Electrochemical levelling and polishing processing method with nanometer precision and device thereof

A processing device, electrochemical technology, applied in circuits, electrical components, electrolysis processes, etc., can solve problems such as deep damage layer, surface scratches, metal ion pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

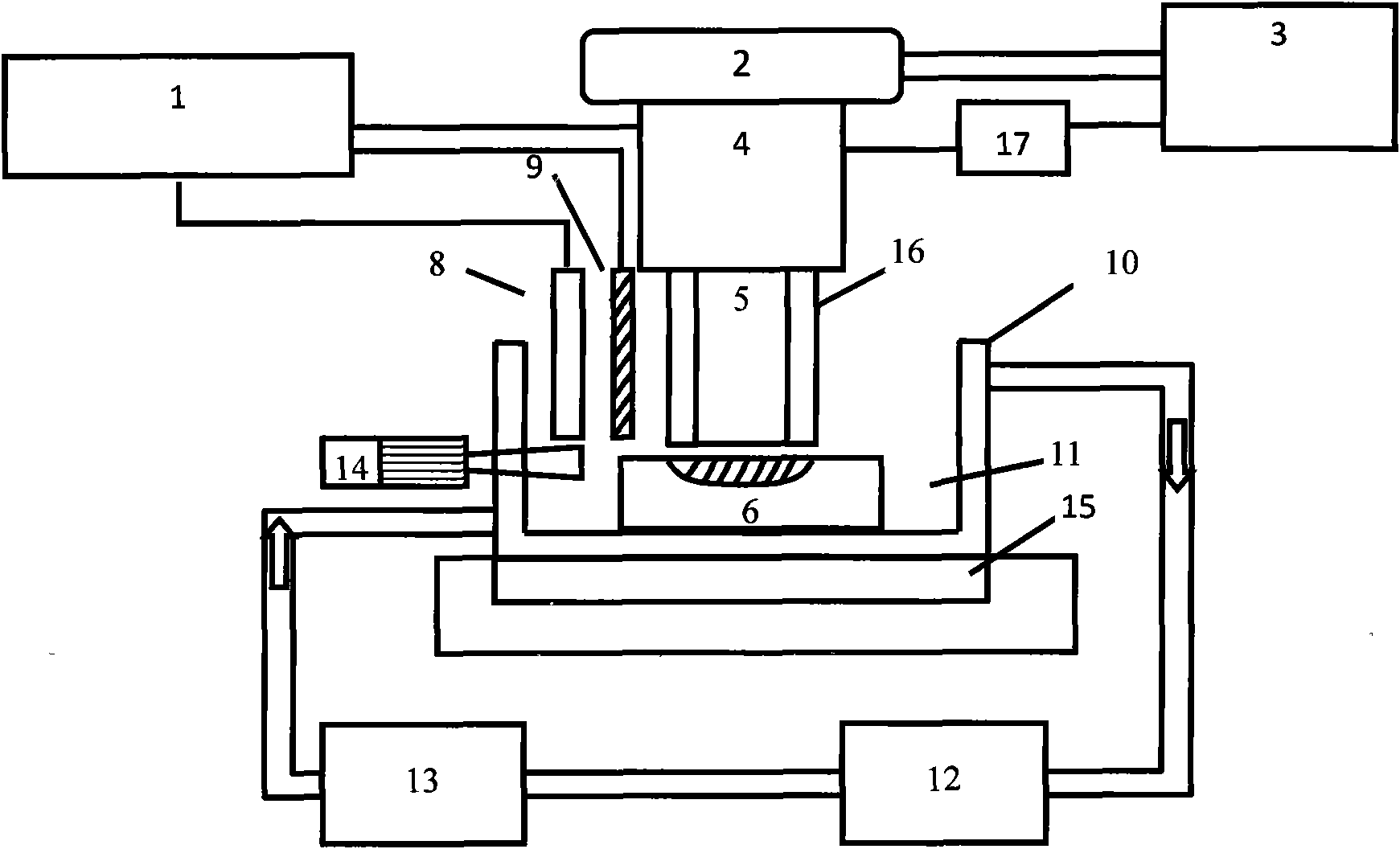

[0058] Example 1: figure 1 A composition schematic diagram of an implementation device example of the leveling and polishing processing method of the present invention is given. The processing tool adopts a platinum disc-shaped tool 5 with nano-flat precision on the surface. The tool 5 is fixed on the lower part of the metal holder 4, and the fiber optic probe 16 of the parallel laser beam distance measuring device 17 fixed on the outside of the tool is also fixed on the metal holder. The bottom of 4, parallel laser beam ranging device 17 links to each other with information processing computer 3, and metal fixed frame 4 can adopt two sections of cylinders with different diameters, and its top connects the Z-axis (vertical axis) micro-drive controller 2 of drive unit, The Z-axis micro-driver 2 is connected to the information processing computer 3; the electrochemical system is provided with a potentiostat 1, an auxiliary electrode 8, a reference electrode 9, a container 10, a ...

Embodiment 2

[0062] Example 2: Figure 6 A microscopic image of the silicon surface of Example 2 of polishing on the silicon surface according to the present invention is given. Processing conditions: the circulating solution contains 0.1mol / dm 3 Ammonium Fluoride (NH 4 F), 1mmol / dm 3 Tetramethylammonium bromide ((CH 4 ) 4 NBr), 0.01mol / dm 3 L-cystine (L-cystine) and 0.5mol / dm 3 Sulfuric acid (H 2 SO 4 ); its temperature is maintained at 30°C during the entire etching and leveling process; after the electrochemical etching reaction control system is started, bromide ions (Br - ) produces bromine (Br 2 ) etch leveling agent; the scavenger is cystine (L-cystine); in the whole leveling and polishing process, the electrode potential of the tool (metal platinum disk electrode) is kept at 0.9V (relative to the saturation potential of the calomel electrode). Among them, the surface of the platinum metal disk is polished by CMP technology, and its flatness accuracy is greater than 60nm,...

Embodiment 3

[0063] Example 3: Figure 7 A microscopic image of the copper surface of Example 3 of the inventive polishing on the copper surface is given. Processing conditions: the circulating solution contains 0.1mol / dm 3 Acetic acid (pH 5.5), 2mg dm -3 Benzotriazole, 10mmol / dm 3 Sodium thiosulfate (Na 2 S 2 o 8 ) and 0.1mol / dm 3 N-acetylcysteine; its temperature is maintained at 30°C throughout the etching and leveling process; after the electrochemical etching reaction control system is started, Na is electrolyzed on the surface of the platinum metal disk 2 S 2 o 8 produce Free radical etching leveling agent; the scavenger is N-acetylcysteine added to the etching solution; the electrode potential of the tool (metal platinum disk electrode) is maintained at -0.5 during the entire leveling and polishing process by a constant potential method V (potential relative to saturated calomel electrode). Among them, the surface of the platinum metal disk is polished by CMP technolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com