Numerical control roof-arc spreading machine

A technology of expanding machine and top arc, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of no one-time forming equipment for shuttle coils, increased production steps and processing costs, and automatic completion of three-dimensional space. Achieve the effects of high degree of automation, high production efficiency and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

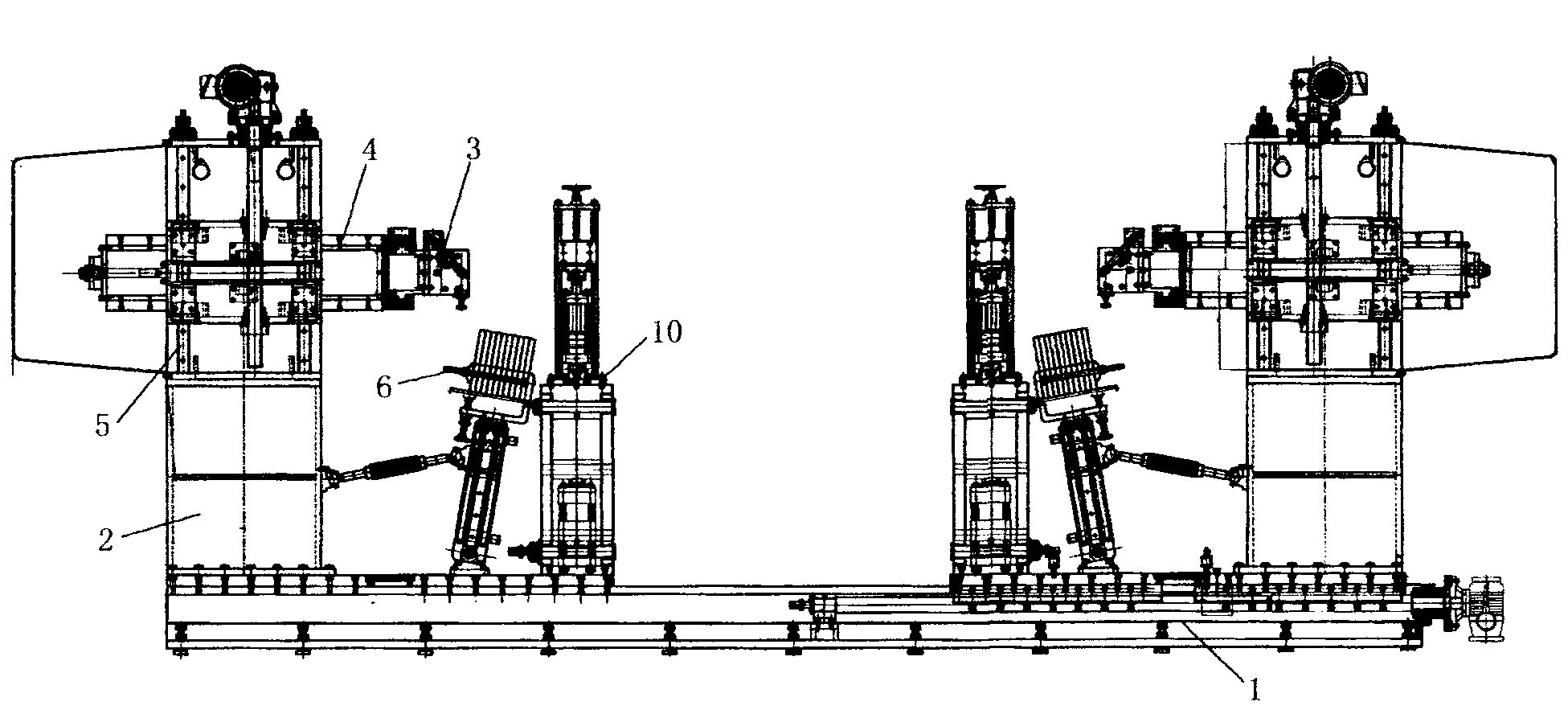

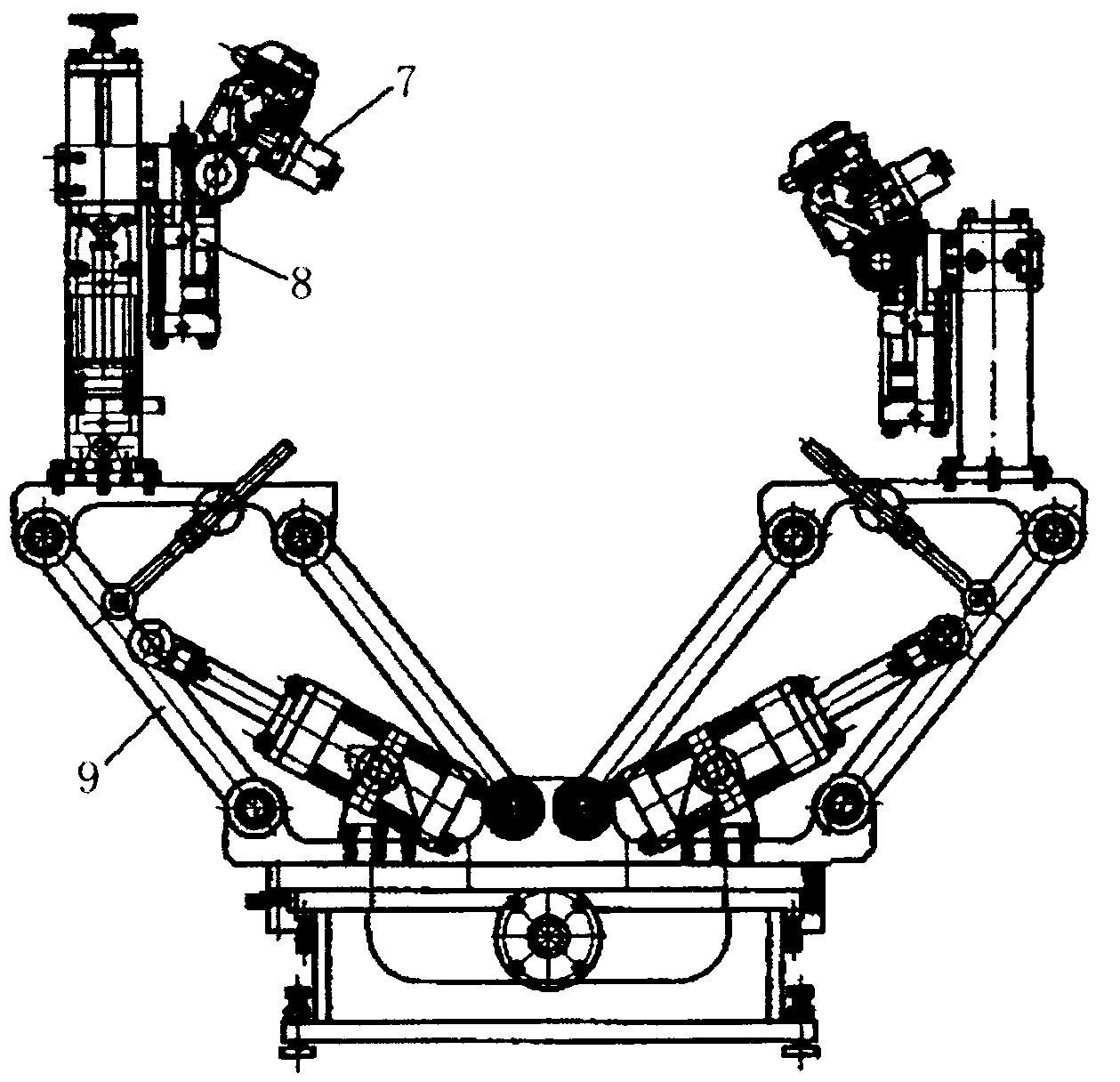

[0017] Such as figure 1 As shown, a numerically controlled top arc expansion machine includes a base rail mechanism 1, four bases 2, two coil nose clamping mechanisms, four wire rod top radian mechanisms 6, and four wire rod clamping expansion mechanisms 10. Hydraulic station and sensor control numerical control circuit system, wherein two bases 2 are respectively arranged on the left half and right half of the upper end of the base rail mechanism 1, and two coil nose clamping mechanisms are respectively connected to the two bases 2, and the other two bases 2 are arranged in the middle of the upper end of the base guide rail mechanism 1, and four wire rod clamping expansion mechanisms 10 are respectively arranged on the upper ends of the two bases 2 in pairs. The rod top radian mechanism 6 is respectively arranged on the side of the four wire rod clamping expansion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com