Multipurpose lid in particular for liquids, particularly for paint can

A paint can and edge technology, applied in the field of multi-functional lids, can solve the problems of high dye replenishment speed, low frequency of use, and short duration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

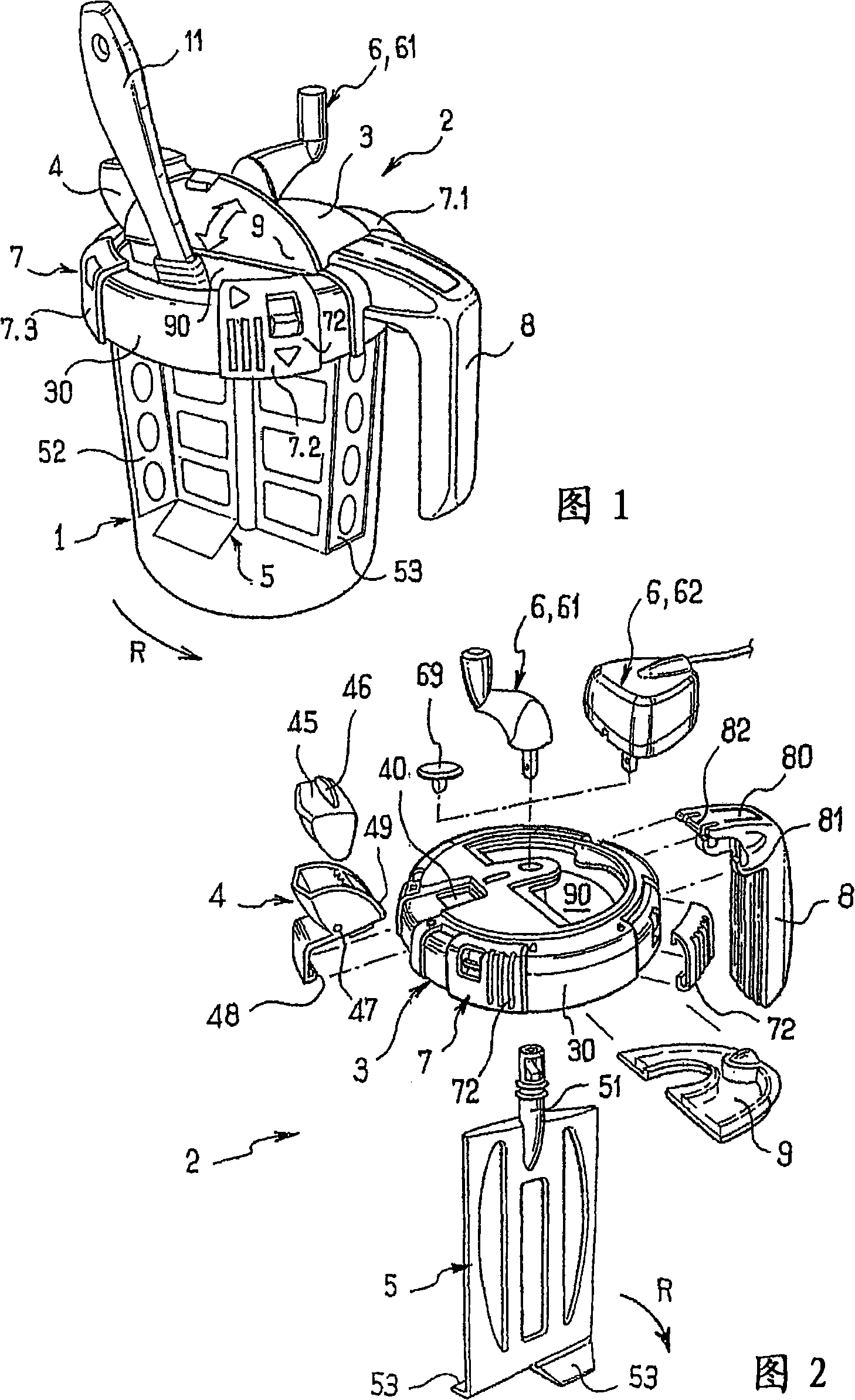

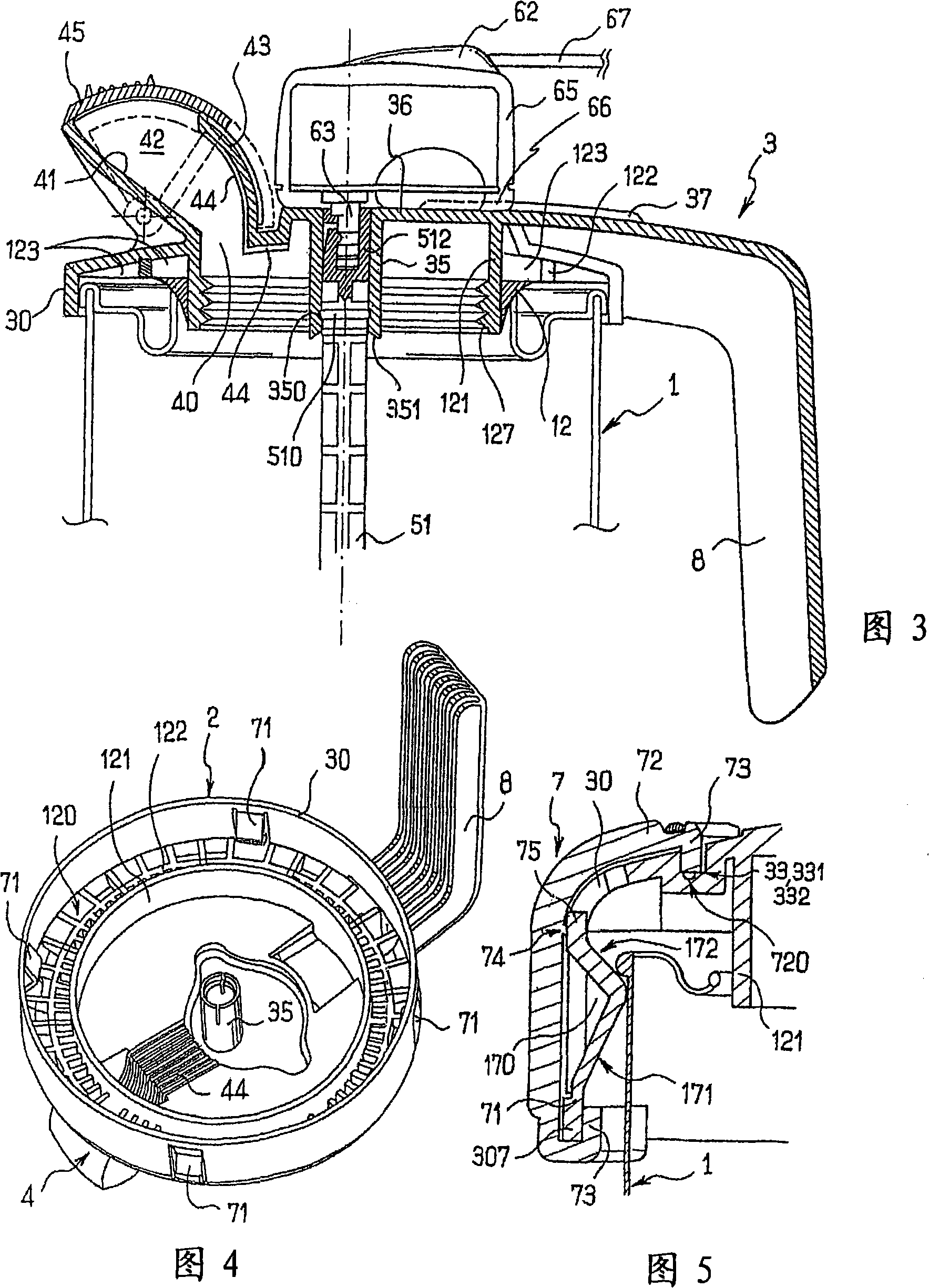

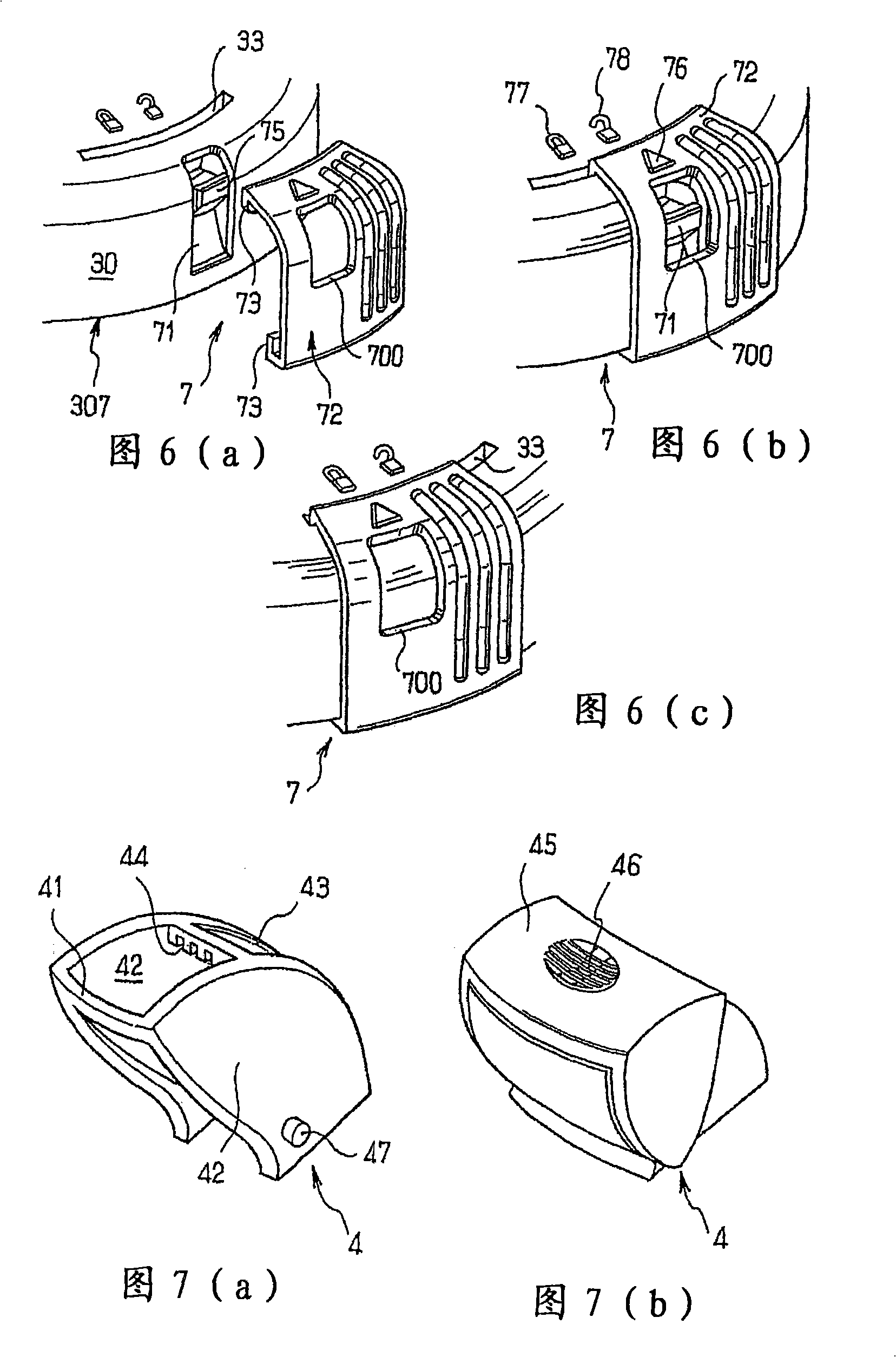

[0046] FIG. 1 shows a paint can 1 equipped with a lid 2 according to the invention, shown in a first embodiment. Figure 2 shows an exploded view of a modular cover according to a second embodiment of the invention. The lid in Figures 1 and 2 essentially comprises a skirt 3 for substantially covering the opening of the can. The pouring spout 4 is mounted on the skirt 3, and the paint can be poured without removing the lid of the tank 1. Stirring members 6 , 5 comprising a blade 5 extending inside the tank 1 and a drive member 6 (here a crankshaft 61 ) for propelling the blade are axially mounted on the skirt 3 . In addition, the lid 2 includes locking members 7, 7.1, 7.2, 7.3 mounted on the peripheral edge 30 of the skirt 3 to together mount the lid on the can, and the lid 2 also includes a handle 8 for when the lid is integrally fitted Cans can be lifted. The lid as shown in Figures 1 and 2 also includes a hatch 9 enabling access through an opening 90 in the skirt 3 to gain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com