Electronic assembly for transmission control module and method of making the same

一种电子组件、电子器件的技术,应用在印刷电路制造、电气元件、电固体器件等方向,能够解决不精确放置、高制造成本、使用寿命或密封性降低等问题,达到简化制造过程、低制造成本、持久防油性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

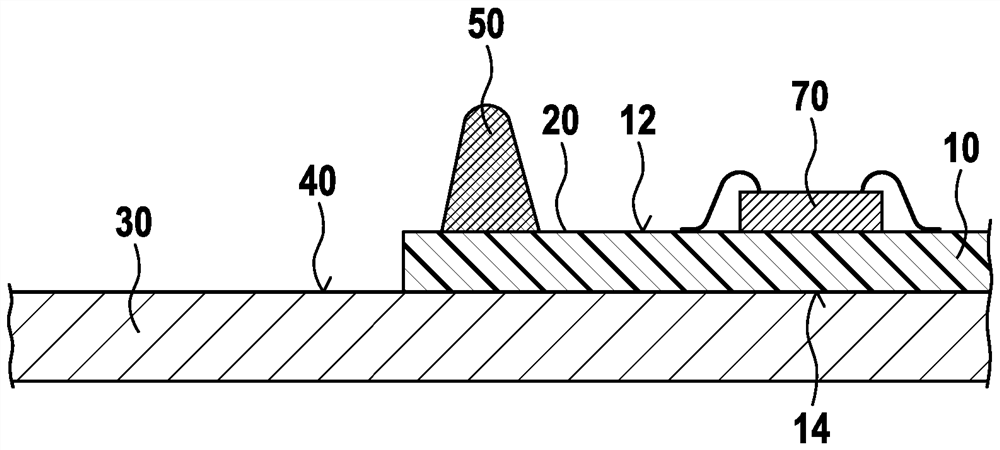

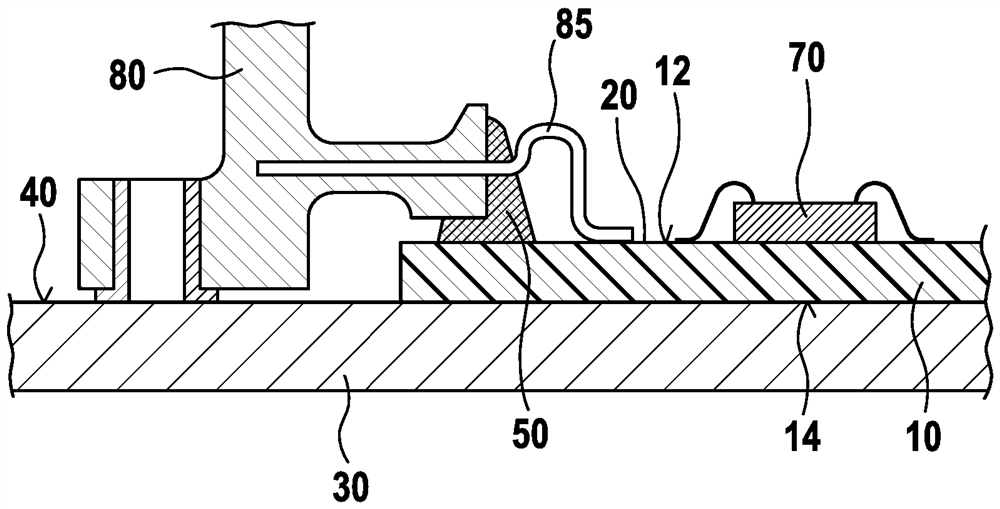

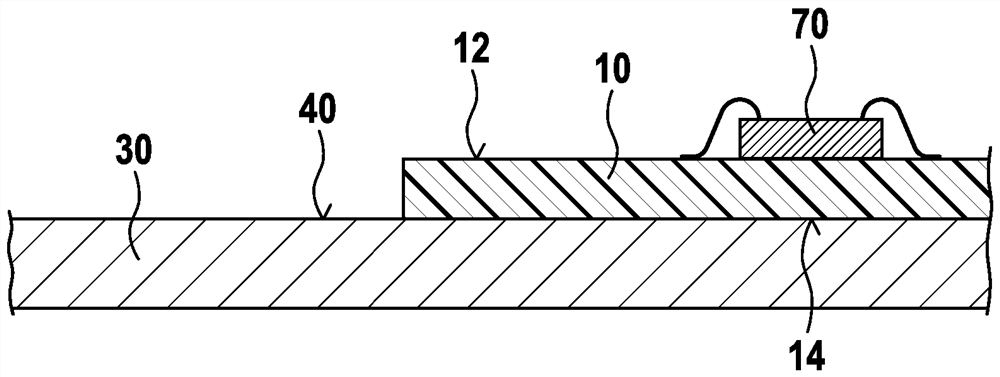

[0027] figure 1 A schematic view is shown after the first step of the method according to the invention for producing an electronic component 5 . Electronic assembly 5 may be part of a transmission control module of the vehicle.

[0028] Firstly, a printed circuit board 10 (eg printed circuit board; PCB) is provided. The printed circuit board 10 has a first side 12 (in figure 1 upper center) and the second side 14 (in the figure 1 lower middle), wherein the second side 14 is opposite to the first side 12 . At least one first electronic component 70 is arranged on the first side 12 of the printed circuit board 10 . The first electronic device 70 is electrically connected to the printed circuit board 10 .

[0029] The printed circuit board 10 is arranged on the reference surface 40 . The second side 14 of the printed circuit board 10 is connected planarly to the reference surface 40 or is fastened thereto. Alternatively, the printed circuit board can also lie flat on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com