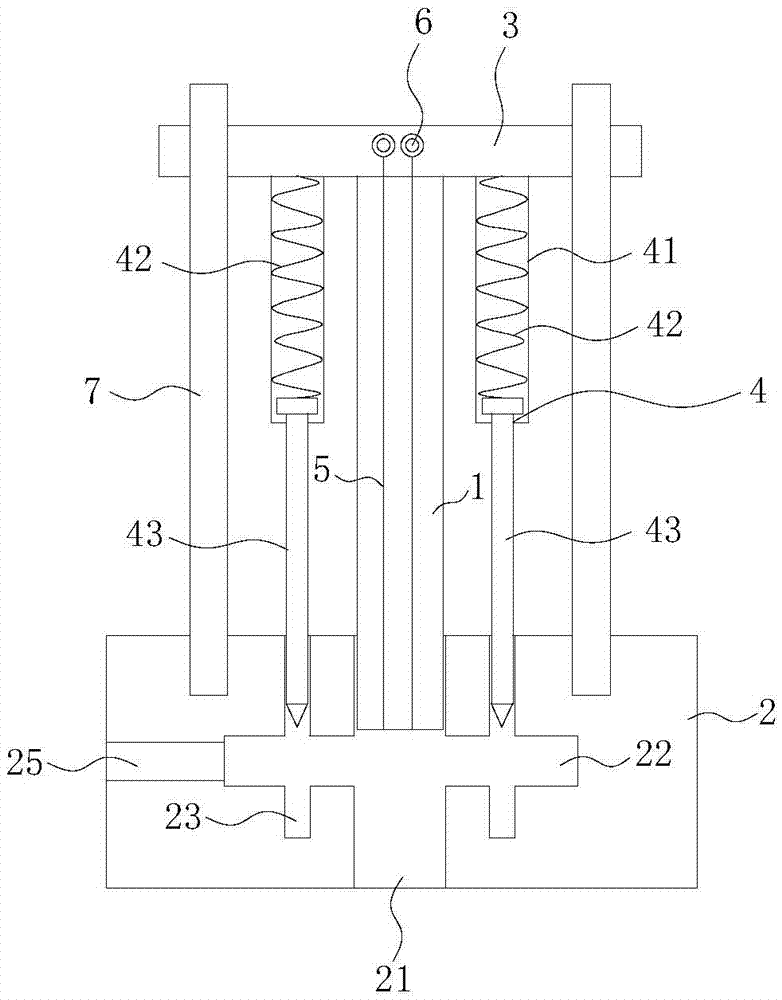

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

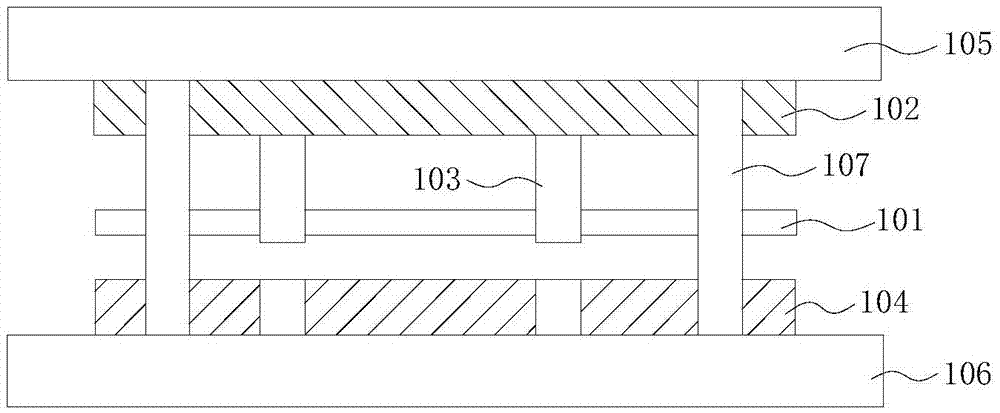

[0030] The invention provides a set punching die, such as figure 2 As shown, it includes a punch 1 and a die 2, the lower end of the punch 1 is provided with a punch edge, which cooperates with the die 2 to complete the punching of the material to be punched;

[0031] A punching opening 21 and a feed opening 22 perpendicular to the punching opening 21 are provided through the die 2, and the material to be punched enters the die 2 from the feed opening 22 and is arranged below the punch 1, and the punch 1 One end is located above the punching slot 21 and can be moved into the punching slot 21 , and punches the plate to be punched along the punching slot 21 . In this embodiment, the punching notch 21 is set through the die 2 , and then the punch 1 will continue to move after the punch 1 completes pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com