Improved anti-theft packaging box equipment

A packaging box and equipment technology, applied in the field of anti-theft packaging box processing, can solve the problems such as affecting the preparation quality of anti-theft packaging boxes, preparation speed, hand shaking, and hole punching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

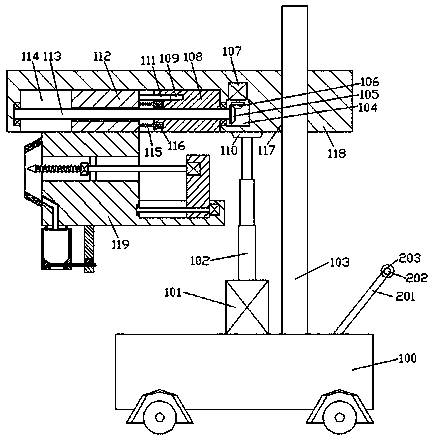

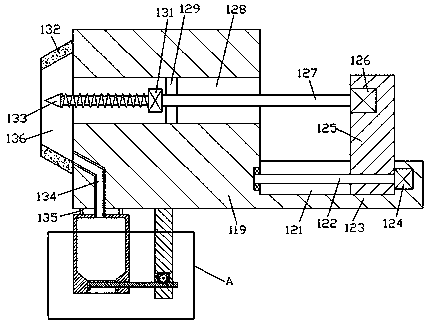

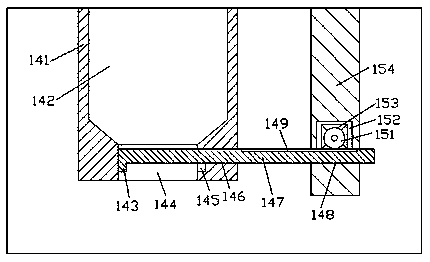

[0012] Combine below Figure 1-3 The present invention will be described in detail.

[0013] refer to Figure 1-3 , an improved anti-theft packing box device according to an embodiment of the present invention, comprising a car frame 100, the top of the car frame 100 is fixed with a vertical pole 103, and a first slide is provided up and down inside the vertical pole 103. Moving chamber 117, the first sliding chamber 117 is slidingly fitted with a landing seat 118, the bottom end surface of the lifting seat 118 is provided with a second sliding chamber 114, and the second sliding chamber 114 is slidingly fitted respectively The first dovetail block 112 and the second dovetail block 108 are installed, and the internal thread of the second dovetail block 108 is fitted with a first screw rod 113, and the gap between the first screw rod 113 and the first dovetail block 112 is Cooperate, and the left extension end of the first screw rod 113 is rotationally connected with the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com