Two-side driving balance type low-speed large-torque axial plunger motor

A low-speed and high-torque axial piston motor technology, which is applied in the field of axial piston motors, can solve the problems of reduced working performance and service life, difficult sealing, and affecting the smooth operation of the cylinder, so as to reduce vibration and noise, Avoid crawling and shaking, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described further below:

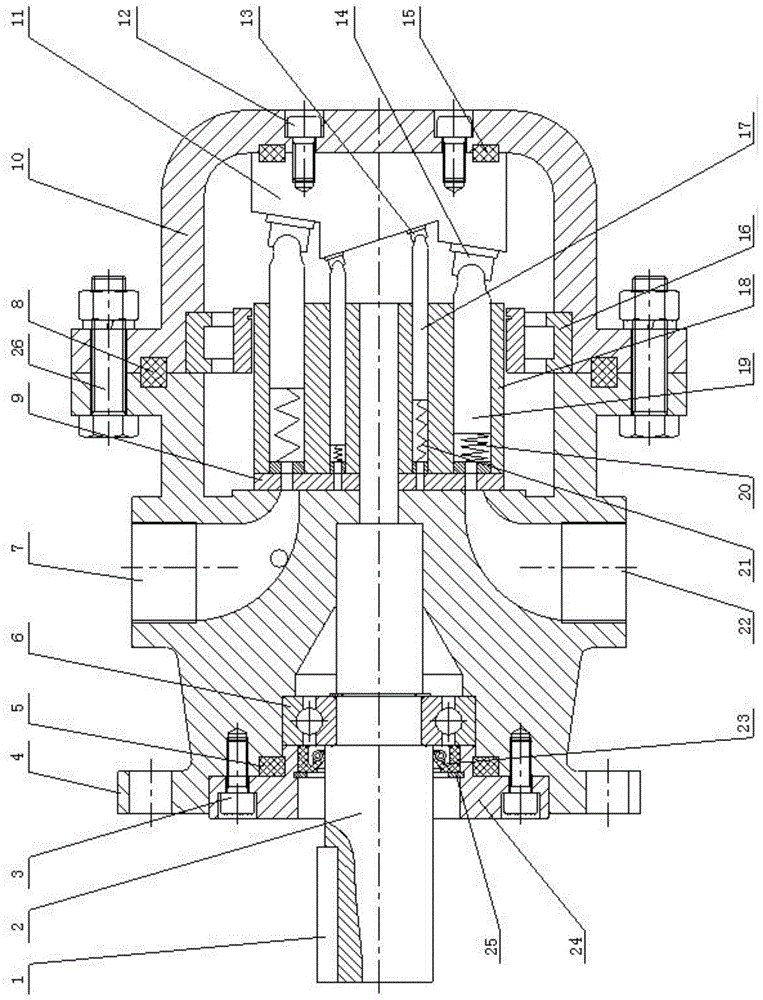

[0030] combine figure 1 — Figure 4 ; A double-sided driven balanced low-speed high-torque axial piston motor, the motor housing is provided with an oil inlet, an oil outlet, including a transmission shaft, the motor housing is composed of a front housing and a rear housing, and the front housing The body 4 and the rear housing 10 are fastened together by the first bolts 26 to form the entire motor housing, and a third sealing ring 8 is provided on the contact end surface of the front housing 4 and the rear housing 10; The front end of the body 4 is equipped with an end cover 24 through the screw 3, and a first sealing ring 5 is installed between the inner end surface of the end cover 24 and the front housing 4. By installing the first sealing ring 5, the front housing 4 can be prevented. Outflow of oil improves its sealing performance.

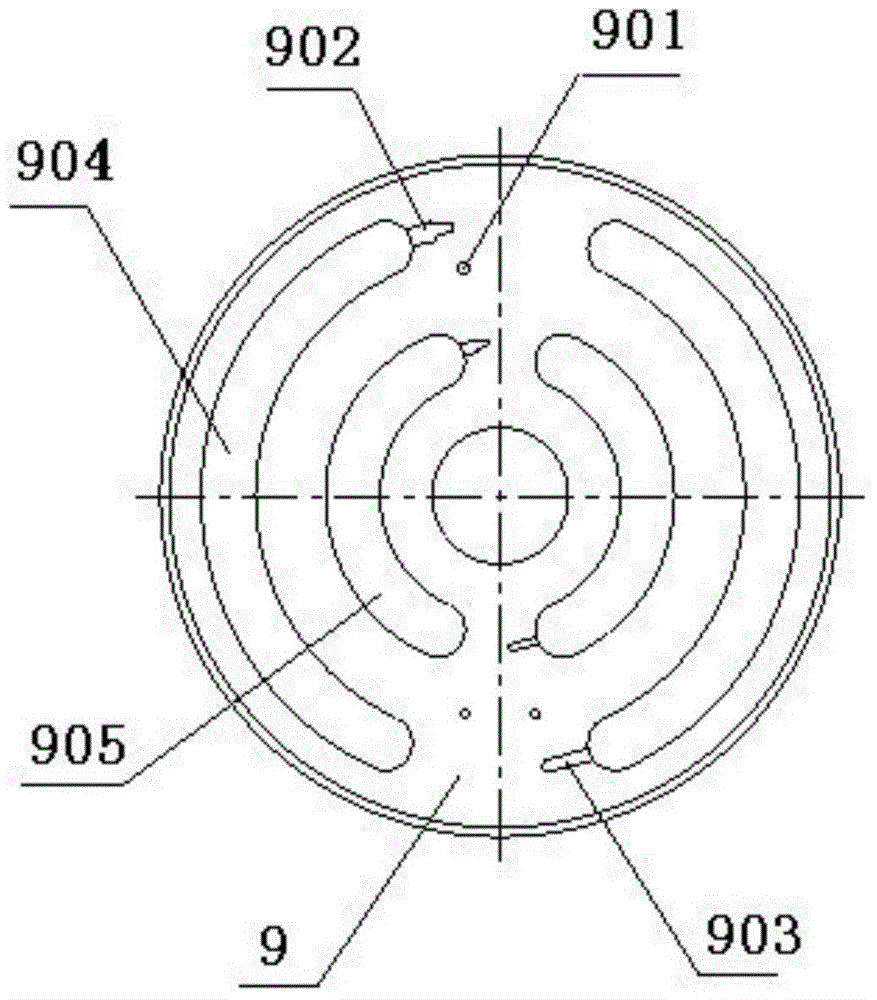

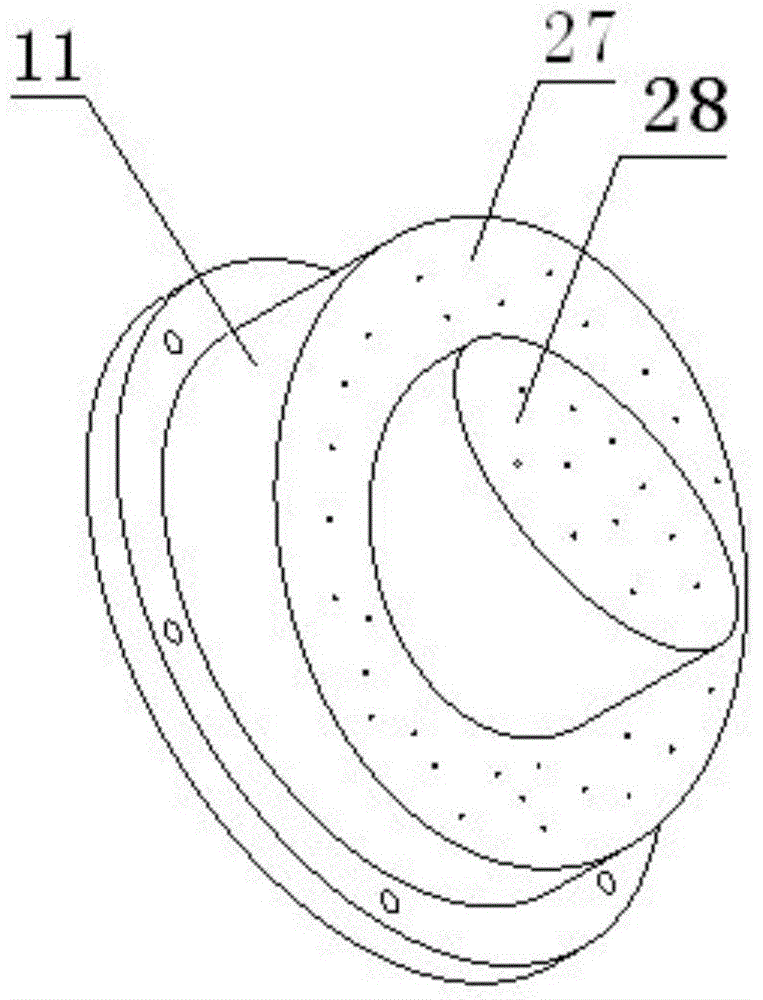

[0031] Components such as a flow plate 9, a swash plate 11, and a cylinder blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com