Combined microstructure guide rail and manufacturing method thereof

A manufacturing method and micro-texturing technology, which can be used in manufacturing tools, large-scale fixed members, metal processing machinery parts, etc. Easy appearance, low cost, and low processing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1. The embodiment of the present invention provides a CA6140 ordinary lathe combined micro-texture guide rail preparation method, the steps are:

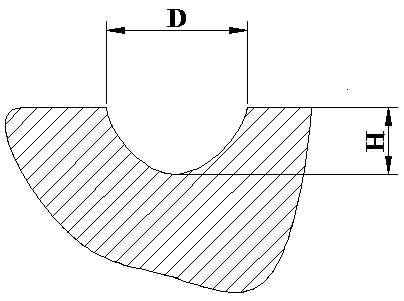

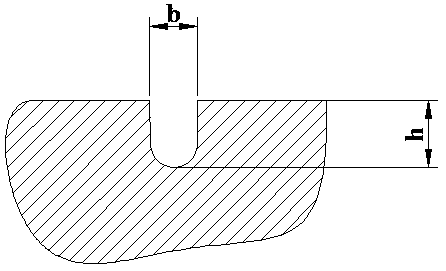

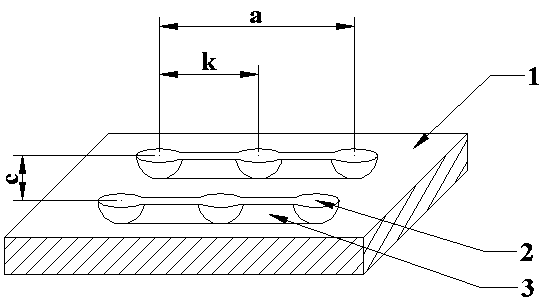

[0027] Step 1, CA6140 ordinary lathe, the guide rail type is a rectangular sliding guide rail, the specific geometric parameters of the shape of the micro-pits 2 are: pit diameter D=65um, pit depth H=5um, feature spacing k=225um, and feature area occupancy Rate S=5%. Specific geometric parameters of micro-groove 3 morphology: groove length a=100mm, groove width b=20um, groove depth h=5um, groove spacing c=225um.

[0028] Step 2, the guide rail surface 1 needs to undergo a pretreatment process before laser micromachining, and the pretreatment process adopts grinding to make the guide rail surface 1 precision meet the requirements of laser micromachining, surface roughness: the arithmetic mean deviation of the parameter profile Ra≤0.8 um, the maximum height of the profile Rz≤3.2um, geometric tolerance: both straightne...

Embodiment 2

[0033]Embodiment 2 is different from Embodiment 1 in that an oil distribution groove is provided on the surface of the guide rail along the length direction of the guide rail, and the shape of the oil distribution groove is a trigonometric function curve. The width of the oil distribution groove is t=1-2mm, and the depth is q=1mm-3mm. A CNC milling machine is used to process triangular function-shaped oil distribution grooves on the surface of the guide rail. The specific processing parameters are: spindle speed 200-600mm / s, feed rate 10-100mm, and cutting depth 1-3mm.

Embodiment 3

[0034] Example 3, such as Figure 5 As shown, the combined micro-texture topography of the present invention is applied to the static guide rail 7 of the triangular guide rail, corresponding to the moving guide rail 6 of the triangular guide rail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com