Laser parallel processing device and processing method for array air holes of leather product

A technology for processing devices and leather products, which is applied in manufacturing tools, metal processing equipment, laser welding equipment, etc., can solve the problems of not being able to fully utilize the performance of high-power lasers and low laser energy, and achieve improved drilling efficiency and high processing accuracy , the effect of flexible and adjustable array hole spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

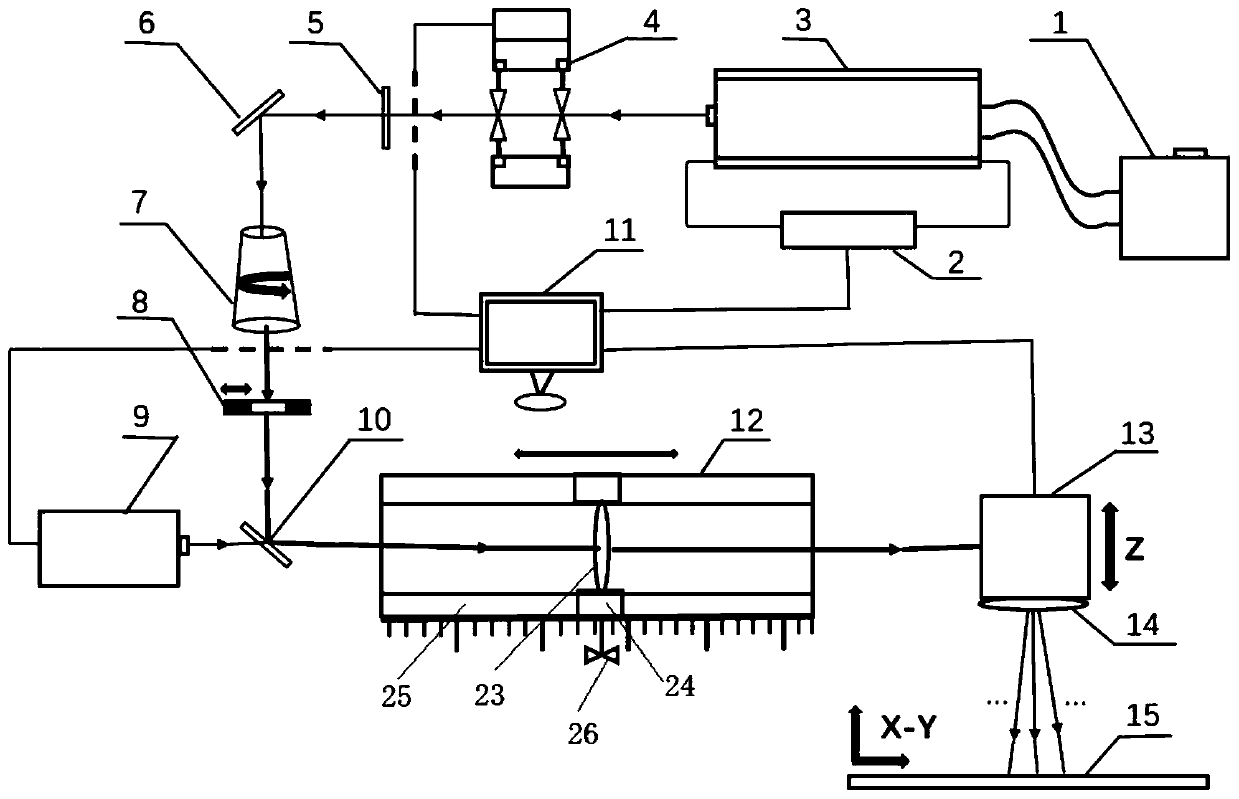

[0049] Attached below figure 1 - attached Figure 4 The processing device disclosed in this embodiment is further described;

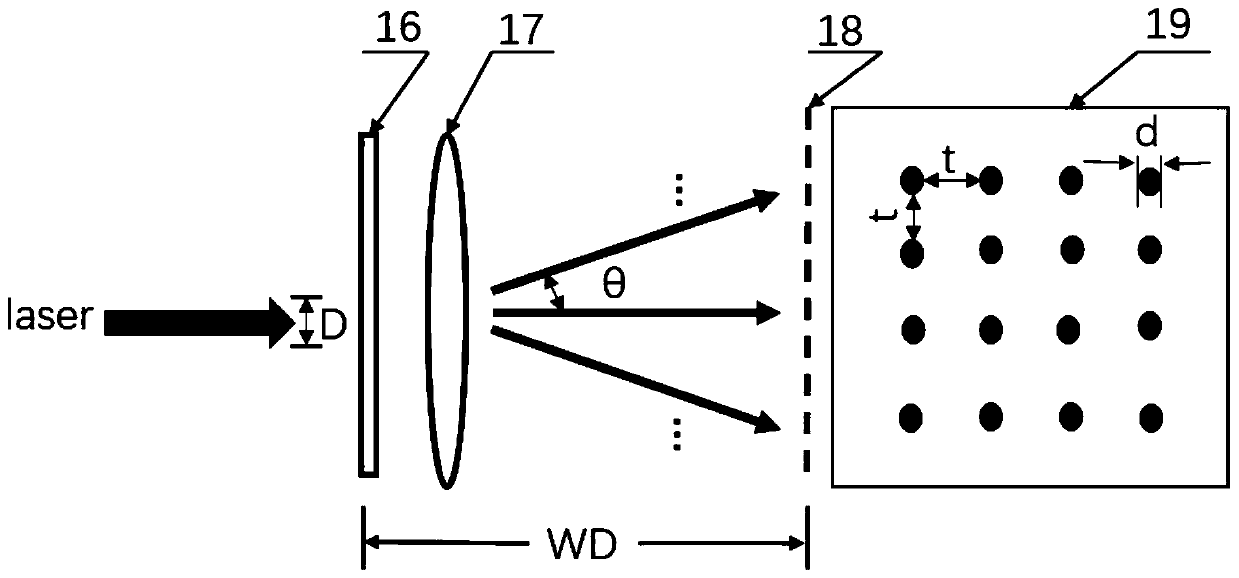

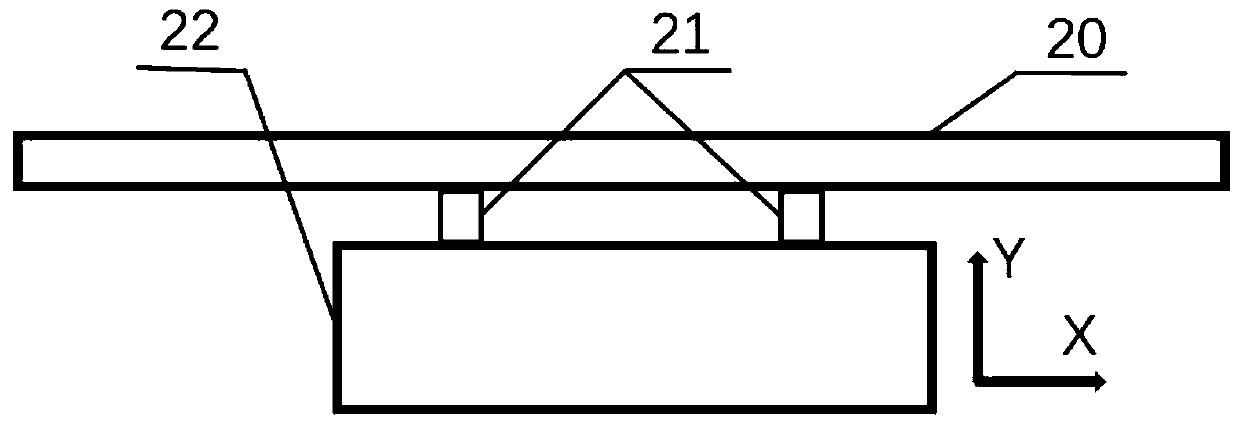

[0050] Refer to attached figure 1 As shown in the figure, the laser parallel processing device for array air holes of leather products includes five parts: laser system, optical light guide system, X-Y two-dimensional honeycomb adsorption platform system, computer control system, and auxiliary processing system. The light outlet of the laser system is opposite to the optical path entrance of the optical light guide system, and the optical path exit of the optical light guide system is opposite to the working area of the X-Y two-dimensional honeycomb adsorption platform system; the optical light guide system shapes and expands the laser beam output by the laser system. After beam, collimation, beam splitting and focusing, guide it to the leather surface to be processed in the processing area of the X-Y two-dimensional honeycomb adsorption platform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com