Perforating device for capacitor film machining

A capacitor film and punching device technology, which is applied in metal processing and other directions, can solve the problems of high cost and bloated mechanism, and achieve the effects of strong applicability, meeting the needs of use, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

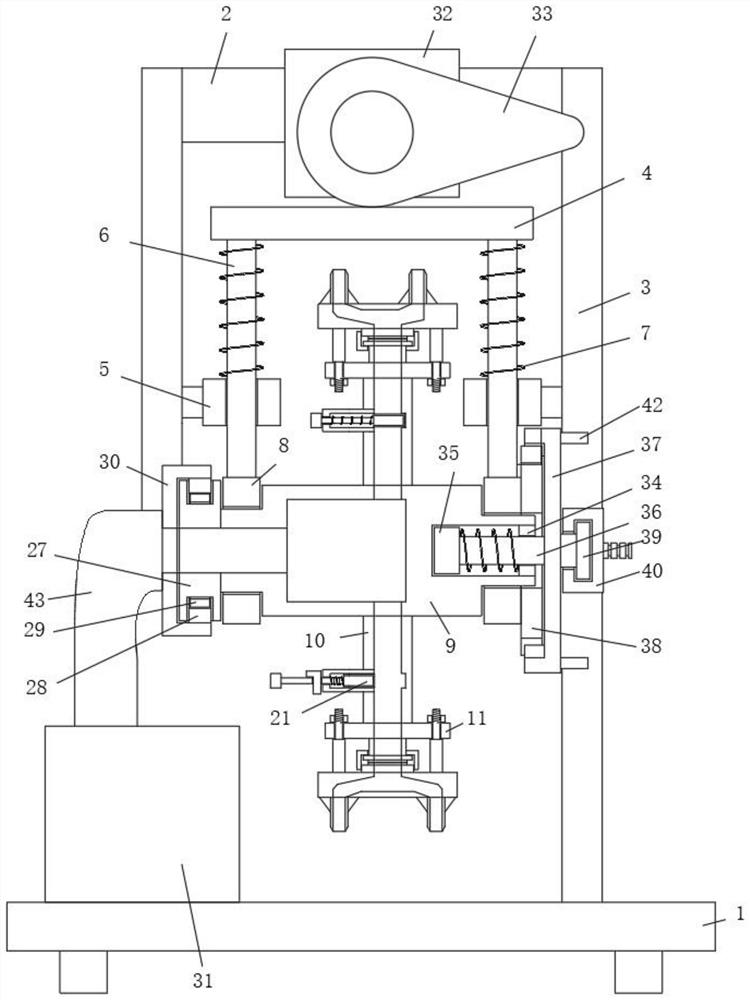

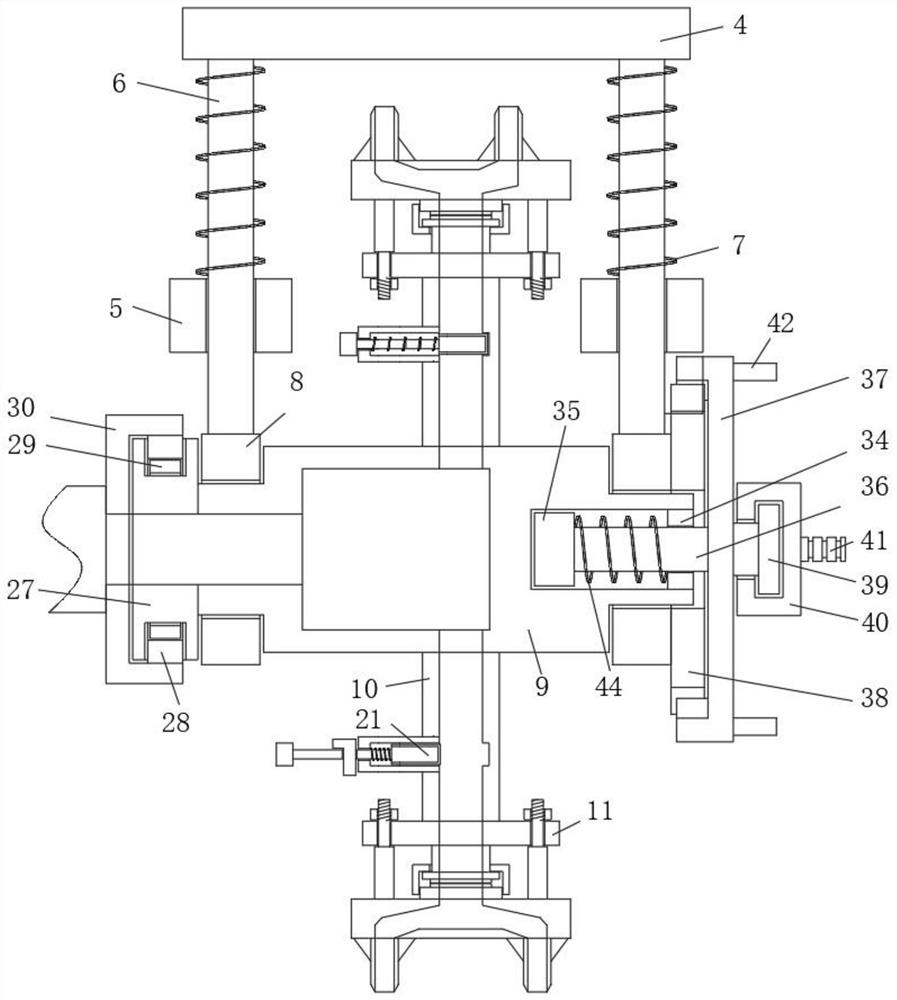

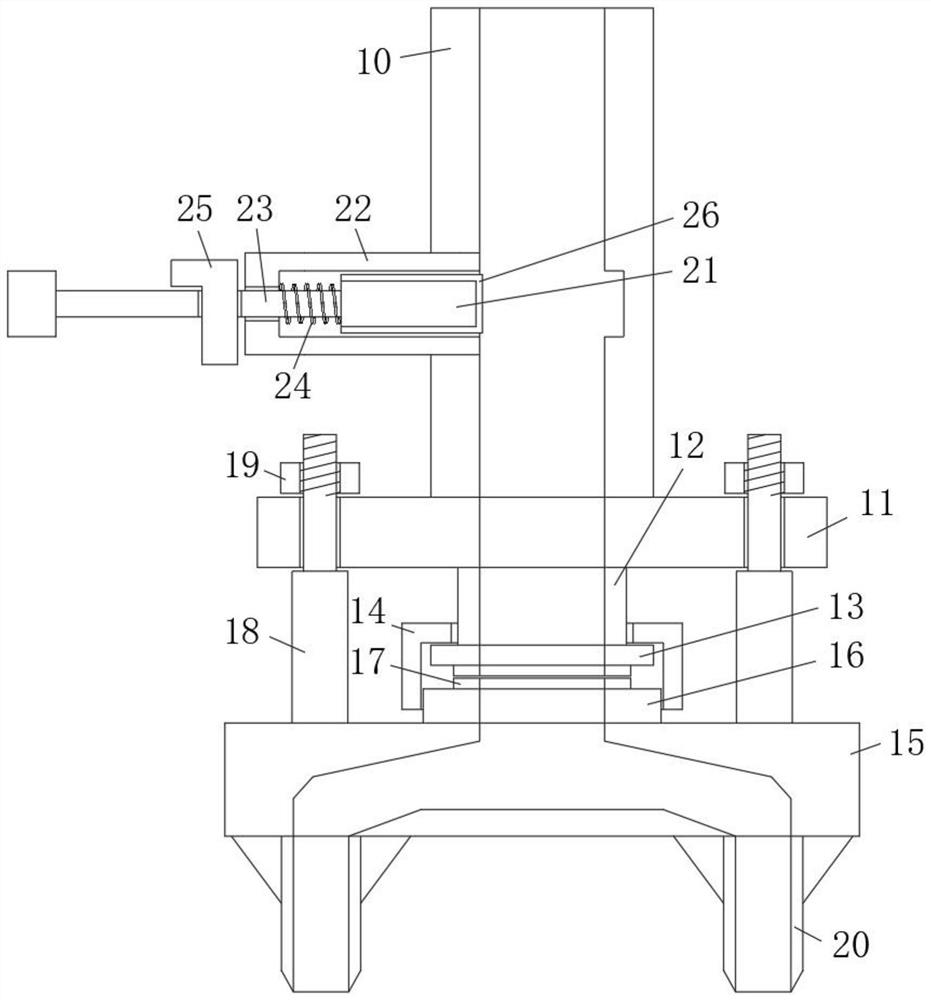

[0028] refer to Figure 1-4 , a punching device for capacitor film processing, comprising a base plate 1, two drum mounting rings 8 are arranged vertically above the base plate 1, and a center shaft cylinder 9 is arranged on a rotating frame between the two drum mounting rings 8, and the center shaft The outer side of the barrel 9 is divergently provided with several installation mechanisms, the end of the installation mechanism is detachably installed with a cutting assembly, the top of the central axis cylinder 9 is provided with a pressing assembly, one end of the central axis cylinder 9 is provided with a suction chamber, and the bottom plate A vacuum cleaner 31 is also installed on the top side of 1, and a connecting pipe 43 is installed on the vacuum cleaner 31. One end of the connecting pipe 43 communicates with the material suction chamber, and a fixing mechanism is arranged between the central axis cylinder 9 and the drum mounting ring 8;

[0029] Install the device o...

Embodiment 2

[0033] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the pressing down assembly includes a hanging plate 4 vertically above the bottom plate 1, and a motor mounting seat 2 is provided on the top side of the hanging plate 4, and the motor mounting seat 2 and the Support columns 3 are arranged between the bottom plates 1, and one side of the support columns 3 is fixedly connected with a rail vertical cylinder 5, and a rail sliding rod 6 slides through the rail vertical cylinder 5, and the top of the rail sliding rod 6 is fixed to the hanging plate 4. A spring 7 is arranged between the track vertical cylinder 5 and the hanging plate 4, the bottom end of the track slide bar 6 is fixed with the drum mounting ring 8, and a motor 32 is fixed on one side of the motor mounting seat 2 by bolts, and the output of the motor 32 A cam 33 is installed on the shaft, and the bottom of the cam 33 is connected in sliding contact with the top sid...

Embodiment 3

[0036] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the end of the central shaft cylinder 9 away from the connecting ring 27 is provided with a polygonal side groove and is slidably connected to a polygonal sliding core 35, and the inner wall of the opening of the polygonal side groove is fixedly connected. Position ring 34, a spring three 44 is arranged between the limit ring 34 and the polygonal sliding core 35, and one side of the polygonal sliding core 35 is fixedly connected with a connecting rod 36, and one end of the connecting rod 36 passes through and is fixed in the limiting ring 34 A safety tooth cover 37 is connected, and one side of the rotating cylinder installation ring 8 is fixedly connected with a safety tooth seat 38, and a circular groove is opened on one side of the safety tooth cover 37, and a tooth groove is provided on the inner wall of the circular groove and is engaged and sleeved on the safety tooth c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com