Punching method used for automobile side trimming maintenance

An automobile side and trimming technology, applied in the field of punching dies, can solve the problems of difficulty in applying to small automobile repair centers and high use costs, and achieve the effects of ensuring punching quality, reducing costs, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

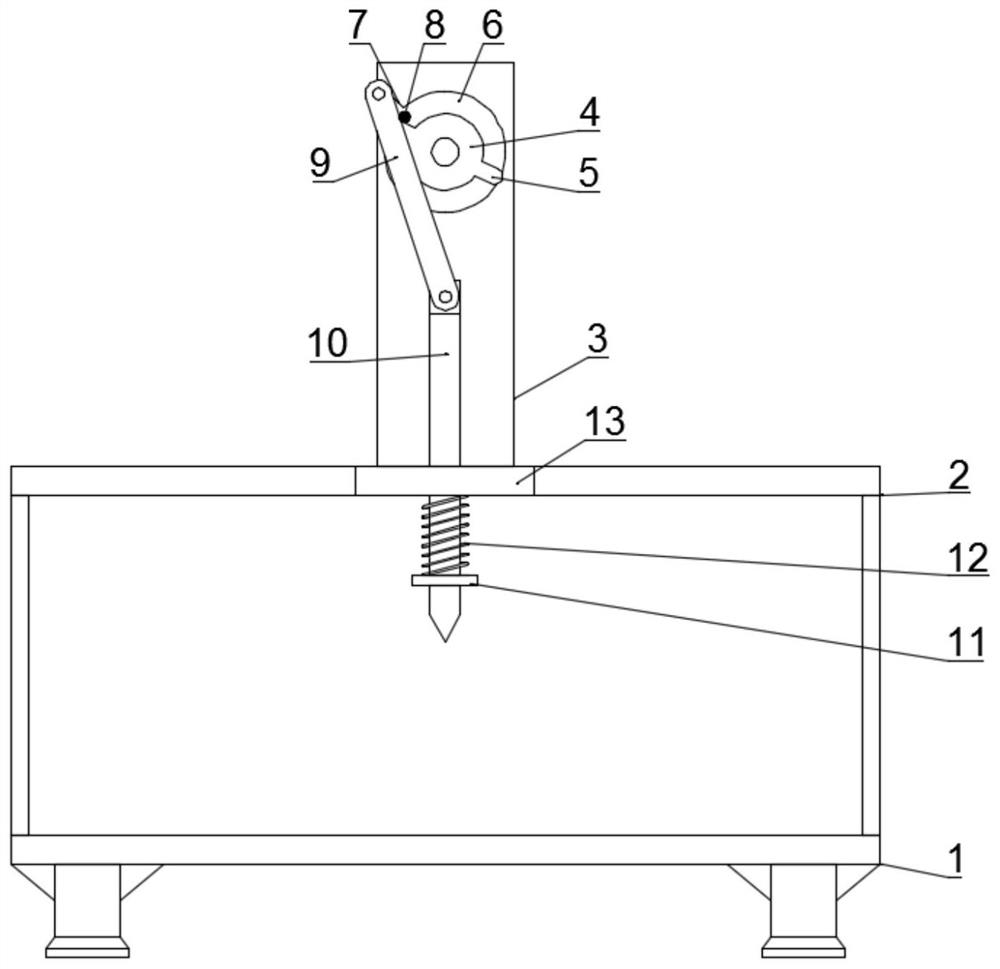

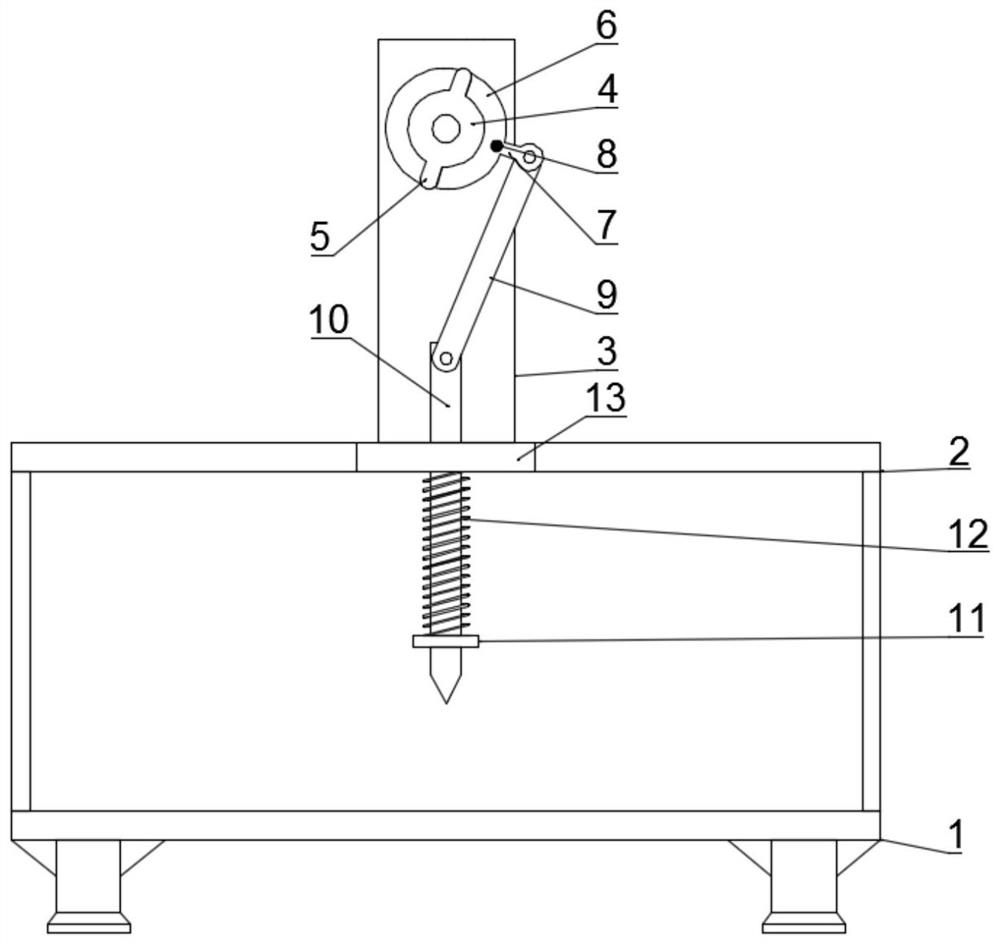

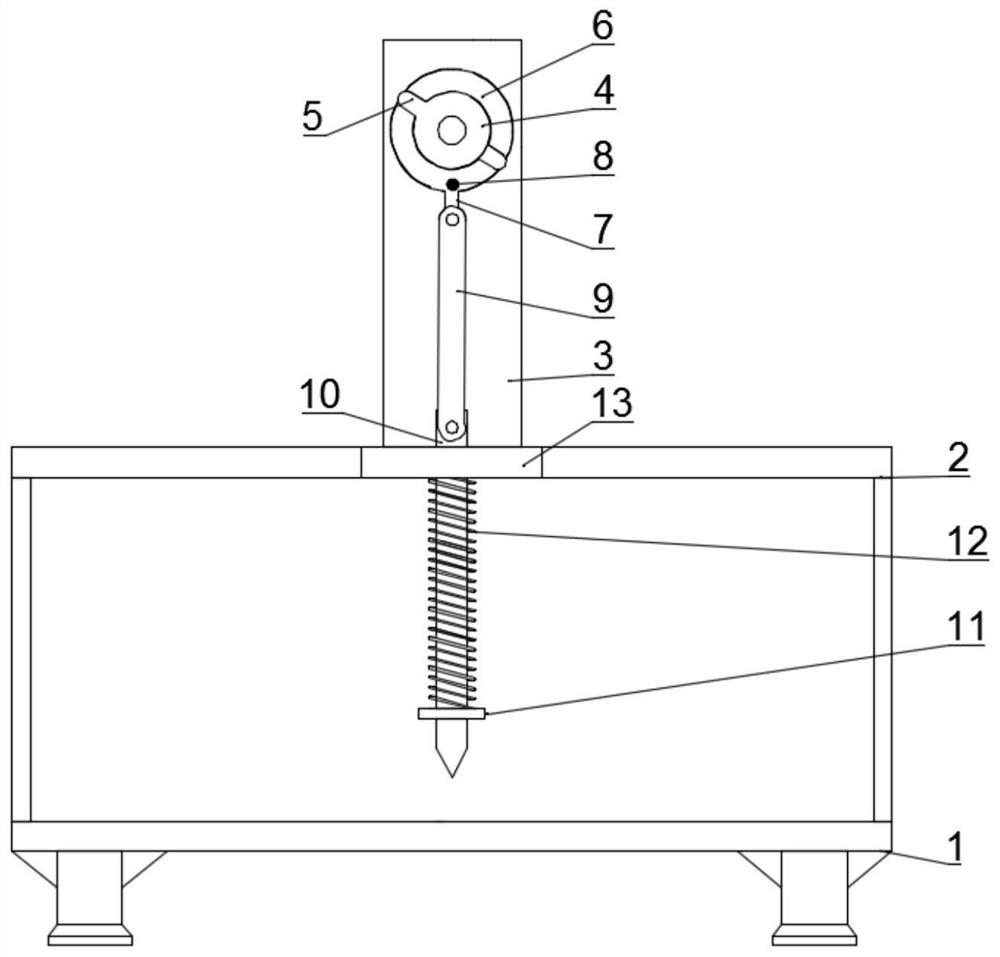

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] Such as Figure 1-8 Shown, a kind of punching method that is used for automobile side trim maintenance, comprises the following steps:

[0035] Step 1, start the first driving mechanism, the first driving mechanism drives the rotating wheel 4 to rotate, and the protruding block 5 arranged on the circumferential end surface of the rotating wheel 4 follows the rotating wheel 4 to rotate;

[0036]Step 2, when the raised block 5 touches the fixed rod 8, the fixed rod 8 rotates following the raised block 5, and the turntable 6 fixedly connected with the fixed rod 8 also rotates, through the first connecting rod 7 and the second The transmission effect of the connecting rod 9 makes the punch 10 move up, and the elastic reset member 12 is compressed at this time;

[0037] Step 3, the protruding block 5 continues to follow the rotation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com