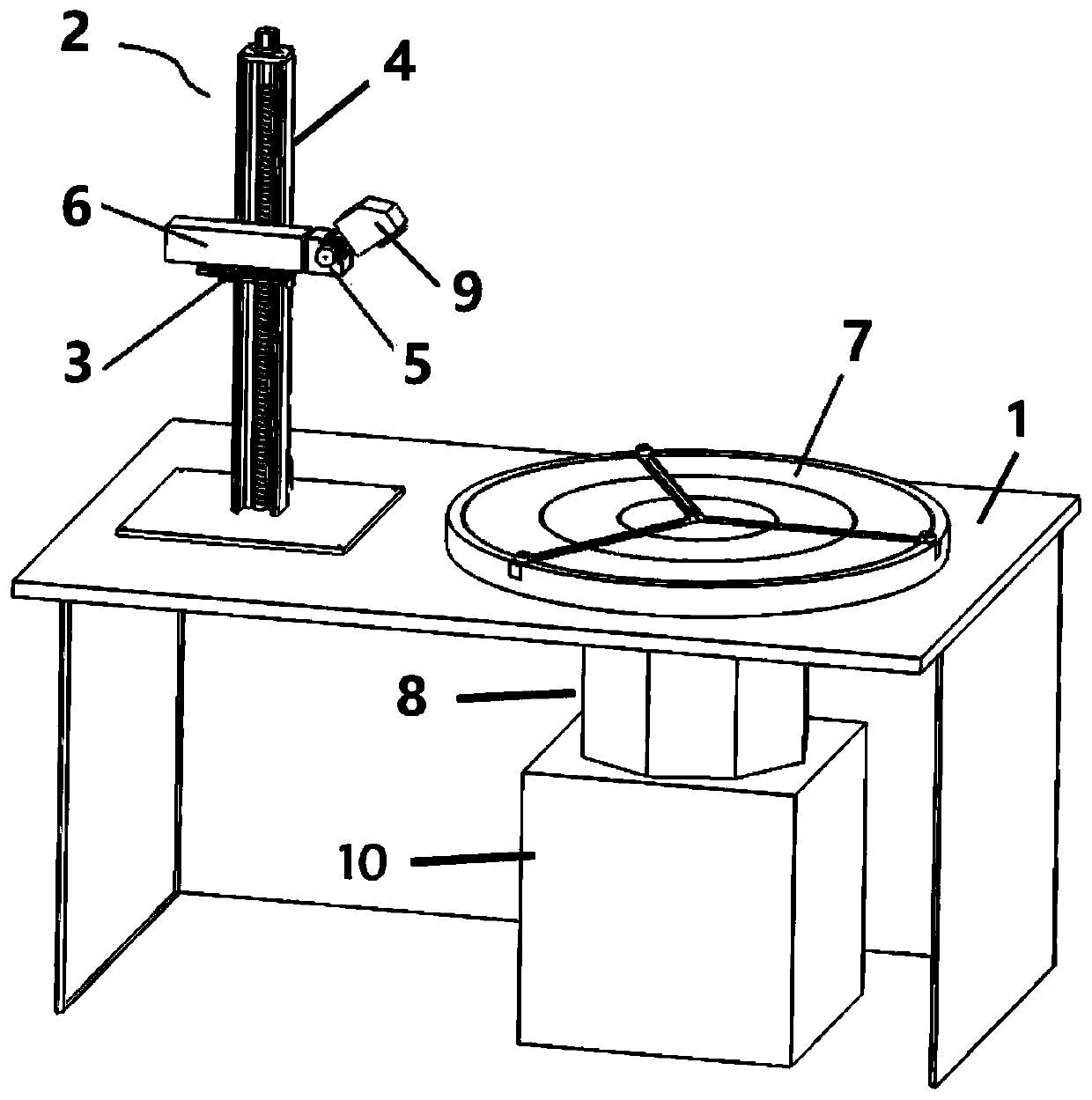

Laser processing platform for circular cylinder punching

A laser processing and annular cylinder technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low beam of laser head, structural limitation, low efficiency, etc., to achieve high processing repeatability, high processing accuracy, Small heat affected zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

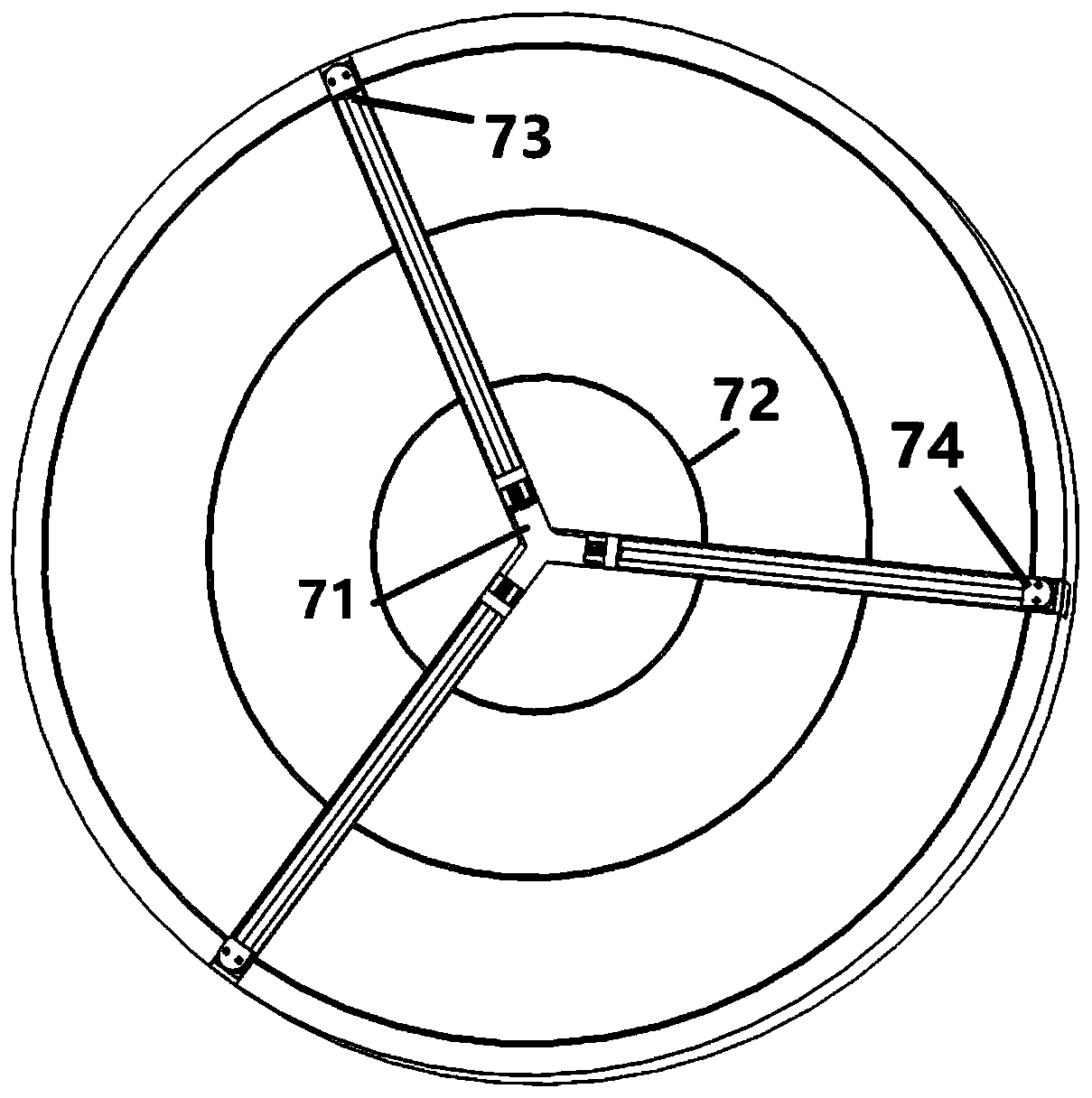

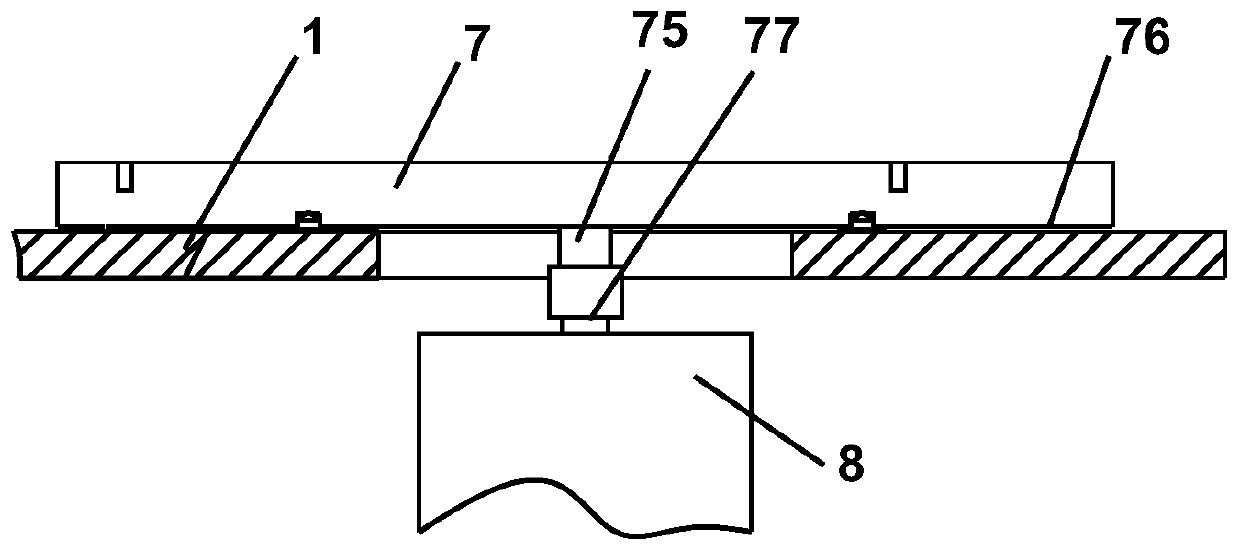

[0034] Place the annular flame tube workpiece on the rotary platform, start the cylinder to control the slider to run until the rubber block is on the inner wall of the cylindrical workpiece, start the laser head motor to drive the laser head to rotate to the processing angle suitable for the cylindrical workpiece, and then stop, adjust the translation The sliding table adjusts the laser focus to the surface of the workpiece and stops. Adjust the lifting slide table to adjust the laser spot to the starting point of processing, scan and punch holes, start the rotary platform motor to drive the rotary platform to rotate to the next processing position to scan and punch holes, and repeat the operation. The flame tube completes a circle of drilling, adjust the lifting slide table to the next processing position, and perform the next circle of drilling.

[0035] The rotary platform is used to carry the annular flame tube to meet the requirements of its rotary processing. The laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com