Multipurpose lid in particular for liquids, particularly for paint can

An edge and locking technology, which is used in mixers with rotary stirring devices, decorative arts, mixers, etc., can solve the problems of high dye replenishment speed, short duration and low frequency of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

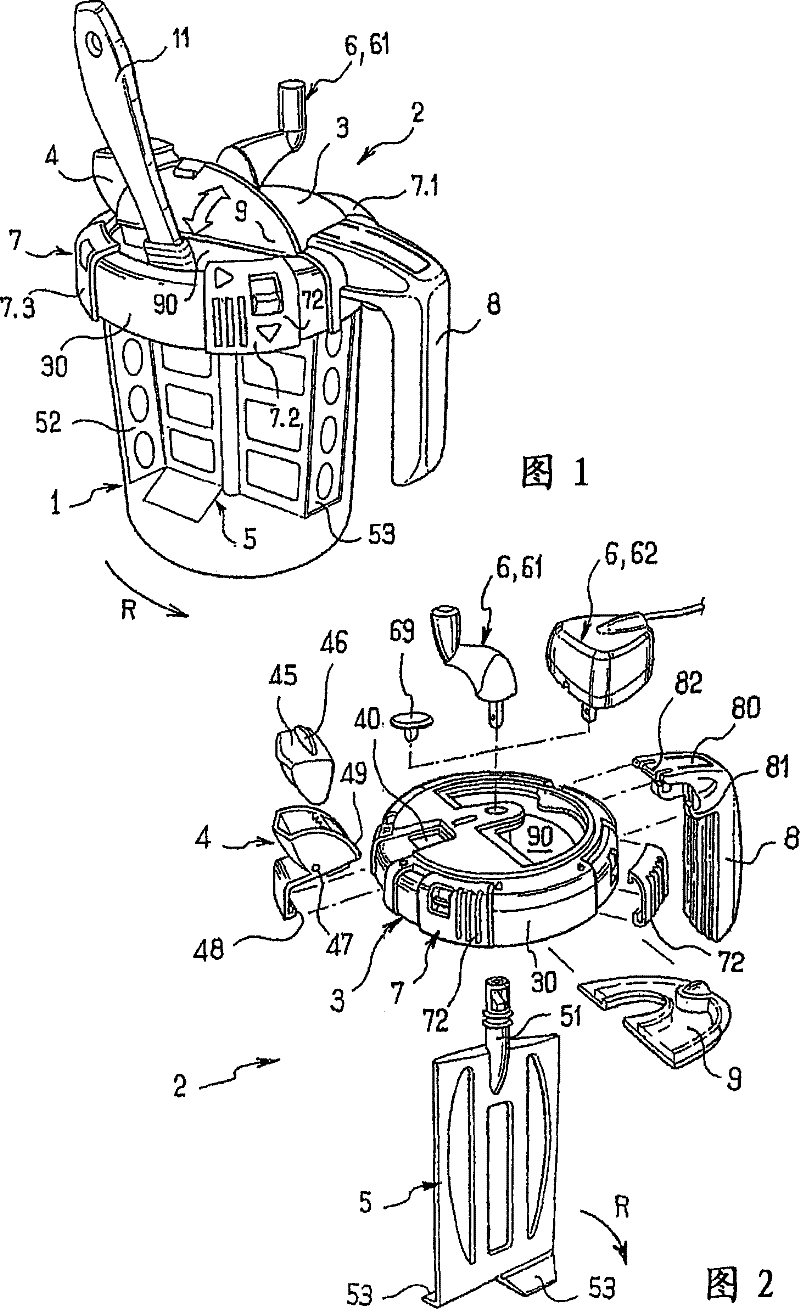

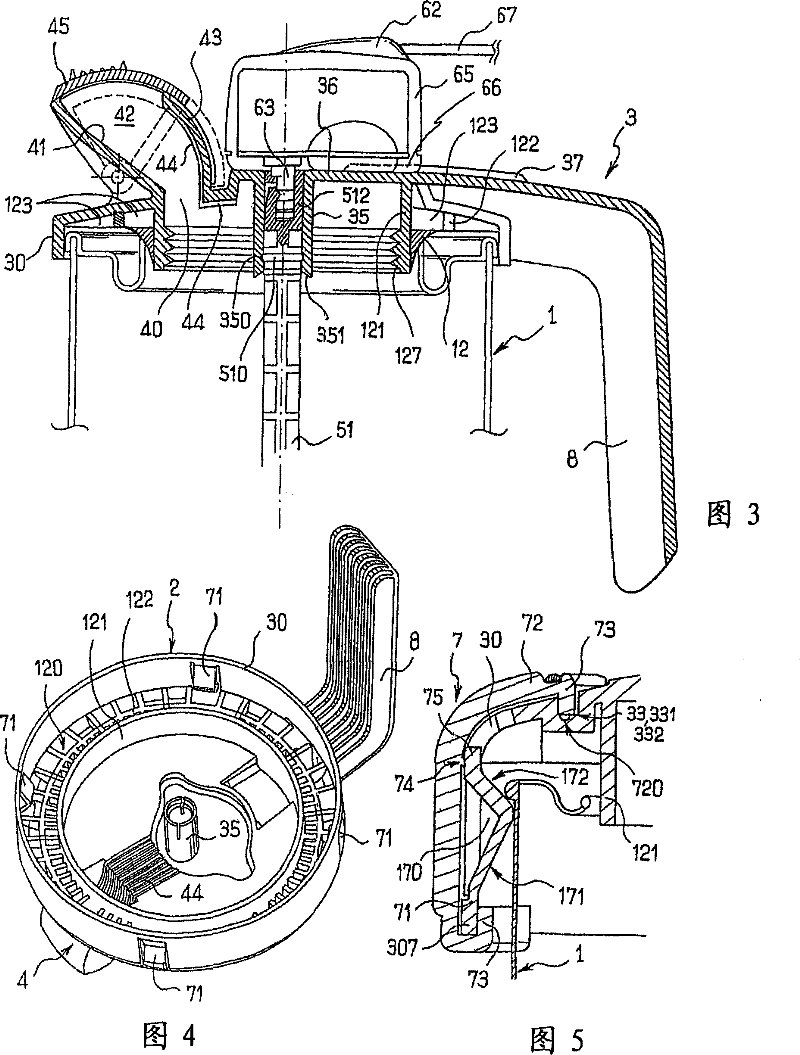

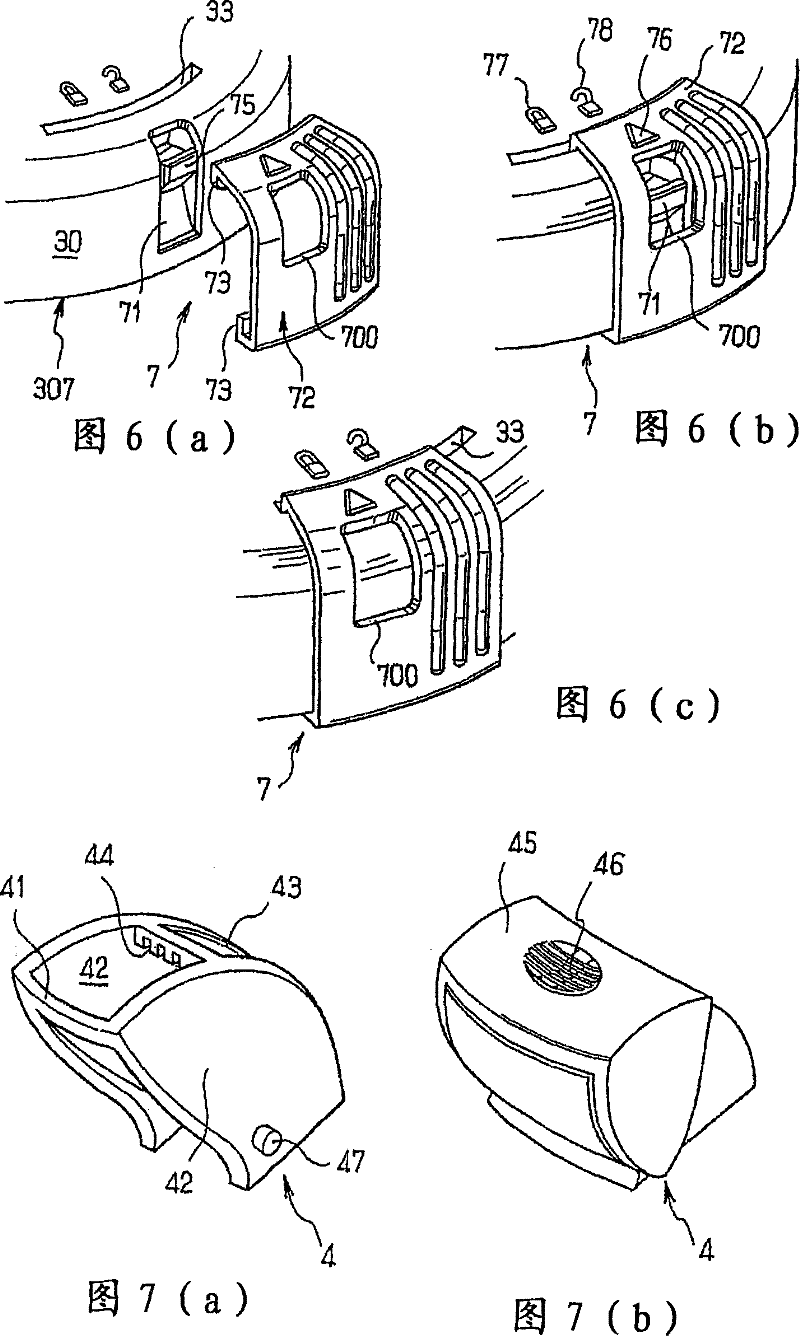

[0046] figure 1 Shown is a paint can 1 equipped with a lid 2 according to the invention shown in the first embodiment. figure 2 An exploded view of the modular cover according to the second embodiment of the invention is shown. figure 1 with figure 2 The lid mainly includes a skirt 3 for basically covering the opening of the tank. The pouring spout 4 is installed on the skirt board 3, and paint can be poured without removing the lid of the tank 1. The stirring members 6 and 5 include a blade 5 extending inside the tank 1 and a driving member 6 (here, a crankshaft 61) for pushing the blade, and the stirring member is mounted on the skirt 3 in the axial direction. In addition, the cover 2 includes locking members 7, 7.1, 7.2, 7.3 installed on the peripheral edge 30 of the skirt board 3 to install the cover on the tank together, and the cover 2 also includes a handle 8 to install the cover integrally. The tank can be lifted. Such as figure 1 with 2 The illustrated lid also incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com