Wear-resistant cylinder hammer for guide rod type diesel pile driver and processing method thereof

A processing method and pile driver technology, which can be used in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as polluting the environment, affecting the service life of cylinder hammers, reducing cylinder hammer sleeves and piston compression strokes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

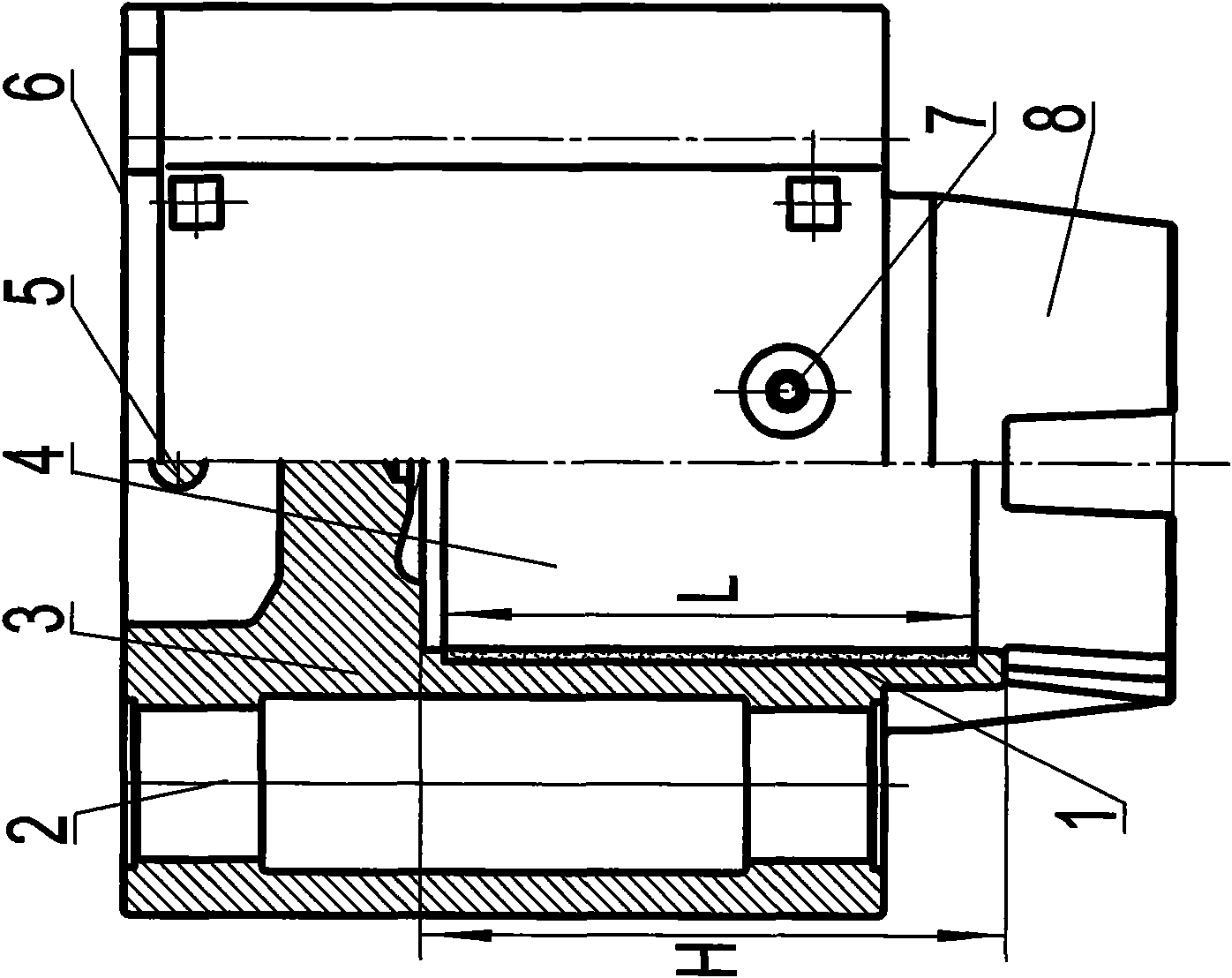

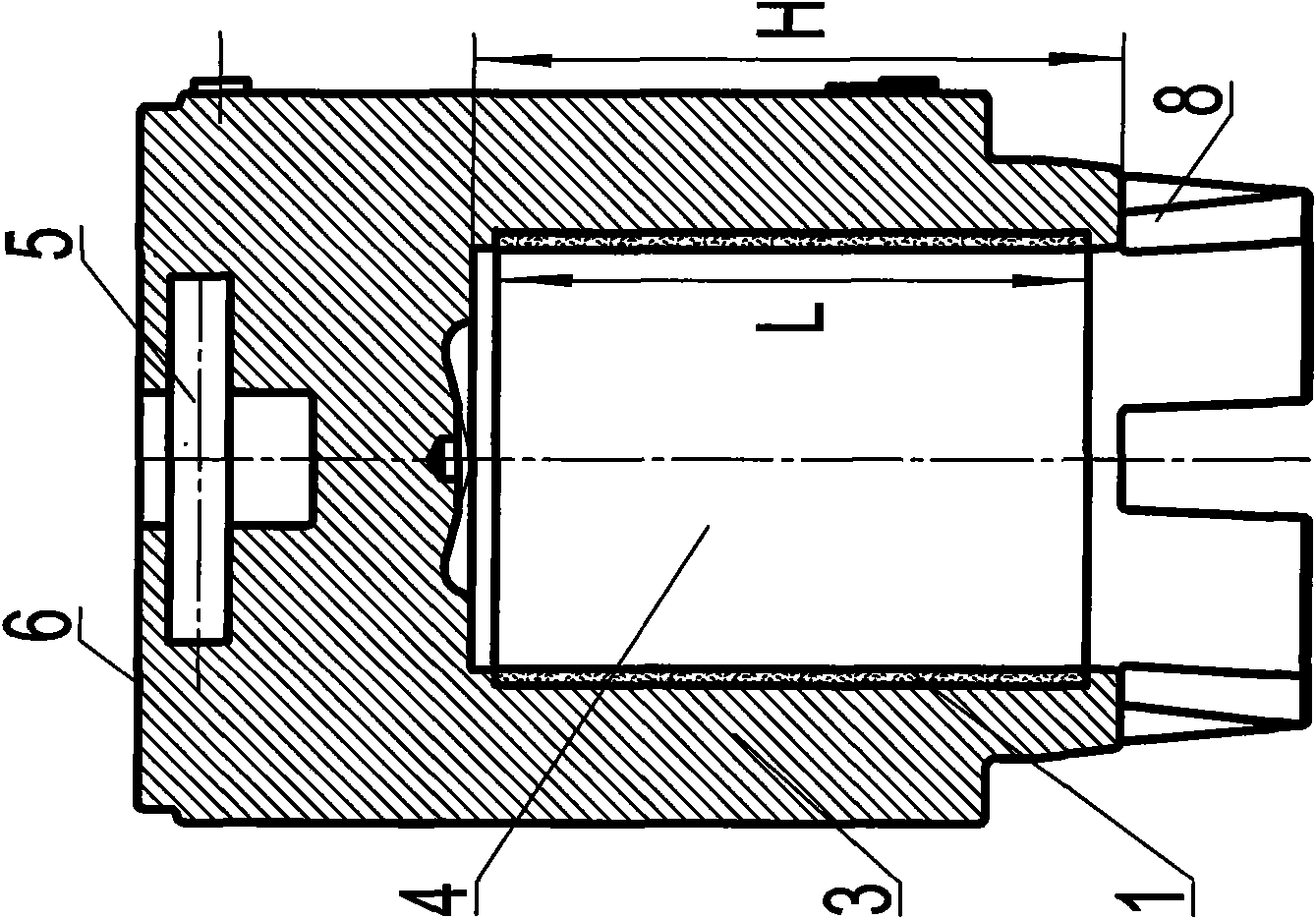

[0018] exist figure 1 , figure 2 In the shown diesel pile driver wear-resistant cylinder hammer, the wear-resistant cylinder hammer includes a cylinder hammer body 3 and a cylinder chamber 4, and the cylinder chamber 4 is arranged at the center of the cylinder hammer body (3). An impact pin seat 7 is provided, and the impact pin seat 7 is used for installing the impact pin of the impact oil pump. The hammer body top surface 6 is provided on the top of the cylinder hammer body 3, and the hammer body top surface 6 can be processed into the processing datum plane of the cylinder cavity 4 and the guide rod slide hole 2, etc., and the two through guide rod slide holes 2 are symmetrically formed. It is arranged on the left and right sides of the cylinder hammer body 3; on the upper part of the cylinder hammer body 3, there is also a lifting hammer pin 5, which is used to lift the cylinder hammer body 3 upward along the two guide rods. The cylinder hammer body 3 is integrally cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com