Combined firework automatic assembling system

A combination of fireworks and automatic assembly technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as heavy labor load, low production efficiency, and affecting the production progress of fireworks, so as to reduce production costs, improve efficiency, and shorten production time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

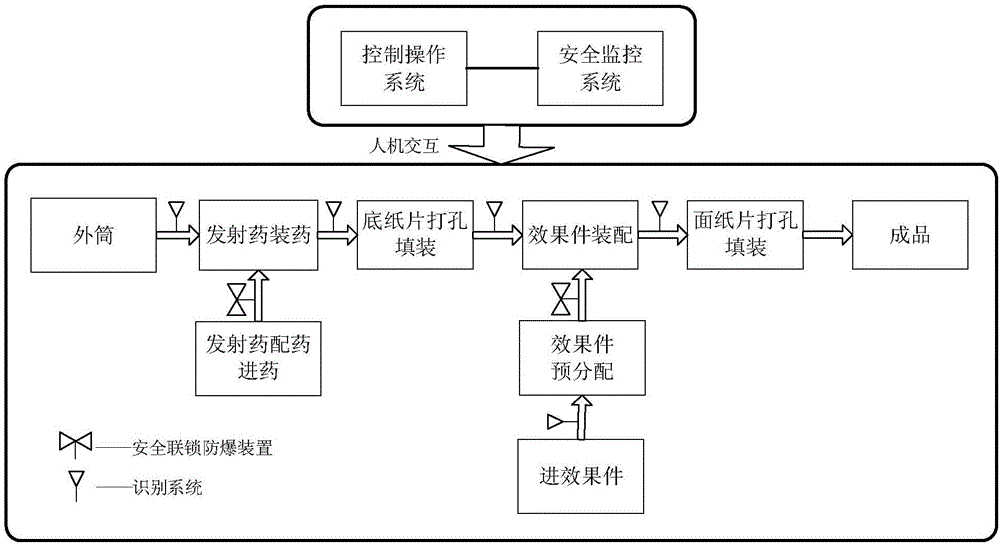

[0040] See attached figure 1 , reflecting a specific structure of the present invention, the combined fireworks automatic assembly system includes a propellant charge sub-system, a bottom paper sheet punching and filling sub-system, and an effect piece filling sub-system, which are sequentially connected by the combined fireworks outer cylinder transmission mechanism. system, facial tissue sheet filling subsystem; it also includes a control operation subsystem and a safety monitoring subsystem, and a safety interlock explosion-proof device and an infrared identification system are set between each subsystem.

[0041] The object of processing is the combined fireworks 6 of twenty rounds (four rows×five / rows).

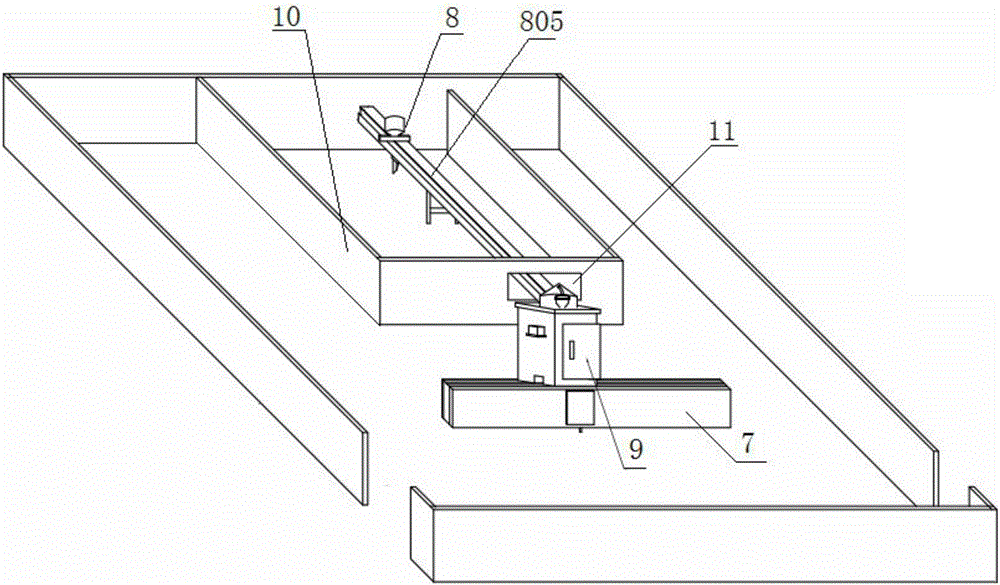

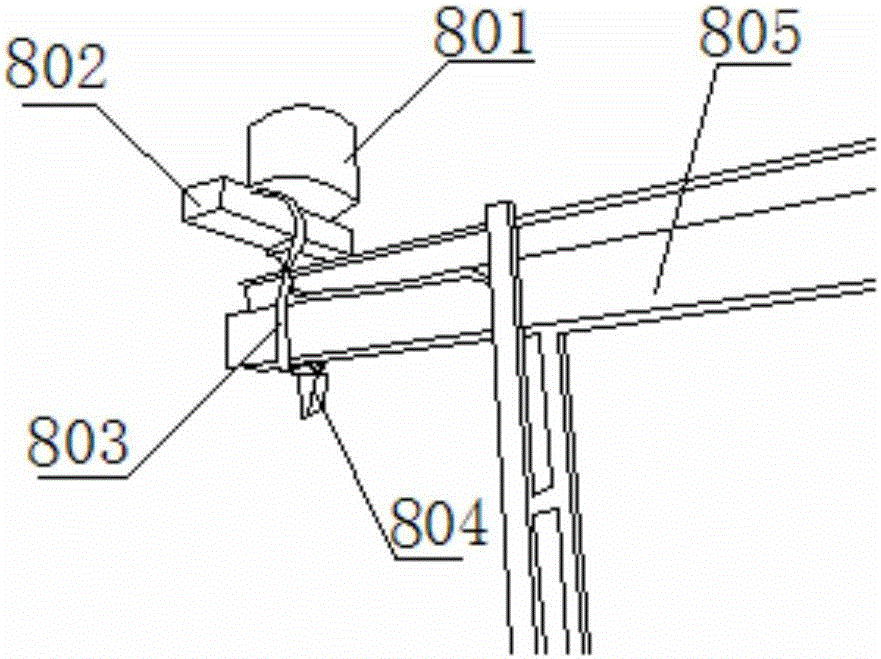

[0042] see Figure 2-6 , the propellant charge subsystem:

[0043] It includes a dispensing unit 8 and a charge unit 9 separated by an explosion-proof wall 10. A safety interlock explosion-proof device is set between the dispensing unit 8 and the charge unit 9. If any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com