Capacitor installing stack structure and installing method of capacitor

A technology of stacking structures and capacitors, which is applied in the direction of capacitors and electrical components, etc., can solve problems such as unspecified size correspondence, and achieve the effects of shortening the height and position alignment time, improving the installation height and position alignment accuracy, and reducing installation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below.

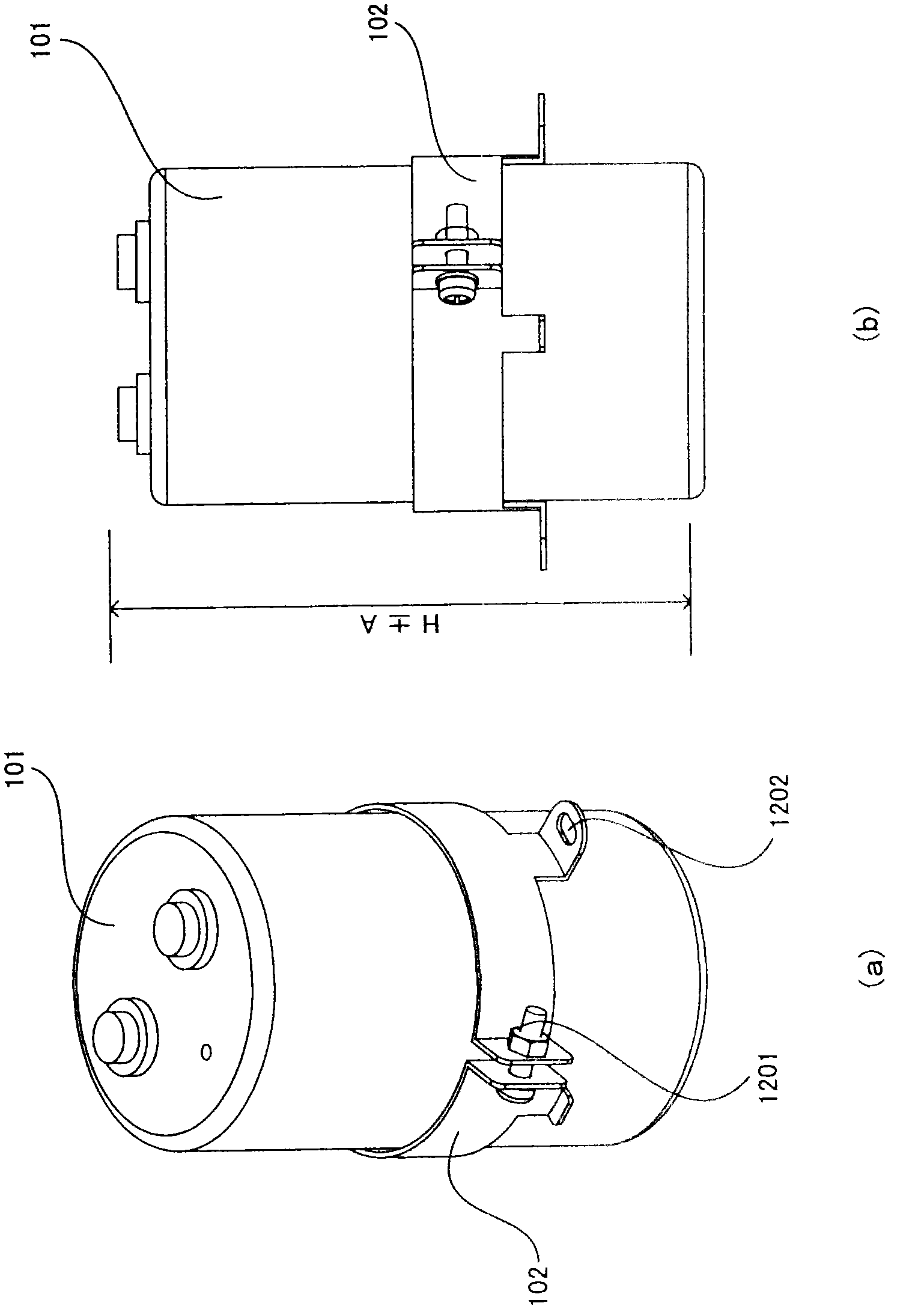

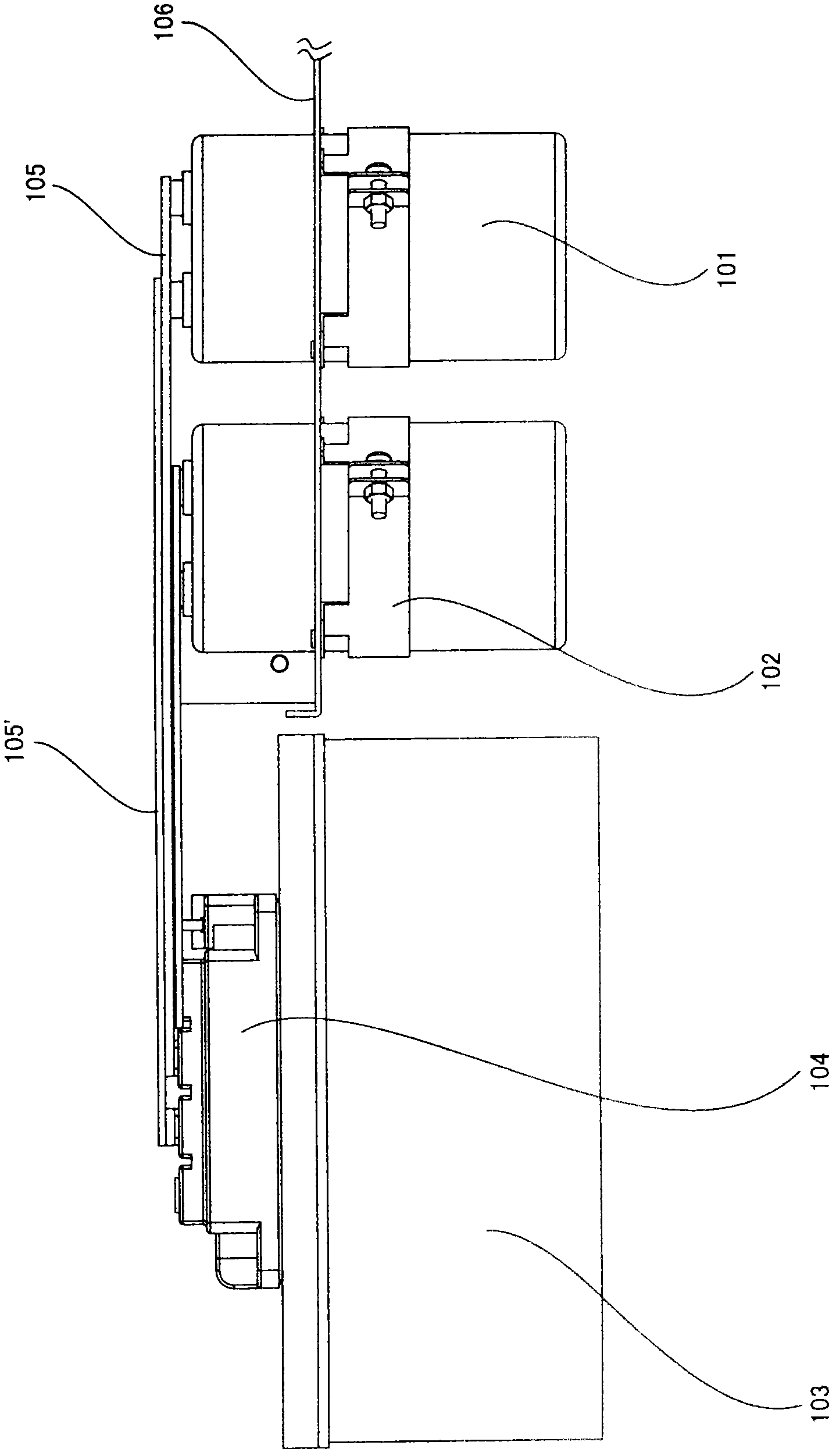

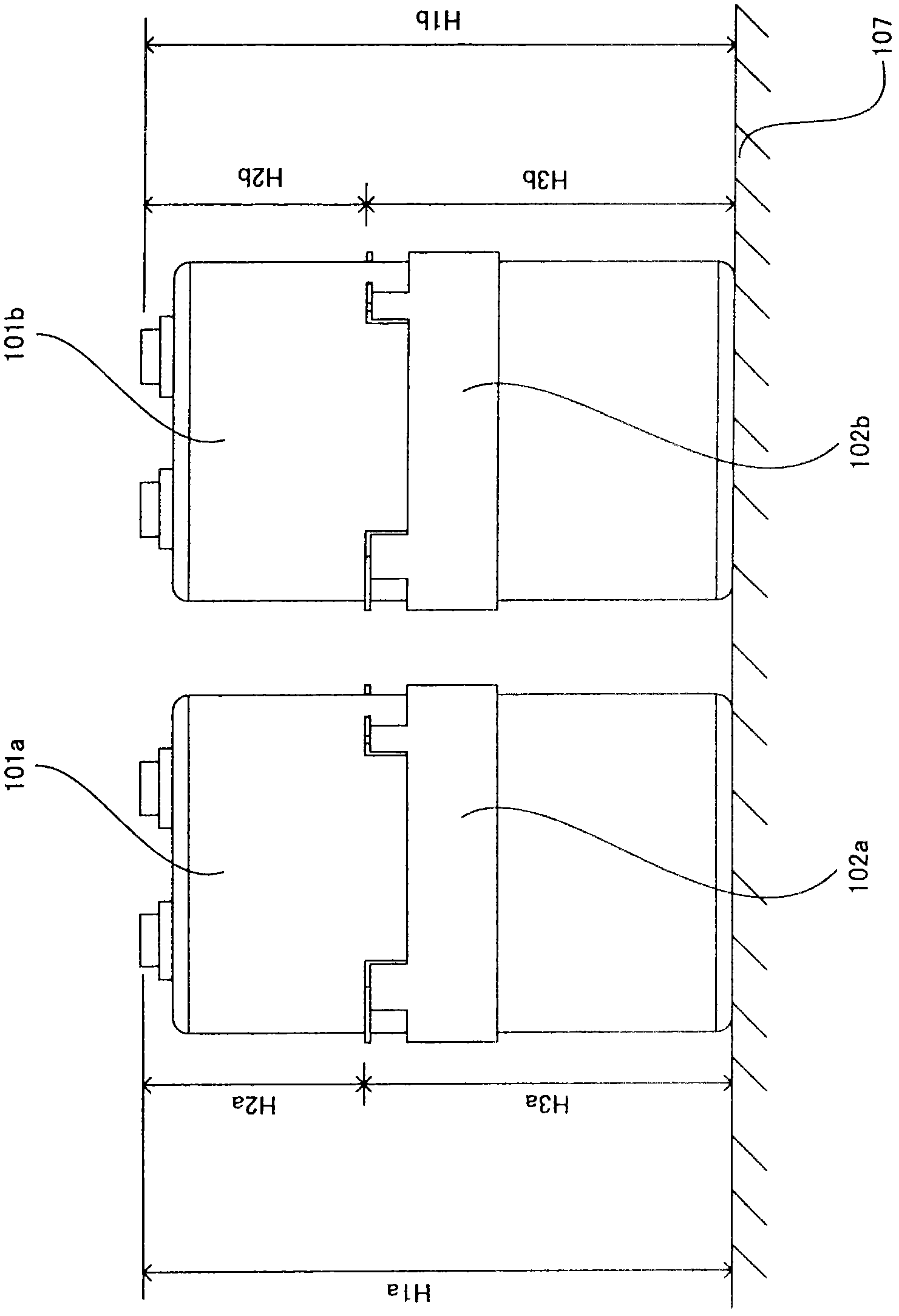

[0029] Figure 4 It is a figure which shows the structure of the capacitor mounting stack structure which concerns on embodiment of this invention, (a) is a back perspective view seen from the left side, (b) is a top view, (c) is a front perspective view seen from the right side, (d) is a rear view, and (e) is a right side view. From Figure 4 It can be seen that the capacitor mounting table 108 is composed of a large L-shaped bent metal plate, and on the left and right of the metal plate, there are provided jigs 109 for achieving height and dimensional accuracy during capacitor mounting by further bending. In addition, a hole for inserting the capacitor 101 is opened in the metal plate constituting the capacitor mounting stand 108 , and the capacitor 101 is inserted through the hole and fixed to the fixing fitting 102 by using a fastening device such as a screw in this state. At this time, ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com