Pitch carbon fiber precursor spinning device

A pitch carbon fiber and spinning device technology, which is applied in the fields of fiber chemical characteristics, melt spinning, textiles and papermaking, etc., can solve the problem that the uniformity of pitch melt flow cannot be taken into account, and the pitch melt is easy to entrain gas and impurities, which cannot be realized Pitch carbon fiber winding and other issues, to achieve the effect of simple structure, high degree of automation, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

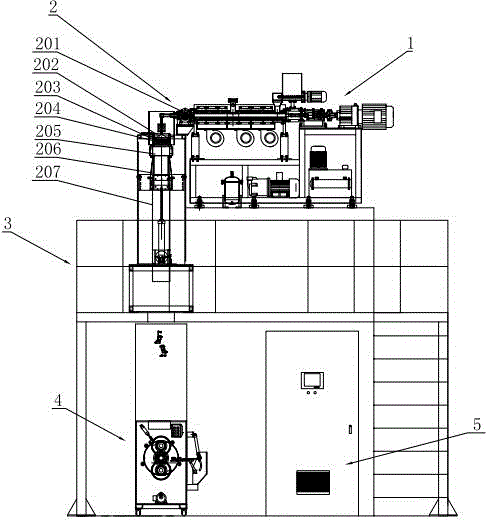

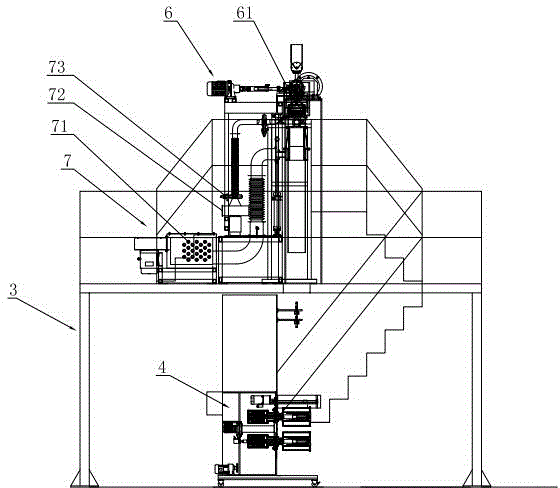

[0026] Such as figure 1 , figure 2 As shown, the pitch carbon fiber precursor spinning device includes a main frame 3, an extrusion assembly 1 for stirring the melt is installed on the main frame 3, and a spinning assembly 2 and a metering pump are arranged at the output end of the extrusion assembly 1 61. The metering pump 61 is driven and controlled by the metering pump power source 6. It also includes a winding head assembly 4 and an electric control cabinet 5 for winding the wire into a coil, and the winding head assembly 4 and the electric cabinet 5 are installed at the bottom of the main frame 3 .

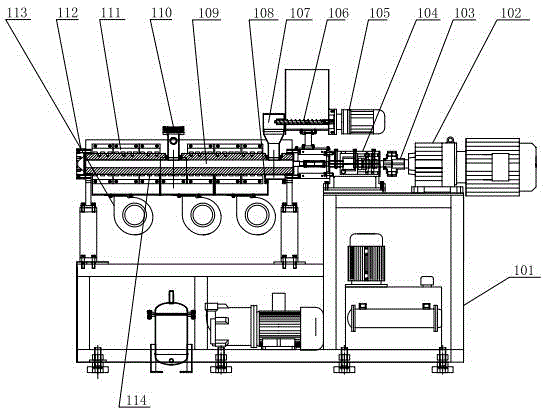

[0027] Such as image 3 As shown, the specific structure of the extrusion assembly 1 is as follows: including the first sub-frame 101 and the fan temperature control port 113, the reducer 102 is installed on the first sub-frame 101, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com