Automatic feed punching machine

An automatic feeding and punching machine technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as imperfections in the field of continuous punching, achieve improved punching quality and punching efficiency, and stable feeding effect Sustained and conducive to the promotion and application of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

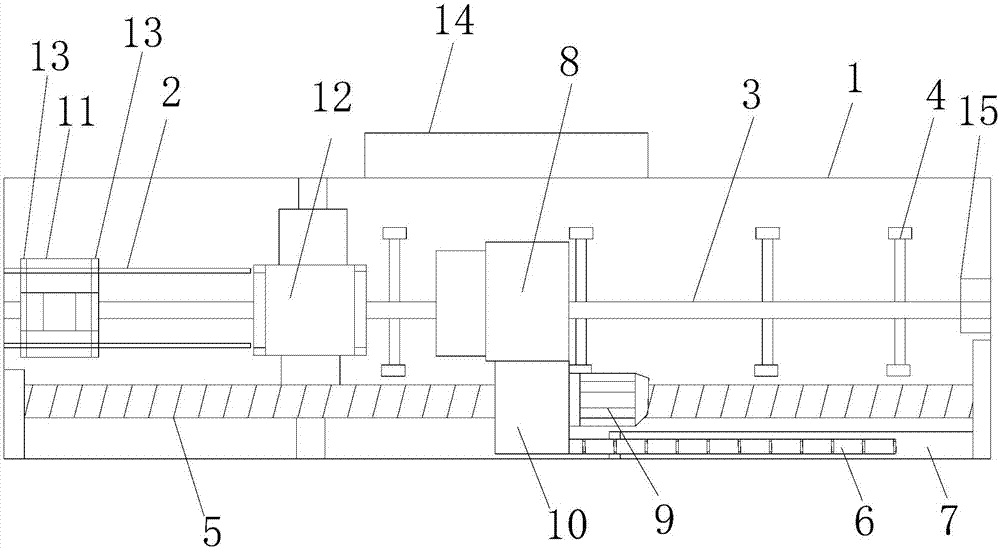

[0014] refer to figure 1 , an automatic feeding punching machine of the present invention, comprising a frame 1, a slide rail 2, a limit rod 3, an auxiliary conveying roller 4, a stroke screw 5, a finishing chain 6, a chain groove 7, a claw feeder 8, and a servo motor 9 , rotating screw sleeve 10, vertical stamping die set 11, horizontal stamping die set 12, auxiliary gripper 13, control center 14, the limit rod 3 is arranged on the top of the frame 1, and the limit rod 3 is horizontally arranged on On the top of the frame 1, several auxiliary conveying rollers 4 are arranged on the frame 1 directly below the stop bar 3, and the head end of the stop bar 3 is provided with a vertical stamping module 11, and the frame 1 The top is provided with a slide rail 2, the vertical stamping die set 11 is installed on the top of the frame 1 through the slide rail 2, the vertical stamping die set 11 is provided with an auxiliary gripper 13, and the vertical stamping die set 11 The right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com