Method and device for packaging flexible OLED screens through laser welding

A laser welding and flexible technology, which is applied in the field of laser welding and packaging of flexible OLED screens, can solve the problems of thermal influence of components and high cost, and achieve the effect of improving quality, good consistency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

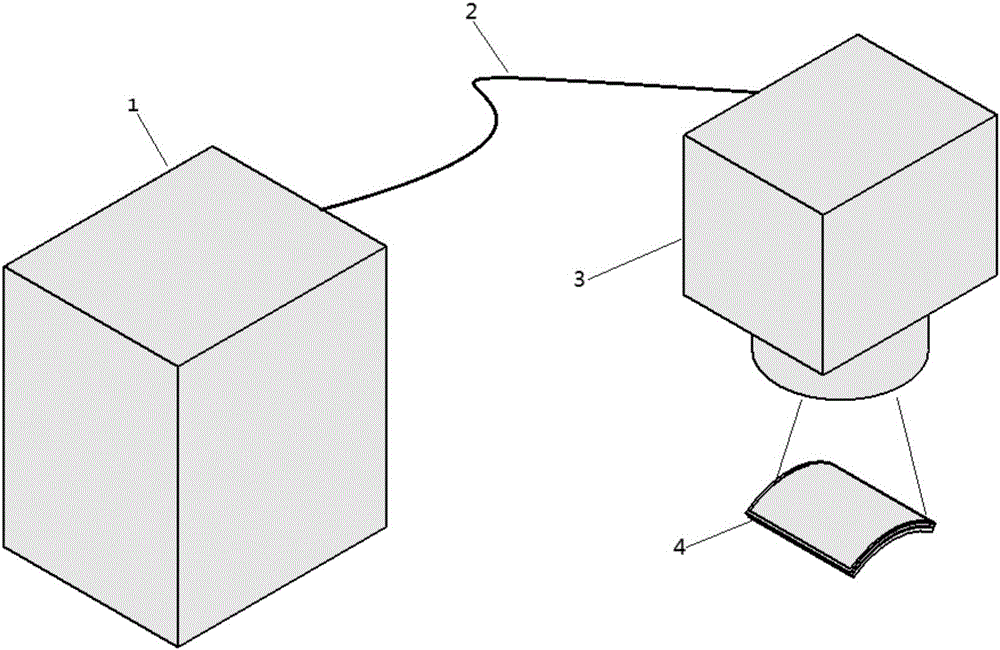

[0023] see figure 1 , figure 1 It is a structural representation of the device and OLED screen of the present invention. The present invention proposes a device for laser welding and packaging a flexible OLED screen, which includes: a laser 1 , an optical fiber 2 and a 3D dynamic focusing vibrating head 3 . Among them, in the working state, while maintaining the external pressure that makes the upper and lower packaging materials of the flexible OLED screen 4 tightly bonded, the laser 1 emits continuous laser light, and transmits the continuous laser light to the 3D dynamic focusing vibrating lens 3 through the optical fiber 2, 3D dynamic The focusing vibrating head 3 automatically adjusts the focus through its own structure and control program, so that the laser spots and energy reaching the flexible OLED screen 4 are consistent. The 3D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com