Patents

Literature

36results about How to "No mechanical stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrochemical levelling and polishing processing method with nanometer precision and device thereof

ActiveCN101880907ANo mechanical damageNo pollution problemElectrolysis componentsSemiconductor/solid-state device manufacturingElectrochemical responseLiquid layer

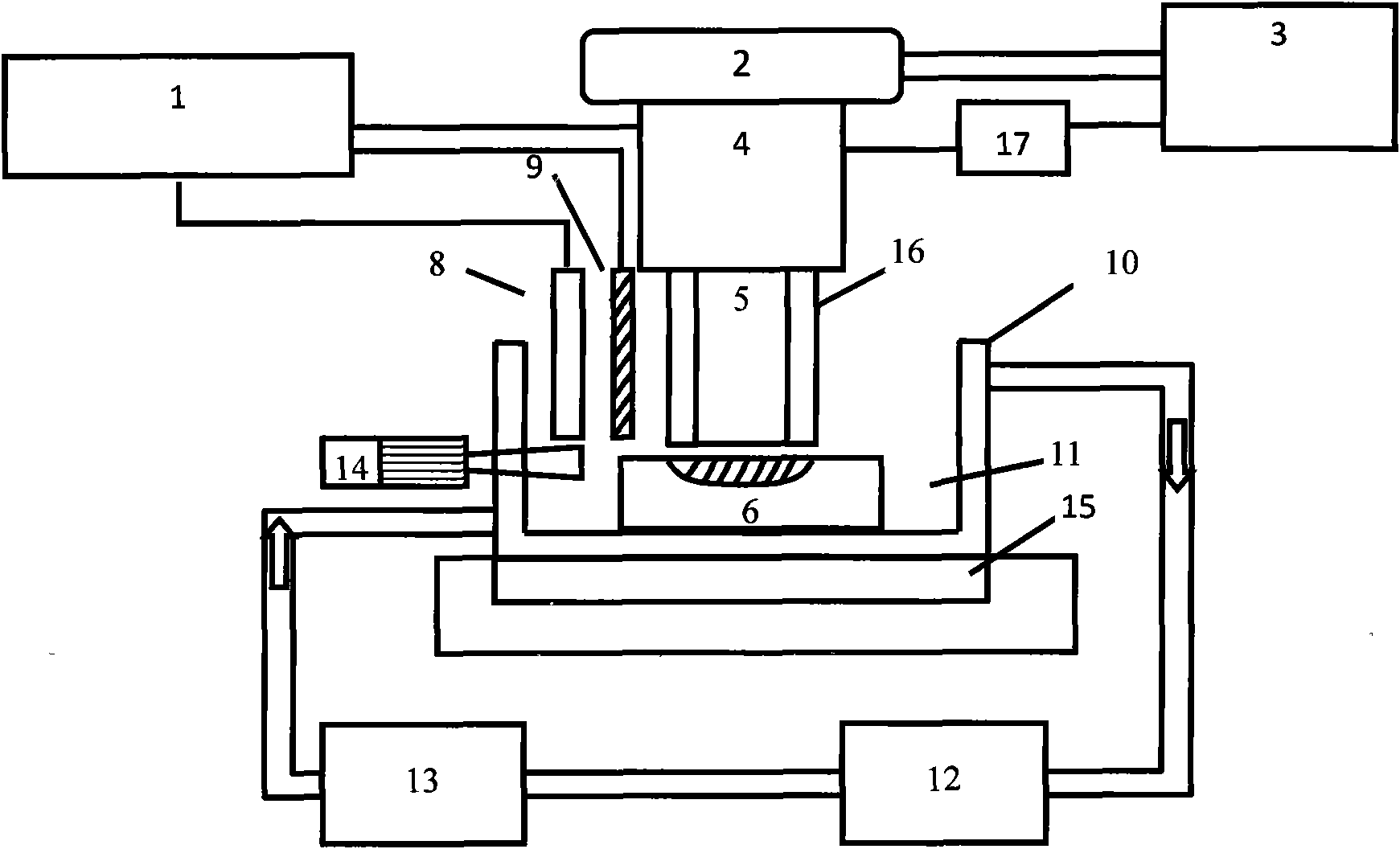

The invention provides an electrochemical levelling and polishing processing method with nanometer precision and a device thereof, relating to an electrochemical etching levelling and polishing technology. The device is provided with a cutter with nanometer levelling precision, an electrochemical reaction control system capable of accurately controlling the thickness of an etching levelling agent liquid layer in nanoscale, a solution circulating device, a solution thermostat and an automatic control system. The method is implemented by the following steps: preparing the cutter with nanometer levelling precision to serve as an electrochemical working electrode, and placing the cutter at the bottom of a container together with a workpiece; immersing the cutter in a solution, starting an electrochemical system, generating the etching levelling agent on the surface of the cutter, compressing the etching levelling agent liquid layer on the cutter surface into a nanoscale thickness, and regulating and controlling the thickness of the etching levelling agent liquid layer; driving a tri-dimensional micro-drive device, leading the cutter to approach the workpiece gradually, and regulating and controlling the distance and parallelism between the workpiece surface and the cutter; and leading the cutter to move toward the workpiece surface, and enabling the constraint etching levelling agent liquid layer on the cuter surface to contact with the workpiece surface until the whole workpiece is etched, leveled and polished.

Owner:XIAMEN UNIV

Method for engraving character or graphics on metal mold

InactiveCN101670490ANo extrusion stressNo mechanical stressActive medium materialLaser beam welding apparatusGraphicsHeat-affected zone

The invention discloses a method for engraving a character or a graphics on a metal mold. The method comprises the following steps: firstly, placing the metal mold on a three-dimensional work table ofa laser engraving machine, and adjusting the metal mould to a corresponding engraving position; secondly, making a character or a graphics to be engraved and adjusting the parameters of the laser engraving machine; and thirdly, scanning layer by layer to reach a required depth. The method for engraving the character or the graphics on the metal mold can solve the problems of the complex flow of the conventional CNC or EDM and liquid medicine corrosion process, simplify the structure design of the mould without generating mechanical extrusion or stress in the process and has the advantages ofsmall heat-affected region, fine process, no deformation of a workpiece, high processing efficiency, low cost and easy operation without pollution.

Owner:天津滨海雷克斯激光科技发展有限公司

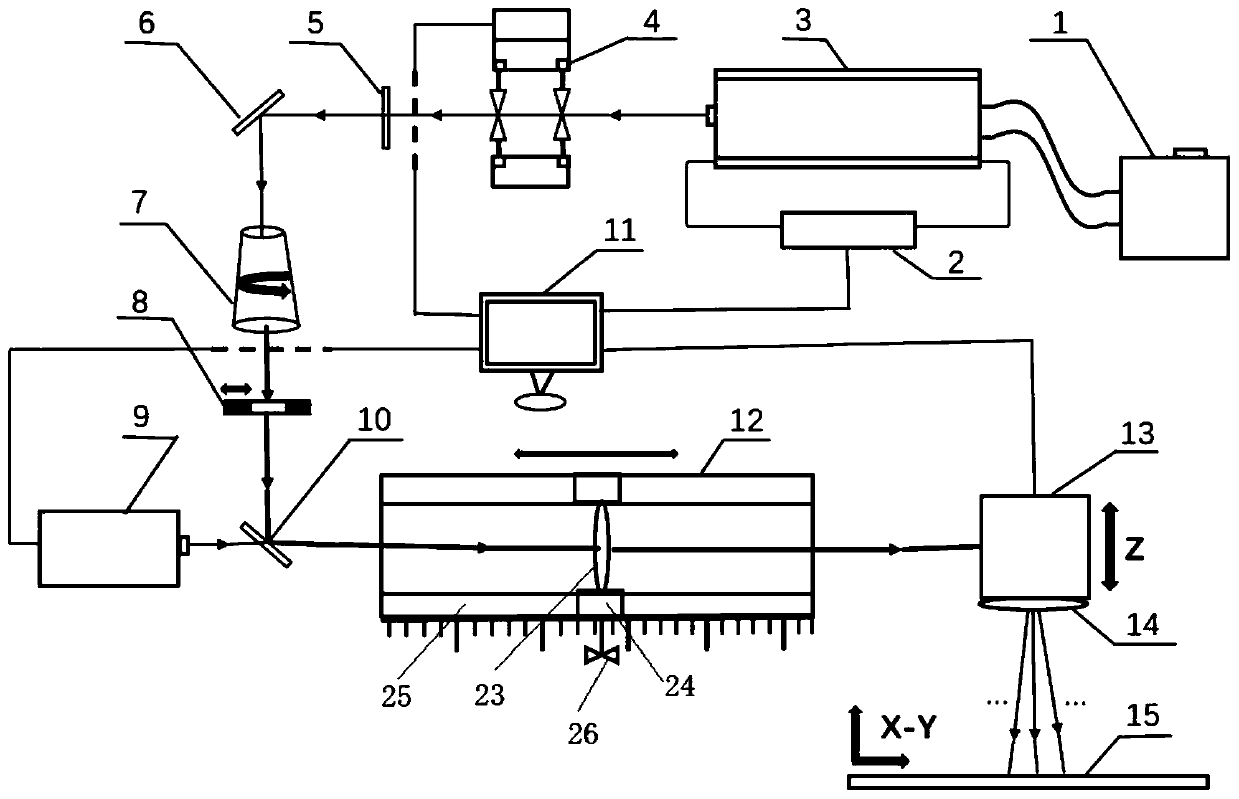

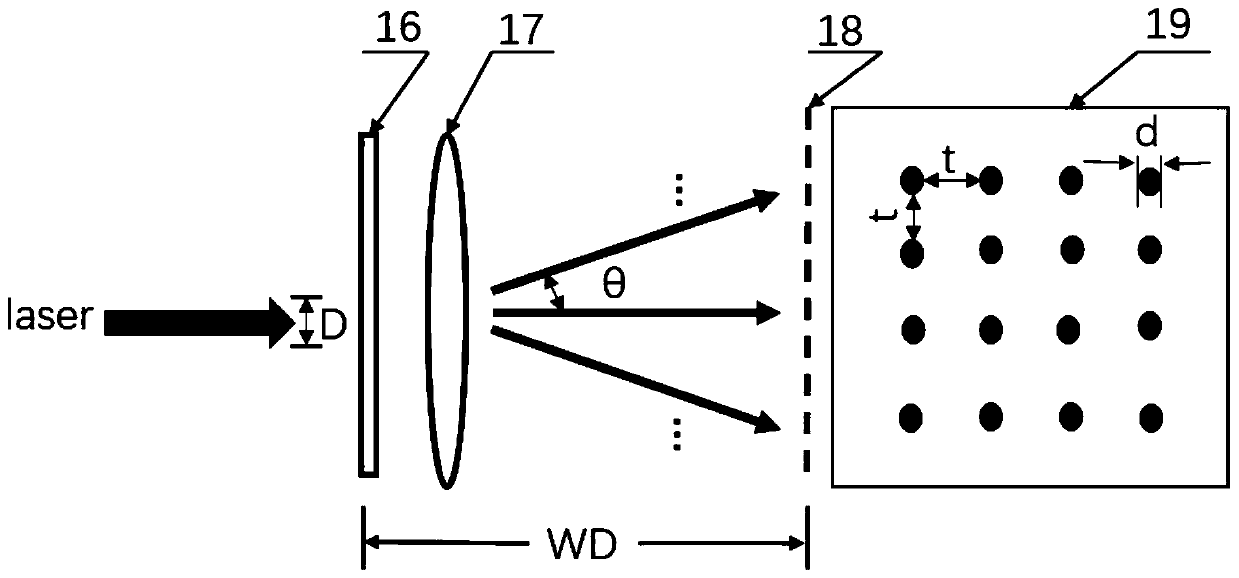

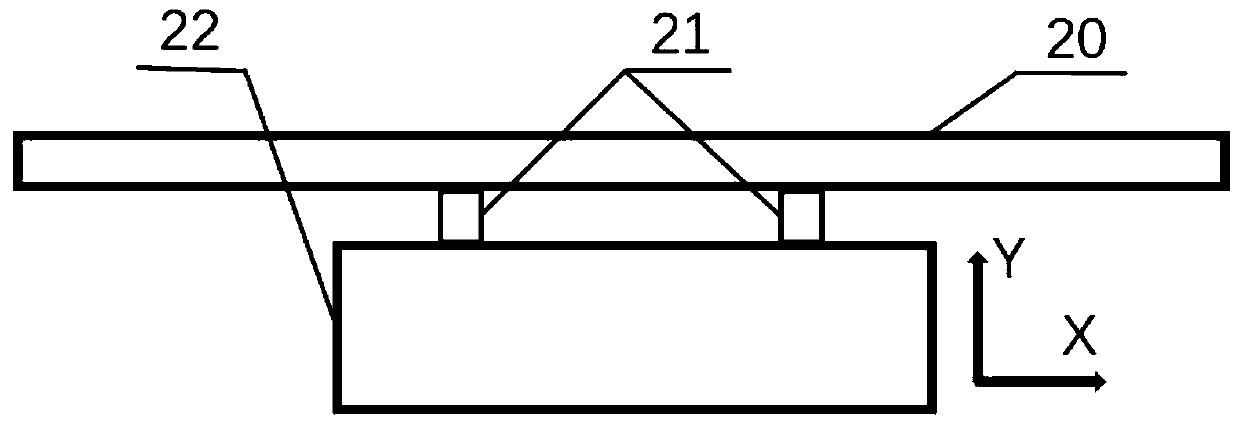

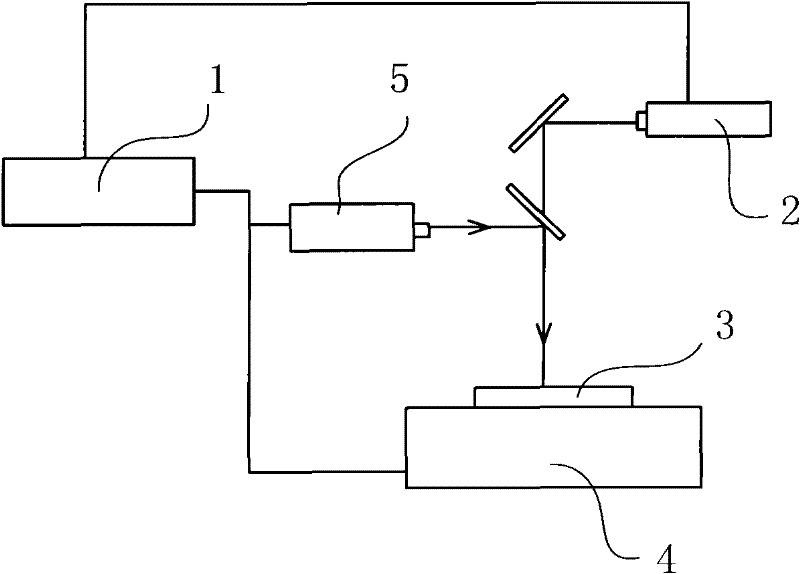

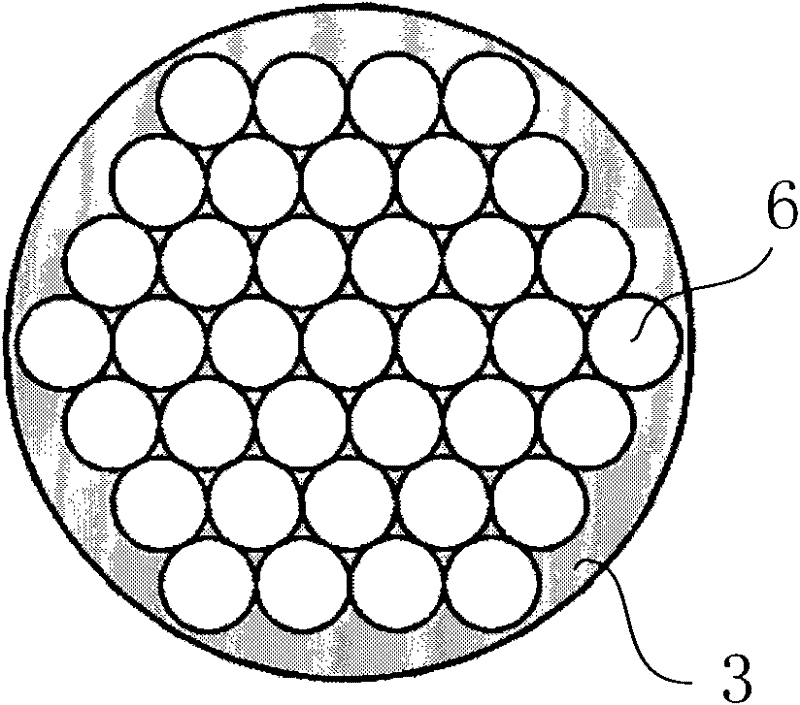

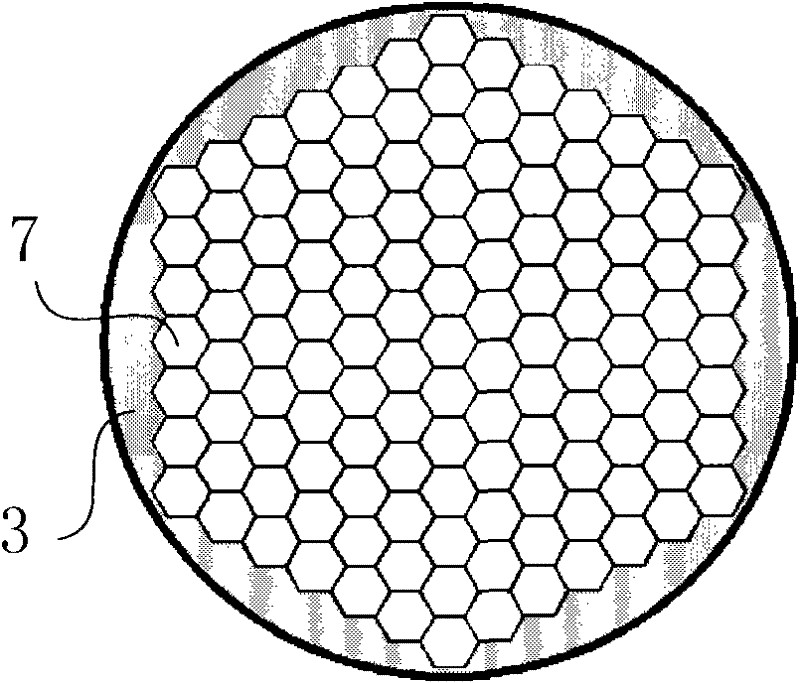

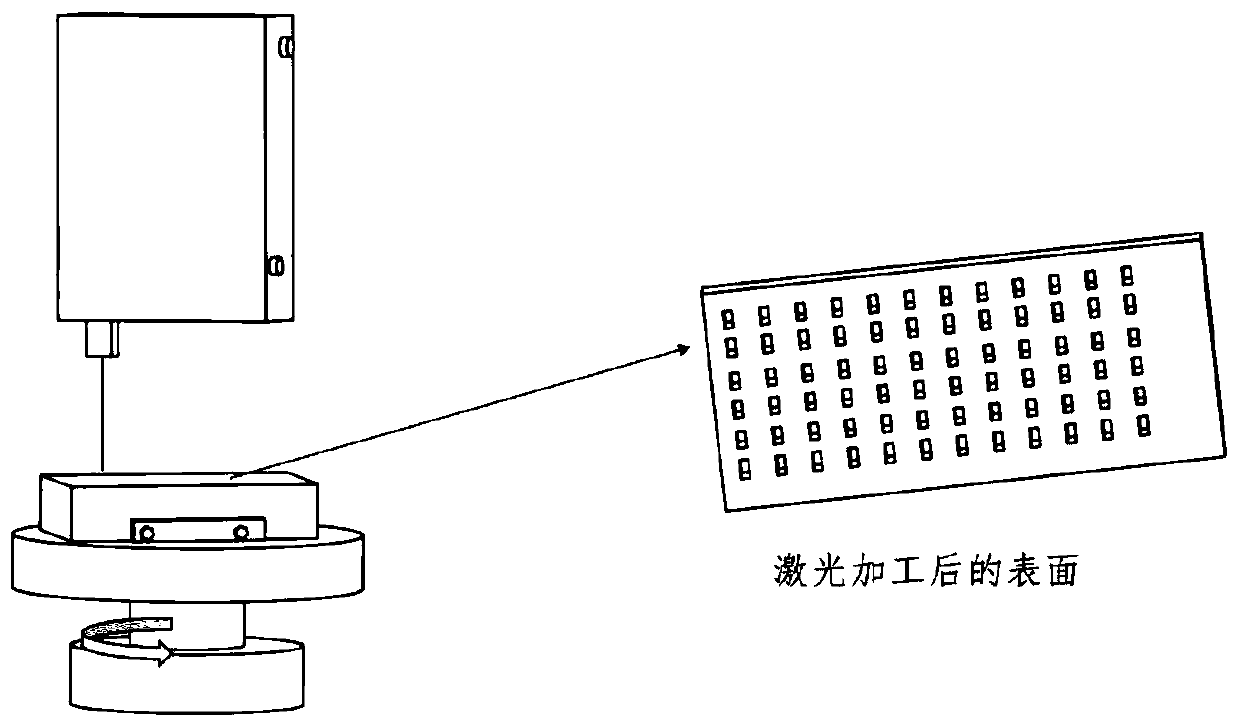

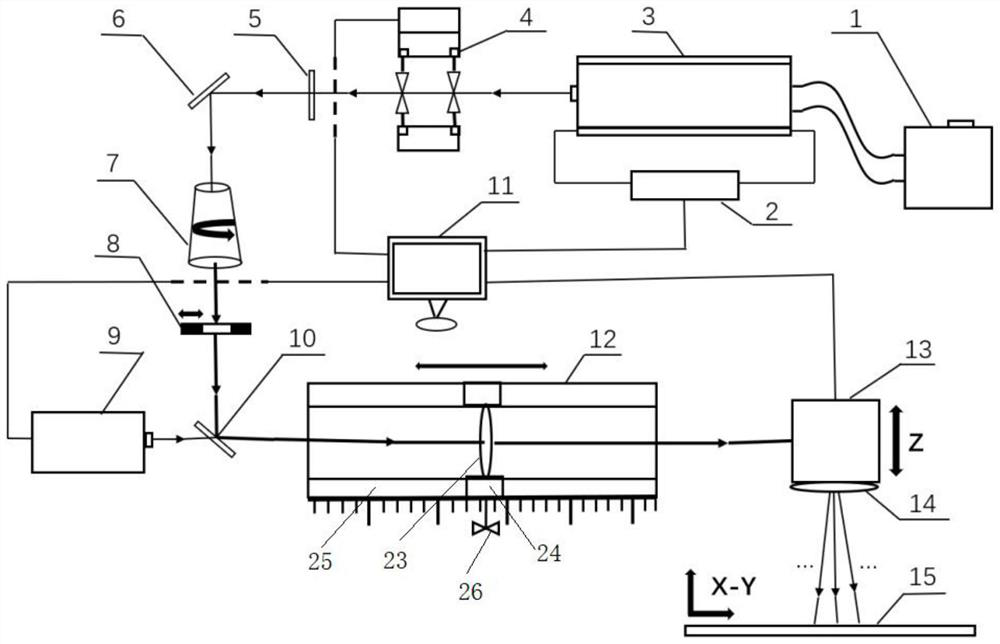

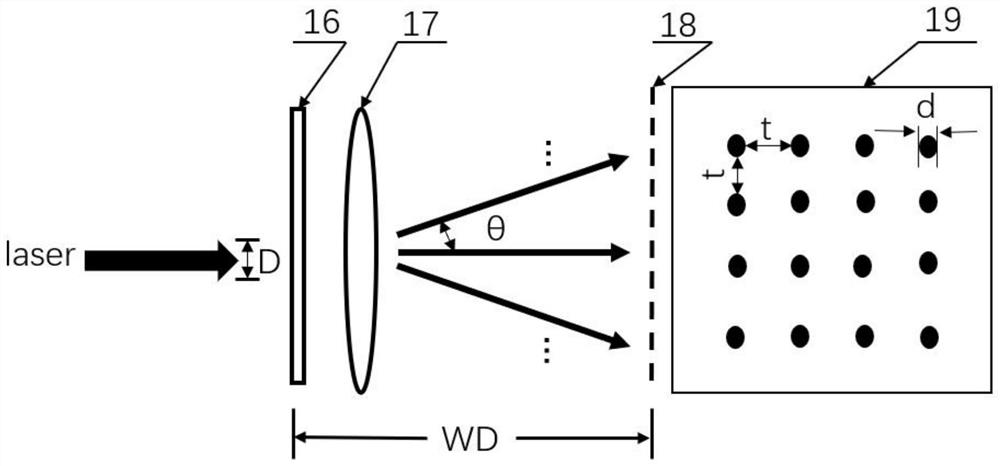

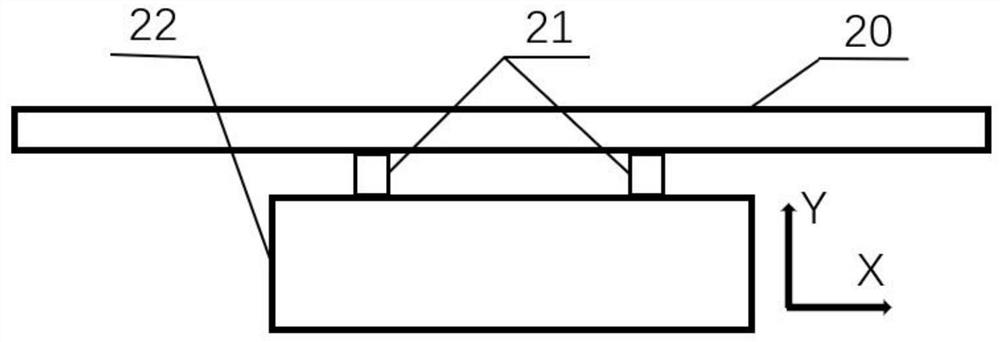

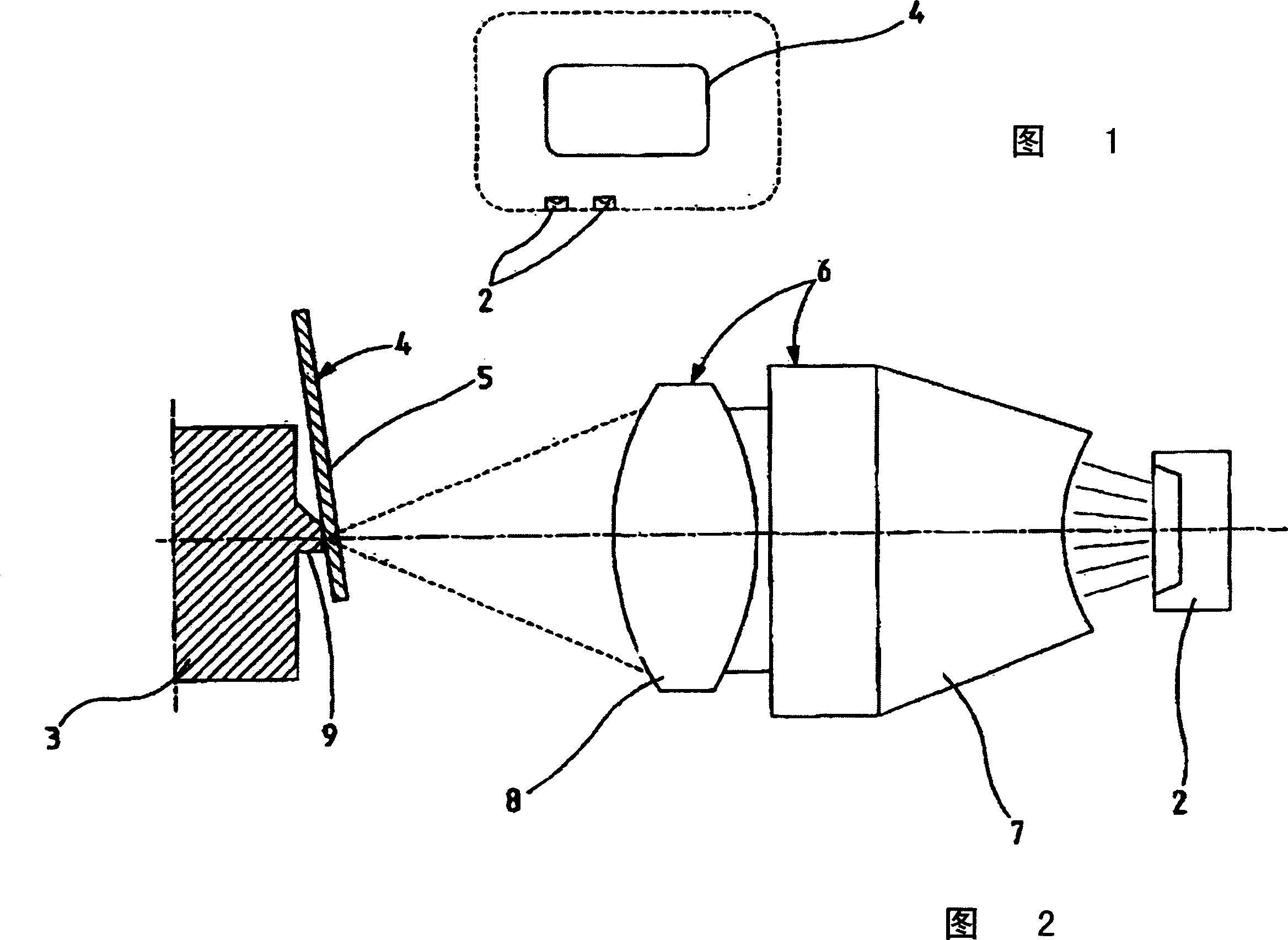

Laser parallel processing device and processing method for array air holes of leather product

ActiveCN110560936AMeet processing needsImprove drilling efficiencyLaser beam welding apparatusComputer control systemBeam expander

The invention discloses a laser parallel processing device and processing method for array air holes of a leather product. The laser parallel processing device comprises a laser system, an optical light guide system,an X-Y two-dimensional honeycomb adsorption platform system and a computer control system, wherein an optical path outlet of the laser system is opposite to an optical path inlet of the optical light guide system, and an optical path outlet of the optical light guide system is opposite to a working area of the X-Y two-dimensional honeycomb adsorption platform system; the optical light guide system involves a pneumatic optical shutter, a quarter slide, a reflector, an adjustable beam expander lens, an adjustable diaphragm, a dichroic mirror, a laser beam splitting unit and a scanning galvanometer; and a laser beam optical path output by the laser system sequentially passes through the pneumatic optical shutter, the quarter slide, the reflector, the adjustable beam expander lens, the adjustable diaphragm, a surface of the dichroic mirror, the laser beam splitting unit, the scanning galvanometer, and a to-be-processed leather surface, and the other surface of the dichroicmirror is provided with a red light unit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

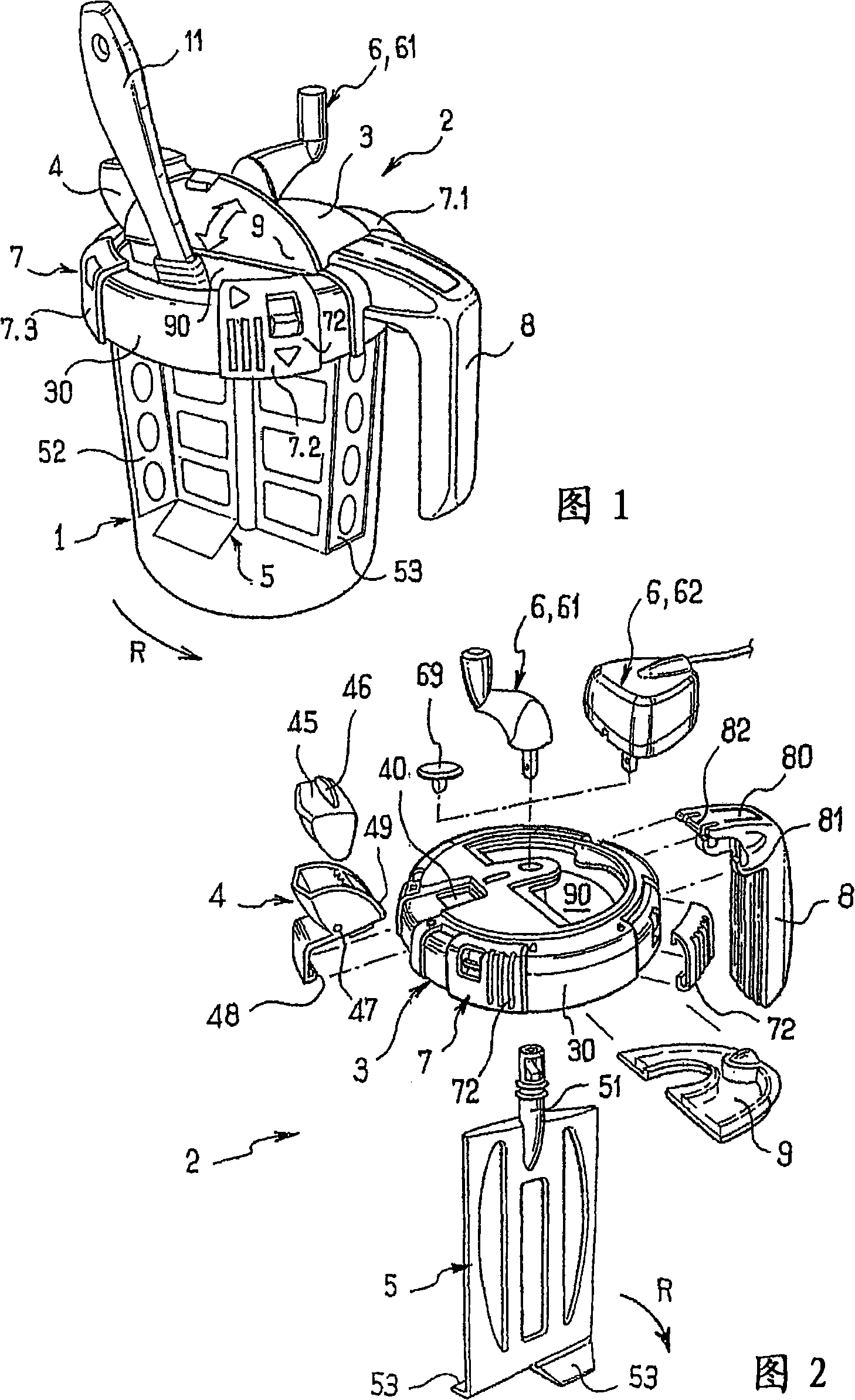

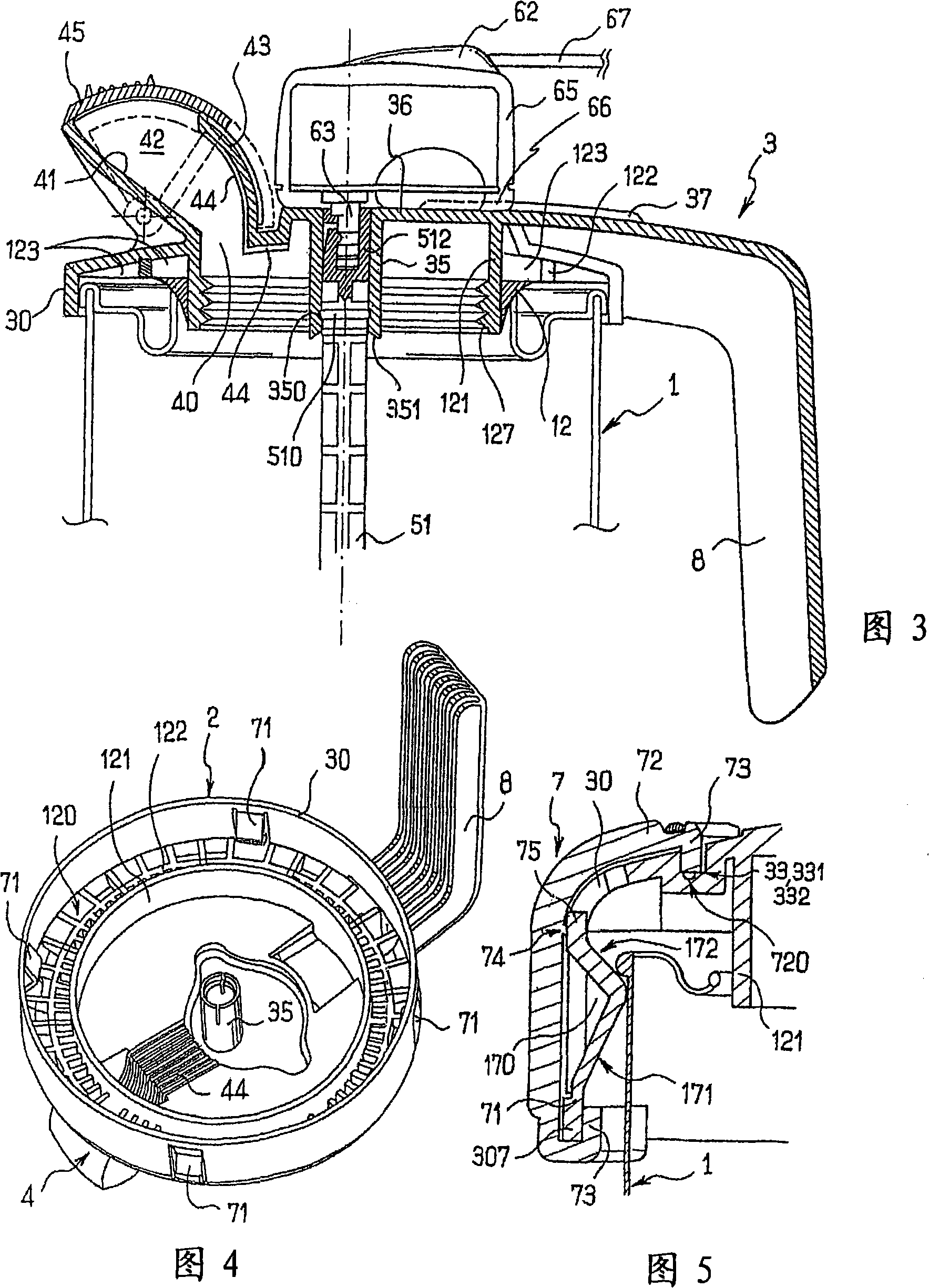

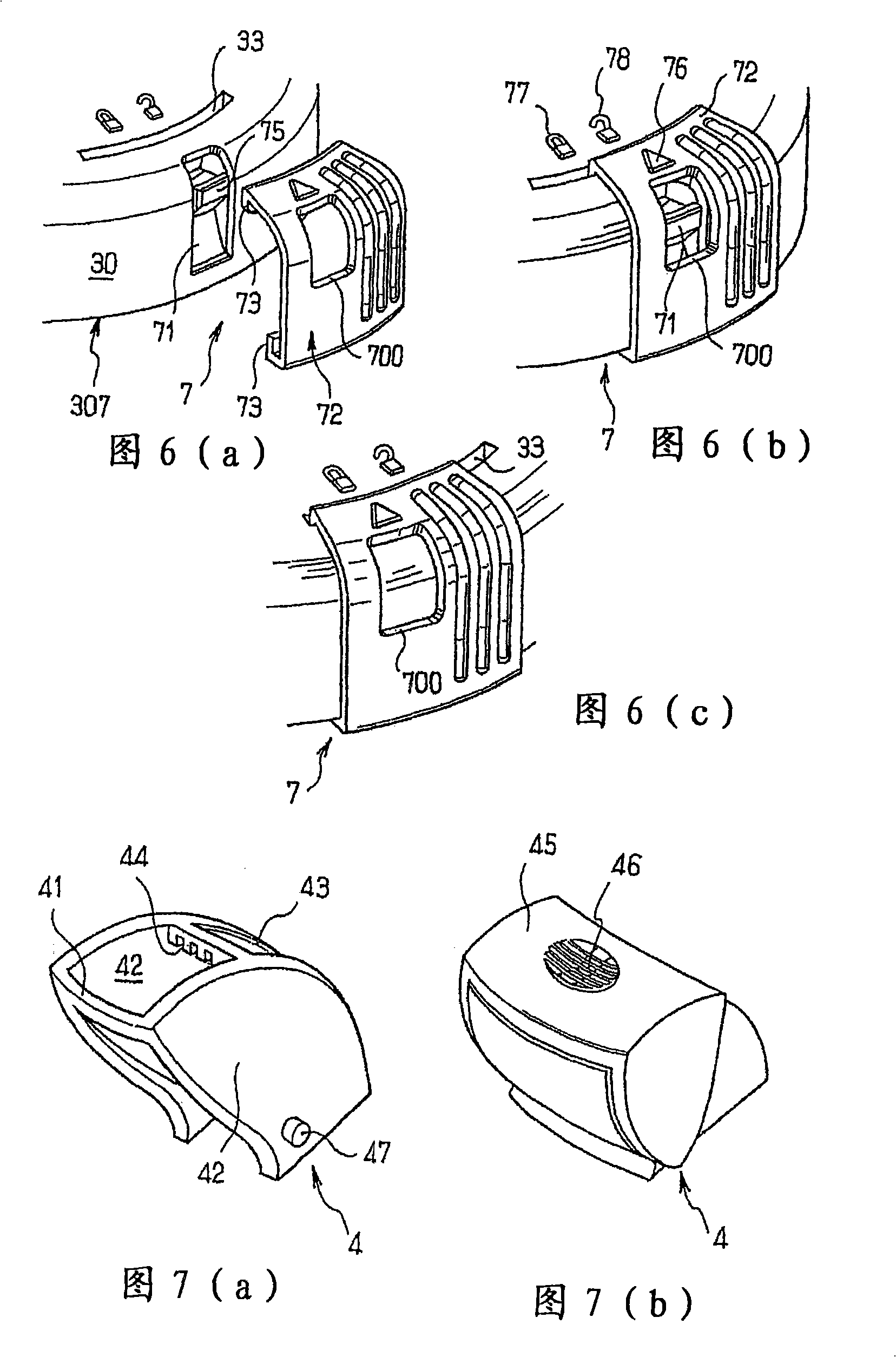

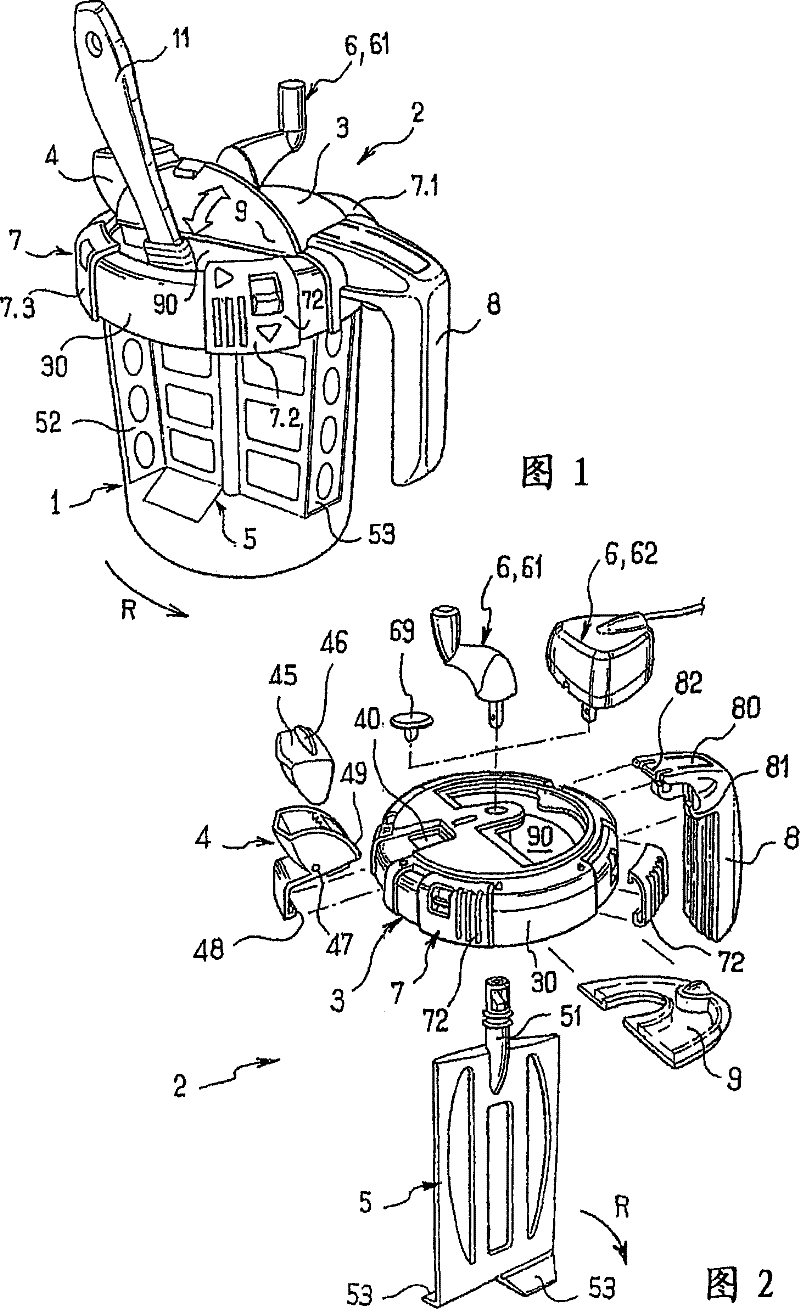

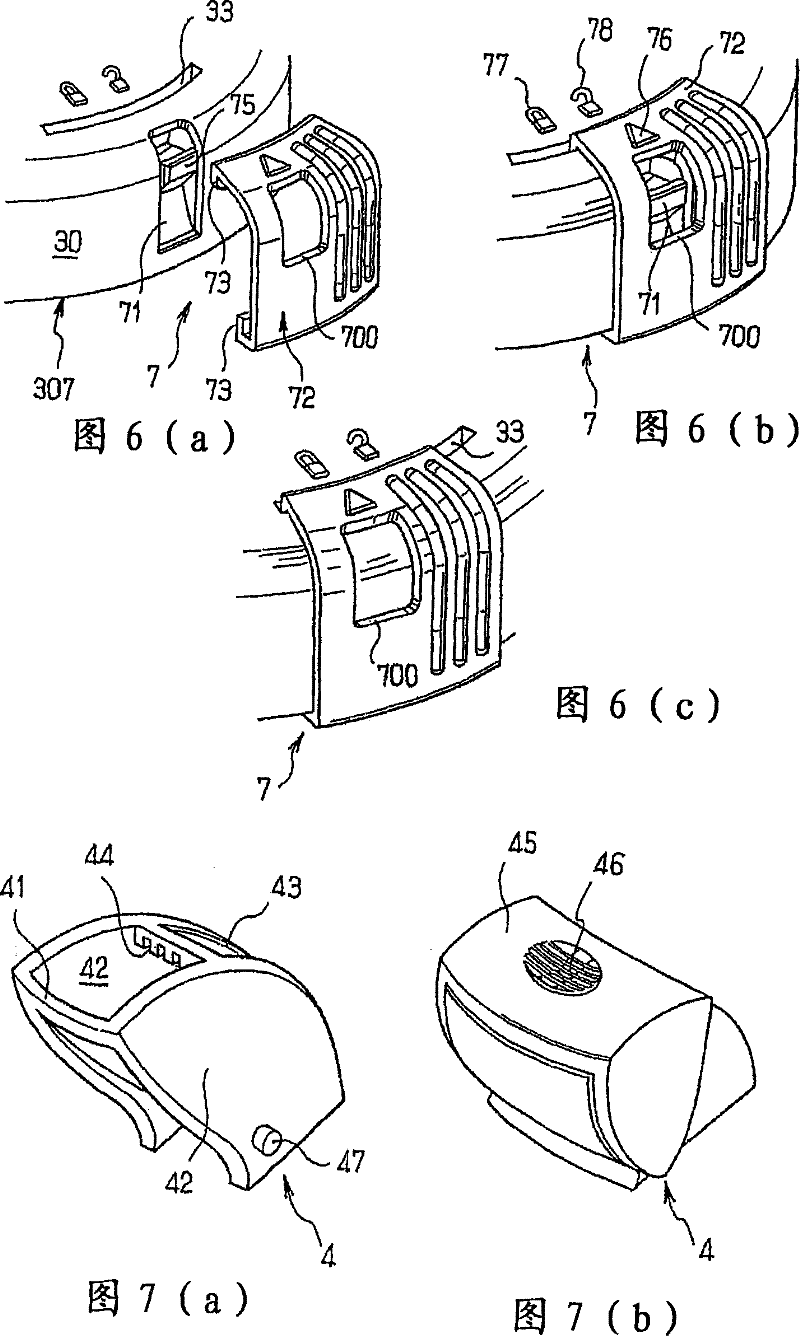

Multipurpose lid in particular for liquids, particularly for paint can

InactiveCN101312892AExtended shelf lifeReduce wasteClosuresRotary stirring mixersEngineeringMechanical engineering

The invention concerns a lid (2) comprising a skirt (3) for covering the opening of a can (1), in particular a paint can. The invention is characterized in that the skirt (3) comprises a peripheral edge (30), at least one stud (71) formed in the edge (30) and elastically coupled to said edge (30), at least one lock (72) mounted sliding on said edge such that said lock may take up a locking position wherein said lock is adapted to retain said stud in a position for engaging the lid on the can.

Owner:蒂埃里·加西亚

Method for manufacturing special-shaped chip through laser cutting

InactiveCN102456625ASimple and efficient operationImprove processing efficiencySemiconductor/solid-state device manufacturingLaser beam welding apparatusImage sensorLaser cutting

The invention relates to a method for manufacturing a special-shaped chip through laser cutting, which is characterized in that: firstly, a semiconductor silicon wafer needed to be cut is positioned through the match of a computer system and a charge coupled device image sensor; secondly, laser beams are adopted to be vertically irradiated on the surface of the semiconductor silicon wafer; thirdly, a workbench for load bearing the semiconductor silicon wafer is moved so as to be moved relatively to the laser beams; and finally, the laser beams are used for cutting the semiconductor silicon wafer in a melting and vaporizating manner according to set parameters so as to obtain the special-shaped chip. Therefore, mechanical stress cannot be generated in the process, so that the semiconductor chip to be processed cannot be damaged, and the semiconductor chip can be processed quickly, high-efficiently, simply and conveniently.

Owner:SUZHOU TIANHONG LASER

Laser wire stripping device

InactiveCN101599623ANo deformationIncrease productivityLine/current collector detailsApparatus for removing/armouring cablesCoaxial cableElectrical conductor

The invention provides a laser wire stripping device, comprising a rack, a working platform, a laser generation chamber, laser heads, a movement mechanism and a control mechanism; wherein, the laser generated by the laser generation chamber is transmitted to the laser heads by a reflection mirror group to realize laser light path transmission; the movement mechanism controls the laser heads to realize wire stripping; the laser heads are symmetrically arranged with one at an upper position and the other at a lower position by taking the working platform as a symmetrical surface; the movement mechanism comprises a Y axis movement part for realizing forward and back motion, an X axis for realizing side-to-side motion and an upper and lower laser switching mechanism for realizing up-and-down motion; the device of the invention has the advantages of high working efficiency and low equipment cost, in addition, the device can well strip coaxial cable metallic shield layers and aluminium foil shield layers, does not cause shield layer deformation, does not damage insulating layers and conductors, features high yield and the like.

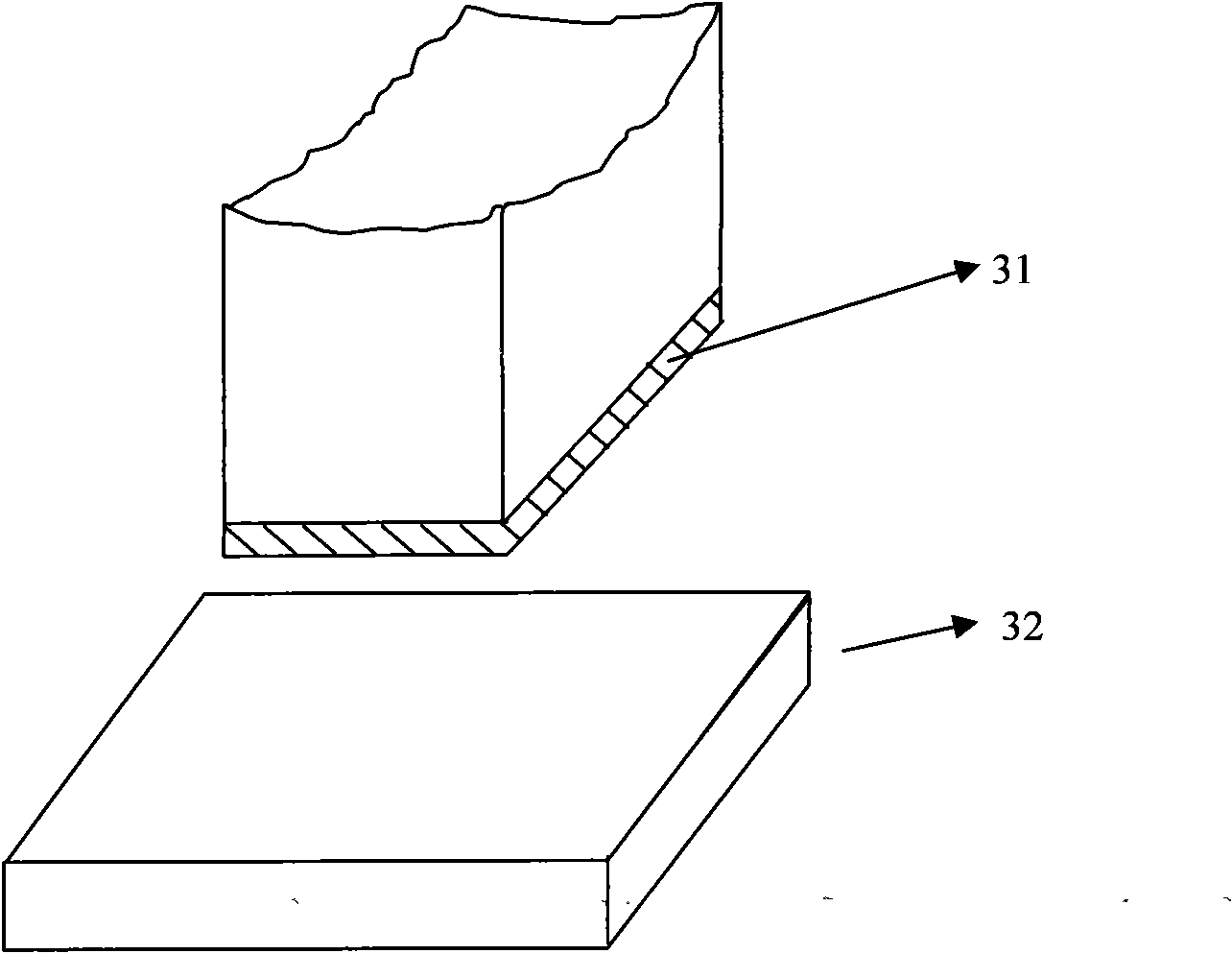

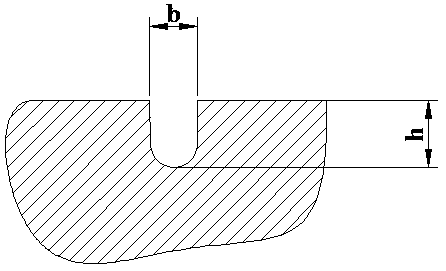

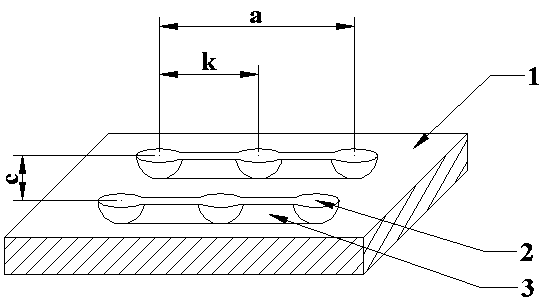

Combined microstructure guide rail and manufacturing method thereof

PendingCN108098364AAvoid crawlingImprove wear resistanceLarge fixed membersWear resistanceMachine tool

The invention discloses a combined microstructure guide rail and a manufacturing method thereof, and relates to the technical field of surface treatment of machine tool guide rails. The combined microstructure guide rail is characterized in that a combined microstructure is distributed on the surface of the guide rail; the combined microstructure is in pit morphology and micro groove morphology; and the micro groove morphology is characterized in that micro grooves connected with single pits in the length direction of the guide rail are processed in micro pit morphology arrays. According to the combined microstructure guide rail, the crawling phenomenon of the guide rail is solved, lubricating performance is improved, abrasion resistance is improved, the service life of the guide rail canbe effectively prolonged, and comprehensive performance is improved.

Owner:NANTONG UNIVERSITY +1

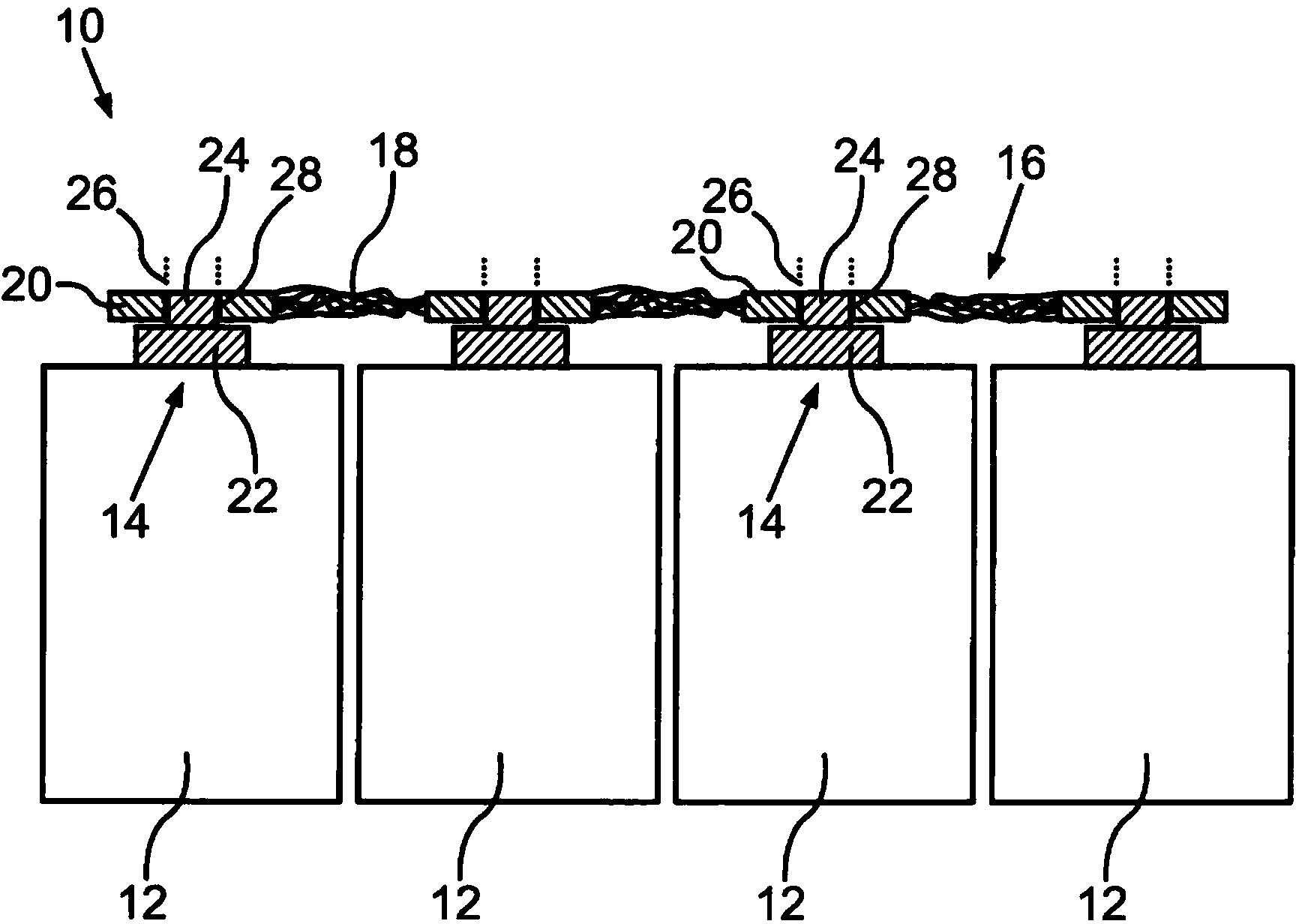

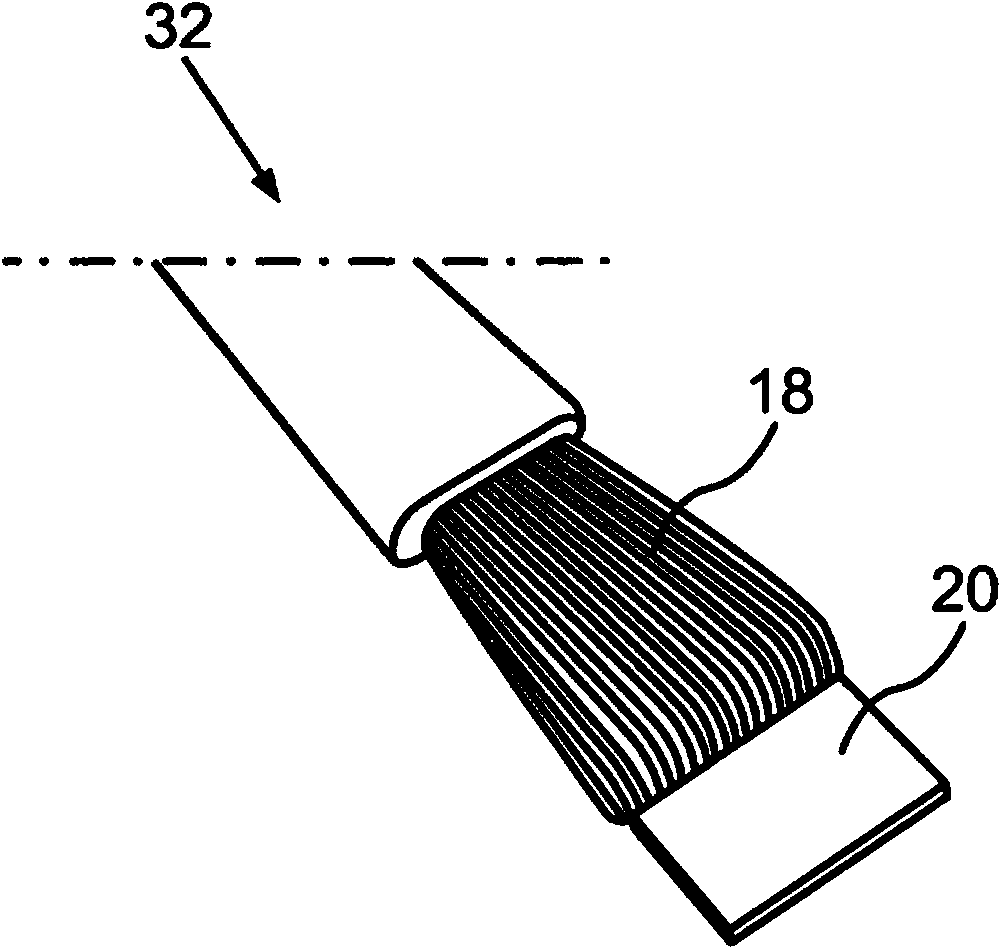

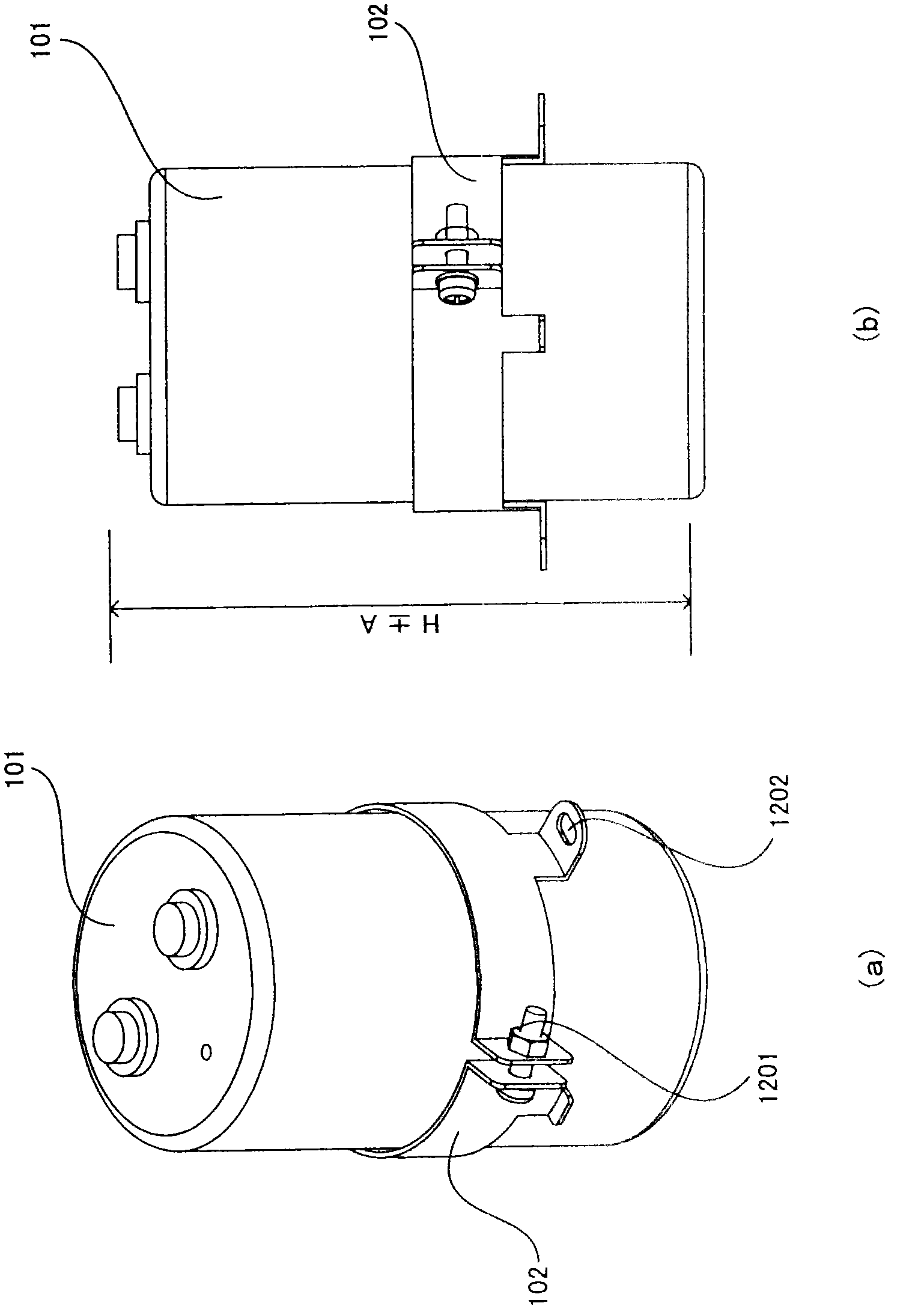

Battery having a connecting element comprising multiple individual wires

ActiveCN104145352ASafe and reliable connectionProcess safetyLine/current collector detailsFinal product manufactureEngineeringBattery cell

The invention relates to a battery (10), in particular for a vehicle, having at least two battery cells (12) and having at least one connecting element (16) that connects at least one electrical terminal (14) of a first battery cell (12) to an electrical terminal (14) of at least one further battery cell (12). The connecting element (16) comprises a plurality of individual wires (18) that are compacted in a respective connecting area (20). The connecting element (16) is in contact with the respective electrical terminal (14) of the battery cell (12) in the respective connecting area (20) of said connecting element. The invention further relates to a method for making such a battery (10).

Owner:AUDI AG

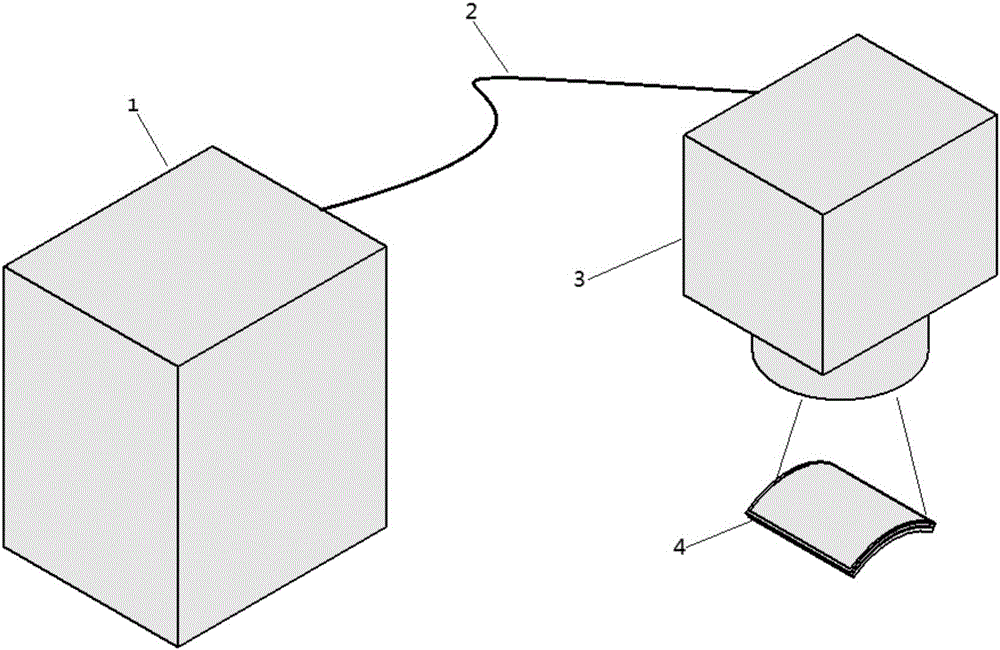

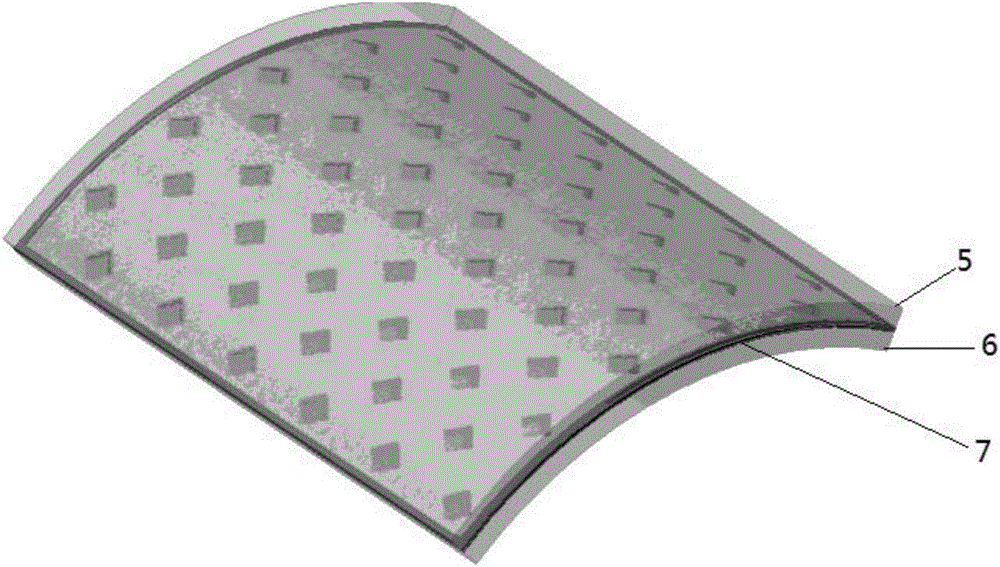

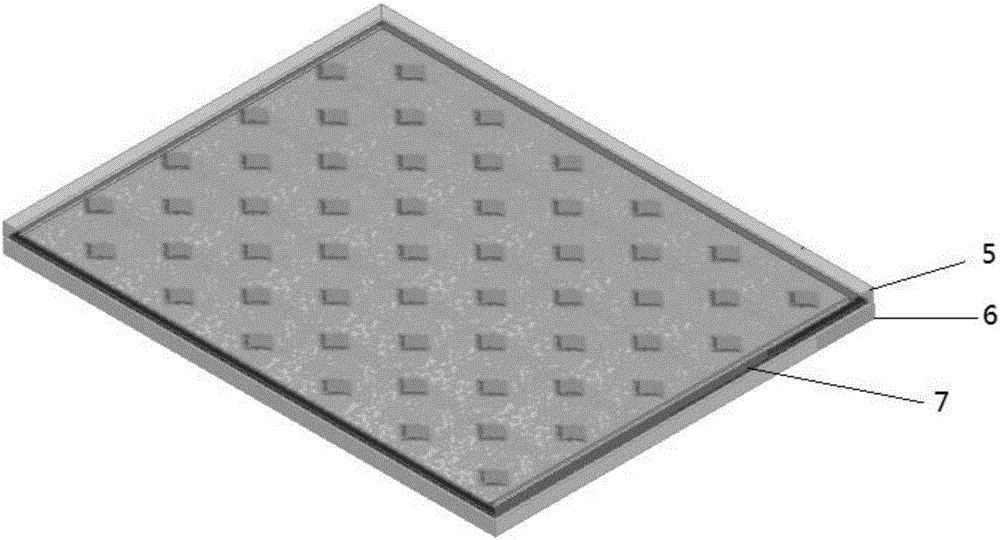

Method and device for packaging flexible OLED screens through laser welding

The invention provides a method and device for packaging flexible OLED screens through laser welding. The method comprises the steps that laser beams emitted by a laser device are transmitted to a 3D dynamic focusing vibration lens, and through high-speed scanning of the 3D dynamic focusing vibration lens, the laser beams penetrate through upper layer light-transmitting materials of the flexible OLED screens and reach lower layer light absorbing materials of the flexible OLED screens; and through a set packaging track, contact faces of upper layer packaging materials and lower layer packaging materials of the flexible OLED screens are fused. The process is simple, the consistency is good, and automatic production can be achieved easily.

Owner:HANS LASER TECH IND GRP CO LTD

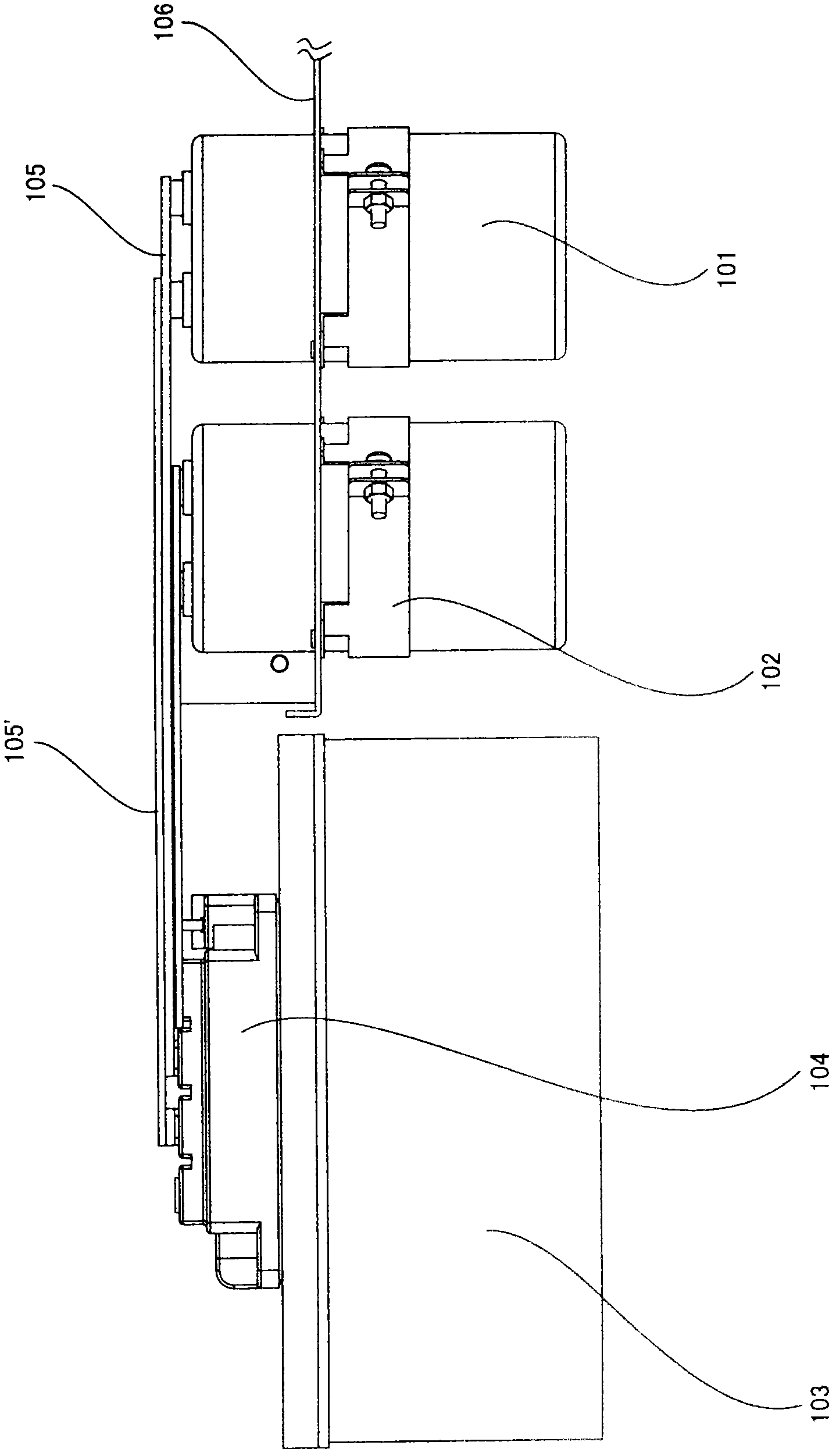

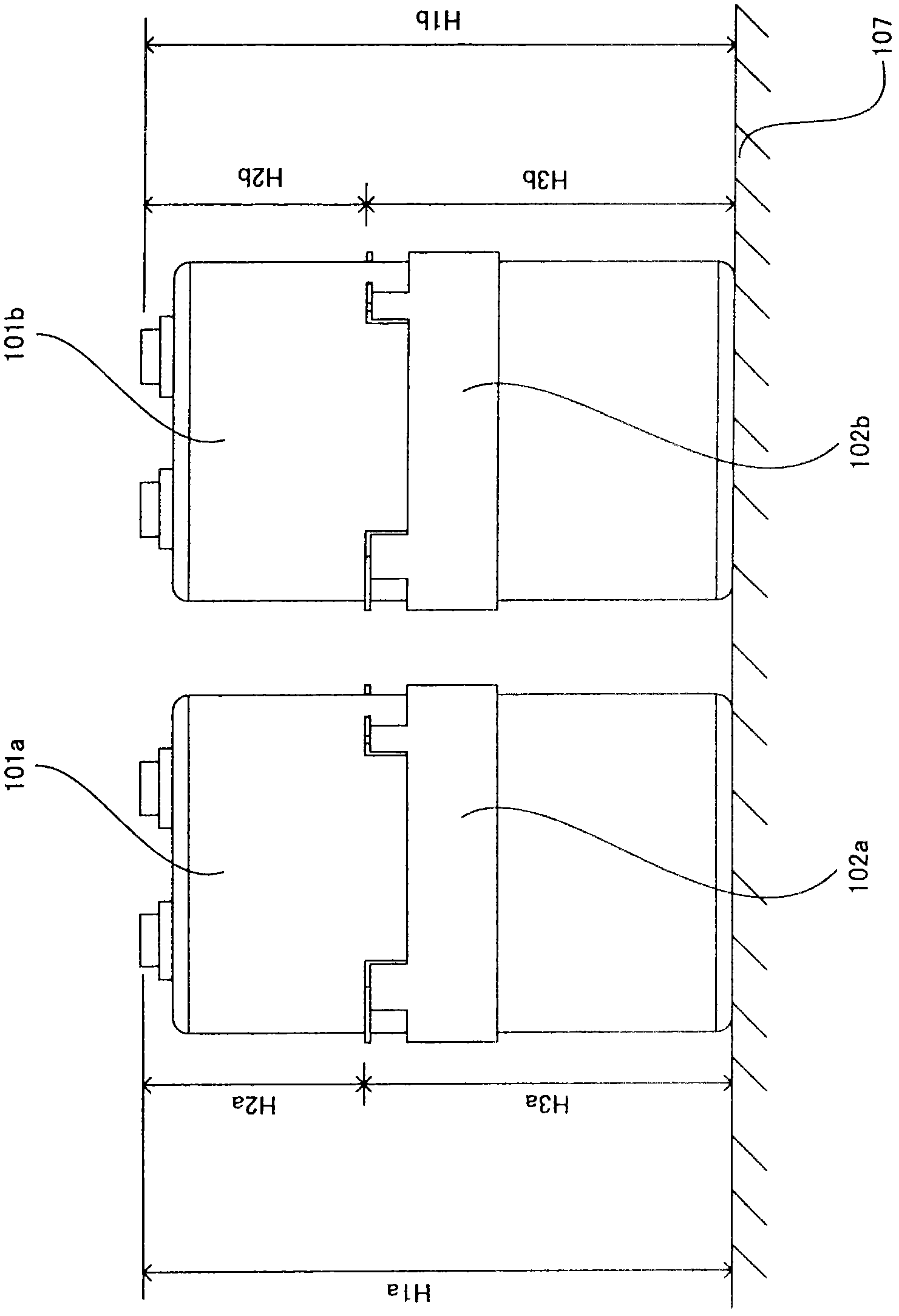

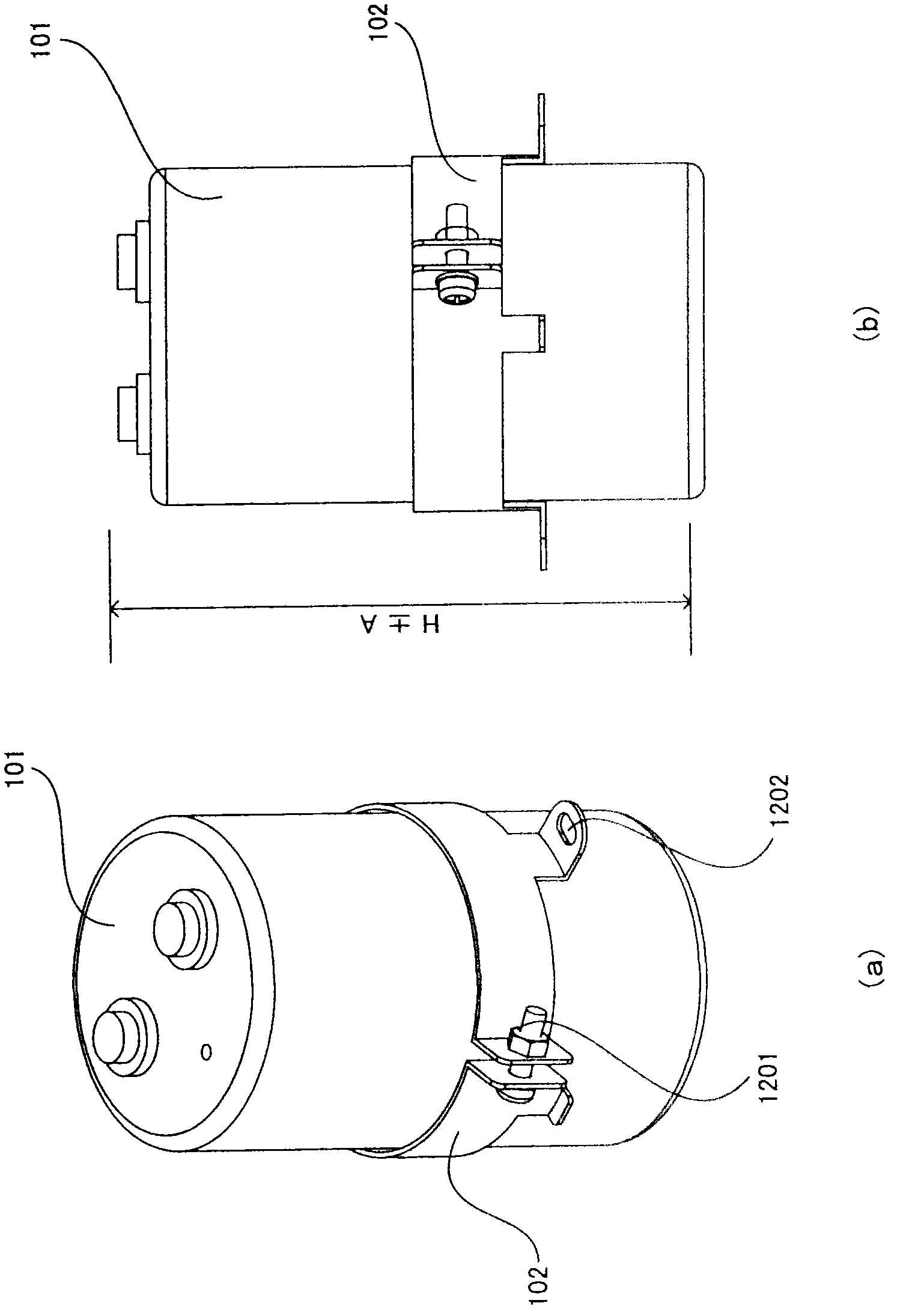

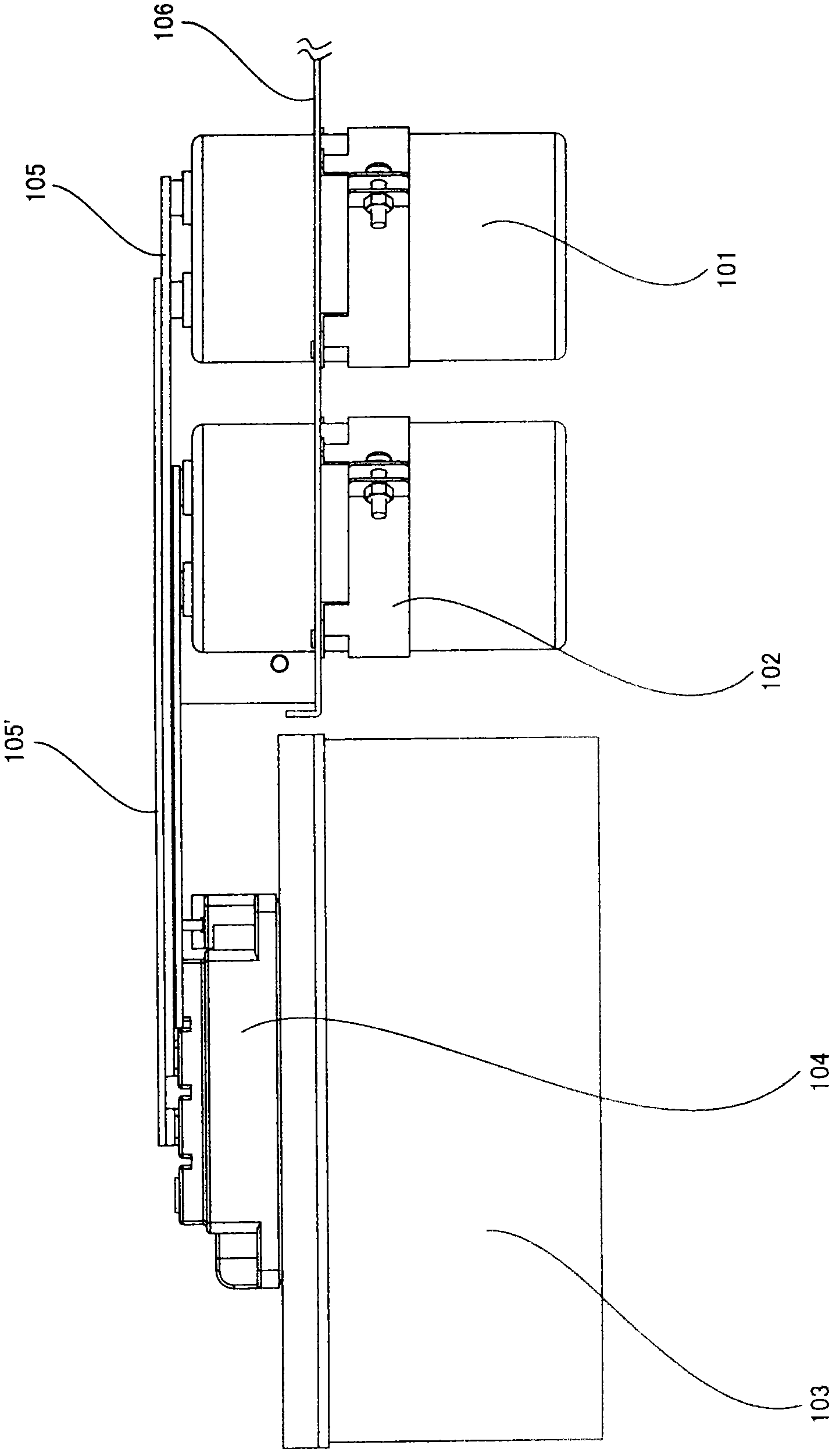

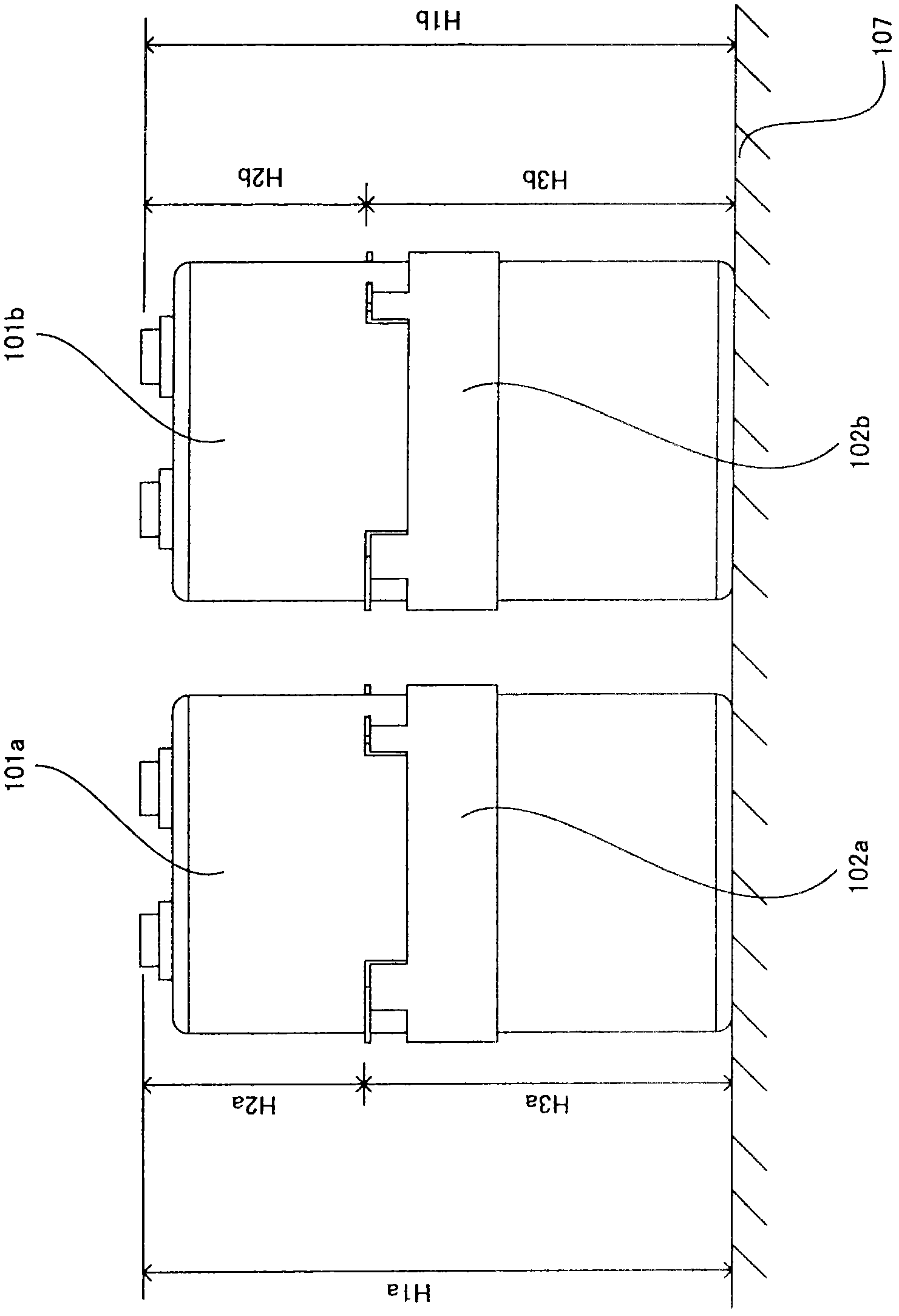

Capacitor installing stack structure and installing method of capacitor

The present invention provides a capacitor installing stack structure, wherein a capacitor installing platform is reversedly arranged on an operating platform, thus clamping parts arranged at left and right side of the capacitor installing platform can play a clamping function to ensure a specified size H2T defined by the clamping parts, then the capacitor is inserted into an installing hole of the capacitor installing platform which is reversedly arranged when in a reversal state, thus a distance H2C from the horizontal operating platform to a terminal arranged at an upper part of the capacitor can be set as the same with the specified size H2T defined by the clamping parts. Under the state, the capacitor can be fixed on the capacitor installing platform by using fixing parts.

Owner:FUJI ELECTRIC CO LTD

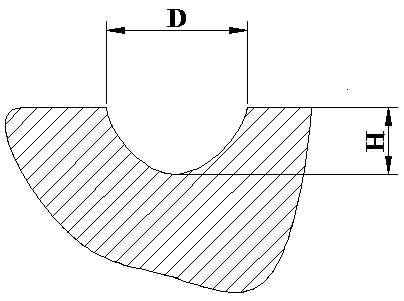

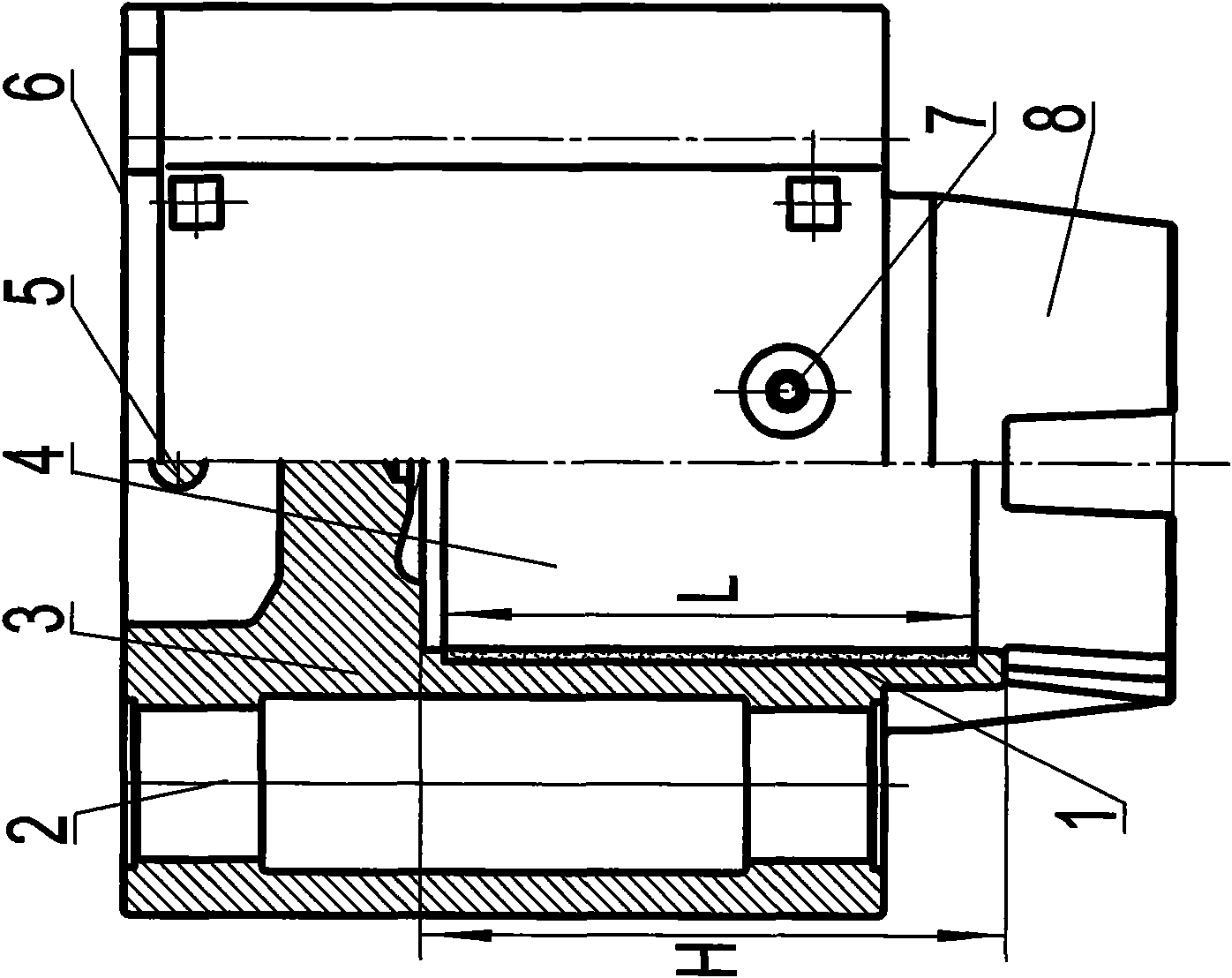

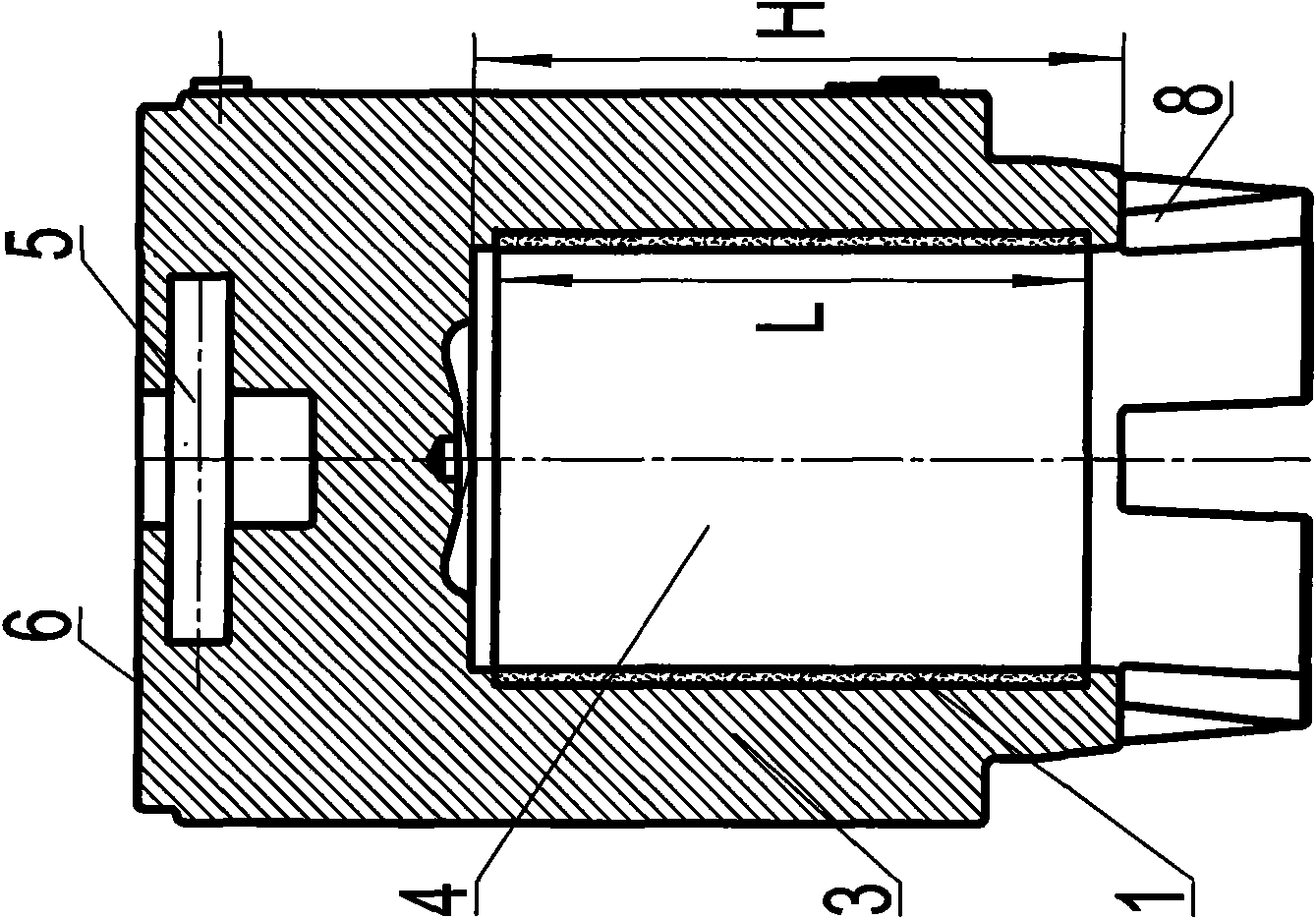

Wear-resistant cylinder hammer for guide rod type diesel pile driver and processing method thereof

InactiveCN101619577AHigh surface hardnessImprove surface wear resistanceBulkheads/pilesWear resistantEngineering

The invention discloses a wear-resistant cylinder hammer for a guide rod type diesel pile driver, which comprises a cylinder hammer body and a cylinder cavity, wherein the cylinder cavity is arranged on the cylinder hammer body; the cavity wall of the cylinder cavity is provided with a hardening layer; and the ratio of the width L of the hardening layer to the hole depth H of the cylinder cavity (4) is that L / H is between 0.8 and 1.0. To obtain the wear-resistant cylinder hammer, a processing method at least comprises the steps of: a, performing casting forming, in which a formed cylinder hammer blank with a blank hole of the cylinder cavity is cast; b, processing a cavity hole of the cylinder cavity, namely processing the cavity hole of the cylinder cavity on the formed cylinder hammer blank by a turning or / and boring processing method; c, grinding the cavity wall of the cylinder cavity, namely performing grinding processing on the cavity wall of the cylinder cavity; and d, performing surface quenching on the cavity wall of the cylinder cavity. The wear-resistant cylinder hammer has the highly hard and wear-resistant cavity wall of the cylinder cavity, and has high blow efficiency and long service life. The processing method has a reasonable process and convenient implementation.

Owner:束为林

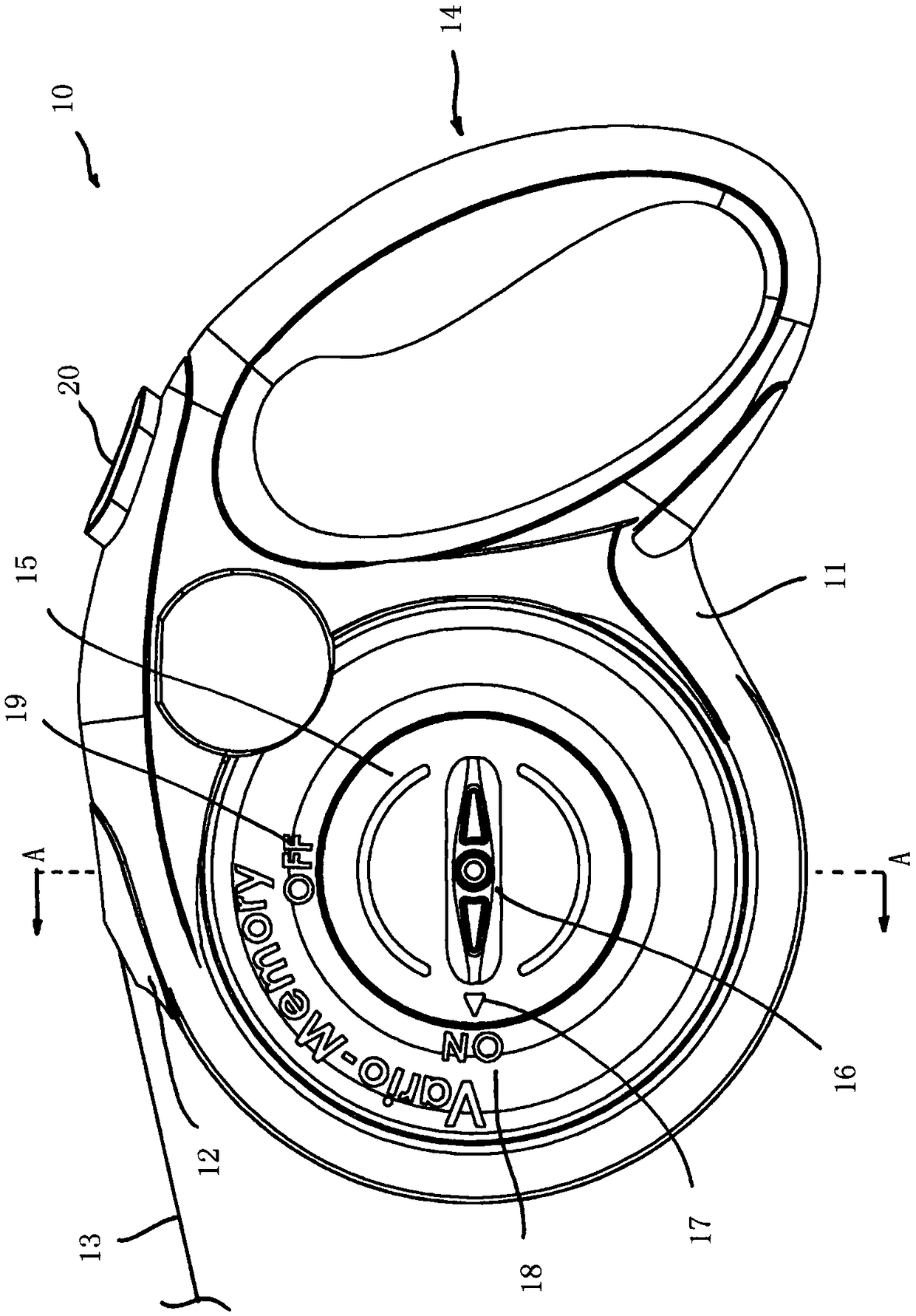

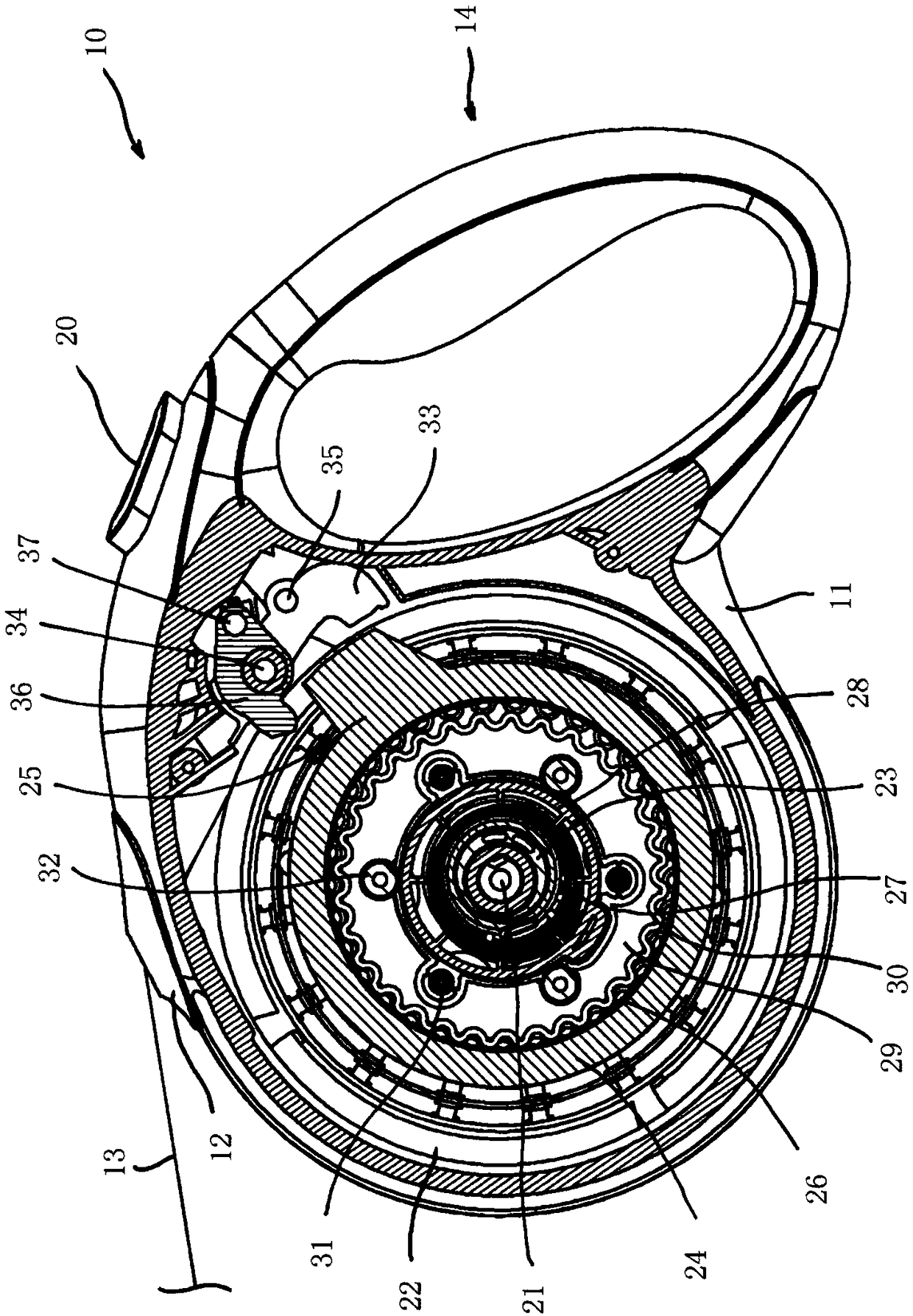

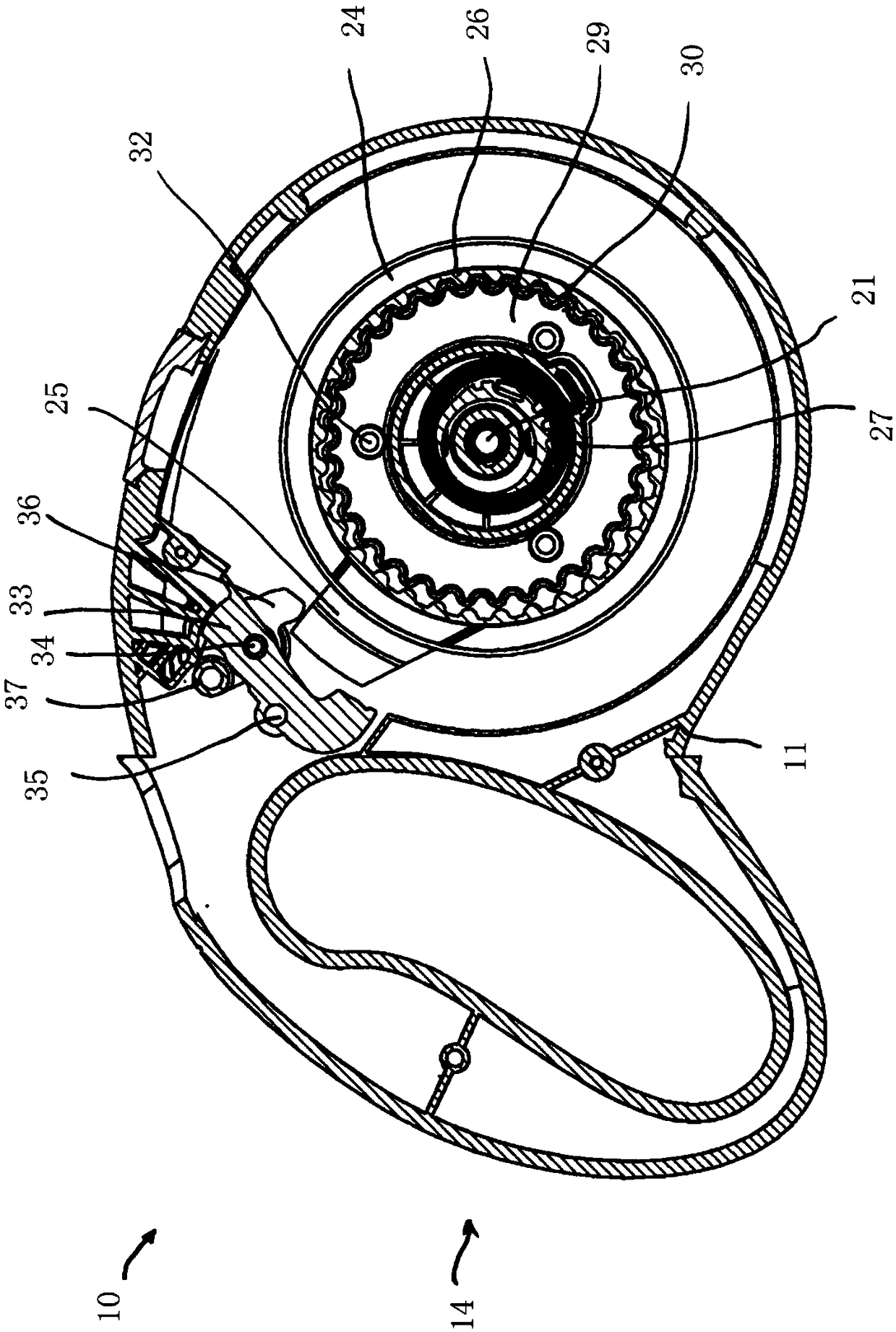

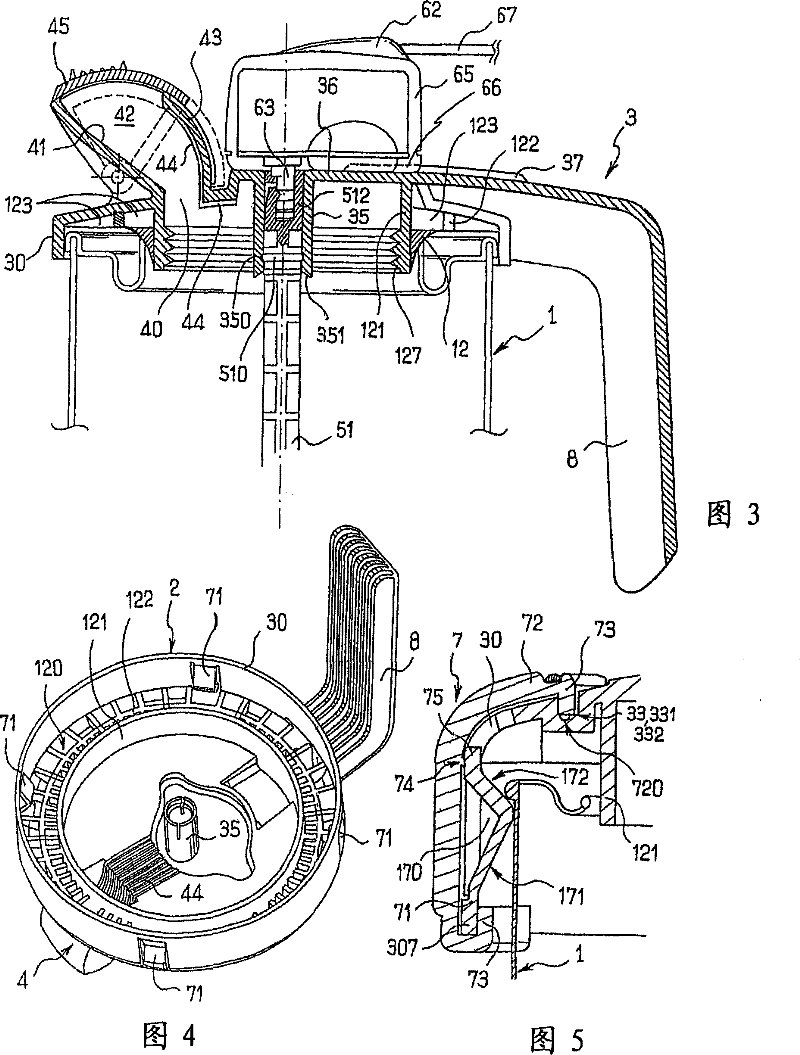

Rolling device for rolling and unrolling leash

InactiveCN108782308ASafe operation and low wearGood force fitTaming and training devicesElectrical and Electronics engineering

Owner:FLEXI BOGDAHN TECHN

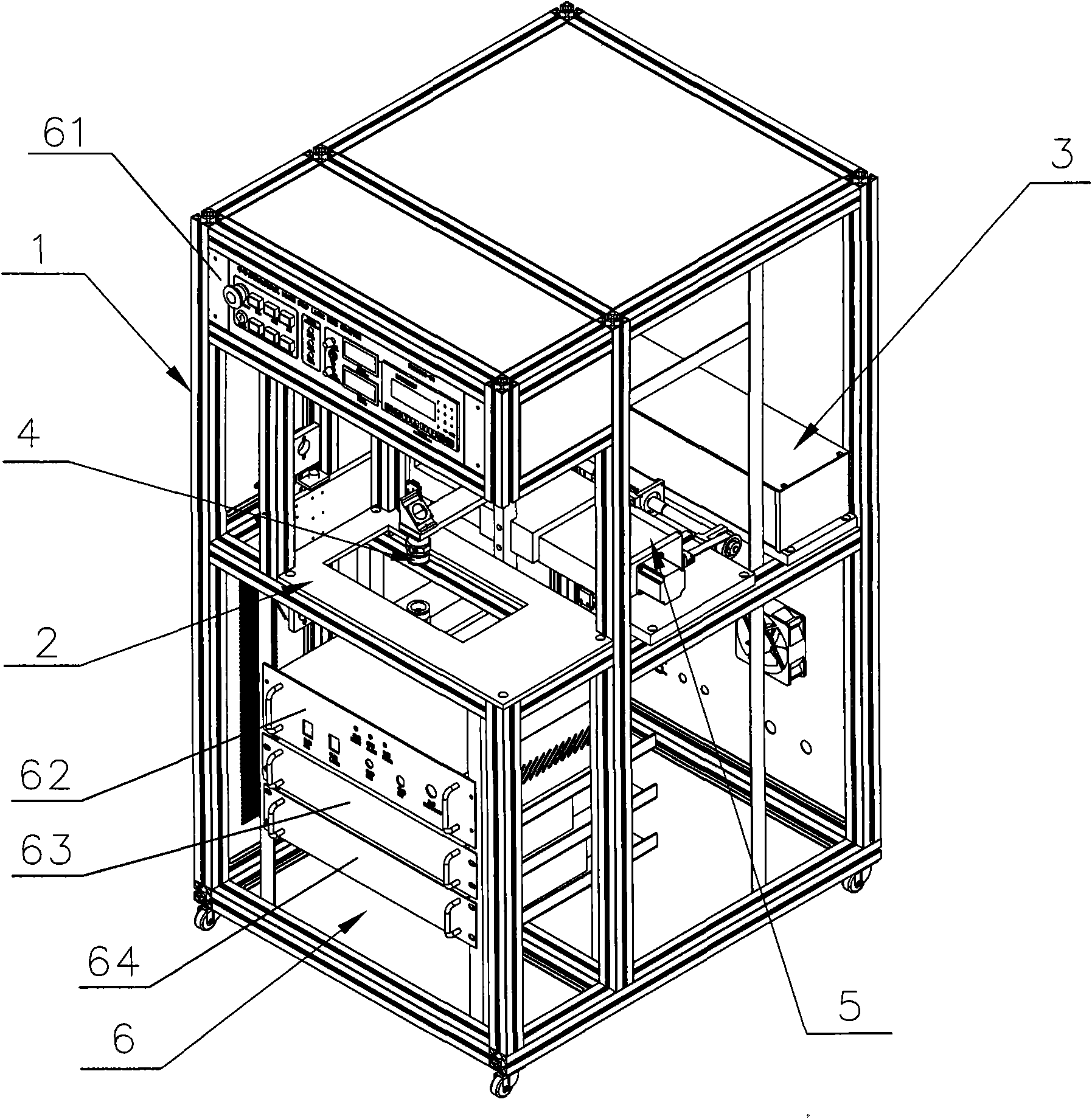

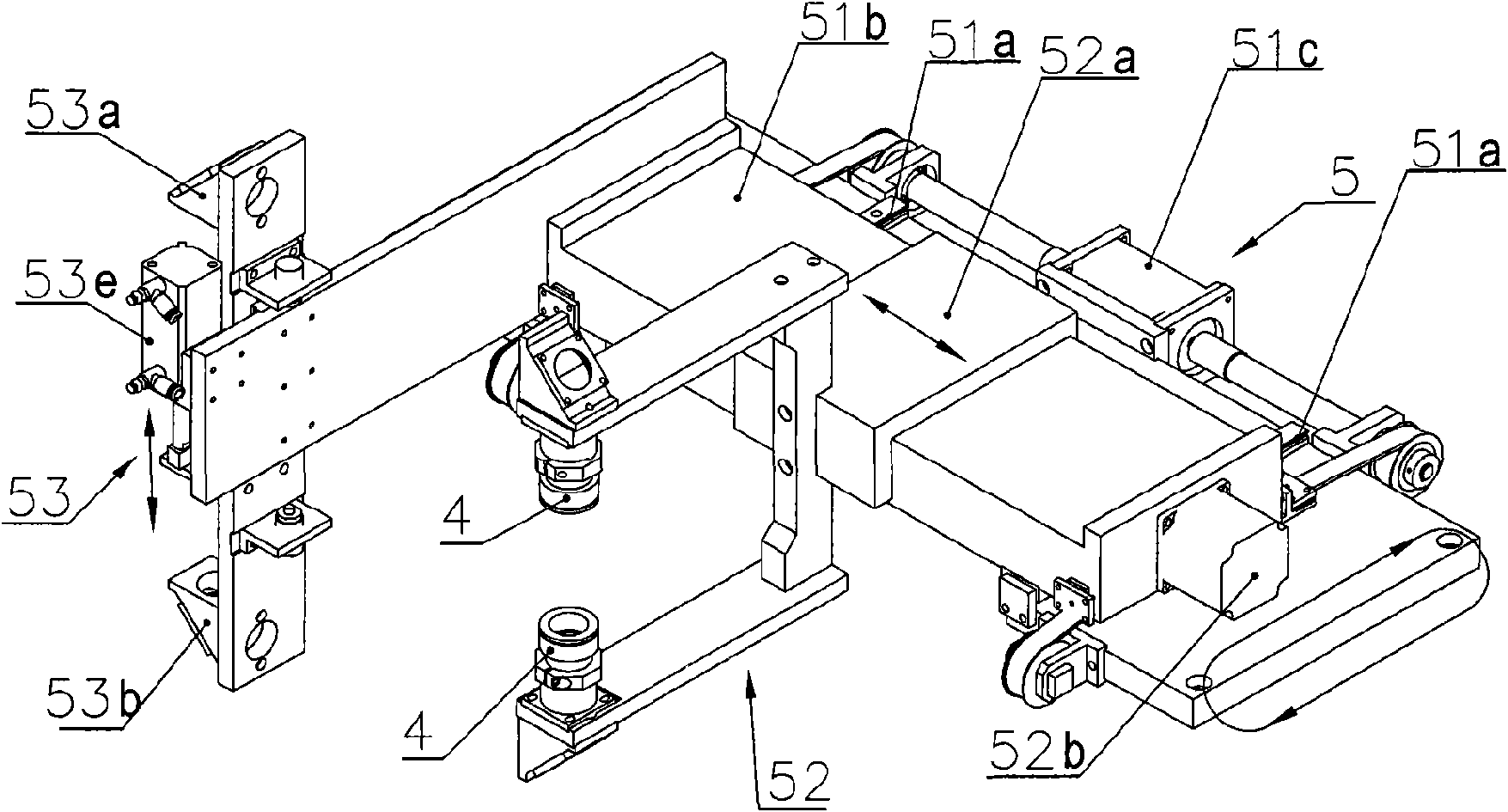

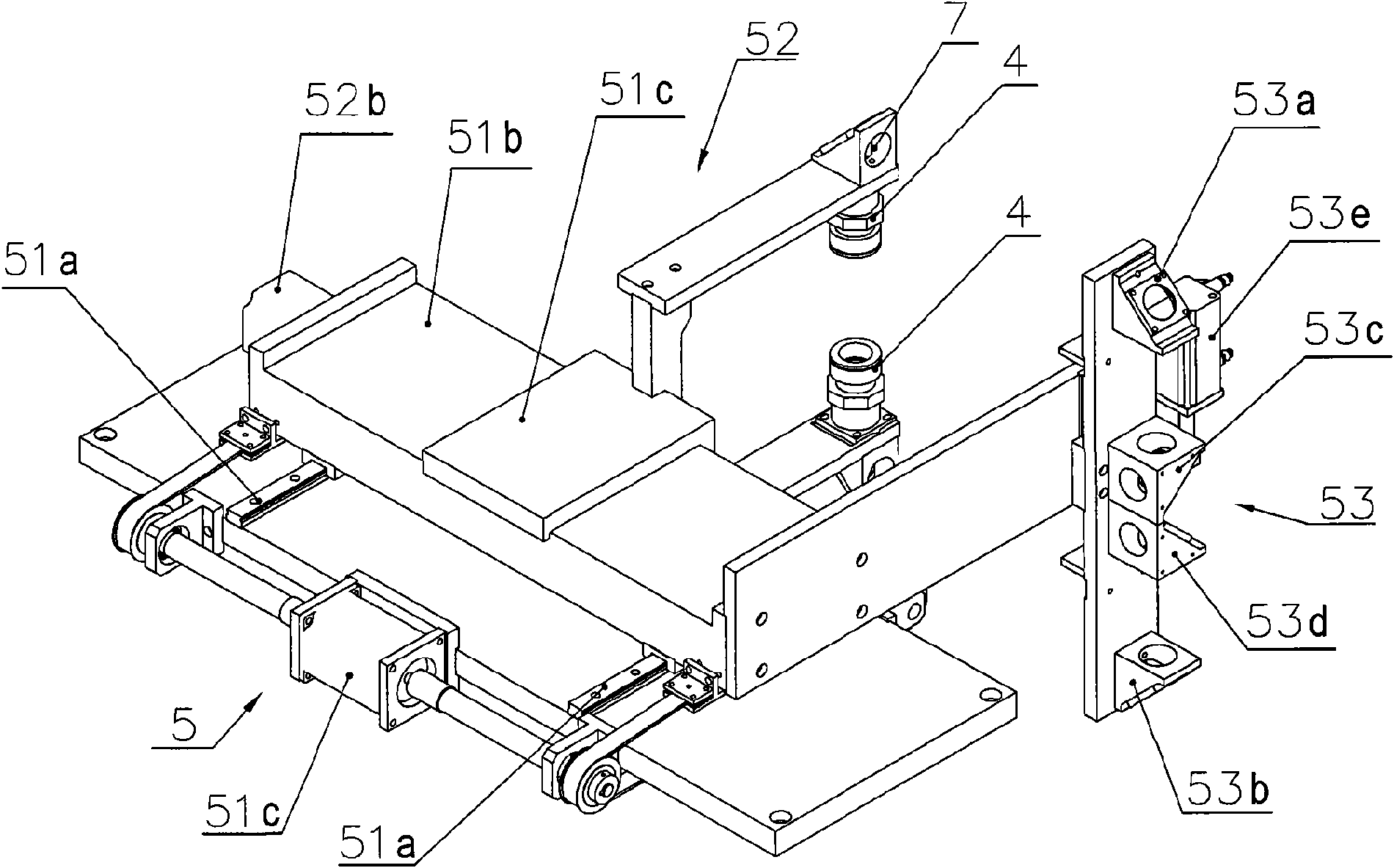

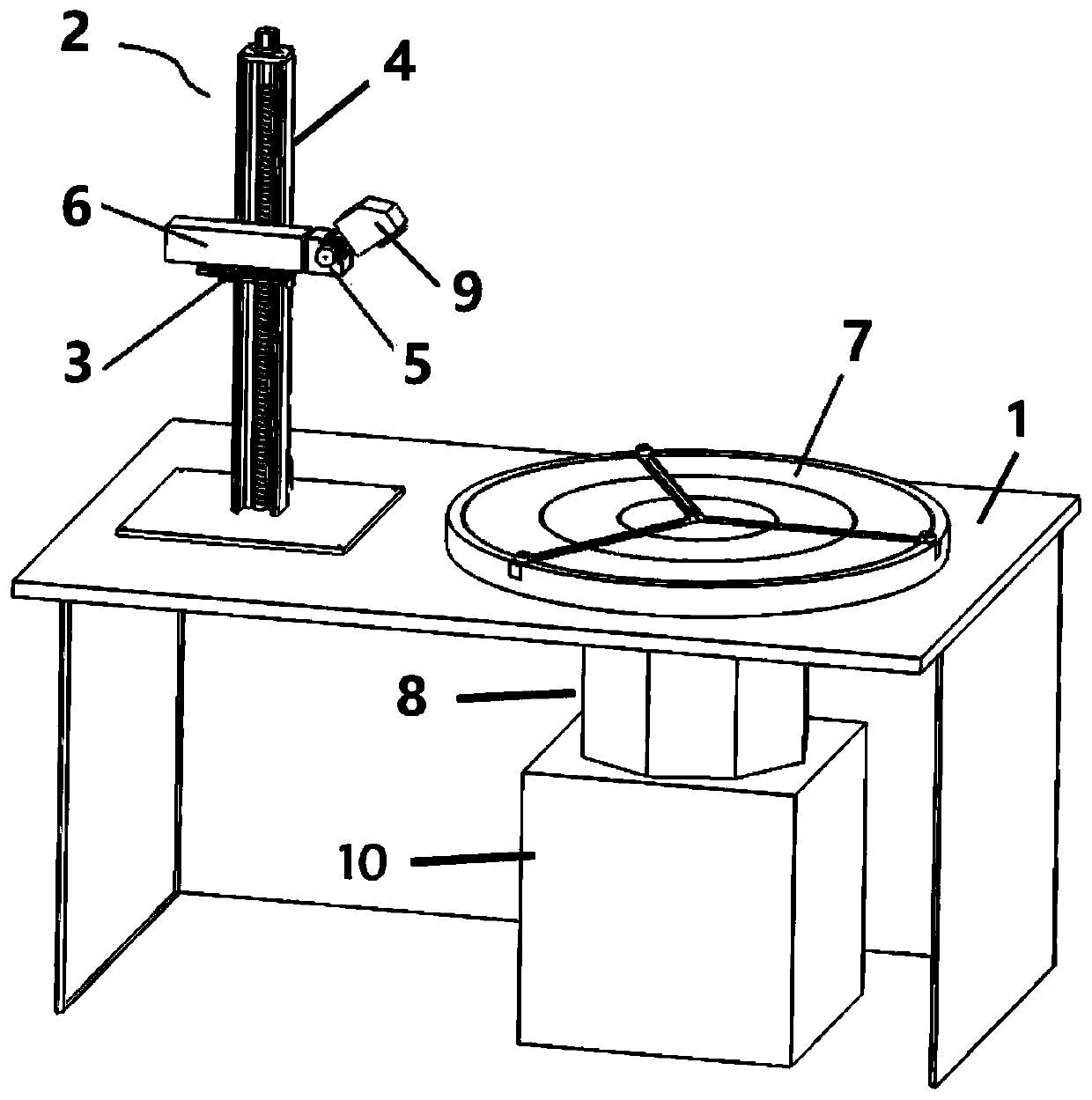

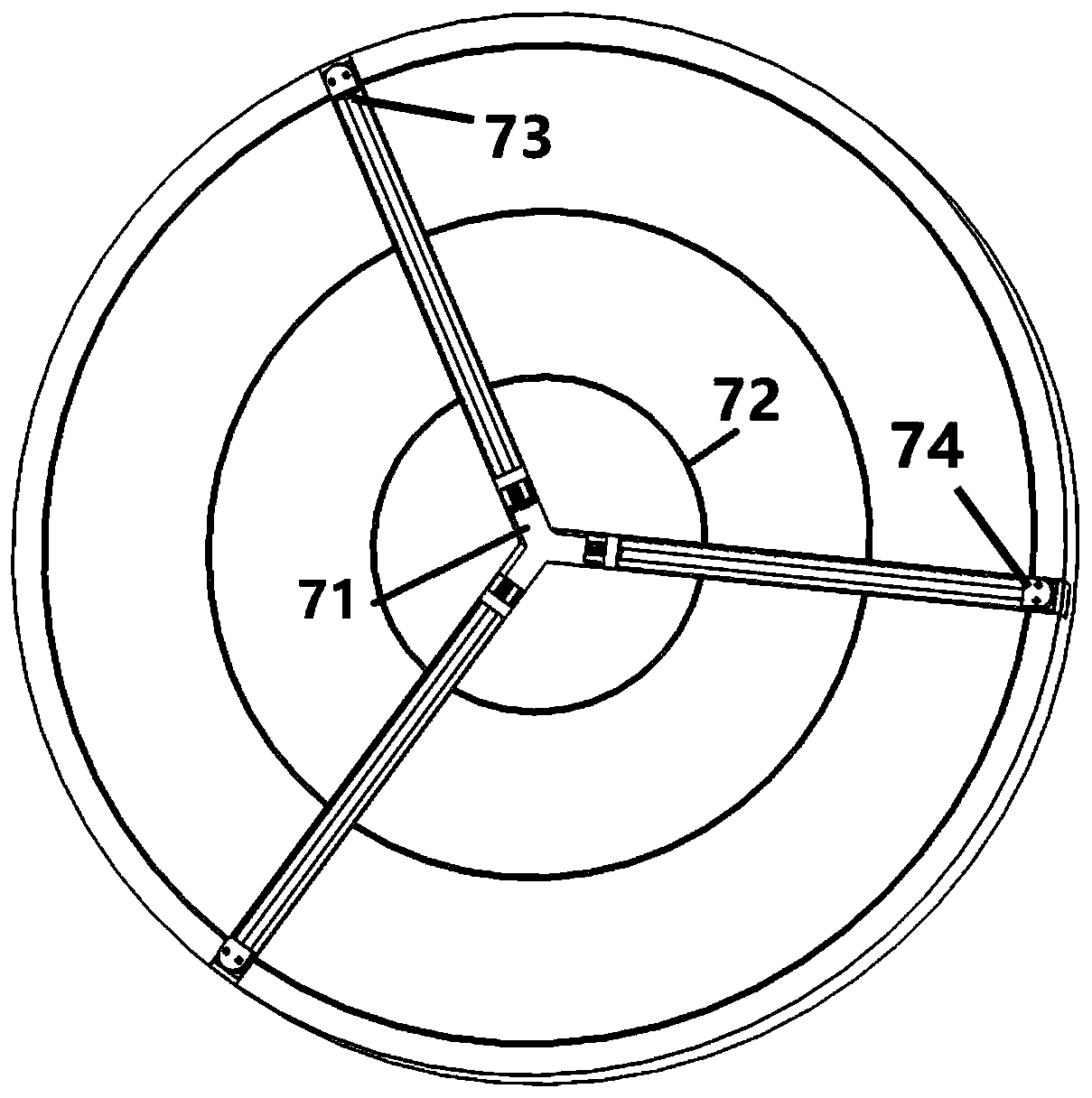

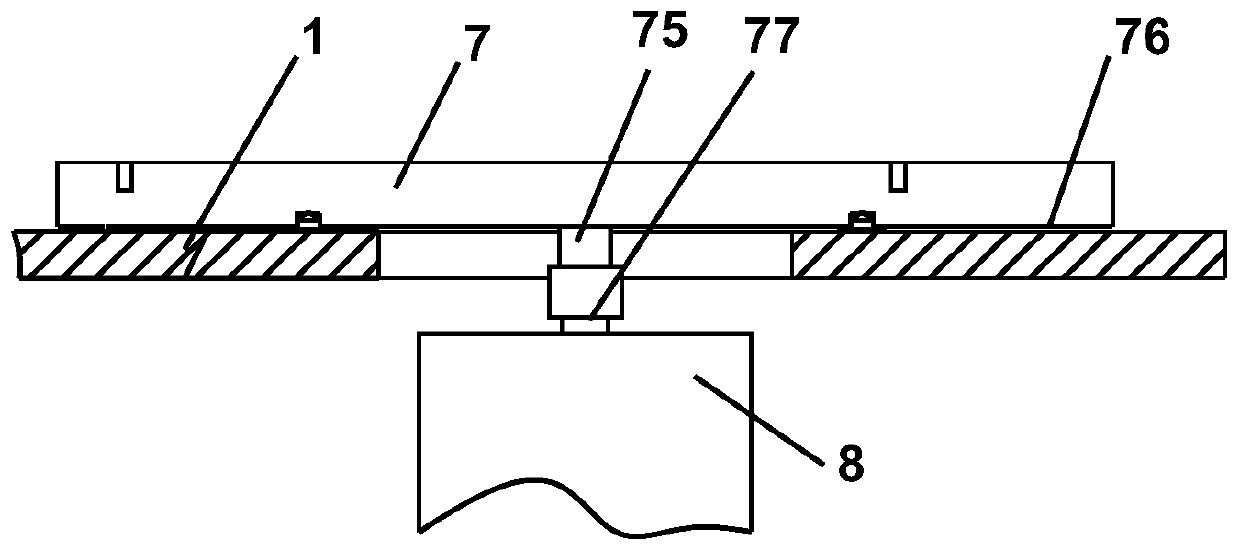

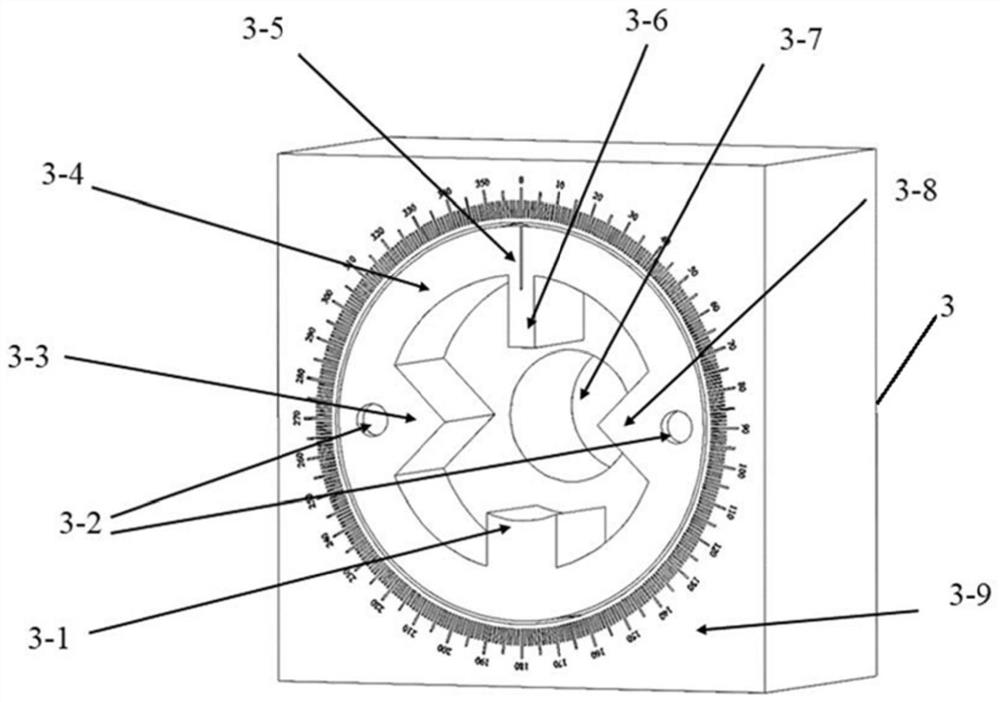

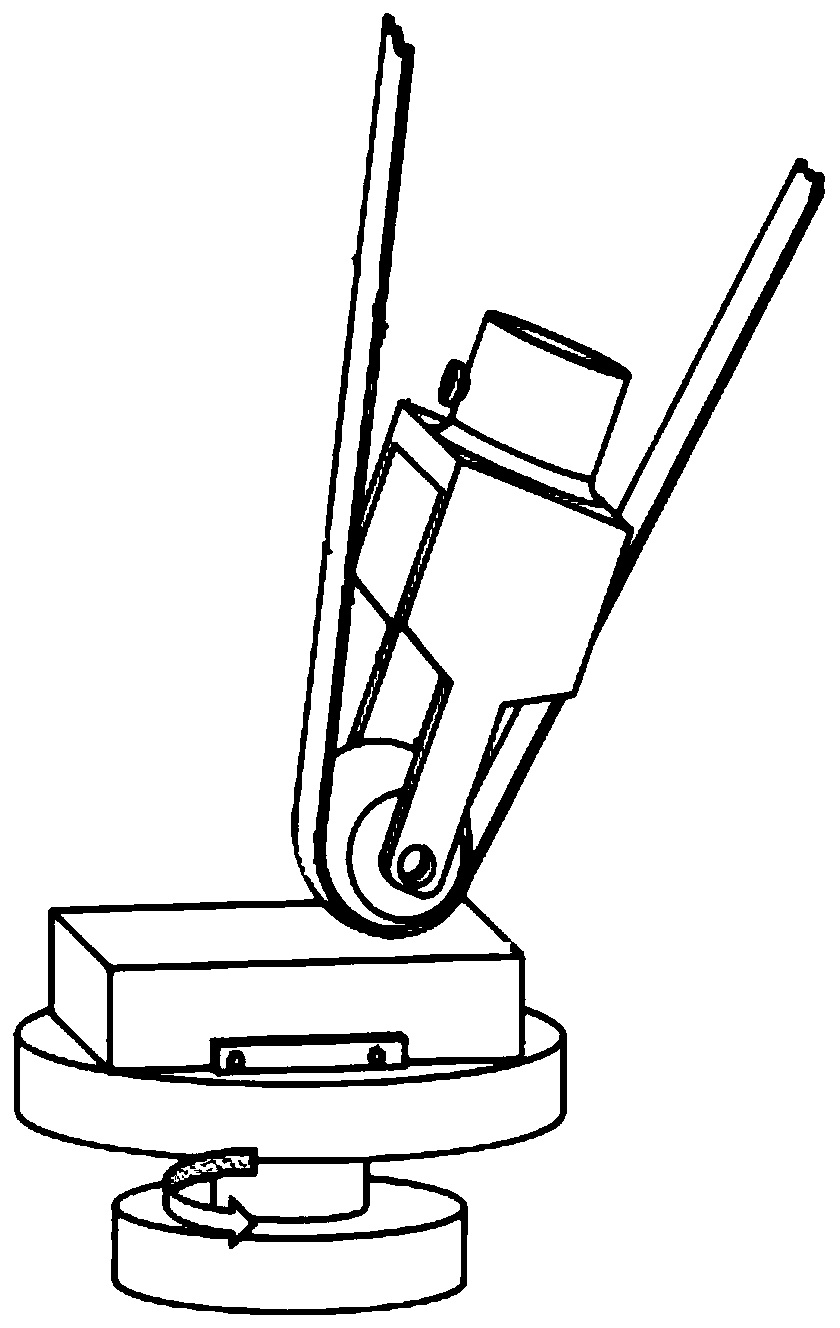

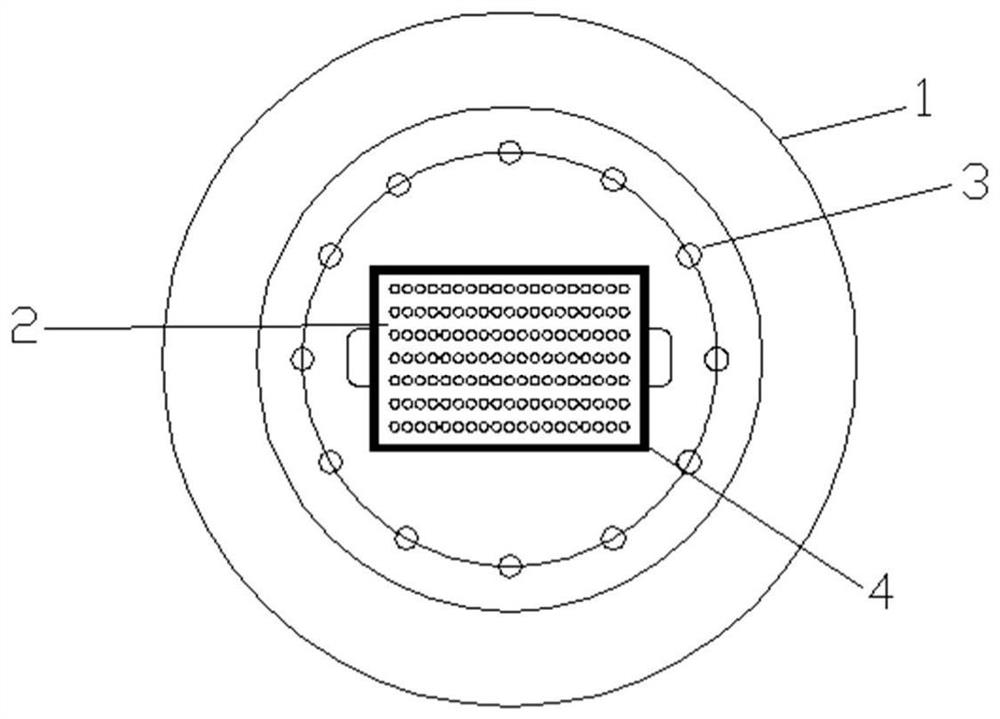

Laser processing platform for circular cylinder punching

PendingCN109877471AMeet the punching needsSmall light spotLaser beam welding apparatusCircular discPunching

The invention relates to a laser processing platform for circular cylinder punching. The laser processing platform comprises a working table. The working table is provided with a rotating platform anda laser bracket. The laser bracket comprises a lifting sliding table, a translation sliding table and a laser generator, the lifting sliding table is provided with the translation sliding table, andthe laser generator is disposed on the translation sliding table. The front end of the laser generator is fixedly connected with an angle adjustment joint, and a laser head is connected with the lasergenerator through the angle adjustment joint. The rotating platform is driven by the rotating platform motor on the lower part of the working table, and the rotating platform is a disc table. Three radial grooves and a plurality of annular grooves with the center of the disc as the center of the circle are uniformly distributed on the rotating platform. The three radial grooves are internally provided with rodless cylinders, and rubber blocks are disposed on sliding blocks of the rodless cylinders. The laser processing platform meets the punching requirements of large-sized cylindrical workpieces, the translation sliding table is arranged to realize the laser rapid focusing adjustment, the laser head for angle adjustment realizes processing of a vertical cylinder, a cone cylinder and a cylinder plane, and the rotating platform is arranged to realize rotary curved surface processing.

Owner:UNIV OF SCI & TECH LIAONING

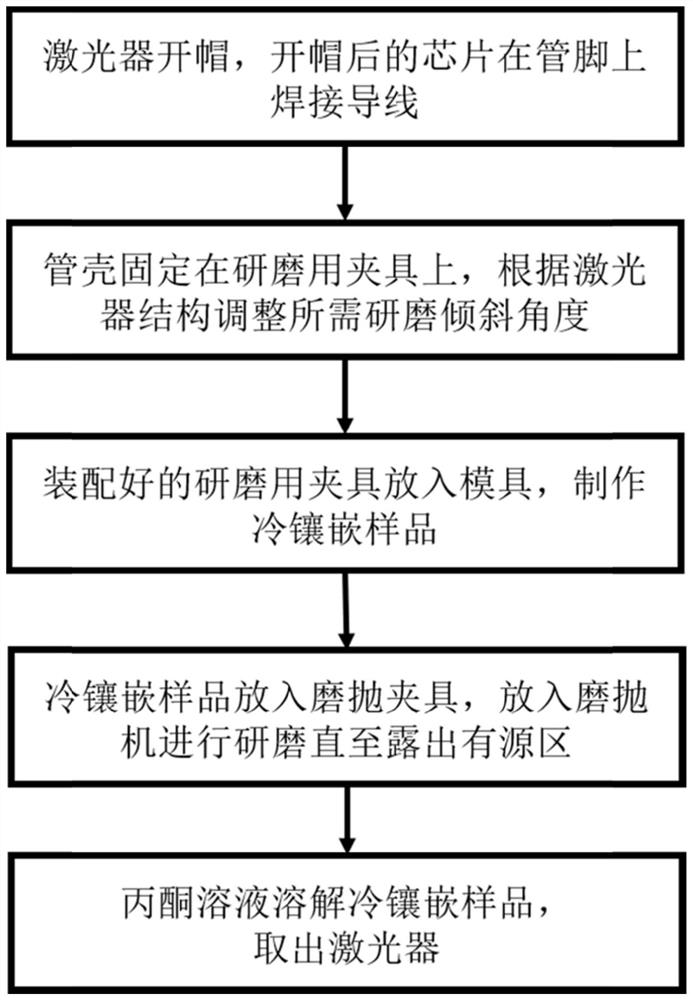

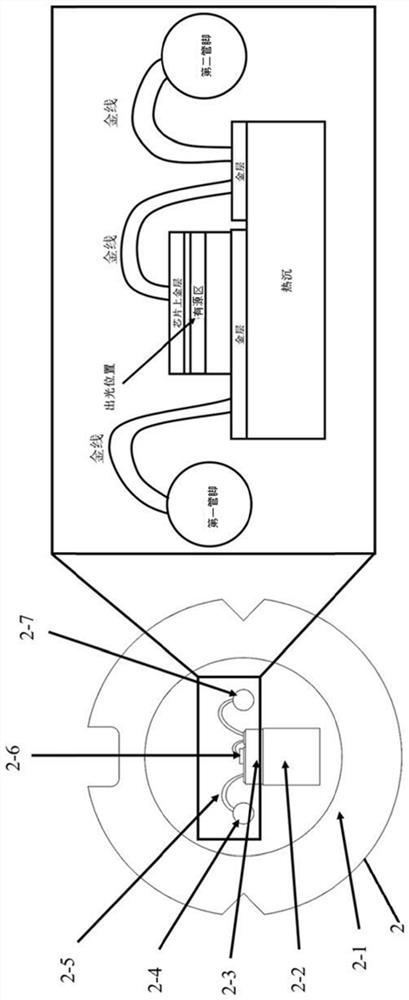

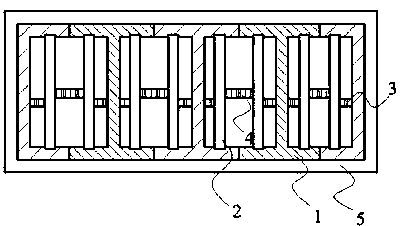

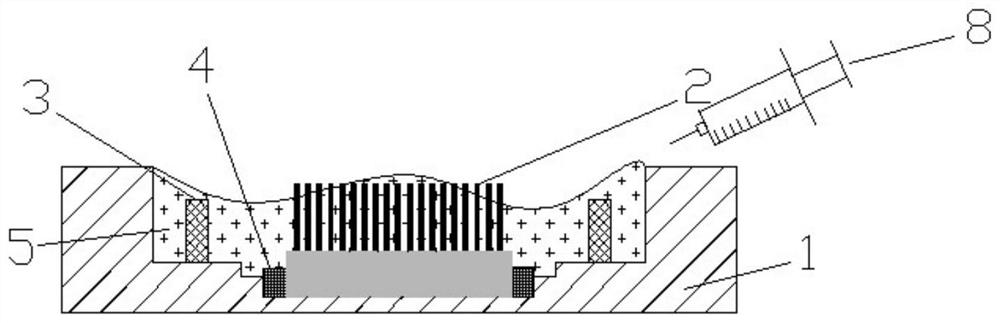

Intermediate fixture and method for semiconductor laser failure analysis sample preparation

ActiveCN113092225BReduce processing costsEasy to manufactureElectronic circuit testingPreparing sample for investigationPhotoluminescenceErbium lasers

The invention discloses an intermediate fixture and a method thereof for preparing semiconductor laser failure analysis samples. The intermediate fixture includes a first clamping part and a second clamping part; the first clamping part is used to clamp a TO laser, and holds a TO The first clamping part of the laser can obtain the cold mounting sample after injection molding, and the second clamping part is used to fix the cold mounting sample and control its grinding thickness; the first clamping part includes the first shell and the cylindrical block; the second The clamping part includes a second shell, an adjusting part and a pad; the pad can move up and down under the action of the adjusting part, and at the same time adjust the size of the part of the cold mounting sample exposed to the sample groove. The preparation process of the present invention has no high-temperature operation and effectively protects the chip; at the same time, no expensive micro-nano processing equipment is required, and the sample preparation process is simple and easy to operate; the prepared samples can be directly used for electroluminescence, photoluminescence and electron beam induced current failure analysis and defect detection.

Owner:ZHEJIANG UNIV

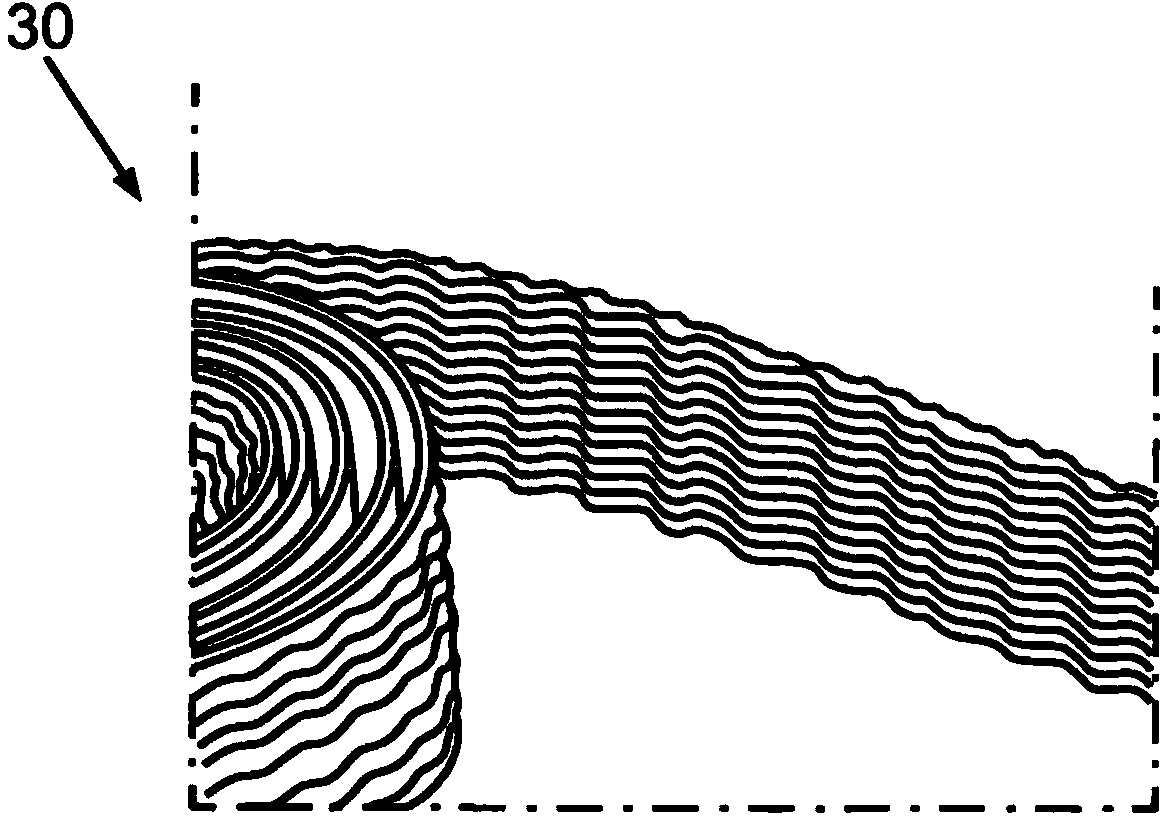

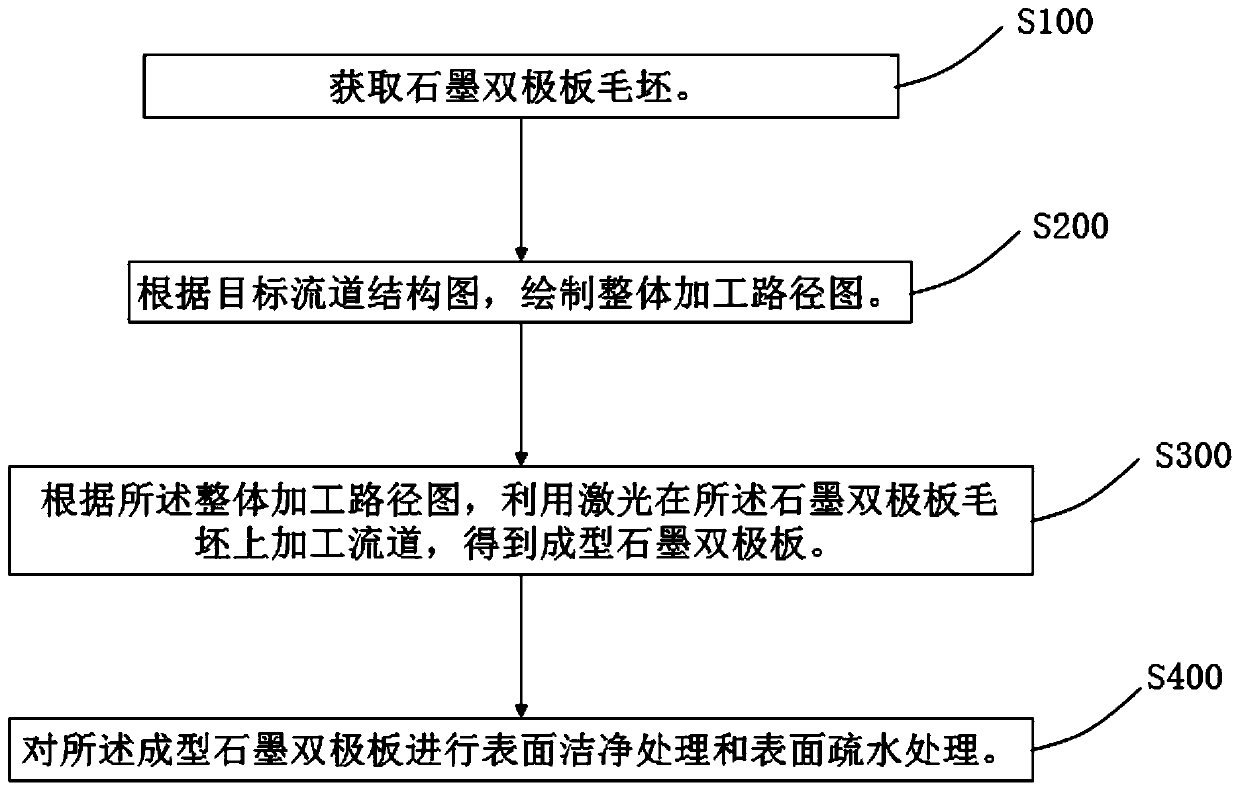

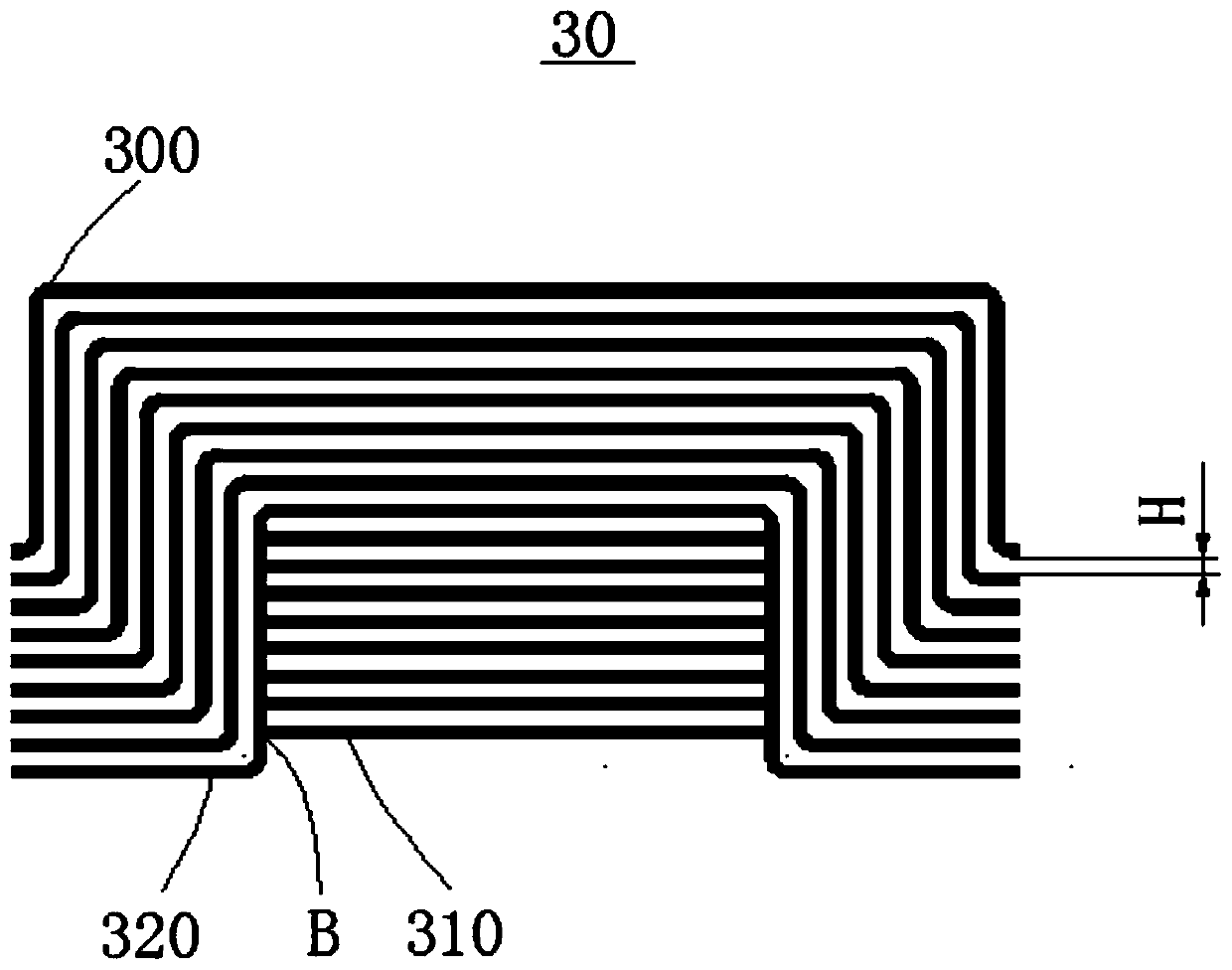

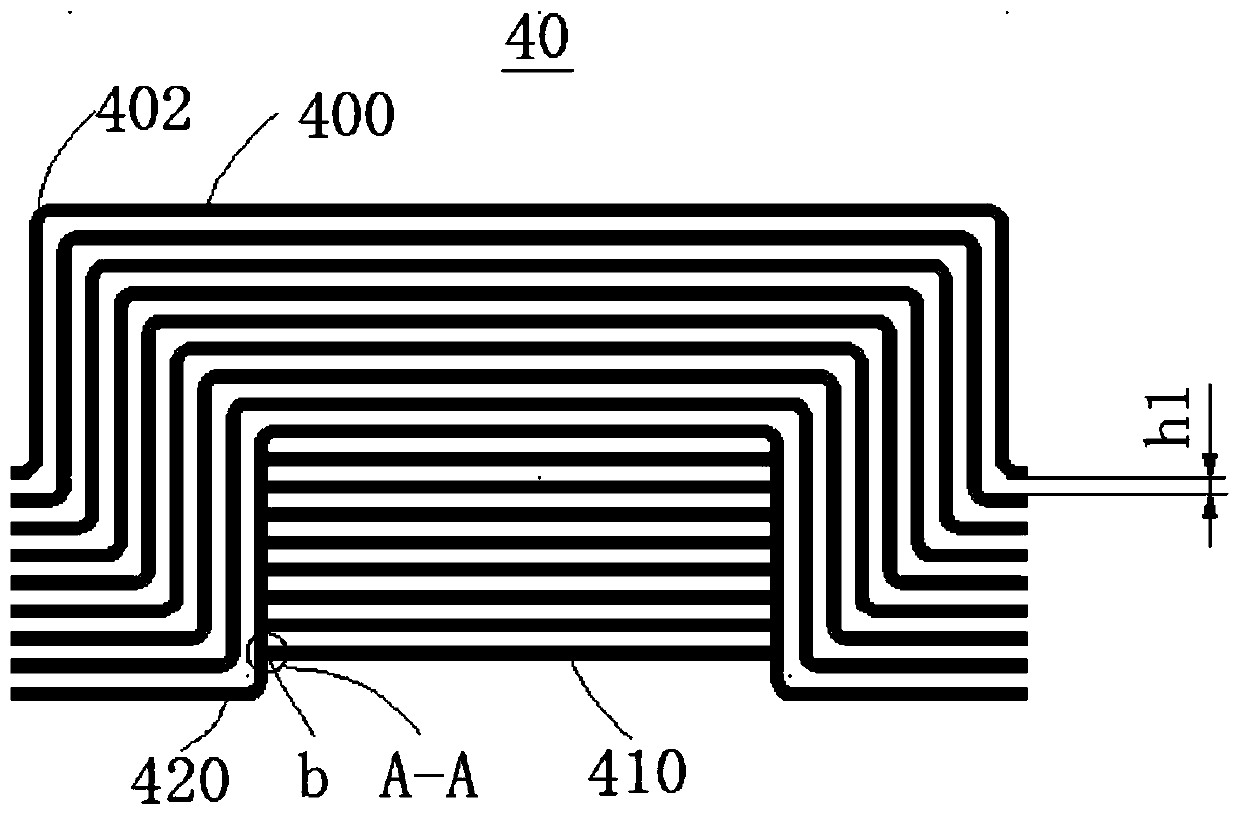

Machining method of fuel cell bipolar plate

The invention relates to a machining method of a fuel cell bipolar plate. According to the machining method, flow channels are processed on a graphite bipolar plate blank by utilizing laser accordingto a target flow channel structure chart, so that a formed graphite bipolar plate is obtained. The spot diameter of the laser in the method of the invention is micron-sized. According to the machiningmethod, the laser is used for machining the flow channels, so that no mechanical stress is generated in laser machining; the spot diameter is small, and therefore the laser can machine the flow channels with narrower ridge width which are arranged more densely; and the ultra-dense flow channels are beneficial to the diffusion of reaction gas and the improvement of the performance of the bipolar plate. The machining method further involves surface cleaning treatment and surface hydrophobic treatment performed on the formed graphite bipolar plate, so that and water does not tend to accumulate in the flow channels which have been subjected to the surface hydrophobic treatment. The gas conveying capacity of the bipolar plate formed by the machining method is enhanced, and the performance of the bipolar plate is also improved.

Owner:TSINGHUA UNIV

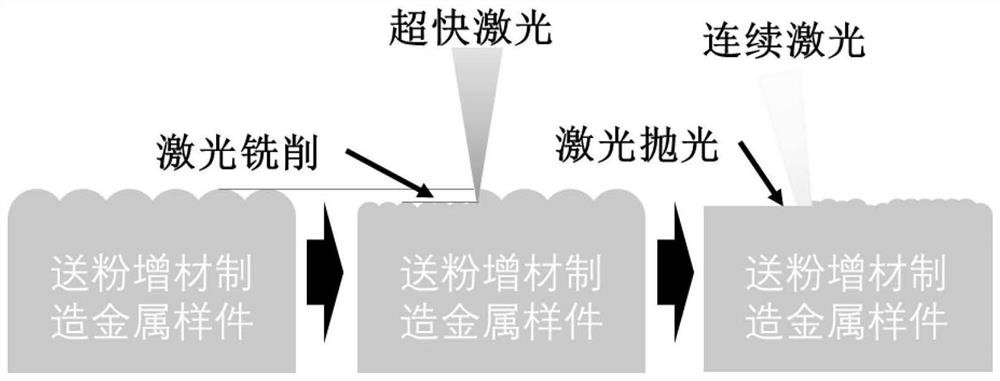

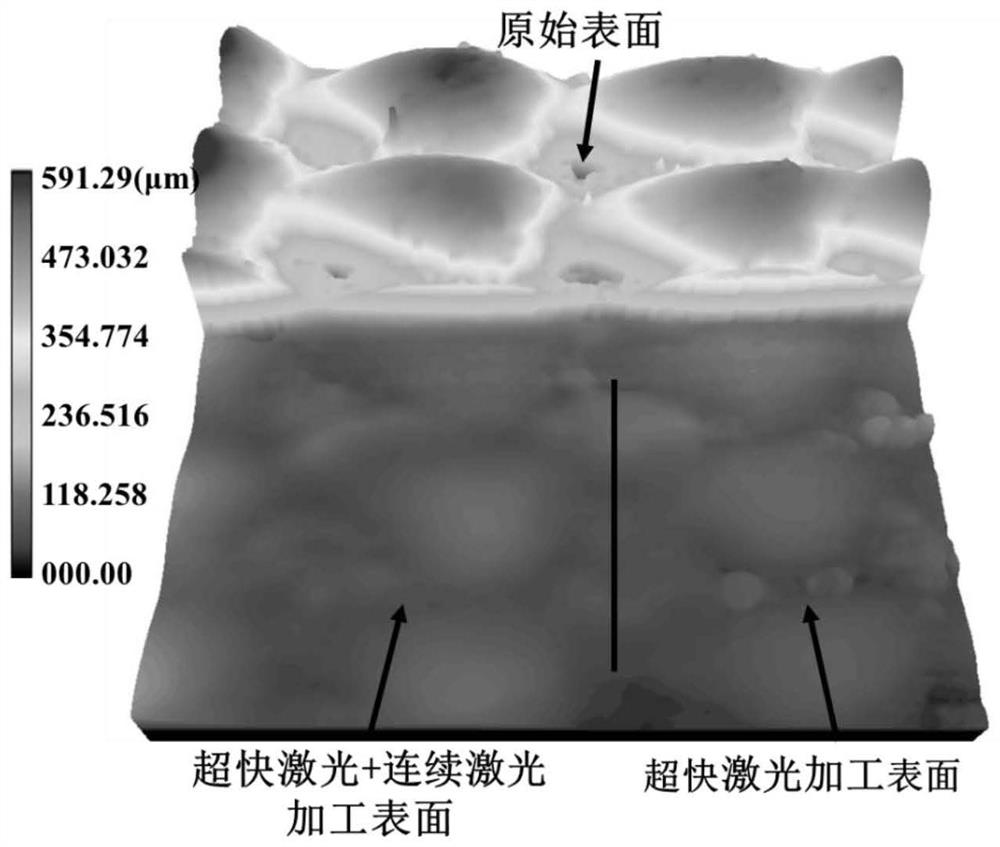

Ultrafast-continuous laser asynchronous polishing powder feeding additive manufacturing metal surface process

PendingCN112548343AReduce wavinessReduce roughnessLaser beam welding apparatusIncreasing energy efficiencyMolten stateMachined surface

The invention provides an ultrafast-continuous laser asynchronous polishing powder feeding additive manufacturing metal surface process. The ultrafast-continuous laser asynchronous polishing powder feeding additive manufacturing metal surface process comprises the following steps of performing laser micro-milling on the surface of a powder feeding additive manufacturing metal material by using ultrafast laser, and removing a macroscopic convex deposition layer on the surface of the powder feeding additive manufacturing metal material to obtain a sample piece with a flat processing surface; putting the sample piece into an oxygen isolation container, introducing protective gas, performing laser polishing on the machined surface of the sample piece by utilizing the continuous laser, heatinga machined surface material to a molten state, forming material micro-flow by surface tension of a liquid material, removing micro-morphology left by laser micro-milling, and performing cooling and solidifying to form a smooth surface; and achieving surface polishing of the surface of the powder feeding additive manufacturing metal material from large waviness to the submicron level. Non-contact polishing is adopted, mechanical stress cannot be generated on the surface of the material, and introduction of related machining defects is avoided. Compared with a traditional polishing process, automatic machining can be achieved, the machining efficiency is high, and environmental pollution is small.

Owner:SHANGHAI PLATFORM FOR SMART MFG CO LTD

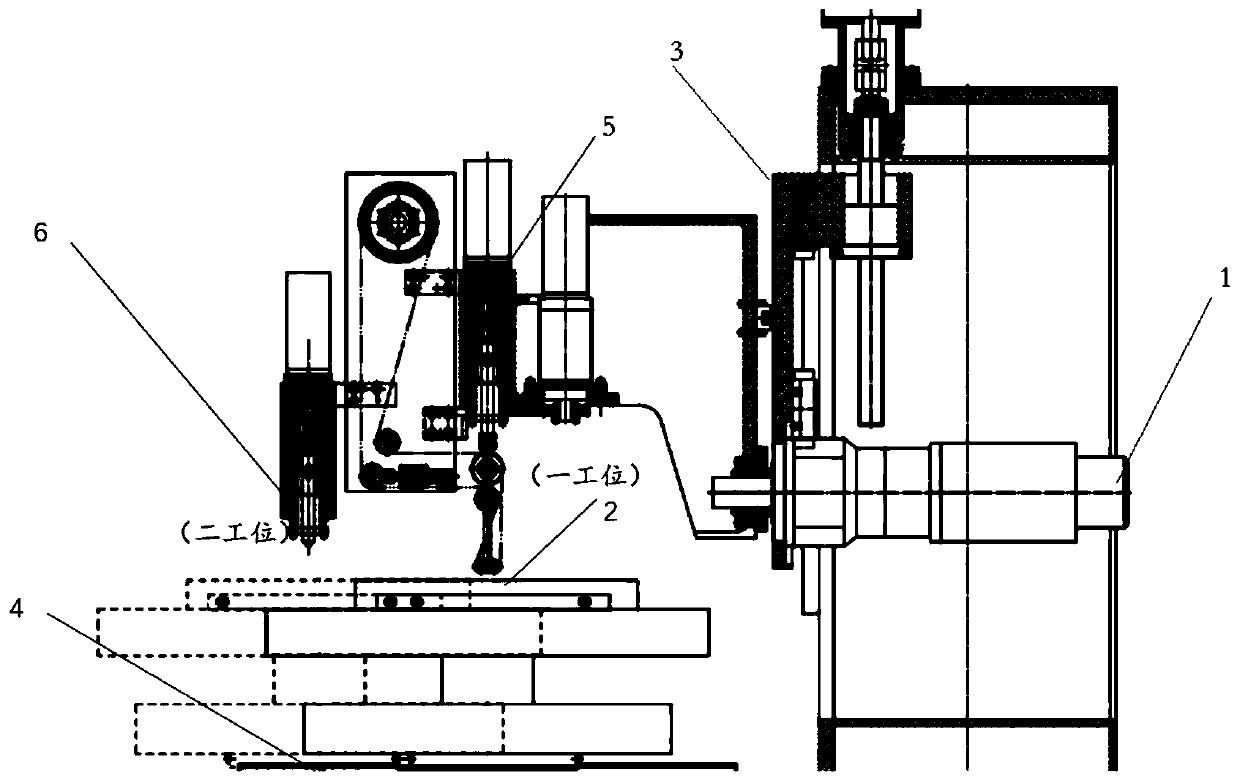

Equipment and method for processing micro-surface structure

InactiveCN109702487AIntegrity guaranteedReduce distortionOther manufacturing equipments/toolsMicro structureLaser etching

The invention discloses equipment for processing a micro-surface structure. The equipment comprises a surface polish-grinding device, a laser etching device, an apparatus fixing device suspending rackand a pedestal. The surface polish-grinding device and the laser etching device are successively arranged on the suspending rack; the pedestal supports the suspending rack; the surface polish-grinding device comprises a polish-grinding head for polish-grinding the surface of a to-be-processed apparatus; the polish-grinding head is controlled by a first driving mechanism to lift; the laser etchingdevice comprises a laser head for etching the to-be-processed apparatus with laser; the laser head is controlled by a second driving mechanism to lift; the apparatus fixing device is used for fixingthe to-be-processed apparatus. According to the apparatus processed by the technical means, the surface micro-structure is obtained while the surface integrity is ensured. The invention also providesa method of processing the micro-surface structure with the beneficial effects.

Owner:CHONGQING UNIV

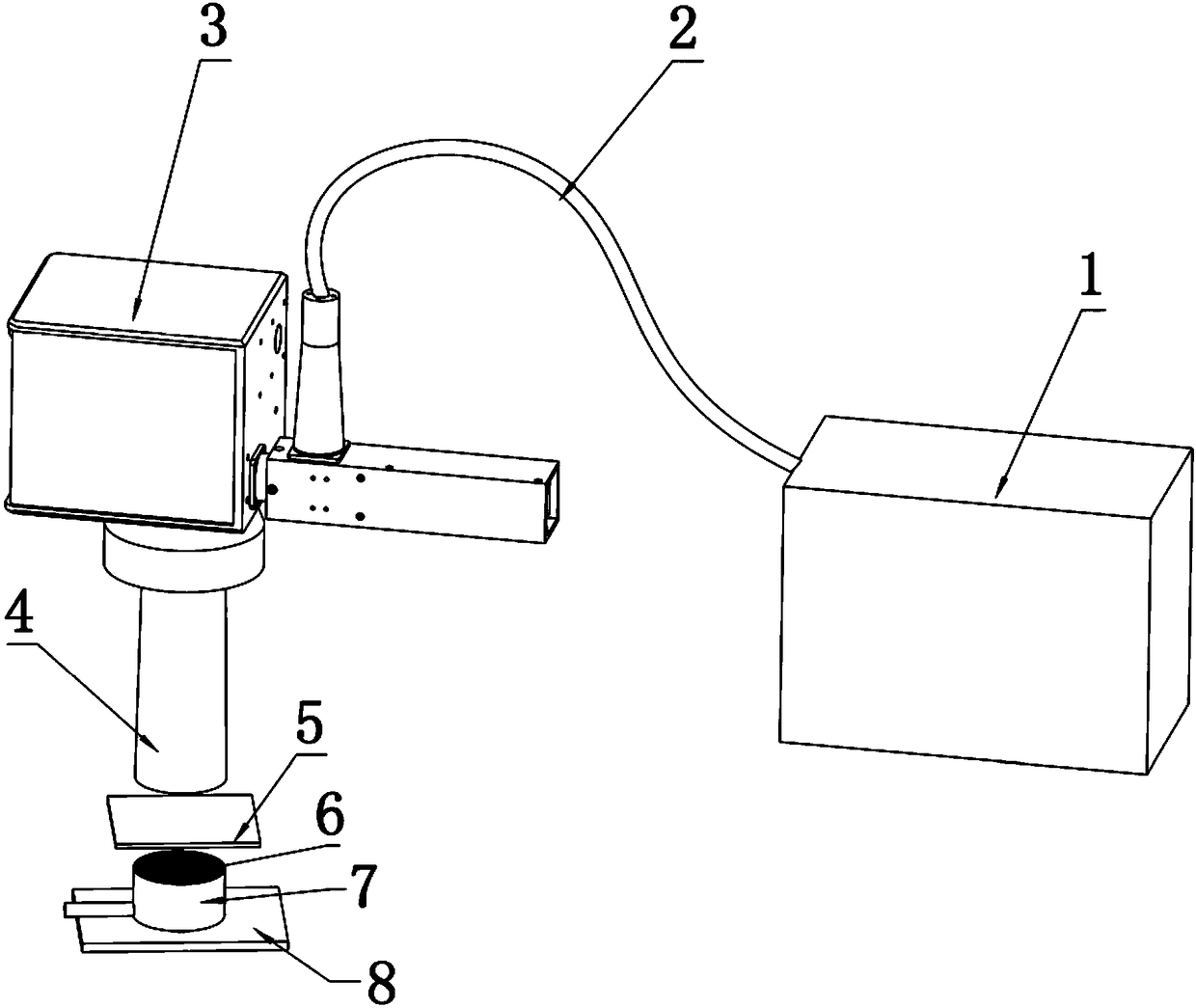

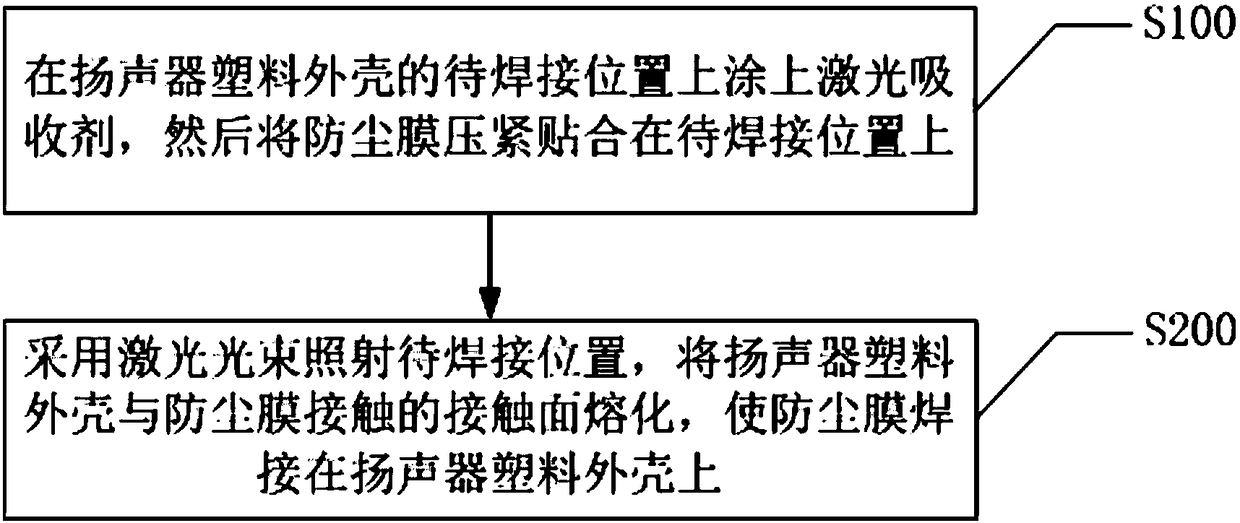

Laser welding method and device for loudspeaker dustproof film

The invention discloses a laser welding method and device for a loudspeaker dustproof film. The laser welding method comprises the steps that the to-be-welded position of a loudspeaker plastic shell is coated with a laser absorbent, and then the dustproof film is tightly pressed and attached to the to-be-welded position; and a laser beam is adopted to illuminate the to-be-welded position, and thecontact surface, making contact with the dustproof film, of the loudspeaker plastic shell is melted, so that the dustproof film is welded to the loudspeaker plastic shell. According to the laser welding method for the loudspeaker dustproof film, non-contact-type welding processing of loudspeaker plastic shell plastic and the dustproof film is achieved, auxiliary materials do not need to be added,processing traces cannot be seen after welding is conducted, the appearance is attractive, the enough strength is ensured through whole face processing, the quality of a product is greatly improved, the whole service life is greatly prolonged, secondary pollution and waste cannot be caused, and mechanical stress and thermal stress are not produced; and the laser welding method is simple in processand good in consistency, and automatic production is easy to realize.

Owner:HANS LASER TECH IND GRP CO LTD

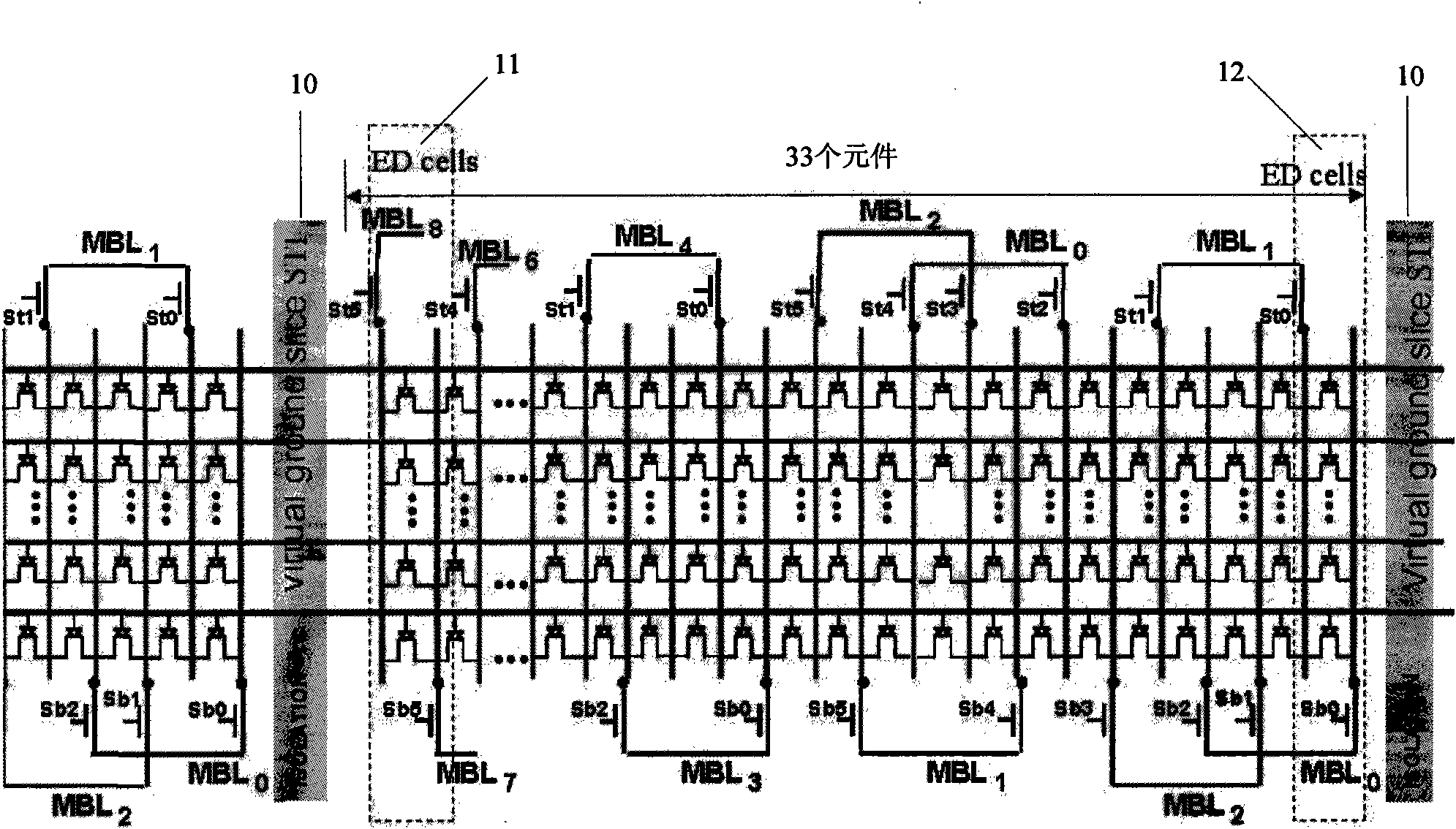

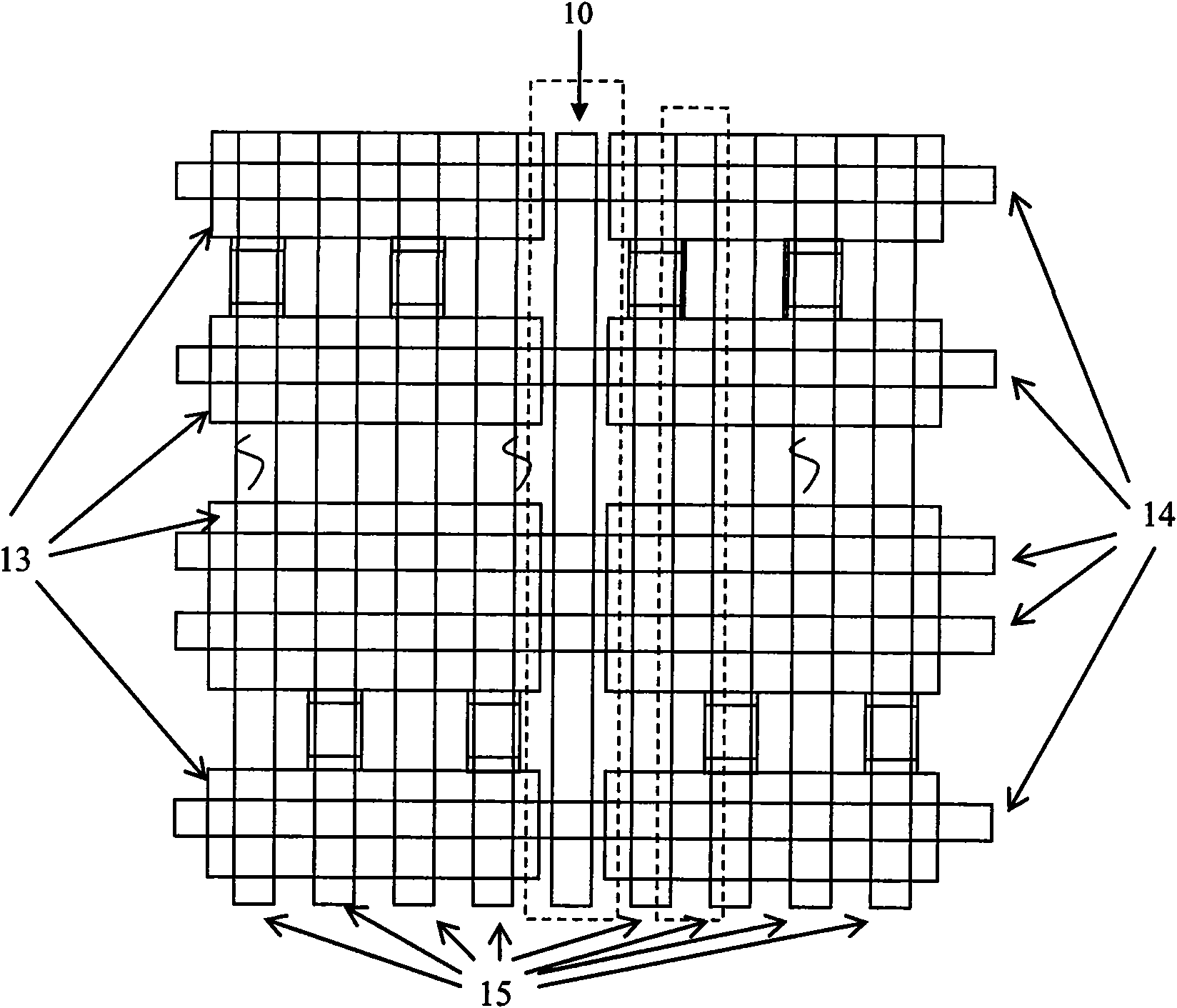

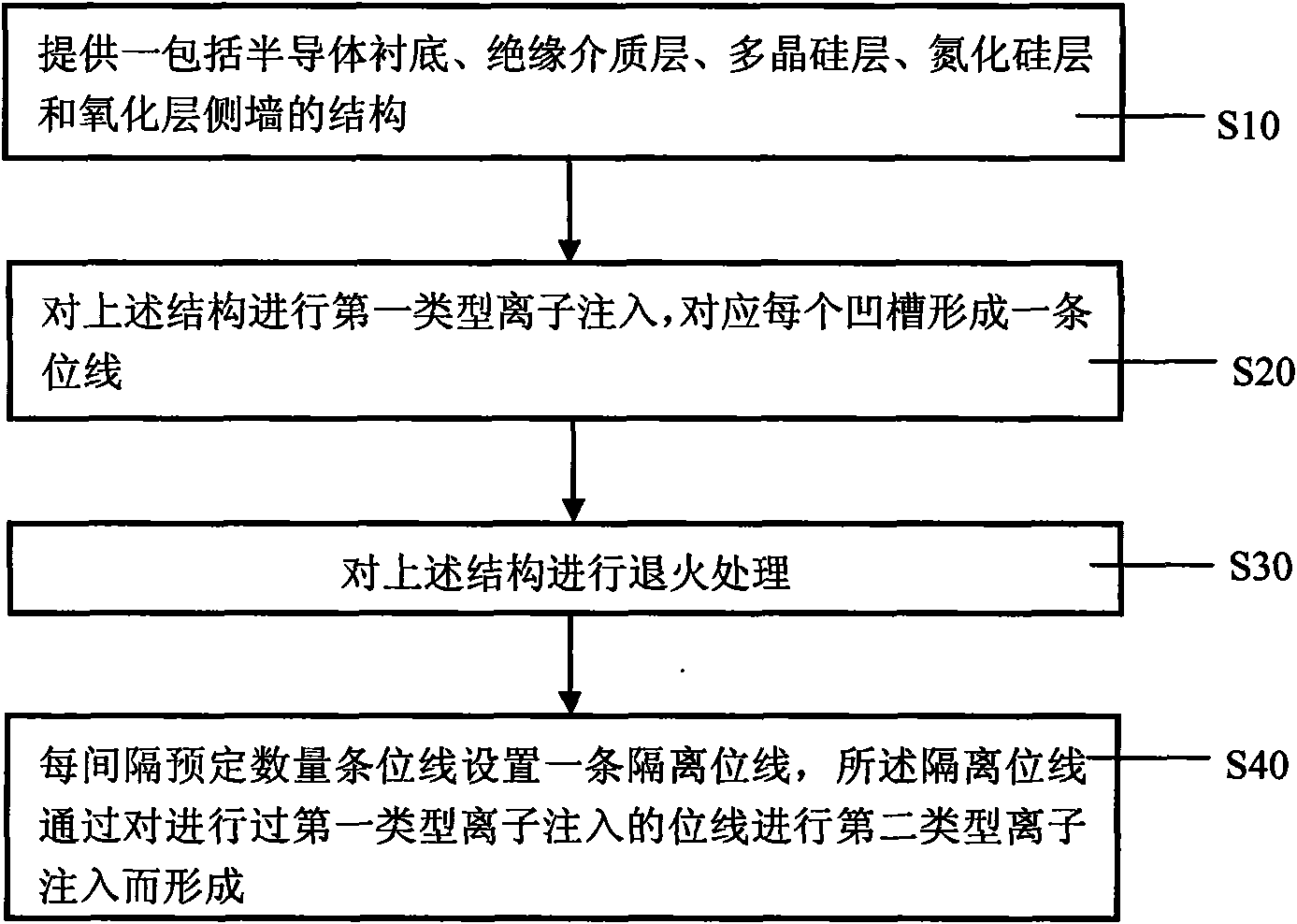

Flash memory manufacturing method

InactiveCN101924075AImprove isolationNo mechanical stressSemiconductor/solid-state device manufacturingBit lineMedia layer

The invention provides a flash memory manufacturing method which comprises the following steps: providing a structure comprising a semiconductor substrate, an insulating medium layer, a polycrystalline silicon layer, a silicon nitride layer and an oxide layer side wall; carrying out first type ion implantation on the structure, and forming a plurality of bit lines corresponding to each groove; carrying out annealing treatment on the structure; and arranging isolated bit lines at the interval of a preset number of bit lines, wherein the isolated bit line is formed by carrying out second type ion implantation on the bit line after the first type ion implantation. The flash memory manufacturing method provided by the invention can achieve the effect identical with the effect achieved by shallow trench isolation, and can not generate mechanical stress simultaneously.

Owner:SEMICON MFG INT (SHANGHAI) CORP

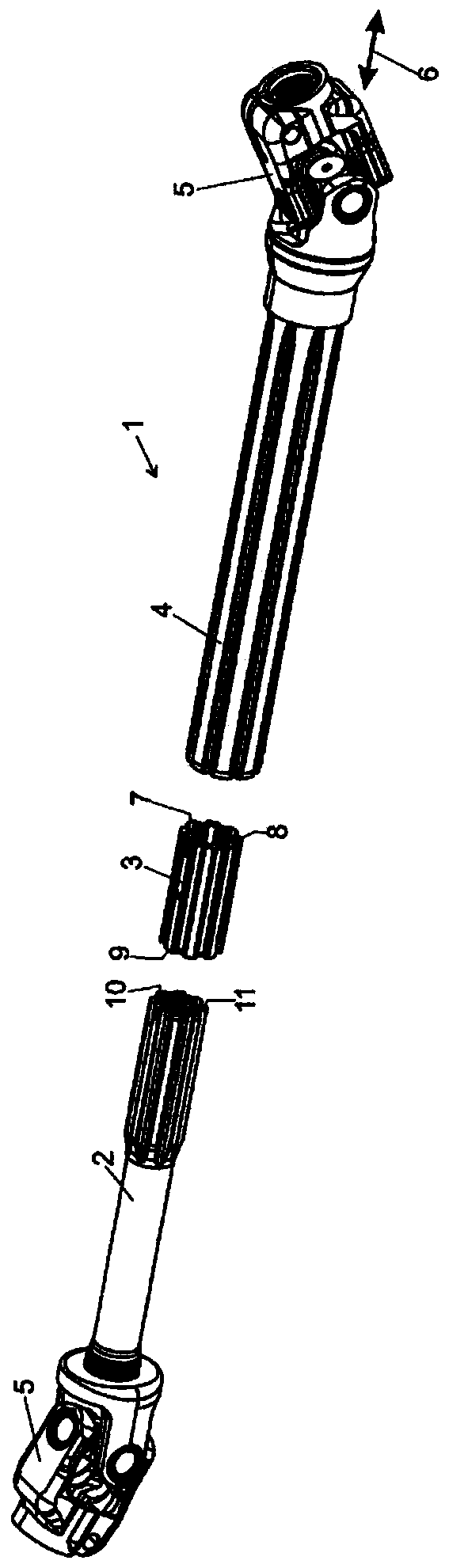

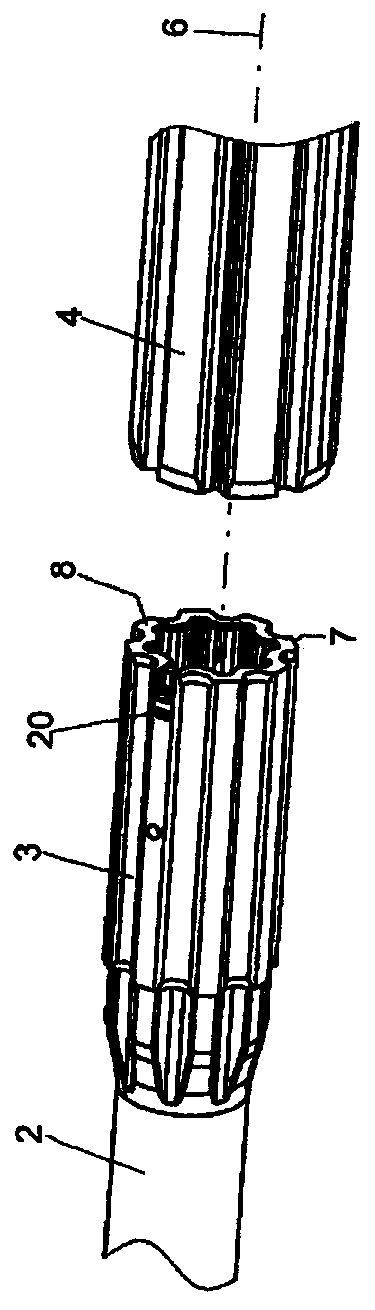

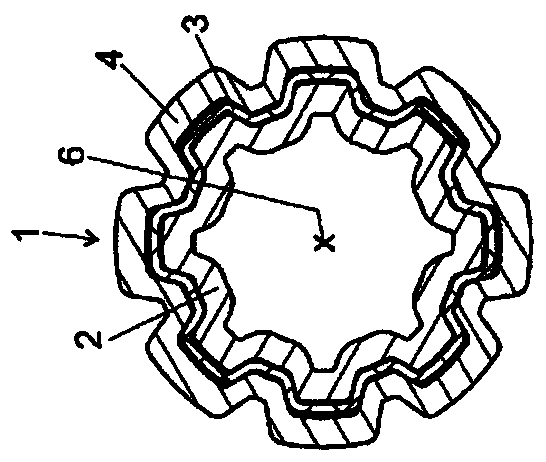

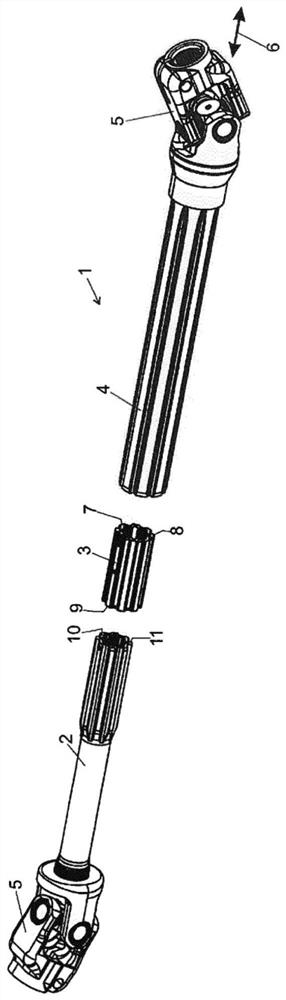

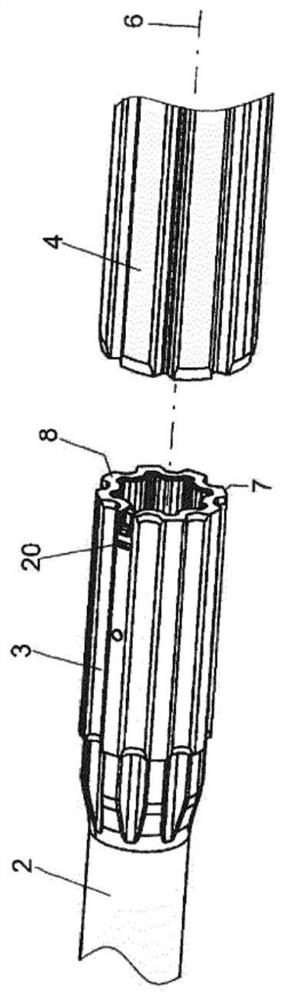

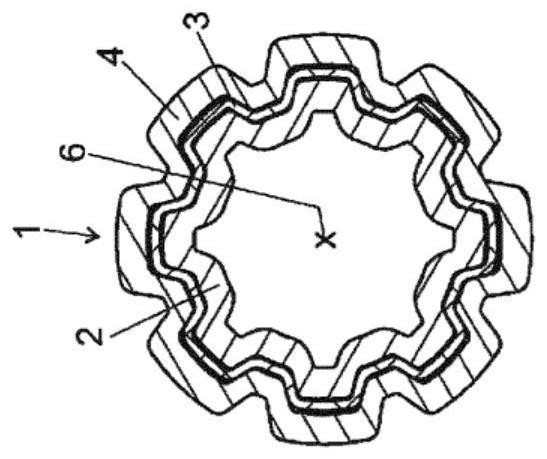

Length-adjustable steering shaft for a motor vehicle, and profiled sleeve for a steering shaft

ActiveCN110234559ANo mechanical stressNo swellingClutchesYielding couplingRotational axisControl theory

A length-adjustable steering shaft (1) for a motor vehicle, having an inner shaft part (2), which is held coaxially, and so as to be displaceable in a rotational axis direction (6), in an outer shaftpart (4), wherein the two shaft parts (2, 4), in cross section, have profiles which engage into one another for the purposes of transmitting torques, and on the inner shaft part (2), there is arrangeda profiled sleeve (3) on which the outer shaft part (4) is arranged in telescopic fashion, is improved with regard to simplified production in that the profiled sleeve (3), in a first end region (7)which in the assembled state surrounds a free end (10) of the inner shaft part (2), has at least one radially inwardly protruding stop (8) for the abutment against a face surface (11) of the inner shaft part (2) in one axial direction (6), and in that an end region (12) of the inner shaft part (2) is equipped with a radially outwardly protruding projection (13) for the abutment of the profiled sleeve (3) in the opposite axial direction (6). The invention furthermore encompasses a profiled sleeve (3) for the abovementioned steering shaft (1), which profiled sleeve, with regard to simplified assembly, has at least one radially inwardly protruding stop (8) in a first end region (7).

Owner:THYSSENKRUPP PRESTA AG +1

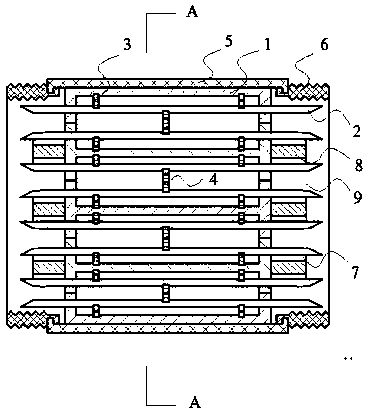

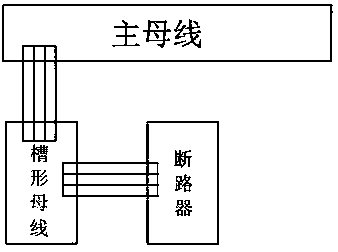

A connection device for the grooved busbar in the cabinet and the switch circuit breaker

ActiveCN106785945BHigh mechanical strengthEasy to assembleBus-bar/wiring layoutsBusbarElectrical connection

The invention discloses a connecting device, in particular a connecting device for a busbar channel and switch circuit breaker in switchgear and belongs to the technical field of distribution switchgear. The device comprises multiple insulation modules provided with mounting grooves and conductive plug strips, wherein the insulation modules press the conductive plug strips in the mounting grooves to form busbar plug channels, the device further comprises outer protective cases which sleeve the insulation modules and are used for protection and reinforcement, the insulation modules sleeve the conductive plug strips through the outer protective cases, and insulation partitions for isolation are arranged among plug channels. With the adoption of the connecting device, the problem that circuits for electrical connection in the switchgear are complex is solved, so that inner connecting units are modular, the connecting device is easy to assemble and free from maintenance due to adoption of the plug manner, the structure in the switchgear is effectively optimized, and the cost is reduced.

Owner:四川瀚舟铜铝复合材料有限公司

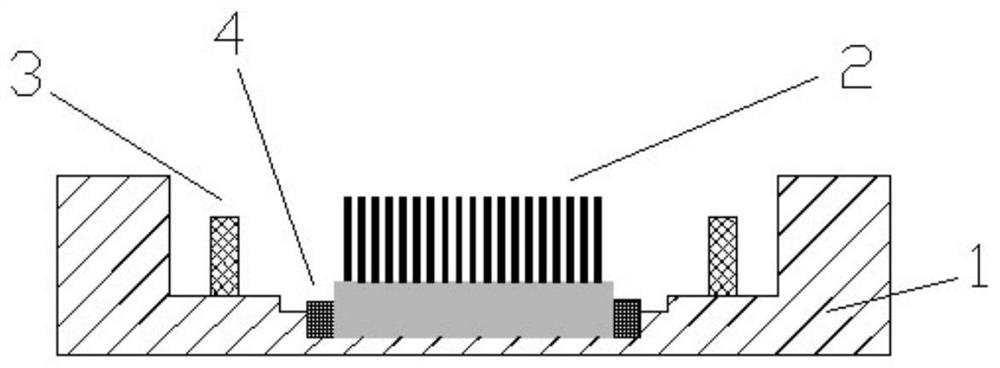

Non-destructive grinding method and device for welding column of CCGA device

ActiveCN113421830ANon-destructive grindingWear leveling achievedSemiconductor/solid-state device manufacturingGrinding machinesEconomic benefitsStructural engineering

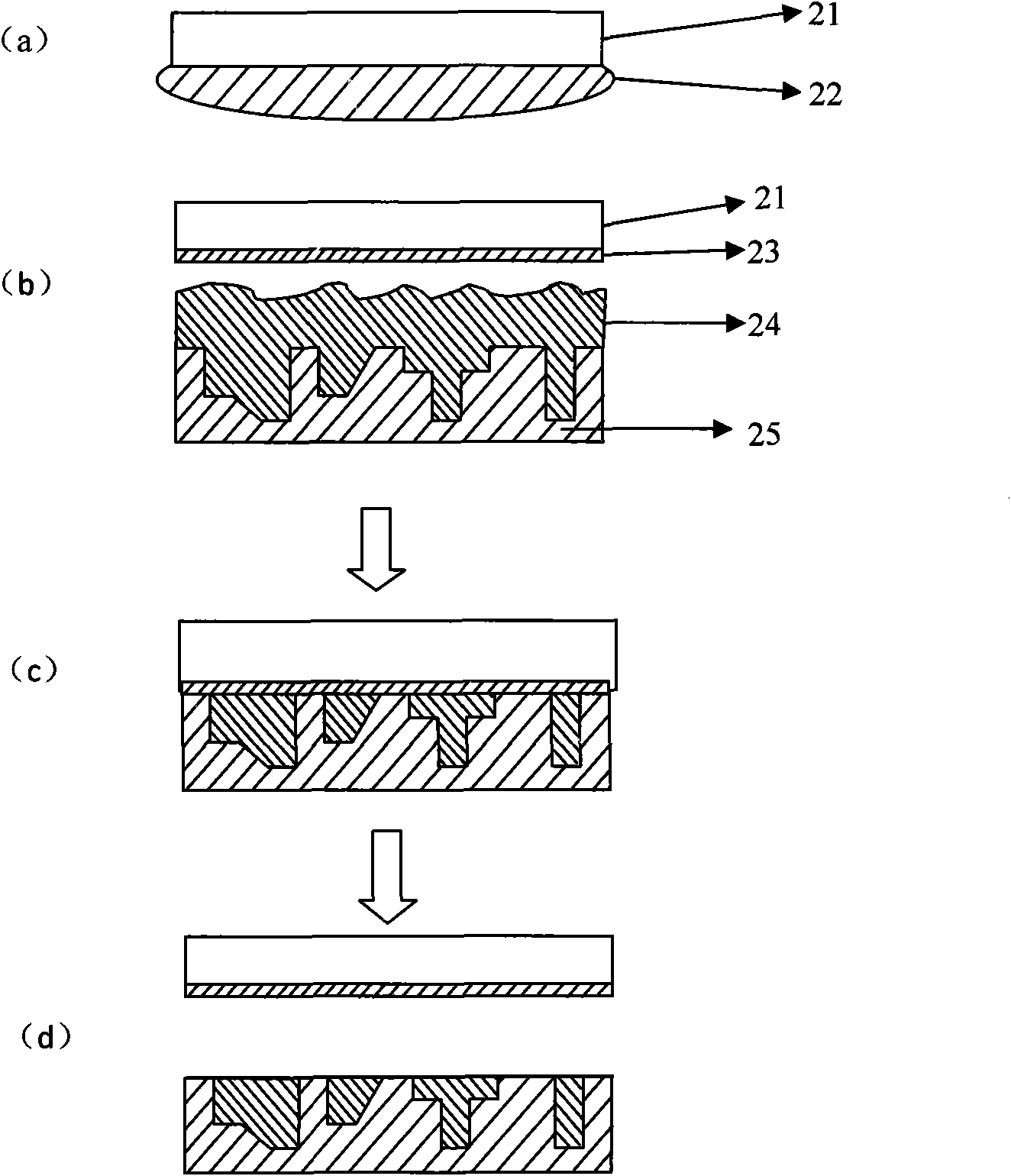

The invention discloses a non-destructive grinding method and device for a welding column of a CCGA device. The method comprises the steps of carrying out potting on the welding column end of the CCGA device to be trimmed through adopting a method for carrying out potting on the welding column of the CCGA device to be trimmed through injection molding resin, then grinding the potted welding column end of the CCGA device to be trimmed until the remaining height of the welding column meets the design requirement, fixing the welding column through adopting an injection molding method before being ground so as to ensure that the side wall of the welding column cannot be damaged in the grinding process, the perpendicularity of the welding column cannot become poor, and finally, removing injection molding resin for potting the welding column in a chemical dissolution mode after grinding is completed. Therefore, no mechanical stress exists in the whole process, lossless grinding of the welding column is achieved, the welding column deformation and damage caused by mechanical clamping can be greatly reduced, and the method has important application value for manufacturing high-reliability CCGA and has good application prospects and economic benefits. Through detection, high-quality welding column grinding with the perpendicularity within 3 degrees and no mechanical damage to the side wall can be achieved, and the method is superior to a column planting grinding method in the current industry.

Owner:珠海天成先进半导体科技有限公司

Laser parallel processing device and processing method for array vent holes of leather products

ActiveCN110560936BMeet processing needsImprove drilling efficiencyLaser beam welding apparatusBeam expanderLight guide

The invention discloses a laser parallel processing device and processing method for array air holes of leather products, including a laser system, an optical light guide system, an X-Y two-dimensional honeycomb adsorption platform system, a computer control system, an optical path exit of the laser system and an optical The light path entrance of the light guide system is opposite, and the light path exit of the optical light guide system is opposite to the working area of the X-Y two-dimensional honeycomb adsorption platform system; the optical light guide system includes a pneumatic shutter, a quarter slide, a mirror, Adjustable beam expander, adjustable diaphragm, dichroic mirror, laser beam splitting unit, scanning galvanometer; the optical path of the laser beam output by the laser system is a pneumatic shutter, a quarter glass, a mirror, and an adjustable Beam expander, adjustable aperture, one side of the dichroic mirror, laser beam splitting unit, scanning galvanometer, leather surface to be processed, and the other side of the dichroic mirror is provided with an indicating red light unit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

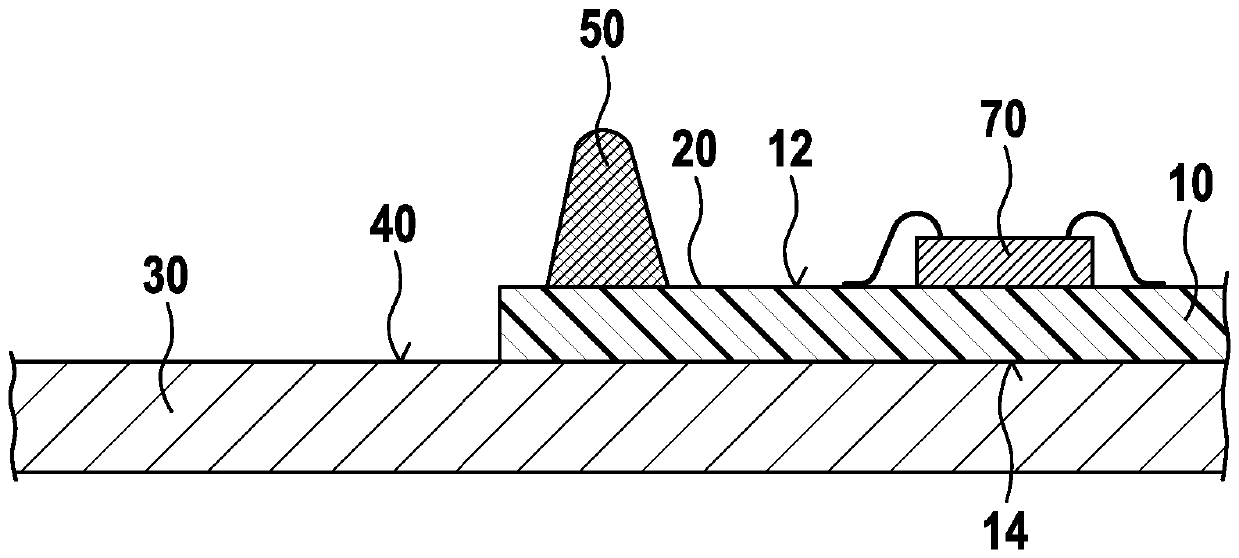

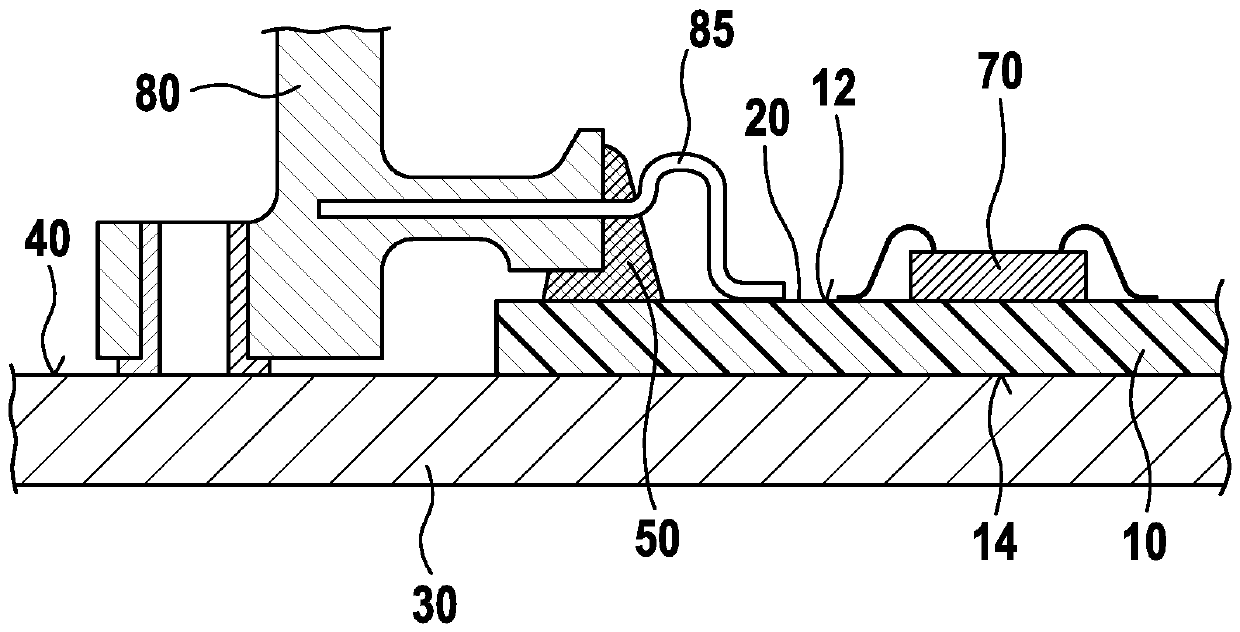

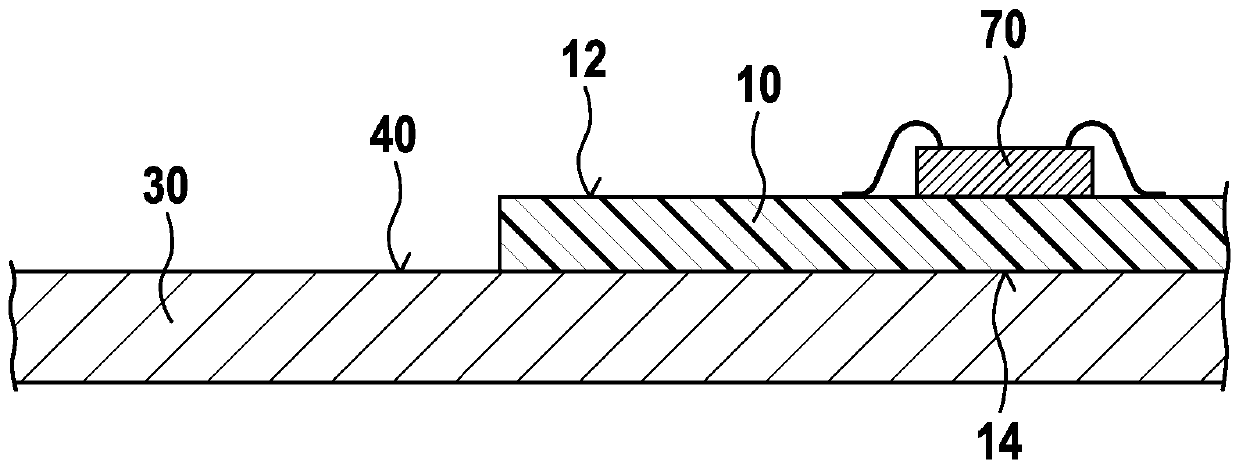

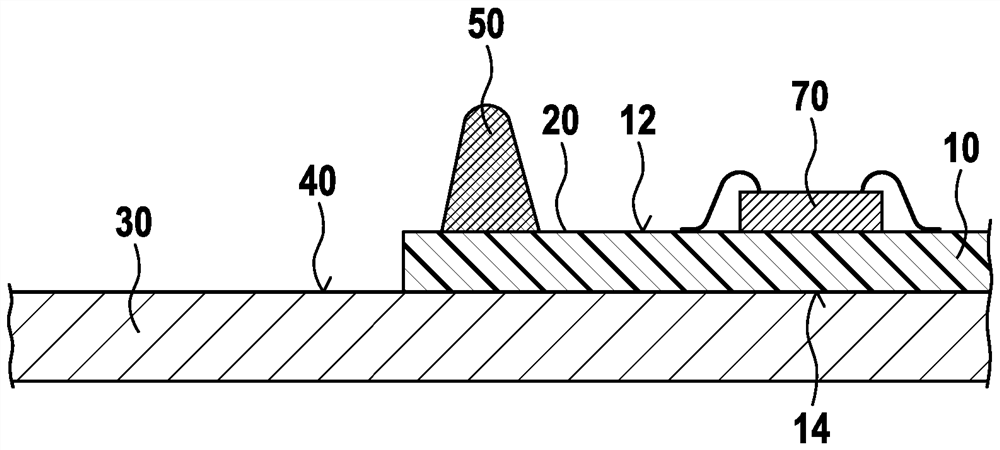

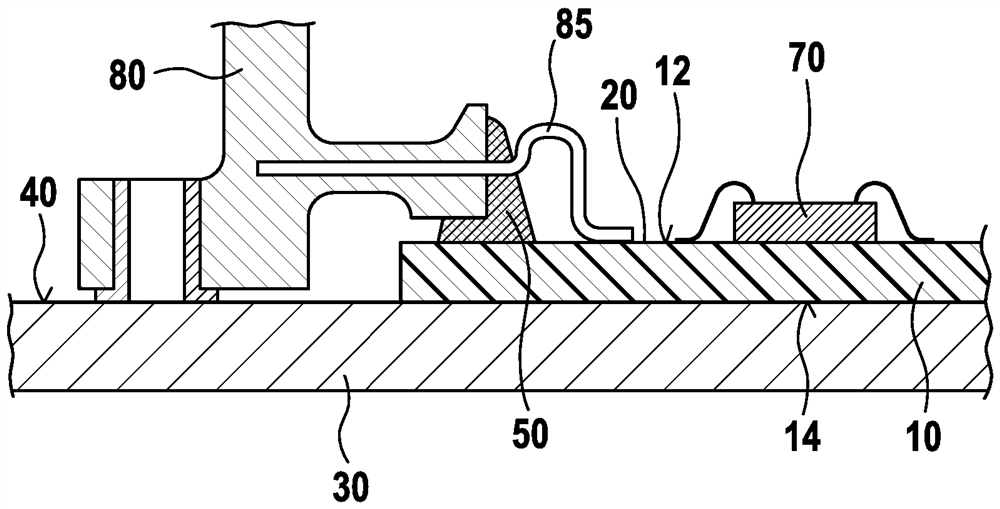

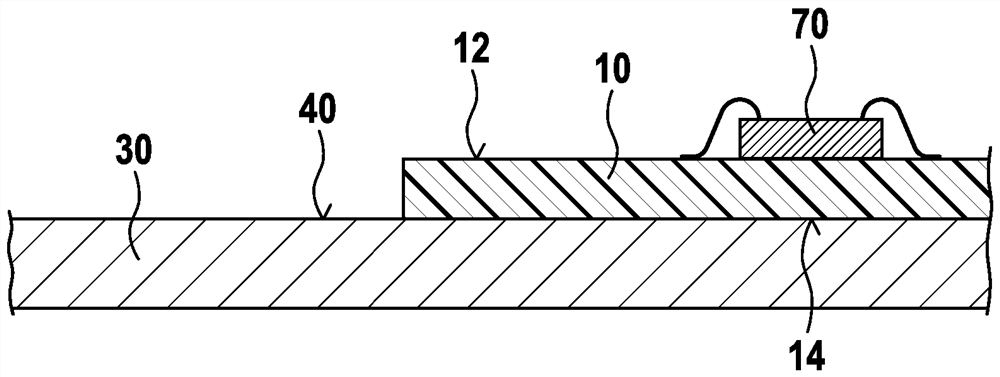

Method for producing an electronic assembly, and electronic assembly, in particular for a transmission control module

ActiveCN109792848AImprove robustnessReduce manufacturing costCasings with connectors and PCBFinal product manufactureEngineeringElectronic component

The invention relates to a method for producing an electronic assembly (5), in particular for a transmission control module, having the following steps: providing a printed circuit board (10) with a first face (12) and a second face (14) facing away from the first face (12) and with at least one first electronic component (70) arranged on the first face (12) of the printed circuit board (10); arranging the printed circuit board (10) such that the second face (14) lies at least partly on a reference surface (40); applying a sealing material (50) which is substantially not flowable prior to being cured onto the first face (12), said sealing material (50) being applied such that the sealing material (50) surrounds a sub-region (20) of the first face (12) of the printed circuit board (10); arranging a second component (80) at least partly on the reference surface (40) such that the second component (80) is at least partly pressed into the sealing material (50); electrically connecting thesecond component (80) to the printed circuit board (10) by means of an electric connection line (85); applying a covering material (60), in particular a covering material (60) which is flowable priorto being cured, onto the printed circuit board (10) first face (12) sub-region (20) surrounded by the sealing material (50) and onto the first component (70); curing the sealing material (50); and curing the covering material (60).

Owner:ROBERT BOSCH GMBH

Capacitor installing stack structure and installing method of capacitor

The present invention provides a capacitor installing stack structure, wherein a capacitor installing platform is reversedly arranged on an operating platform, thus clamping parts arranged at left and right side of the capacitor installing platform can play a clamping function to ensure a specified size H2T defined by the clamping parts, then the capacitor is inserted into an installing hole of the capacitor installing platform which is reversedly arranged when in a reversal state, thus a distance H2C from the horizontal operating platform to a terminal arranged at an upper part of the capacitor can be set as the same with the specified size H2T defined by the clamping parts. Under the state, the capacitor can be fixed on the capacitor installing platform by using fixing parts.

Owner:FUJI ELECTRIC CO LTD

Apparatus for durable joining of two workpieces having at least one source of energy

InactiveCN1958273ALess protective measuresNo mechanical stressElectric switchesDomestic articlesEngineeringLight-emitting diode

Owner:约翰逊电气奥尔登堡有限责任两合公司

Electronic assembly for transmission control module and method of making the same

ActiveCN109792848BImprove robustnessReduce manufacturing costCasings with connectors and PCBFinal product manufactureElectronic componentPrinted circuit board

A method for producing an electronic assembly (5), in particular an electronic assembly (5) for a gearbox control module, is specified, the method comprising the steps of: providing a printed circuit board (10) having a first A side (12) and a second side (14) facing away from the first side (12) and having at least one first electronic component (70) arranged on the first side (12) of the printed circuit board (10) ; the printed circuit board ( 10 ) is at least partially arranged on the reference surface ( 40 ) with the second side ( 14 ); applying a sealing material ( 50 ) which is substantially non-flowable before age hardening to the first side ( 12), wherein the sealing material (50) is coated such that the sealing material (50) surrounds a partial area (20) of the first side (12) of the printed circuit board (10); the second device (80 ) is at least partially arranged on the reference surface (40), so that the second device (80) is partially pressed into the sealing material (50); the second device (80) is electrically connected to the printed circuit board (10); applying a covering material (60), in particular a covering material (60) that is flowable before age hardening, to the first side (12) of the printed circuit board (10) The partial area (20) surrounded by the sealing material (50) is applied to the first component (70); the sealing material (50) is age-hardened; and the covering material (60) is age-hardened.

Owner:ROBERT BOSCH GMBH

Multipurpose lid in particular for liquids, particularly for paint can

InactiveCN101312892BExtended shelf lifeReduce wasteClosuresRotary stirring mixersEngineeringMechanical engineering

The invention concerns a lid (2) comprising a skirt (3) for covering the opening of a can (1), in particular a paint can. The invention is characterized in that the skirt (3) comprises a peripheral edge (30), at least one stud (71) formed in the edge (30) and elastically coupled to said edge (30), at least one lock (72) mounted sliding on said edge such that said lock may take up a locking position wherein said lock is adapted to retain said stud in a position for engaging the lid on the can.

Owner:蒂埃里·加西亚

Length-adjustable steering shafts for motor vehicles and profiled sleeves for steering shafts

ActiveCN110234559BOptimize the fixing methodNo mechanical stressClutchesYielding couplingRotational axisControl theory

A length-adjustable steering shaft (1) for a motor vehicle has an inner shaft part (2) held coaxially on an outer shaft part ( 4), wherein the two shaft parts (2, 4) have in cross-section a profile that engages with each other for the purpose of torque transmission, a special-shaped sleeve (3) is provided on the inner shaft part (2), and the outer The shaft part (4) is arranged on the special-shaped sleeve in a telescopic manner. The improvement of the steering shaft in terms of simplified production is that the special-shaped sleeve (3) surrounds the free end of the inner shaft part (2) in the assembled state. (10) has in the first end region (7) at least one radially inwardly protruding stop ( 8), and in that the end region (12) of the inner shaft part (2) is equipped with radially outwardly protruding projections (13) for abutting against the profiled sleeve (3) in the opposite axial direction (6) . The invention also comprises a profiled sleeve (3) for the aforementioned steering shaft (1) which, with regard to simplified assembly, has at least one radially inwardly protruding stop located in the first end region (7) Department (8).

Owner:THYSSENKRUPP PRESTA AG +1

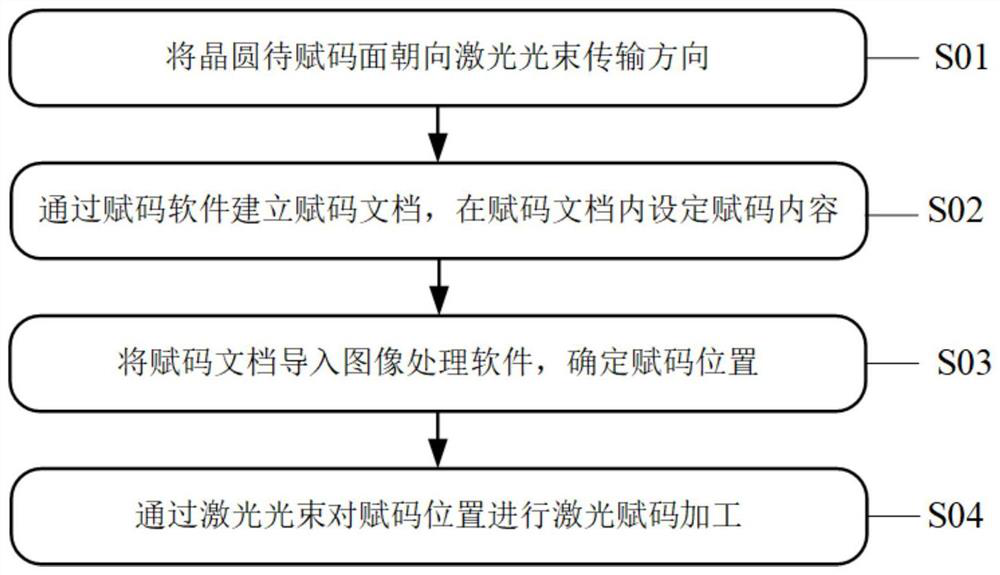

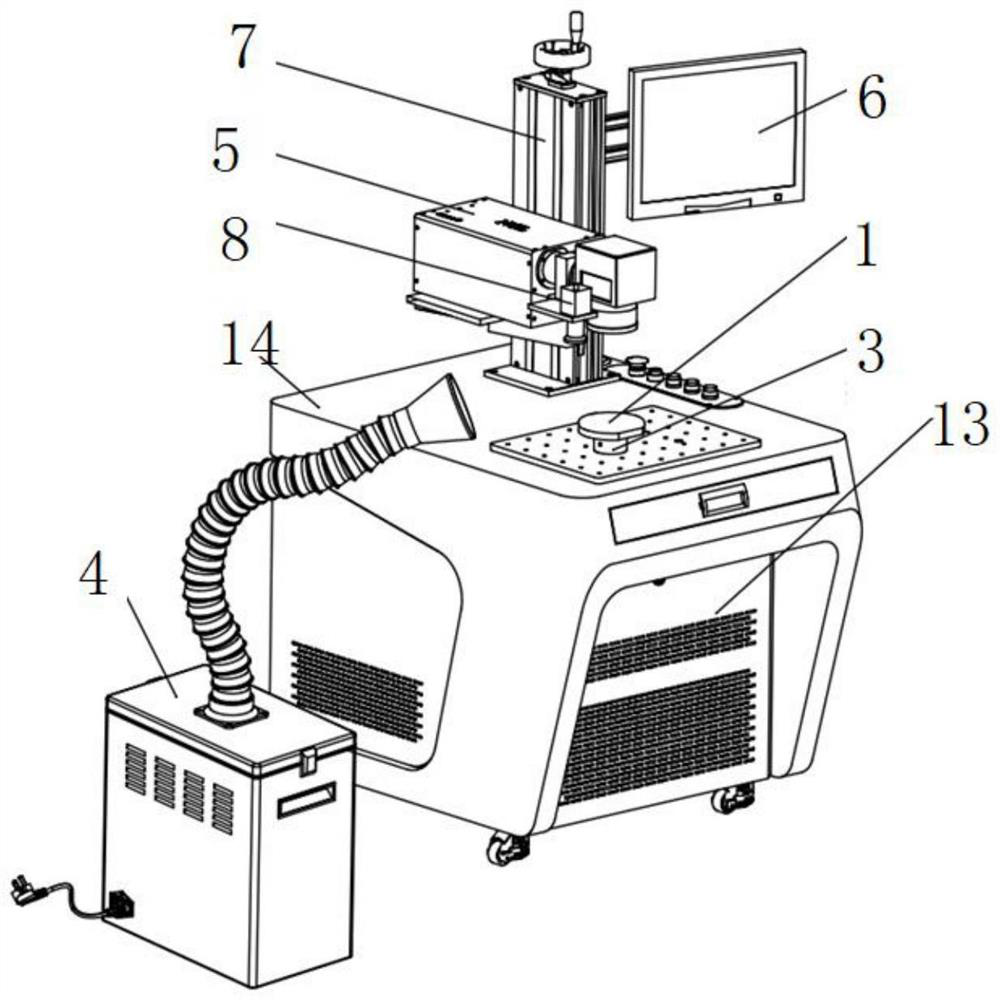

Wafer laser coding method and wafer laser coding system

PendingCN114192992ANo consumables requiredNo pollution in the processSemiconductor/solid-state device manufacturingLaser beam welding apparatusMachine visionHigh energy

The invention discloses a wafer laser tagging method and a wafer laser tagging system. The wafer laser tagging method comprises the following steps: enabling a to-be-tagged surface of a wafer to face the transmission direction of a laser beam; establishing a tagging document through tagging software, and setting tagging contents in the tagging document; importing the tagging document into image processing software, and determining a tagging position; laser tagging processing is conducted on the tagging position through a laser beam; the processing process is free of consumables and pollution, the cost is lower, and the anti-counterfeiting property is better; a hyperfine mark is formed on the surface or inside the wafer under the action of a high-energy-density laser beam; non-contact machining is adopted, mechanical stress is avoided, and the product quality can be effectively improved; and positioning and code assigning can be achieved through machine vision, the alignment precision is high, the clamp can be placed at any angle within the machining plane range, the code assigning position consistency is good, and the production efficiency is greatly improved.

Owner:南光高科(厦门)激光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com