Punching device for machining

A punching device and mechanical processing technology, which is applied in the direction of driving devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing the investment cost of processing equipment and reducing the drilling efficiency, so as to improve the drilling efficiency and reduce the use of The effect of quantity and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

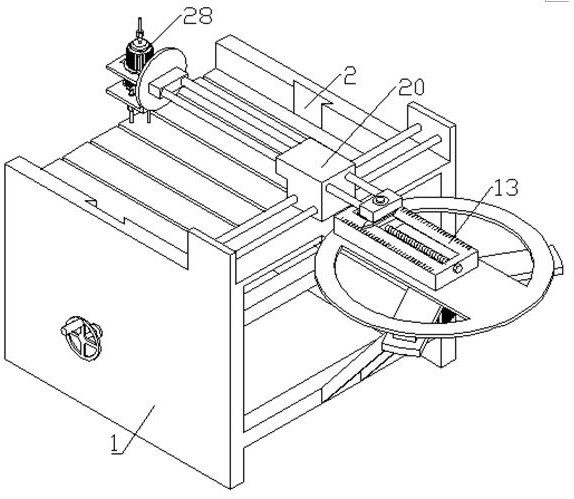

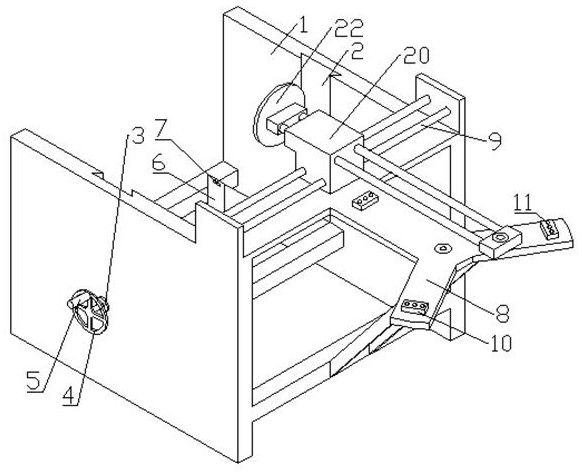

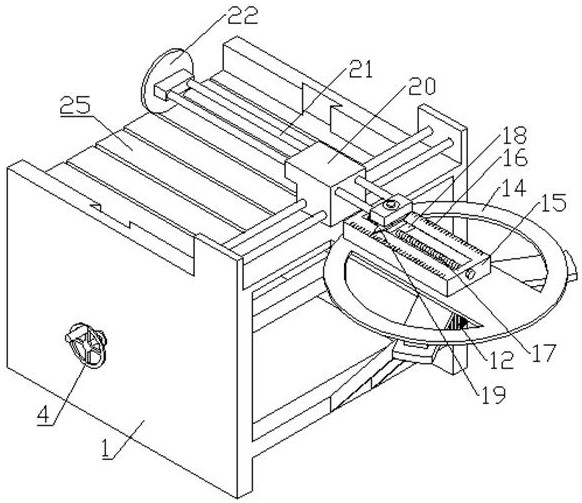

[0017] like Figure 1-5 As shown, a punching device for mechanical processing includes a main body 1, a dovetail groove 2, a transmission screw 3, a transmission disc 4, a handle 5, a lower wedge 6, a T-shaped slot 7, a support frame 8, a No. 1 polished rod 9, Mounting base 10, ball 11, right speed regulating motor 12, adjustment part 13, the inner wall of the main body 1 has a vertical dovetail groove 2 at the front and rear ends, and the bottom of the main body 1 is connected with a horizontal transmission screw 3 for rotation. The front end of the transmission screw 3 is fixed with a vertical transmission disc 4, the front end of the transmission disc 4 is rotatably connected with a horizontal handle 5, and the transmission screw 3 is threaded with a vertical lower wedge 6, in order to ensure transmission Screw rod 3 and lower wedge block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com