Gripper used for semiconductor laser chamber surface filming and bar loading device

A laser and semiconductor technology, applied in the structure of optical resonator cavity, clamps, manufacturing tools, etc., can solve the problems of laser bar mechanical damage, cavity surface contamination or damage, troublesome bar installation, etc., achieving long service life and easy processing. , the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

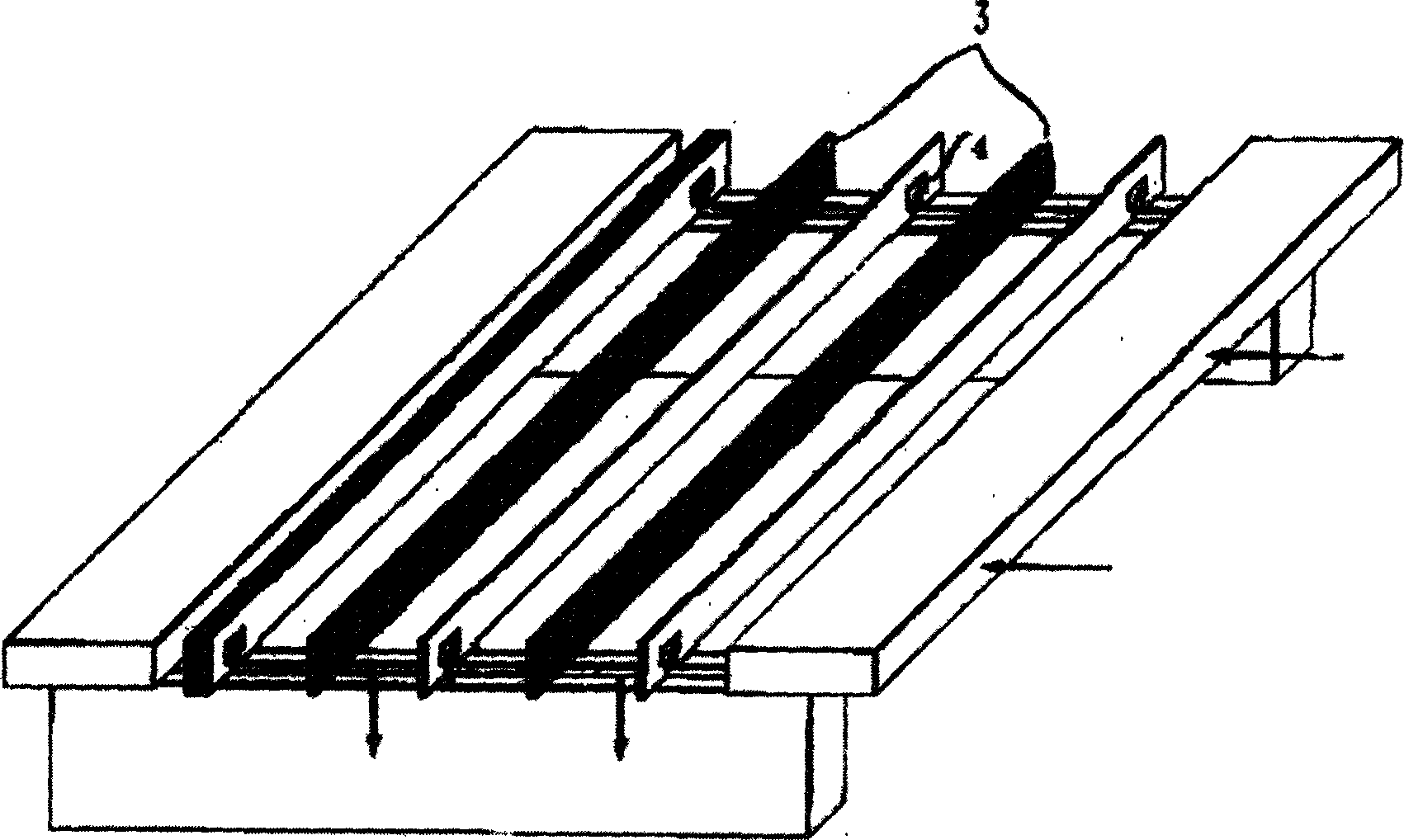

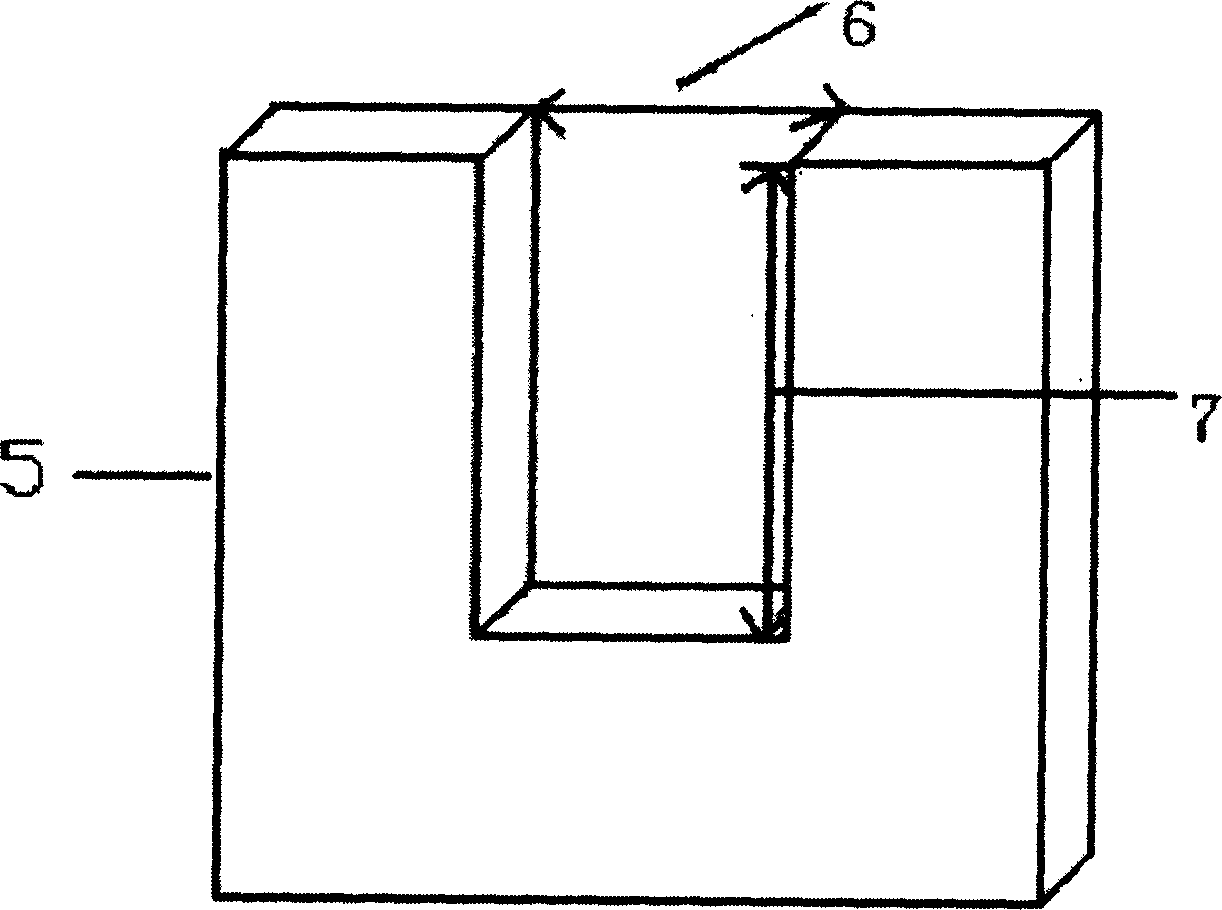

[0024] A laser bar with a length of 12mm and a width (laser cavity length) of 750um is coated. then in Figure 4 The concave plate in the outer layer can have a concave width of about 10.5mm; the concave plate in the middle can have a concave width of about 12.5mm, and the thickness of the concave plate can be 760um. The concave depth can be 5mm shallower than that of the concave plates on both sides, and the thickness of the strip thin plate can be 750um.

[0025] For the fixture strip device for semiconductor laser cavity surface coating, the base 17 is a flat plate with a strip plate 18 fixed on the base, and a strip plate 19 is connected with the strip plate 18 fixed on the base. Three concave plates 9 stacked together are sandwiched between these two shaped plates.

[0026] When in use, the three concave plates are assembled together by screws, such as Figure 4 Shown in the three concave plates 9 stacked together in the middle, and fixed on the mounting device base 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com